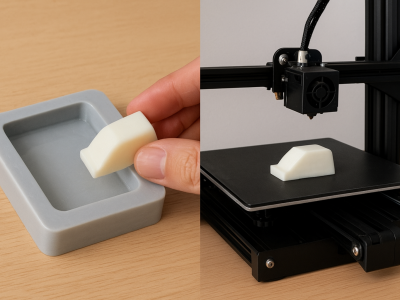

You may wonder if silicone vacuum casting and 3D printing costs are more favorable for your project. This is crucial when you require silicone molds or prototypes. The true answer hinges on the quantity of parts you need and their intended functionality. If you only need one or two pieces, 3D printing is typically the more economical option, and it also delivers your parts more quickly. However, if you require a larger number of parts, the silicone vacuum casting and 3D printing costs will vary. Here’s a quick comparison to help you understand how they stack up: FactorVacuum Casting3D PrintingTooling…

You want your training sessions to be great. Professional trainers pick platinum silicone mannequins because they last a long time. They look real and help keep you safe. When you consider silicone vs tpe mannequins, you see why silicone is the superior option. Silicone mannequins do not get damaged easily. They feel like real skin and do not cause health problems. If you want something you can trust and that is worth the money, silicone is the best choice. Key Takeaways Platinum silicone mannequins are strong and last a long time. They can last more than 45 years. This makes…

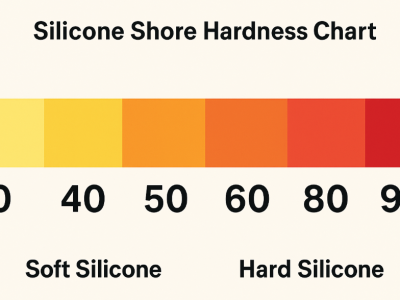

Imagine you need to pick the right silicone part for a seal or a gasket. How do you know if it will be soft enough to seal or hard enough to hold its shape? The silicone shore hardness chart is your go-to tool for answering these questions quickly. By referring to the silicone shore hardness chart, you can easily compare different silicone materials and make informed choices for your projects. This quick understanding leads to better engineering decisions. Key Takeaways Always look at the shore hardness number before you pick silicone. This number tells you if the material is soft…

When you pick the best silicone for prototype molds, Shore A hardness is important. Shore A shows how soft or hard the silicone feels. It goes from very bendy to very stiff. This scale helps you choose a silicone that fits your project. Softer silicone is good for tiny details. Harder silicone lasts longer when used a lot. Here is a quick look at common Shore A values: Shore A HardnessDescription10°Very bendy, for special uses20°Soft, like a rubber band40°Bendy, like a pencil eraser60°Good for tubes and gaskets70°Tough, like tire tread80°Hard, can take the place of plastic You can find top…

If you want to outsource vacuum casting China in 2025, you should first decide what your project needs. You also need to get your CAD files ready. Good 3D drawings help suppliers give you fast and correct quotes. You should check the newest cost ranges before you choose. For example, mold costs are often between $200 and $1,000. Per-part costs are usually between $10 and $100. Cost TypeCost RangeMold Costs$200 - $1,000Per-Part Costs$10 - $100 Picking the right supplier is very important for quality and delivery. If you know each step of the process, you can avoid mistakes. This also…

If you want to work fast and save money, use silicone molds for small batches. You get quick results and can change things easily. This works best if you make less than 500 pieces. However, when considering silicone mold vs steel mold, if you need more parts or stronger molds, it's time to switch to steel molds. Steel molds last much longer and can create tricky shapes very well. Steel molds, especially heat-treated steel, last five to ten times longer than aluminum. This makes them better for making lots of parts. Here is a simple look at why makers change…

You might wonder how many parts you can get from one silicone mold. Most molds give you anywhere from 25 to 256 parts before showing signs of wear. Some high-tech molds even make up to 1.5 million tiny parts every day. The silicone mold life cycle changes a lot depending on things like how often you use it, how clean you keep it, and what materials you cast. Check out the table below to see what can affect how long your mold lasts: FactorImpact on Mold Life CycleHumidityMoisture can cause corrosion in some materials.CleanlinessClean molds last longer and work better.Frequency…

When you need a prototype, you probably want the most cost-effective solution. If you only need a few parts, 3D printing usually gives you the best price. Once you need more parts or larger models, vacuum casting steps in as the winner. The vacuum casting vs 3d printing cost question really comes down to how many parts you need and how big they are. Key Takeaways 3D printing works best for small groups of parts. It is good for less than 20 parts. The starting cost is lower and setup is fast. Vacuum casting saves money when you make 20…

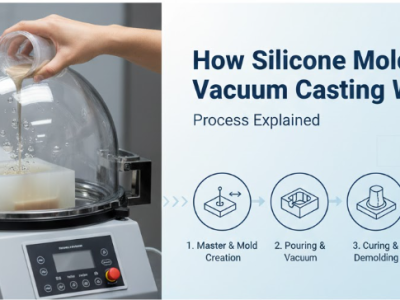

When you use the vacuum casting process explained here, you start with a high-quality master model. You get the surface ready so it is smooth. Then you make a silicone mold that copies every detail of your high-quality master model. You mix and remove air from the silicone. Next, you pour it over the high-quality master model and let it harden. After you check the mold, you fill it with resin using the vacuum casting process explained. This makes sure there are no air bubbles. The vacuum casting process explained makes copies of the high-quality master model. These copies have…

When you need a prototype, understanding the differences between CNC milling vs turning prototypes is crucial. Opt for milling if your part has intricate shapes or unique features. On the other hand, choose turning if your part is round or cylindrical in shape. Selecting the appropriate process can significantly save you time and money. Refer to this table to see how your choice between CNC milling vs turning prototypes affects cost and speed: CNC Process TypeImpact on CostImpact on TimeSimple DesignsLower costsFaster machining timeComplex GeometriesHigher costsSlower machining time3-axis CNCMost cost-effective for simple partsQuick setup and machining5-axis CNCMore expensive but faster…

You check CNC Machining Tolerances to see if a part is made the right way. Many machines can make parts with a tolerance of ±0.02 mm. This is much thinner than a human hair. Some special machines can go as tight as ±0.0025 mm. The table below shows usual tolerances for different CNC processes: CNC ProcessTolerance (inches)Tolerance (mm)3-axis CNC Milling± 0.0050.135-axis CNC Milling± 0.0050.13Lathe± 0.0050.13 Many things can change how close your parts are to the design: Material properties Type of machining Things like tool wear and how good the operator is You need to know these things to pick…

You pick the best CNC machining material by matching it to your project. Think about what your part needs to do. Does it need to stand up to heat? Does it need to resist chemicals? Does it need to look a certain way? When considering CNC machining material selection, check the main things to think about: CriteriaDescriptionEnvironmentalStands up to heat, fire, or chemicals.ElectricalCarries or blocks electricity.MechanicalIs strong, tough, or hard to wear out.CosmeticGives color, see-through look, or feel.SizeFits the size of the material you have.CostMakes sure price and quality are balanced. Ask experts for help if you are not sure.…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.