You should pick CNC text marking if you want deep and lasting marks on your parts. Laser marking is best for high accuracy, fast work, and clear marks. The CNC engraving process uses a computer system and a CNC engraving machine to cut into materials, while laser marking employs a laser engraver or laser marking machine that does not touch the part. Here is how CNC text marking vs laser marking differs:

Feature | CNC Text Marking | Laser Marking |

|---|---|---|

Process | Touches part, tool changes | Does not touch, quick setup |

Depth | Deep (more than 0.5 mm) | Shallow (0.1-0.3 mm) |

Legibility | High, depends on how deep | High, always the same |

Compatibility | Works with many materials | Not for shiny copper or chrome |

Cost | $15-30 for each part | $5-15 for each part |

You need to think about what is most important: accuracy, speed, how long the mark lasts, or cost. Laser marking and CNC text marking both create marks that endure, but each is better suited for different jobs. More people are purchasing laser marking machines now, indicating a growing preference for laser technology. If you want special marks on parts with very good accuracy, laser marking could be the best choice.

Key Takeaways

Pick CNC engraving if you want deep marks that last. These marks can handle rough use and do not wear off easily. This way is best for parts that face tough conditions.

Use laser marking when you need fast and clear marks. It helps make detailed marks quickly on many materials.

Think about what your parts are made of. CNC engraving works great on metal and plastic. Laser marking works on many things but may not work well on shiny surfaces.

Try both ways on sample parts first. This helps you see which one looks better and lasts longer before making many parts.

Look at your budget and how many parts you need. CNC engraving is good for small amounts. Laser marking saves money when you make lots of parts.

CNC Text Marking vs Laser Text Marking — Quick Answer

When you pick between cnc text marking and laser marking, think about what your parts need most. If you want marks that are deep and last a long time, cnc engraving is a good choice. This method uses a cnc engraving machine with computer control to cut into the material. The marks do not wear off easily and stay clear for many years.

If you want marks that are easy to see, have fine details, or need to make many parts fast, laser marking is better. A laser engraver or laser marking machine does not touch the part. The laser beam makes marks that are sharp and easy to read. You can mark lots of parts quickly. This works well for serial numbers, barcodes, and logos.

Tip: Pick cnc engraving if your parts will rub against things, get cleaned a lot, or be outside. Use laser engraving if you need text or pictures that look sharp and clear.

Here is a simple chart to help you choose:

Engraving Type | Key Features | Best Use Cases |

|---|---|---|

CNC Engraving | Deep, lasting marks; strong against wear | Good for parts that must stay readable for a long time |

Laser Engraving | High detail; sharp contrast; fine lines | Best for lots of parts and surface-level markings |

You should also think about what the part is made of. Cnc engraving works on metal, plastic, and wood. Laser marking works on most things, but shiny copper or chrome can bounce the laser away. Both laser etching and laser engraving use a laser, but laser etching makes shallow marks. Laser engraving goes deeper and is easier to see on small letters.

If you want the fastest way, laser marking is best. The laser etching machine or laser marking machine can finish many parts faster than cnc. For the best detail, laser engraving is the winner. For the strongest marks, cnc engraving is the best pick.

CNC Text Engraving vs Laser Text Marking — Key Differences

When you look at cnc text marking and laser marking, you notice they work in different ways. Cnc engraving machines use computer control to cut into the material. This makes deep marks that last a long time. The marks stay even if the part gets used a lot. On the other hand, a laser engraver or laser marking machine uses a strong laser. The laser burns the top of the part but does not touch it. This gives you sharp and clean lines with very good accuracy.

Comparison Table: CNC Text vs Laser Text

Feature | CNC Engraving | Laser Engraving |

|---|---|---|

Process Mechanics | Uses a cutting tool that contacts material | Utilizes a high-powered laser to vaporize material without contact |

Setup Time | Typically straightforward | Requires more initial setup time |

Labor Requirements | Needs operator to load/unload parts | Minimal operator intervention after setup |

Marking Depth | Provides deeper engravings | More superficial markings |

Durability of Markings | Longer-lasting due to physical cutting | Can wear off on softer metals |

Production Speed | Slower for large batches | Faster for large quantities |

Material Flexibility | Greater flexibility in materials | Can be used on a wider variety of materials |

Visibility on Polished Surfaces | Better long-term visibility | Relies on surface changes for visibility |

Cnc engraving has some strong points. The mark is cut into the part, not just on the surface. This means your text or logo will not fade, even if the part gets hot or scratched. You can use cnc engraving for tough, clear marks on metal or plastic. But you need someone who knows how to run the machine. It also takes more time and can cost more if you have many parts.

Laser engraving is fast and works on many materials. You can use a laser engraving machine or laser etching machine for lots of jobs. The laser does not touch the part, so there is less risk of damage. It is easy to get fine details and the same results every time. This is great for things like serial numbers or barcodes. The laser is best for small letters and very clear marks.

Tip: Pick cnc engraving if you want deep marks that you can feel and that last. Choose laser marking if you need fast, detailed, and repeatable marks on the surface.

Think about what your part is made of and where it will be used. For parts that go outside or get used a lot, cnc engraving is stronger. For making lots of parts or when you want marks that are easy to see, laser marking is a better pick.

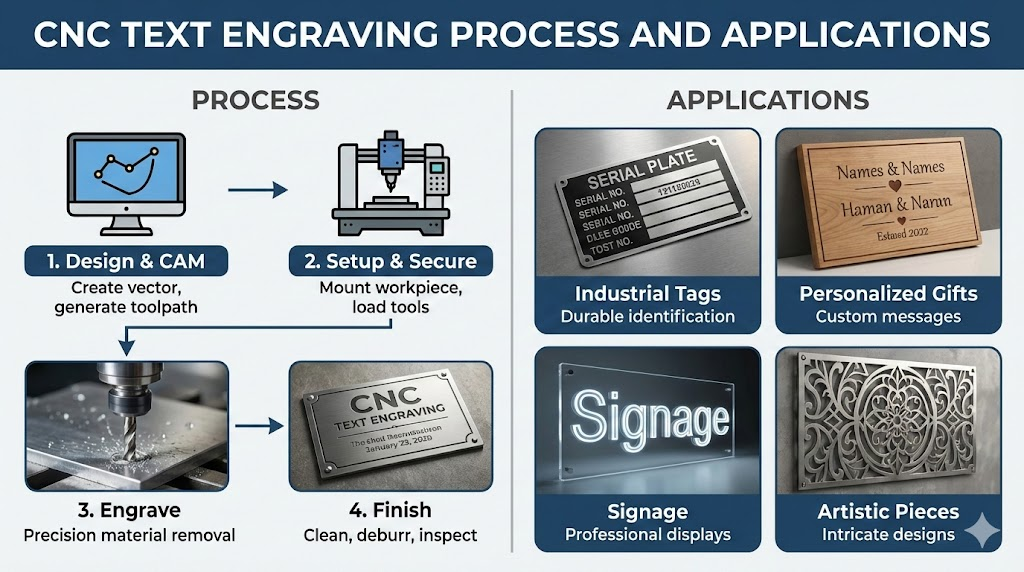

CNC Text Engraving Process and Applications

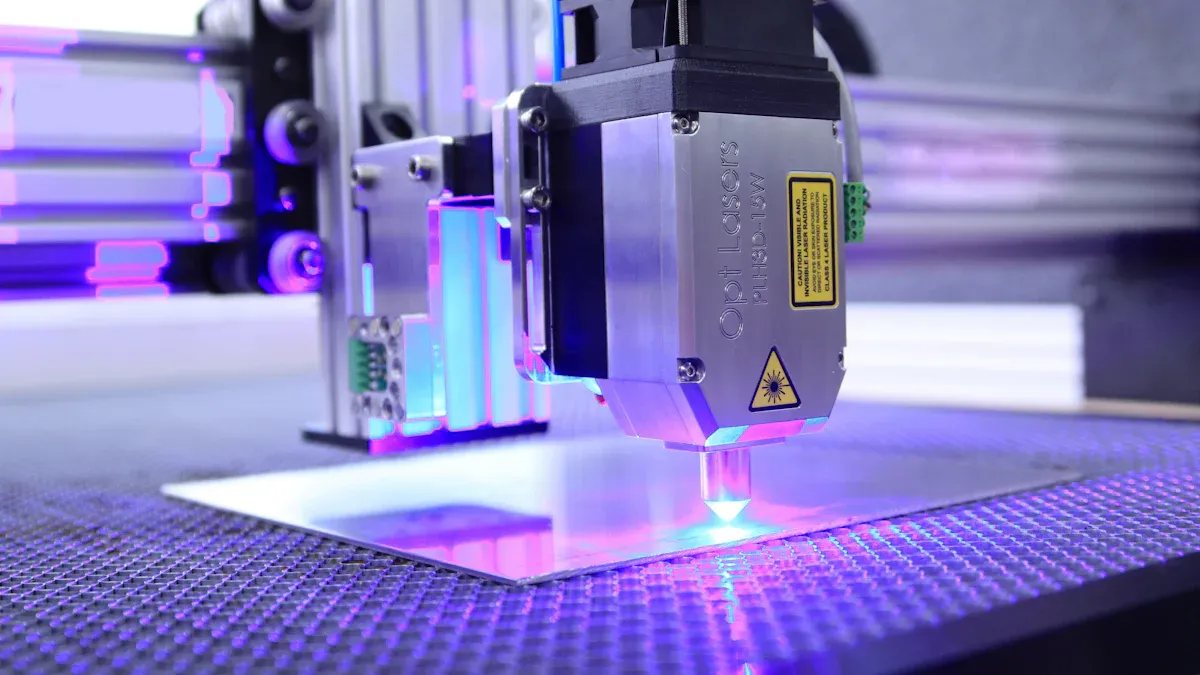

How CNC Text Engraving Works

CNC text engraving gives you very accurate and lasting marks. This method uses a cnc machine to cut words or pictures into your parts. Here is how it works:

Design Creation: First, you make your text or logo in CAD software. You can change the size, shape, and depth.

Converting Design to Machine Code: Next, you use CAM software to turn your design into G-code. The cnc machine reads this code.

Setup: You put your material on the machine and make sure it is tight. You also pick the right tool for engraving.

Engraving: The cnc machine follows the G-code and cuts your part with great care.

Post-Processing: You clean away dust, check the mark, and add any finish.

Tip: Picking the best tool and settings helps you stop problems like tool wear or blurry letters. This is extra important on curved parts.

Materials Suitable for CNC Text Engraving

You can use cnc engraving on lots of materials. The table below shows some choices and how they work:

Material Type | Performance Characteristics |

|---|---|

Wood | Soft, needs deeper cuts, less detail |

Metals | Includes aluminum, steel, brass, copper, silver, gold; engraves well with less force |

Plastics | Hard plastics like acrylic and polycarbonate work best; need sharp tools and slow speed |

Aluminum and steel are good for marking because they last long and do not rust. Plastics are great for small designs and light parts.

Typical CNC Text Marking Applications

CNC engraving is used in many jobs. Here are some examples:

Sign Making: You can make road signs and ads that last in all weather.

Jewelry: Jewelers use cnc engraving for names or patterns on jewelry.

Industrial Marking: Factories use it for strong marks on machines, safety signs, and directions.

CNC text marking gives you deep marks that stay easy to read for years. If you want marks that show up well and last long, cnc engraving is a good pick. Laser marking, laser engraving, and laser etching machines are fast and make surface marks, but cnc engraving is best for deep and tough marks. You can count on this process for parts that must stay marked and clear.

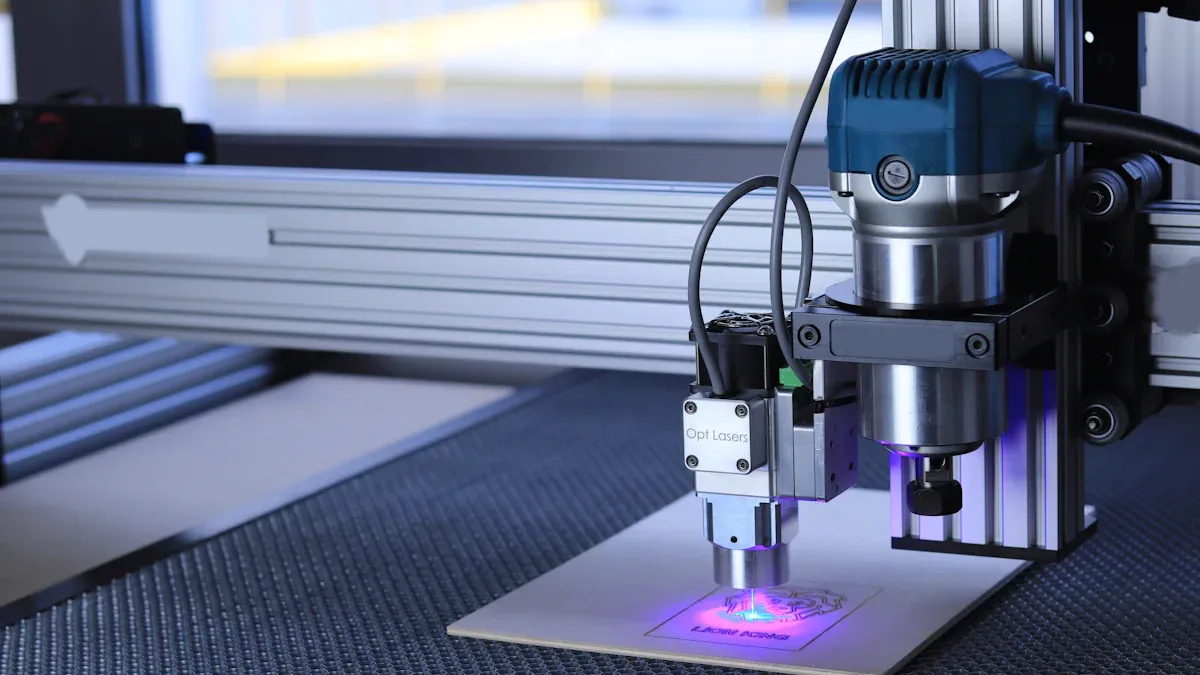

Laser Text Marking Process and Applications

How Laser Text Marking Works

A laser marks text by changing the surface with a strong light. The laser does not cut deep like cnc engraving. It makes bright marks on the top layer. This keeps the part strong and safe. You can pick laser marking, laser engraving, or laser etching. Each one changes the surface in its own way.

Laser marking uses a weak beam to color or burn the top.

Laser engraving makes deeper marks by burning away some material.

Laser etching melts the top to make raised marks.

Here is a simple chart:

Process Type | Description | Penetration Level |

|---|---|---|

Laser Marking | Adds readable info on the top with almost no depth. | Minimal to None |

Laser Engraving | Puts info below the top with clear depth. | Evident Penetration |

Laser Etching | Melts the top to make marks. | Surface Level |

You can use a laser engraving machine, laser etching machine, or laser marking machine for these jobs. The process is quick and needs little setup. You get clear and repeatable marks every time.

Materials Suitable for Laser Text Marking

Laser text marking works on lots of materials. You can mark metals, plastics, and polymers. Metals give strong and neat marks. Polymers are used in factories and need clear labels. Plastics act differently, so you must know how each type works with lasers.

Material Type | Compatibility with Laser Marking | Key Properties |

|---|---|---|

Metals | High | Strong, does not rust, neat marks |

Plastics | Variable | Many types, need to know how they react to lasers |

Polymers | High | Used a lot in factories, important for labels and brands |

Fiber lasers work well for metals and tough plastics. CO2 lasers are best for things like wood and other non-metals. UV and green lasers help mark soft surfaces. Fast lasers give great detail for special parts.

Typical Laser Text Applications

Laser text marking is used in many jobs. Electronics and chips need marks that last through heat and shaking. Tooling and factories use laser marking for quick, strong labels. Consumer goods and packages use it for brands and marks that are good for the planet. Cars and planes need marks that stay clear in hard places. Medical tools need marks that do not wash off and meet rules.

Application | Key Benefits |

|---|---|

Electronics and Semiconductors | Very neat marks, no touching, lasts through heat and shaking. |

Tooling and General Manufacturing | Quick, strong labels, easy to see after many uses, helps track parts. |

Consumer Goods and Packaging | Sharp brands, marks that stay, good for the planet, no ink needed. |

Automotive and Aerospace | Clear marks, stays in tough places, helps with checks and tracking. |

Medical Devices and Instruments | Marks that do not wash off, safe from cleaning, meets health rules. |

You can stop problems like bad marks or weak color by changing laser settings and keeping your machine clean. Taking care of your tools and learning how to use them helps you get the best marks. When you look at cnc text marking vs laser marking, laser gives you fast, flexible, and clear marks for many kinds of parts.

CNC Text Engraving vs Laser Text — Engineering Comparison

Text Depth and Wear Resistance

You want your marks to last a long time. CNC engraving cuts deep into the material. This makes the marks strong and hard to wear away. You can use cnc engraving for parts that get used a lot or cleaned often. High-power fiber lasers can also make deep marks. These marks last longer and resist wear. Laser marking usually makes shallow marks. These marks look nice but can wear off faster on soft metals. Deep laser engraving takes off more material. It gives better wear resistance but takes more time.

CNC engraving: Deep marks, very strong, and exact.

Laser marking: Shallow marks, quick, and saves money.

Deep laser engraving: Lasts longer, but is slower.

Legibility of Small Fonts

You need text that is easy to read. This is important for small fonts. Laser marking gives very clear and sharp lines. The laser beam makes fine details and neat edges. You can use a laser marking machine for tiny letters or codes. These marks stay easy to read. CNC engraving also works well. But very small fonts may lose detail if the tool is too big. Laser etching is good for small, detailed marks on many materials.

Tip: Pick laser marking for the clearest small fonts and tricky designs.

Speed and Production Volume

Speed is important when you have lots of parts. Laser marking is the fastest way to mark parts. You can use it for big production lines. Laser etching is faster than engraving but not as fast as marking. CNC engraving takes more time. It removes more material and may need to go over the part many times.

Process | Speed | Production Volume |

|---|---|---|

Laser Marking | Fastest cycle time | Best for lots of parts |

Laser Etching | Medium speed | Quicker than engraving |

Laser Engraving | Slowest | Needs more passes |

Laser marking helps you finish more parts quickly.

Cost for Low vs High Volume Text Marking

You want to save money. For small jobs, cnc engraving is a good choice. You get strong marks, but it is slower and costs more for each part. For big jobs, laser marking saves you money. The laser works fast and needs less help from people. You can mark many parts quickly and keep costs low. Laser engraving costs more than marking but makes deeper marks. Pick the process that fits your budget and how many parts you need.

Note: Laser marking is best for big batches. CNC engraving is better for small jobs that need deep marks.

How to Choose the Right Text Marking Method

Choosing the right text marking method for your parts helps you get the best results. You need to look at the material, how long you want the mark to last, and how you want it to look. Each process works better for certain jobs. You can use cnc engraving for deep marks or laser marking for fast and detailed marks.

Best Text Marking Method by Material

You should match the marking method to your material. Some materials work better with laser, while others need cnc engraving. Use this table to help you decide:

Criteria | Description |

|---|---|

Assess Material Compatibility | Check how your material reacts to laser or cnc engraving. This helps you avoid mistakes. |

Select Marking Method Based on Material Hardness | Use low-power laser for soft materials. Pick high-power laser or cnc for hard materials. |

Consider Environmental Exposure | Choose a method that stands up to wear, chemicals, or weather. |

Optimize for Readability | Make sure your marks are easy to see. Use high-contrast and the right font size. |

Test Before Full Production | Try your marking process on a sample part first. Adjust settings to get the best results. |

If you use metals like steel or aluminum, cnc engraving gives you strong marks. Plastics and polymers often work well with laser marking. Shiny surfaces like chrome may not mark well with a laser marking machine.

Best Method for Permanent Text

You want your marks to last for years. Deep engraving works best for permanent text. Use cnc engraving for parts that face lots of wear or cleaning. Laser engraving also makes lasting marks, especially with fiber lasers. If your parts go outside or get used a lot, pick a process that cuts deep. Laser etching makes shallow marks, so it is not the best for permanent text.

Tip: For permanent marks, choose cnc engraving or deep laser engraving. These methods keep your text readable even after heavy use.

Best Method for Aesthetic Text

You may want your marks to look sharp and clean. Laser marking gives you fine lines and high contrast. This process works well for logos, serial numbers, and small fonts. You can use laser to create detailed designs on many parts. Cnc engraving also makes neat marks, but laser marking is faster and gives you more options for style. If you want the best look, try laser marking or laser engraving.

Note: Test your marking process on a sample part to see how it looks. Adjust settings for the best appearance.

Final Recommendation for CNC Text vs Laser Text Marking

You face an important choice when you need to add text to your parts. Both cnc and laser methods give you strong options. You should look at your needs before you pick a process. If you want deep and tough marks, cnc engraving works best. This process cuts into the material and gives you marks that last for years. You can use cnc engraving for parts that see a lot of wear or need to stay readable in harsh places.

Laser marking gives you speed and detail. You can use laser for fast jobs and for parts that need clear, sharp text. Laser engraving also gives you good results if you want deeper marks but still need fine lines. Laser etching works well for surface marks that do not need to last as long. You can use laser for many materials, but shiny metals like chrome may not work well.

Tip: Test both cnc and laser on a sample part before you decide. This helps you see which process gives you the look and strength you want.

Here is a quick guide to help you choose:

Need | Best Method |

|---|---|

Deep, permanent marks | cnc engraving |

High detail, fast marking | laser marking |

Small fonts, fine lines | laser engraving |

Surface marks, quick jobs | laser etching |

You should also think about cost and how many parts you need to mark. Laser marking works well for big batches. Cnc engraving fits small runs or special jobs. Always match the process to your material and your needs. You get the best results when you choose the right marking method for your parts.

You have two strong options for text marking on your parts. Laser marking gives you fast, clear results on many materials. Laser engraving works well for detailed designs and large batches. CNC engraving creates deep, lasting marks and works best when you need strong wear resistance. The table below shows the main pros and cons:

Method | Pros | Cons |

|---|---|---|

Laser Engraving | Wide material use, fast, crisp finish | Can wear off softer metals |

CNC Engraving | Deep, long-lasting engraving, simple setup | Needs parts secured during engraving |

Think about your material, budget, and how long you want the marking to last. You can test both laser and cnc processes or talk to a marking expert. Choose the best method for your parts and get the results you need.

FAQ

What is the main difference between cnc engraving and laser engraving?

You use cnc engraving to cut deep marks into your parts. Laser engraving uses a beam of light to make marks on the surface. Cnc gives you strong, lasting marks. Laser gives you fast, detailed results.

Can I use laser marking on all materials?

You can use laser marking on many materials. Metals, plastics, and polymers work well. Shiny surfaces like chrome or copper may not mark well with a laser. Always test your parts before starting the process.

Which process is best for small, detailed text?

Laser engraving works best for small, detailed text. The laser creates sharp lines and clear letters. You get high contrast and easy-to-read marks. Cnc engraving also works, but laser gives you better detail for tiny fonts.

Is cnc engraving better for outdoor parts?

You should pick cnc engraving for outdoor parts. The engraving process cuts deep into the material. Your marks stay readable even after weather, cleaning, or heavy use. Laser etching makes shallow marks that may wear off outside.

How do I choose between laser and cnc for my marking needs?

You need to look at your parts, the material, and how long you want the marks to last. Use cnc for deep, permanent engraving. Pick laser for fast, detailed marking. Test both methods to see which process fits your needs.

LKprototype

LKprototype