You might wonder how many parts you can get from one silicone mold. Most molds give you anywhere from 25 to 256 parts before showing signs of wear. Some high-tech molds even make up to 1.5 million tiny parts every day. The silicone mold life cycle changes a lot depending on things like how often you use it, how clean you keep it, and what materials you cast. Check out the table below to see what can affect how long your mold lasts: FactorImpact on Mold Life CycleHumidityMoisture can cause corrosion in some materials.CleanlinessClean molds last longer and work better.Frequency…

When you need a prototype, you probably want the most cost-effective solution. If you only need a few parts, 3D printing usually gives you the best price. Once you need more parts or larger models, vacuum casting steps in as the winner. The vacuum casting vs 3d printing cost question really comes down to how many parts you need and how big they are. Key Takeaways 3D printing works best for small groups of parts. It is good for less than 20 parts. The starting cost is lower and setup is fast. Vacuum casting saves money when you make 20…

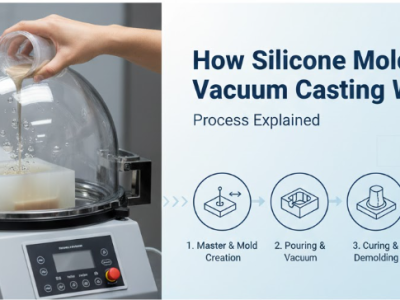

When you use the vacuum casting process explained here, you start with a high-quality master model. You get the surface ready so it is smooth. Then you make a silicone mold that copies every detail of your high-quality master model. You mix and remove air from the silicone. Next, you pour it over the high-quality master model and let it harden. After you check the mold, you fill it with resin using the vacuum casting process explained. This makes sure there are no air bubbles. The vacuum casting process explained makes copies of the high-quality master model. These copies have…

You can make snap-fits for polyurethane cast parts by seeing how the material bends and returns to shape. Vacuum casting snap fit design uses flexible polyurethane. This material does not wear out fast and can be used many times. You should look at how the snap-fit works. Check how strong the material is. Try not to have weak spots that can break. If you learn about stress points and fit tolerances, you can make joints that are strong and work well. Key Takeaways Pick flexible polyurethane for snap-fits. It bends without breaking and lasts a long time when used often.…

You need to choose the right fillet radius for strong and accurate parts. For vacuum casting fillet radius, experts suggest using at least a quarter of the wall thickness, not less than 1.5 mm, or a minimum of 0.5 mm for very small features. A good fillet helps the material flow better into the mold. It also reduces sharp corners that can cause weak spots or defects. Key Takeaways Use at least a 1.5 mm fillet radius for most parts. This helps stop weak spots and keeps parts strong. For small features, use a fillet radius of at least 0.5…

You need clear rules for vacuum casting rib boss design to achieve strong, high-quality parts. Follow these key guidelines for best results: Keep rib thickness less than 60% of the wall thickness. Limit rib height to less than three times the rib thickness. Make boss wall thickness no more than 60% of the wall. Use a minimum boss height and diameter of 1 mm. Apply these vacuum casting guidelines to boost part strength, prevent warping, and improve manufacturability. Key Takeaways Make sure rib thickness is less than 60% of the wall thickness. This helps make the part stronger and stops…

You must handle vacuum casting mold undercuts with good planning. Using the right methods helps a lot. Fixing undercuts lets you take out your part easily. It also keeps your mold safe. Many makers have problems like: Air bubbles happen if degassing or venting is not done well Parts do not cure right if time is too short or heat is wrong Mold can bend if you choose the wrong silicone hardness Parts stick if you forget release agents or use bad mold designs You can beat these problems with smart actions and expert advice. Key Takeaways Think about your…

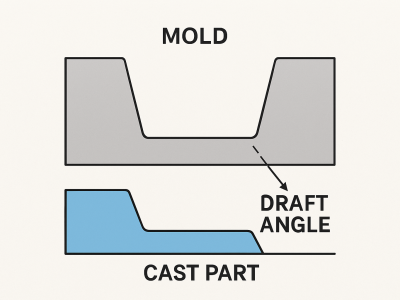

You should use a 1-2 degree vacuum casting draft angle for most parts. This small angle helps you remove parts from the mold without damage. When you add a draft angle, you make it easier to pull the part out and avoid sticking. This protects the silicone mold and keeps the part quality high. In vacuum casting, even a small draft of 1-2 degrees can make a big difference in how well your parts turn out. Key Takeaways Use a draft angle of 1-2 degrees for most vacuum cast parts. This helps the part come out of the mold easily.…

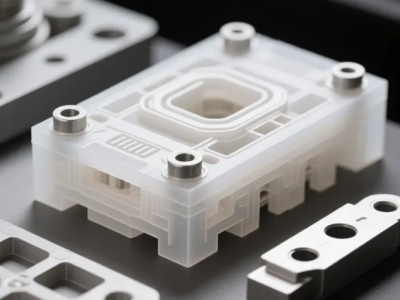

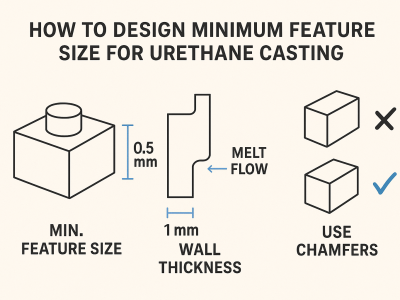

When you design custom urethane parts, knowing the right limits is important, especially regarding vacuum casting minimum feature size. This helps you make parts that are strong and work well. For urethane, the best wall thickness is 0.040 inches, and you can use 0.020 inches for small parts. ParameterRecommended ValueFeasible ValueWall Thickness0.040 in0.020 in Keep letters and numbers at least 1.3 mm apart. Make sure features are at least 0.050 inches apart. If you follow these vacuum casting rules, including the vacuum casting minimum feature size, you can avoid weak spots. You also prevent surprises in the size of your…

You have an important job in medical device prototype development. This process helps you change an idea into a real prototype. The prototype can help patients and make care better. In 2025, you will see new problems and chances in medical device design, testing, and prototyping. Every step, from idea to pilot prototype, affects the final product. You need to know about the materials, costs, and steps in development. This helps you make good choices and build safe, useful devices. Key Takeaways Learn about how to make a medical device prototype. Start with an idea. Then test it to make…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.