Liquid silicone injection molding is a quick and accurate way to make parts from liquid silicone rubber. This process is special because it uses machines, gives smooth finishes, and makes parts that fit very well. You get fast production and spend less money on workers than with hand molding. Things like seals, medical tools, and electrical parts are made using this method. The world market for liquid silicone injection molding is getting bigger, and it may be worth $3,700 million by 2035. Key Takeaways Liquid silicone injection molding works quickly and saves money. It is great for making many parts…

When deciding between silicone mold vs injection mold prototypes, there are several key factors to consider. First, determine how many parts you need. Next, evaluate your budget and how quickly you require the parts. It’s also important to identify the materials you plan to use and assess the complexity of your part design. FactorSilicone Mold (Vacuum Casting)Injection Mold (Injection Molding)Production VolumeSmall runs (up to ~100 units)Large volumes (hundreds of thousands)CostLower tooling cost for small batchesHigh initial cost, better for high volumeSpeedMold in 5-7 days, slower per-part speedMold takes weeks, fast per-part speedMaterial CompatibilityPolyurethane resins, limited optionsWide range of plastics, high…

Choosing between vacuum casting and low volume injection molding depends on your specific needs for small batch production. Vacuum casting has a lower initial cost and allows for easier design changes. On the other hand, low volume injection molding produces parts faster and offers a lower cost per part when producing larger quantities. The table below highlights the key differences: FeatureVacuum CastingLow Volume Injection MoldingSetup CostLow to moderateHigher upfrontPer-Unit CostHigher at scaleLower with volumeLead TimeShorterLonger setup, faster cyclesTool LifeUp to 200 partsUp to 50,000 shots Key Takeaways Vacuum casting works well for small groups and fast samples. It costs less…

Metal injection molding combines fine metal powders with binders to form precise shapes, making it a key process for producing accurate components. This technique is essential for manufacturing small, complex parts with tight tolerances and high strength. Many industries rely on metal injection molding to produce millions of intricate parts each year. The table below highlights the expanding market for metal injection molding, reflecting its growing importance in high-volume production: Market StatisticValueSignificanceMarket size in 2024USD 5.75 billionThere is a big need for exact partsExpected market size by 2030USD 11.09 billionMore people are using metal injection moldingCAGR 2024-203011.6%It is growing fast…

Choosing the right plastic injection molding machine can improve your production. There are three types: hydraulic, electric, and hybrid machines. Each type has special benefits for different production needs. In 2023, the plastic injection molding market was worth $330.41 billion. This shows how important this technology is for making better products faster. The market is expected to grow by 5.4% every year. Knowing how these plastic injection molding machines work helps you stay competitive. Pick the one that fits your goals, like speed, accuracy, or saving energy. Key Takeaways Learn about three types of plastic molding machines: hydraulic, electric, and…

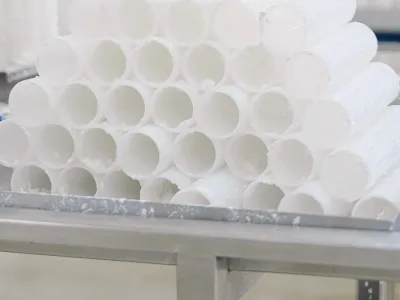

Silicone molding production technology Silicone molds go through four main stages: design, production, use, and care. Each stage is important for keeping the mold working well and lasting longer. Knowing these steps helps improve performance and avoid delays. The silicone molding industry is becoming more important. The market was worth 3.45 billion USD in 2023. It may grow to 5.5 billion USD by 2032. Makers now use greener materials and better tools to meet custom needs. New technologies improve how molds are made and checked. Lightweight silicone rubbers are popular for saving fuel in some industries. These changes show why…

The injection molding industry is changing fast, offering cool injection molding jobs near me. New technology and automation are improving how things are made. These changes need workers with skills and flexibility. Around the world, this field is growing. In 2024, Asia-Pacific will make 40% of the money because of more need for medical tools and eco-friendly materials. If you want a job in injection molding, learn the skills and get certified to succeed in this exciting field. Key Takeaways The injection molding industry is growing fast. It may reach $511.7 billion by 2031. This growth means more jobs for…

Choosing the right method for manufacturing products is crucial. Polyurethane casting and injection molding differ in several aspects, such as production volume, cost, time, and materials. Polyurethane casting is ideal for small batches or prototype models, while injection molding is more suitable for large-scale production due to its lower cost per unit. Understanding these differences allows you to select the most effective approach for your project, ensuring optimal results. Key Takeaways Pick urethane casting for small jobs or test models. It is cheaper and helps test designs quickly. Use injection molding if you need many parts made. It costs less…

Have you ever thought about making your product ideas real? Injection molding machines, specifically desktop models, could help you do it. These machines make small amounts of plastic parts fast and easy. Their small size works well for home workshops or tiny businesses. They also don’t cost too much money. Some companies say they save thousands by using injection molding machines. You can use them to test new designs or make custom items. Desktop injection molding is simple and easy to use. It’s a big help for small-scale manufacturing. Key Takeaways Desktop injection molding machines are cheap and great for…

Silicone moulds have revolutionised baking and crafting due to their ease of use. Their non-stick surfaces make them ideal for intricate designs. Perfect for cakes, chocolates, resin, and soap projects, these moulds are increasingly sought after as more people embrace custom and eco-friendly tools. With the growing popularity of home cooking and crafting, silicone moulds enable creative designs while being both practical and visually appealing. Key Takeaways Silicone moulds are useful for baking and crafting. They have non-stick surfaces, so items come out easily without breaking. Use food-safe silicone moulds for baking to stay safe. Check for FDA-approved labels to…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.