You might wonder how many parts you can get from one silicone mold. Most molds give you anywhere from 25 to 256 parts before showing signs of wear. Some high-tech molds even make up to 1.5 million tiny parts every day. The silicone mold life cycle changes a lot depending on things like how often you use it, how clean you keep it, and what materials you cast. Check out the table below to see what can affect how long your mold lasts: FactorImpact on Mold Life CycleHumidityMoisture can cause corrosion in some materials.CleanlinessClean molds last longer and work better.Frequency…

You have an important job in medical device prototype development. This process helps you change an idea into a real prototype. The prototype can help patients and make care better. In 2025, you will see new problems and chances in medical device design, testing, and prototyping. Every step, from idea to pilot prototype, affects the final product. You need to know about the materials, costs, and steps in development. This helps you make good choices and build safe, useful devices. Key Takeaways Learn about how to make a medical device prototype. Start with an idea. Then test it to make…

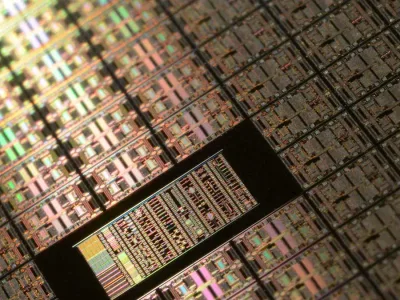

Imagine you order silicon molds for baking, thinking they are flexible trays, but you get hard, breakable blocks instead. This mistake can slow down your work and cost you money. Many people mix up silicon molds and silicone molds. You should know the difference if you make things or design products. Using the right word helps you avoid expensive mistakes and keeps your projects going well. Key Takeaways Silicon is a hard and breakable element. People use it in electronics. Silicone is soft and bends easily. People use it for baking and in medical items. Silicone molds are safe to…

Selecting the right machine parts manufacturer is crucial for your project's success. The choice of a machine parts manufacturer can significantly impact your results. You need a machine parts manufacturer that understands the importance of precision, with machining accuracy reaching as close as ±0.005mm. A reliable machine parts manufacturer ensures on-time delivery more than 95% of the time. Many teams face budget overruns in CNC projects, with up to 68% of cases caused by errors. Working with a knowledgeable machine parts manufacturer who offers rapid prototyping and expertise in materials like ABS or aluminum increases your chances of success. The…

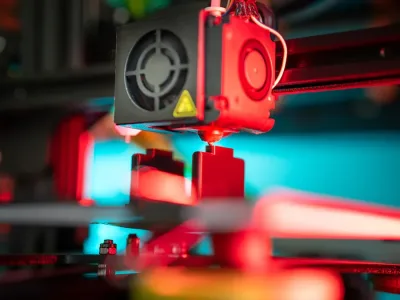

If you want to learn how to make mold 3d model for vacuum casting, you can follow some simple steps and guidelines. Start by creating a 3d model, as this is the foundation for how to make mold 3d model. Pay close attention to the mold design to ensure you can easily remove the finished part. The process of how to make mold 3d model involves having a precise model, careful mold making, and proper casting techniques. Many people achieve consistent and repeatable results by using this method. For instance, silicone molds made from a 3d model can be reused…

You may ask, is it moulding or molding that is correct? Both spellings are right, but it depends on where you are. In the United States, people use molding, while in the UK, Canada, and Australia, moulding is preferred. This difference arose after American dictionaries updated the spelling. The meaning remains the same for both terms, so choose the one your readers are familiar with. When you wonder, is it moulding or molding, simply pick the spelling that fits your audience best. Key Takeaways Both 'molding' and 'moulding' have the same meaning. The spelling changes by where you live. Use…

You may see two ways to spell this word: molding or moulding. In the United States, people use "molding" for most manufacturing words. In the United Kingdom and other places, "moulding" is the usual spelling. This difference is important at work. Studies show that spelling mistakes can make people think you are less skilled. They may also think you do not pay close attention, even in manufacturing jobs. In manufacturing, molding or moulding means shaping things like plastic or metal. You do this by pressing the material into a mold. This process helps make many parts and products. Key Takeaways…

Product prototyping gives you a practical way to turn ideas into testable models. A prototype lets you explore design, function, and user experience before full production. You use prototyping to spot design flaws early, gather user feedback, and reduce costly mistakes. The product prototyping market reached US$ 19.34 billion in 2023, showing its growing importance across industries. When you create a product prototype, you help teams align and make better choices. Early-stage prototyping encourages creativity and speeds up learning. Digital tools and market-driven approaches make prototyping faster and more effective than ever. Key Takeaways Product prototyping turns ideas into testable…

Silicone molds for resin are very useful in manufacturing today. They are flexible and help make accurate and detailed parts for many industries, like cars and healthcare. Silicone molds make production faster, which is great for custom designs and small batches. The Vacuum Casting Machine Market might reach 0.65 million USD in 2023. This shows how important silicone molds are. Industries like electronics and airplanes use these molds to make cheap prototypes. Silicone molds help make work easier while keeping quality and speed high. Key Takeaways Silicone molds are bendable and strong. They help make detailed parts for many industries,…

Silicone is a safe and reliable choice for cooking and storing food. If you're wondering, "Is silicone non-toxic?"—the answer is absolutely yes. It is durable, non-toxic, and ensures your food remains safe. Silicone maintains its properties in both hot and cold conditions, making it an excellent option for kitchen use. Key Takeaways Silicone is safe and non-toxic for food use. It doesn’t release bad chemicals, so it’s good for cooking and storing food. Check for FDA food grade silicone labels. These labels mean the silicone is safe and has no harmful stuff. Silicone handles very hot and very cold temperatures,…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.