Share a little biographical information to fill out your profile. This may be shown publicly.

CNC, or computer numerical control, plays a transformative role in manufacturing. To understand the CNC meaning, it refers to the use of computers to control machines, enabling faster and more precise work. Unlike traditional methods, CNC relies on programmed software to operate machines, ensuring consistent results every time. This technology supports modern factories by reducing errors, saving time, and increasing production efficiency. The impact of CNC on industries has been significant. For instance: CNC machine sales reached $66.4 billion in 2023. Projections suggest sales could grow to $162.16 billion by 2032, with an annual growth rate of 10.43%. CNC also…

Vacuum casting uses silicone molds and vacuum chambers to make detailed parts. It is helpful for creating small batches that look like final products. This process makes prototypes very accurate and meets industry rules. The vacuum casting market is growing fast. It was worth $1.5 billion in 2022 and may grow 7.5% each year until 2030. Industries like cars, planes, and healthcare use vacuum casting to make high-quality parts. It works quickly and saves money, so manufacturers like it for making precise parts fast. Key Takeaways Vacuum casting is great for making detailed models and small amounts. It saves money…

A CNC Wood Cutting Machine uses speed and accuracy for woodworking jobs. You can change settings like spindle speed, cutting depth, and feed rate to get different results. For example: Spindle speeds from 8000 to 12,000 RPM work for many wood types. Cutting depths between 0.08 and 0.20 inches make deeper cuts while keeping good quality. Feed rates of 0.003 to 0.005 inches per tooth balance smooth surfaces and tool wear. These settings help the machine cut solid wood and hardwood up to 150mm thick well. Knowing these settings lets you improve the machine for your needs. Key Takeaways Change…

When a resin 3D print is done, the work isn’t finished. Post-Processing Techniques are essential to make your prints stronger and look better. These steps also ensure that prints are safer to handle. For example, cleaning with ethanol lowers harmful resin chemicals. Curing helps prints last longer by making them tougher. Washing prints well enhances their appearance too. Every step is important if you want great-looking designs. Don’t skip these steps—Post-Processing Techniques help your prints look professional and amazing. Key Takeaways Take off supports slowly to make the print look better. Use proper tools to avoid breaking it.Clean your print…

Choosing the right plastic injection molding machine can improve your production. There are three types: hydraulic, electric, and hybrid machines. Each type has special benefits for different production needs. In 2023, the plastic injection molding market was worth $330.41 billion. This shows how important this technology is for making better products faster. The market is expected to grow by 5.4% every year. Knowing how these plastic injection molding machines work helps you stay competitive. Pick the one that fits your goals, like speed, accuracy, or saving energy. Key Takeaways Learn about three types of plastic molding machines: hydraulic, electric, and…

Micron-level tolerances are the highest level of precision in CNC machining. This means sizes are controlled within an extremely tiny 0.001mm range. Such accuracy is crucial for industries like aerospace and medical devices. Even small errors can affect how things work or make them unsafe. In aerospace, turbine blades need sizes accurate to ±0.005 mm. They also require smooth surfaces below 0.4 µm Ra. One top company cut waste by 30% and improved blade performance by using stricter tolerances. The need for this level of precision is growing. For example: A report by Lucintel shows a 4.7% yearly growth in…

Silicone molding production technology Silicone molds go through four main stages: design, production, use, and care. Each stage is important for keeping the mold working well and lasting longer. Knowing these steps helps improve performance and avoid delays. The silicone molding industry is becoming more important. The market was worth 3.45 billion USD in 2023. It may grow to 5.5 billion USD by 2032. Makers now use greener materials and better tools to meet custom needs. New technologies improve how molds are made and checked. Lightweight silicone rubbers are popular for saving fuel in some industries. These changes show why…

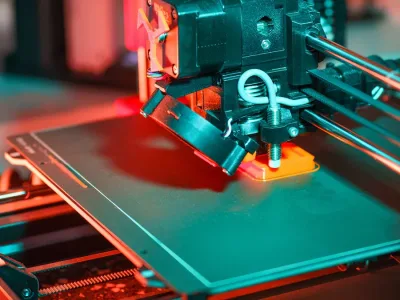

Dual extruder 3D printers are changing how things are made. They let you print with two materials or colors at once. This makes your designs more useful and creative. You can create detailed models, mix hard and soft parts, or use supports that dissolve for tricky shapes. If you want faster printing and better designs, try a dual extruder 3D printer. Whether you're testing ideas, making crafts, or inventing, this tool helps bring your ideas to life. Key Takeaways Dual extruder 3D printers can print with two colors or materials at the same time. This boosts creativity and makes designs…

Silicone molds for resin are very useful in manufacturing today. They are flexible and help make accurate and detailed parts for many industries, like cars and healthcare. Silicone molds make production faster, which is great for custom designs and small batches. The Vacuum Casting Machine Market might reach 0.65 million USD in 2023. This shows how important silicone molds are. Industries like electronics and airplanes use these molds to make cheap prototypes. Silicone molds help make work easier while keeping quality and speed high. Key Takeaways Silicone molds are bendable and strong. They help make detailed parts for many industries,…

Urethane rubber casting is an effective method for creating flexible molds. These durable molds are crafted using liquid urethane rubber casting, making them ideal for replicating intricate designs with precision. The process achieves size tolerances within ±0.010” to ±0.020”, which, while less precise than injection molding, still delivers reliable results. This technique is particularly beneficial for developing and testing new products. A single mold can produce 1–10 parts daily, depending on the type of urethane rubber casting used and the complexity of the part's design. The entire process, from start to finish, typically takes just a few weeks, making it…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.