When deciding on a molding process, you should opt for liquid silicone rubber (LSR) molding over other methods if your product demands high precision, exceptional clarity, or complex shapes. Many engineers choose LSR for these specific reasons: It offers precise control for tight burr management. It provides exceptional clarity, ideal for medical components. It can produce intricate and detailed parts. It has faster cycle times compared to traditional thermoplastic molding. Understanding the differences between liquid silicone molding vs other processes is crucial in selecting the most suitable molding process for your design and manufacturing needs. Key Takeaways Pick liquid silicone…

Liquid silicone injection molding is a quick and accurate way to make parts from liquid silicone rubber. This process is special because it uses machines, gives smooth finishes, and makes parts that fit very well. You get fast production and spend less money on workers than with hand molding. Things like seals, medical tools, and electrical parts are made using this method. The world market for liquid silicone injection molding is getting bigger, and it may be worth $3,700 million by 2035. Key Takeaways Liquid silicone injection molding works quickly and saves money. It is great for making many parts…

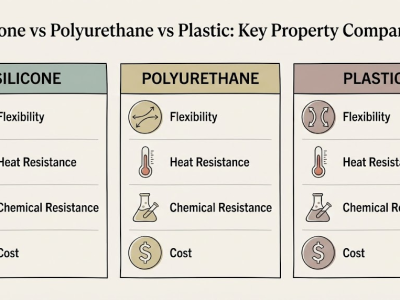

Silicone is often the best choice for epoxy resin mold material. Silicone provides flexibility and durability, making it easy to remove your project from the mold. When you pour resin into silicone molds, you quickly understand why they are favored by many. These molds are suitable for both beginners and experts. Silicone mold rubber and platinum-cured silicone mold rubber work exceptionally well with resin casting. If you plan to reuse a mold, silicone is an excellent option as it creates strong molds that last. Rigid molds like polyurethane mold rubber or plastic are ideal for hard shapes and can also…

If you want to make silicone parts with vacuum casting in China, you should know the steps to do it well. This vacuum casting china guide shows why picking the right supplier and design is important. Vacuum casting lets you make a prototype or small batch fast and without spending a lot. You can make cheap prototypes and get good silicone parts quickly. Tip: A simple guide helps you not make mistakes and get what you want. Key Takeaways Vacuum casting in China helps you save money. It costs less than in Europe or the USA. You can make prototypes…

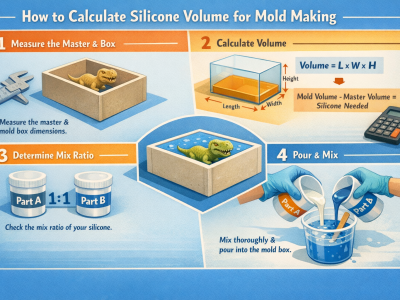

Accurate measurements stop you from wasting silicone and help you calculate silicone volume for mold effectively. They also ensure your mold works correctly. You can find silicone volume using a simple formula: Required Material Volume equals Mold Container Volume minus Model Volume. For regular shapes, use these formulas: ShapeFormulaSquare/RectangleVolume equals length times width times heightCylinderVolume equals π (3.14) times radius squared times height Follow these steps to get the right amount of silicone each time. Key Takeaways It is very important to measure carefully. Measure your mold container and model two times so you do not make mistakes. Use the…

When silicone cure inhibition happens during molding, you need to act fast. Cure inhibition stops silicone from setting. This wastes time and materials. You should find the problem early and fix it the right way. A clean workspace helps stop sticky or soft spots. Using the right cleaning method also helps. The table below shows how different ways can change your results: Type of SiliconeSensitivity to ContaminantsImpact on Production Costs and TimelinesPlatinum CureSensitive to sulfurCosts and time go up because you need a clean workspace and more testingTin CureMore forgivingCosts and time go down, and it is easier for beginners…

You want your training sessions to be great. Professional trainers pick platinum silicone mannequins because they last a long time. They look real and help keep you safe. When you consider silicone vs tpe mannequins, you see why silicone is the superior option. Silicone mannequins do not get damaged easily. They feel like real skin and do not cause health problems. If you want something you can trust and that is worth the money, silicone is the best choice. Key Takeaways Platinum silicone mannequins are strong and last a long time. They can last more than 45 years. This makes…

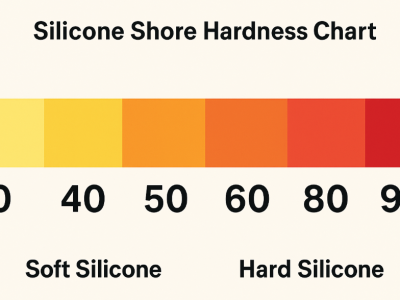

Imagine you need to pick the right silicone part for a seal or a gasket. How do you know if it will be soft enough to seal or hard enough to hold its shape? The silicone shore hardness chart is your go-to tool for answering these questions quickly. By referring to the silicone shore hardness chart, you can easily compare different silicone materials and make informed choices for your projects. This quick understanding leads to better engineering decisions. Key Takeaways Always look at the shore hardness number before you pick silicone. This number tells you if the material is soft…

If you want to work fast and save money, use silicone molds for small batches. You get quick results and can change things easily. This works best if you make less than 500 pieces. However, when considering silicone mold vs steel mold, if you need more parts or stronger molds, it's time to switch to steel molds. Steel molds last much longer and can create tricky shapes very well. Steel molds, especially heat-treated steel, last five to ten times longer than aluminum. This makes them better for making lots of parts. Here is a simple look at why makers change…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.