Imagine you order silicon molds for baking, thinking they are flexible trays, but you get hard, breakable blocks instead. This mistake can slow down your work and cost you money. Many people mix up silicon molds and silicone molds. You should know the difference if you make things or design products. Using the right word helps you avoid expensive mistakes and keeps your projects going well.

Key Takeaways

Silicon is a hard and breakable element. People use it in electronics. Silicone is soft and bends easily. People use it for baking and in medical items.

Silicone molds are safe to use. They last a long time. They can handle heat well. This makes them good for food, medical, and factory uses.

If you order silicon molds instead of silicone molds, you can make expensive mistakes. Silicon molds break fast and do not bend.

Always look at what the mold is made of before you buy it. Check for safety labels and certifications. This helps you use it the right way.

Try out your mold design first. Talk clearly with the people who make the molds. This helps you avoid problems and get good results.

Silicon vs. Silicone

What Is Silicon?

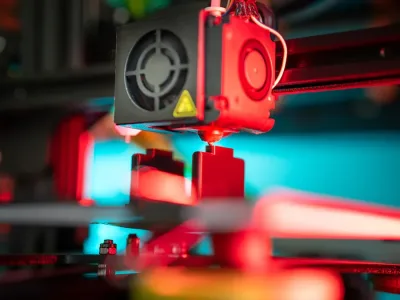

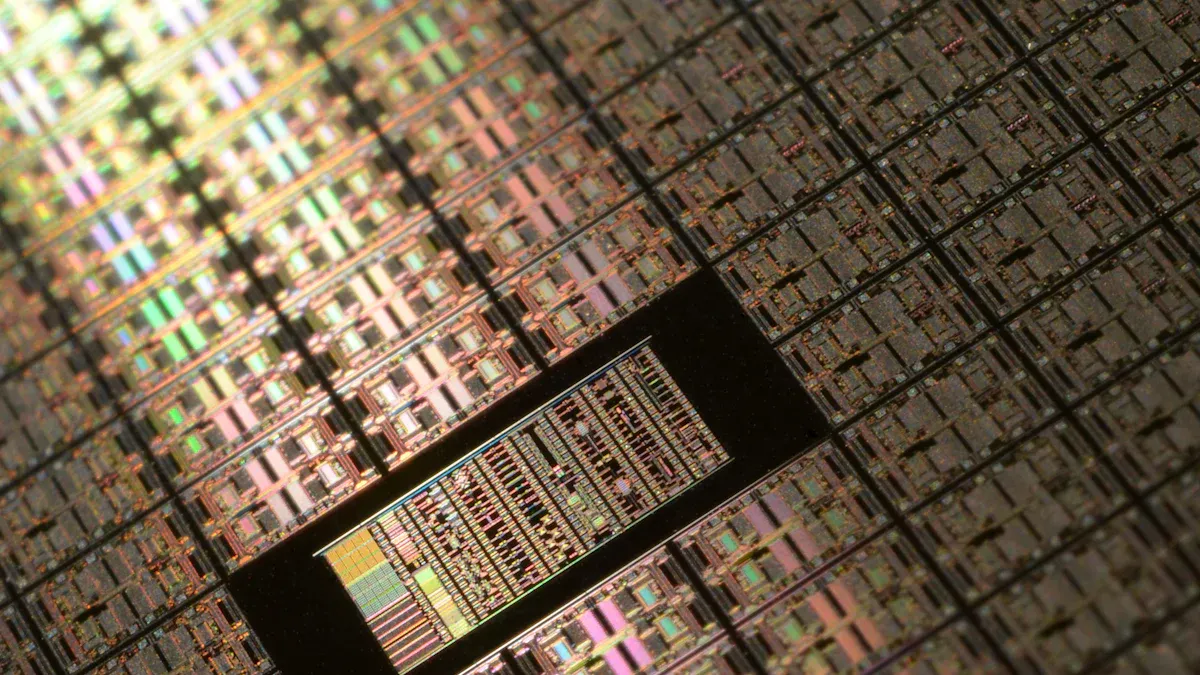

Silicon is a natural element found in the Earth’s crust. It looks shiny and gray. It breaks if you try to bend it. Silicon is not soft or bendy. People make silicon by heating quartz sand with carbon. They use very high heat for this. This makes pure silicon. Many industries use pure silicon. You see silicon in electronics like computer chips. It is also in solar panels. Silicon is in glass, ceramics, and some health products.

What Is Silicone?

Silicone does not come from nature. People make silicone by mixing silicon with oxygen, carbon, and hydrogen. This makes long chains called polymers. These chains make silicone soft and stretchy. Silicone can be shaped into rubber, gel, or liquid. You find silicone in kitchenware and medical devices. It is also in car parts and building materials. Silicone does not get damaged by heat, water, or chemicals. It works well in tough places.

Key Properties

Tip: Knowing the properties helps you pick the right material.

Here is a table that shows how silicon and silicone are different:

Aspect | Silicon | Silicone |

|---|---|---|

Chemical Nature | Element (atomic number 14) | Synthetic polymer (siloxane polymer) |

Atomic Composition | Pure silicon atoms | Silicon and oxygen atoms with organic groups |

Structure | Hard, rigid, crystalline | Flexible, long polymer chains |

Physical Properties | Brittle, conducts electricity | Soft, flexible, insulates electricity |

Occurrence | Found in nature | Made in factories |

Bonding | Strong lattice bonds | Strong Si–O bonds, flexible chains |

Applications | Electronics, semiconductors | Cookware, medical devices, sealants |

Typical Uses

Silicon is used in many high-tech and industrial things:

Computer chips and microprocessors

Solar panels

Glass and ceramics

Construction materials

Alloys for car engines and steel

Silicone is found in everyday and special products:

Baking molds and kitchen tools

Medical implants and tubing

Window and door seals

Automotive gaskets and O-rings

Electronics protection and insulation

Note: If you order silicon molds for baking, you will not get the flexible trays you want. You need silicone for that.

Silicon Molds vs. Silicone Molds

Material Differences

Some people think silicon molds and silicone molds are almost the same. But their materials are very different. Silicon molds are made from silicon. This is a hard and brittle element. You cannot bend these molds. They break if you try. They do not handle heat changes well. Silicone molds are made from a man-made material. This material uses silicon, oxygen, carbon, and hydrogen. That is why silicone molds are flexible and strong.

Here is a table to help you see the main differences:

Property | Silicon Molds (Silicon) | Silicone Molds (Silicone) |

|---|---|---|

Material Composition | Pure silicon element | Synthetic polymer with silicon-oxygen backbone |

Flexibility | Rigid, brittle, breaks under pressure | Highly flexible, bends and returns to shape |

Durability | Prone to cracking, short lifespan | Long-lasting, resists cracking and warping |

Temperature Range | Limited, can shatter with heat changes | -60°C to 230°C, handles extreme temperatures |

Chemical Resistance | Low, reacts with some chemicals | High, resists acids and bases |

Maintenance | Hard to clean, stains easily | Non-stick, easy to clean, stain-resistant |

Silicone molds are special because they keep their shape. They work well even after many uses. You can put them in hot ovens or cold freezers. They do not crack or warp like silicon molds. This makes silicone molds better for most jobs that need to last and bend.

Tip: If you want a mold that lasts and handles heat, always choose silicone molds over silicon molds.

Application Differences

Silicon molds and silicone molds are used for different things. Silicon molds are not common in daily life. You might see them in factories. They help make metal parts or electronics. These molds are not good for baking or crafts. They break too easily and cannot handle big temperature changes.

Silicone molds are everywhere. People use them for baking cakes and making chocolate. They are also used for making soap. Doctors use silicone molds for safe and clean tools. Factories use them to make car parts, gaskets, and seals. Electronics makers use silicone molds to protect parts from heat and water.

Here are some common uses for silicone molds:

Baking trays, cupcake molds, and chocolate forms

Medical devices and tubing that need to be safe and clean

Automotive gaskets and seals that must resist heat and chemicals

Electronics insulation and moisture barriers

Silicone molds come in different types. Liquid Silicone Rubber (LSR) is good for making lots of small, exact items. These include medical tools and food-safe products. High-Consistency Rubber (HCR) is stronger. It is used for tough jobs in factories. You can shape silicone molds in different ways. Some ways are injection molding, compression molding, or extrusion.

Why the Confusion?

Many people mix up silicon molds and silicone molds. The words sound almost the same. Sometimes, sellers say "silicon molds" when they mean "silicone molds." This can cause problems. If you order silicon molds for baking, you get hard blocks. You do not get flexible trays. Your project might stop, and you could lose money.

This mistake can also hurt factories and designers. If you ask for silicon molds but need silicone molds, you get the wrong thing. Your products might not pass safety tests. They could break when used. In food and medical jobs, using the wrong mold can even break the law. Only silicone molds are safe for these uses.

Note: Always check the material before you buy or order molds. Ask your supplier if you are not sure. Using the right word keeps your project safe and on track.

Misconceptions

Interchangeable Terms

Some people use "silicon molds" and "silicone molds" like they mean the same thing. This is a mistake that happens a lot. Silicon molds are hard and not safe for food. Silicone molds are soft, bendy, and safe for many things. If you ask for silicon molds to bake, you will get the wrong item. Always read the label and ask questions if you are not sure.

Silicone Mold Properties

Some people think silicone molds are just for doctors or that they always feel sticky. That is not right. Silicone molds have many good features:

They are very flexible and can show small details, which is great for crafts and baking.

They can handle heat, so you can use them in ovens and freezers.

They last a long time and you can use them again, which saves money.

They do not stick, so it is easy to take out what you made.

They do not get ruined by many chemicals.

They stay bendy in both hot and cold places.

Silicone molds are safe for food and medical things because they do not react with what you put inside.

Cost and Industry Use

Some people think silicone molds are too expensive or only for hospitals. But silicone molds are used in many jobs because they save money and last long. Here is a table that shows where you find them and why:

Industry Sector | Why Use Silicone Molds? |

|---|---|

Medical Devices | Safe, flexible, precise, and durable |

Automotive | Withstand heat, easy to shape, long-lasting |

Electronics | Stable, safe, and precise |

Aircraft | Resist high temperatures, strong, and reliable |

Construction | Durable, safe, and chemical-resistant |

Food and Kitchen | Non-stick, easy to clean, safe for food |

Toys and Household | Flexible, safe, and easy to use |

You can find silicone molds in kitchens, factories, hospitals, and even in toys.

Safety and Compliance

It is important to be safe when using molds for food or medical things. Silicone molds must follow strict rules. For food and medical uses, they must pass FDA tests to show they are safe and not harmful. In Europe, they need LFGB certification. Medical silicone must pass tests to make sure it does not hurt people. Makers also check for chemicals, strength, and cleanliness. These rules keep you safe and make sure the products are good.

Tip: Always buy certified silicone molds if you need them for food, medical, or baby things.

Implications

Product Quality

You want your products to look and work the same every time. The choice between silicon molds and silicone molds affects this goal. Silicone molds give you flexibility and durability. They handle high heat and keep their shape after many uses. You can control the molding pressure and temperature to get smooth, detailed parts. If you use the right pressure, your products will cure evenly and come out perfect. A well-designed silicone mold lets you make items with clean edges and no defects. Regular cleaning and careful handling help you avoid surface problems and keep your molds working longer.

Silicone molds need the right pressure and temperature for best results.

Mold design, like where you put the opening or how smooth the surface is, changes how your product turns out.

Good maintenance and cleaning stop defects and keep quality high.

Tip: Always check your molds for wear and keep them clean to avoid problems with your finished products.

Manufacturing Risks

Choosing the wrong mold material can cause big problems. If you use silicon molds for jobs that need flexibility, you may see cracks or breaks. This shortens the mold’s life and wastes money. The wrong material may not support complex shapes or fine details. You might also pay more for repairs or replacements. Some molds, like steel, last longer but cost more. Others, like aluminum, may not work well for tough jobs or high-volume production.

Wrong mold material leads to shorter mold life.

Complex parts may not form well in the wrong mold.

Costs go up if you need to replace molds often.

Regulatory Issues

You must follow rules when making products for food, medical, or children’s use. Silicone molds often meet strict safety standards, like FDA or LFGB. If you use the wrong material, your products may not pass safety checks. This can lead to recalls or fines. Always check that your molds have the right certifications for your industry. Using certified silicone molds helps you avoid legal trouble and keeps users safe.

Note: Ask your supplier for proof of safety and compliance before you buy molds for regulated products.

Real-World Mistakes

Many companies have made costly mistakes by mixing up silicon molds and silicone molds. For example, a bakery ordered silicon molds for cakes and received hard, brittle trays that broke in the oven. Production stopped, and the bakery lost money. In another case, a medical device maker used the wrong mold material and failed safety tests. The company had to recall products and fix the problem, which took time and money. These stories show why you must choose the right mold and use the correct term.

Choosing the Right Mold

Assessing Needs

You should start by thinking about what you want your mold to do. Look at the part’s shape, size, and how many you need to make. If you need simple parts and want to save money, compression molding with solid silicone works well. For complex shapes or high-precision parts, liquid silicone rubber (LSR) injection molding is a better choice. Co-injection molding lets you create colorful or 3D designs, but it costs more.

Here is a table to help you compare molding methods:

Factor/Aspect | Compression Molding | LSR Injection Molding | Co-injection Molding |

|---|---|---|---|

Part Complexity | Simple | Complex, precise | Multi-color, 3D |

Production Volume | High, slower | High, fast | High, flexible |

Cost | Lower | Higher | Highest |

Durability | Good | Excellent | Excellent |

Tip: Match your mold type to your product’s needs and your budget.

Supplier Questions

When you talk to mold suppliers, ask clear questions to make sure you get the right material. Here are some important questions:

What materials can the mold handle, especially for high heat or tough plastics?

Can you make a mold for my yearly production needs?

What mold material class do you use, and what are its pros and cons?

Can you help me pick the right mold class for my needs?

Are the materials safe for food, medical, or special uses?

Do you offer any warranties for mold durability?

Asking these questions helps you avoid mistakes and get the best results.

Best Practices

You should always test your design before making the final mold. Prototyping helps you spot problems early. Choose a supplier with experience and good communication. Domestic suppliers may offer faster service, while overseas suppliers might save money. Make sure your supplier understands your industry and can meet your quality standards.

Test with prototypes first.

Pick suppliers with a strong track record.

Communicate your needs clearly.

Avoiding Pitfalls

Watch out for common mistakes when choosing mold materials. Uneven wall thickness can cause defects like warping or sink marks. Sharp corners or sudden changes in thickness make parts weak. Use gradual transitions and add draft angles to help parts come out of the mold easily. Avoid undercuts to keep costs and complexity down.

Keep wall thickness even.

Use smooth transitions, not sharp edges.

Add draft angles for easy removal.

Minimize undercuts.

Note: Careful design and planning help you avoid costly errors and get high-quality parts.

You have learned that silicone molds are bendy, strong, and safe for many things. Silicon molds are stiff and can break easily. Always use the correct word so you do not make expensive mistakes. When picking a mold, look at how it is made, what it is made from, and its shape. Make sure the mold works for what you need and that the materials are safe. Talk to experts or suppliers early in your project. Their help can stop mistakes and make sure your products are good and follow the rules.

Quick Checklist:

Make sure you have the right mold material and method

Check if the design and size are correct

Look for safety certificates

Ask experts for help if you are not sure

FAQ

What is the main difference between silicon and silicone molds?

Silicon molds use a hard, brittle element. Silicone molds use a flexible, rubber-like material. You can bend silicone molds, but silicon molds break easily.

Can you use silicone molds for baking and food?

Yes! Silicone molds are safe for baking and food. They do not react with food or melt in the oven. Always check for food-grade certification before use.

Why do some sellers call silicone molds "silicon molds"?

Some sellers make mistakes or use the wrong term. The words sound similar, but they mean different things. Always double-check the product description before you buy.

How do you clean silicone molds?

Wash with warm, soapy water.

Rinse well and let them air dry.

You can also put most silicone molds in the dishwasher.

Tip: Avoid sharp tools that can damage the mold.

LKprototype

LKprototype