Service

Industries

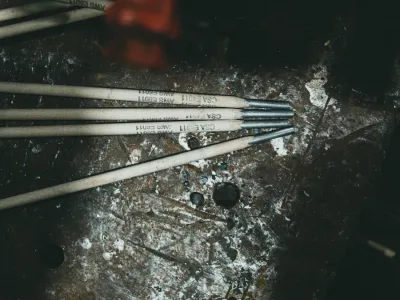

Materials

About

Resources

LKprototype

LKprototype