Service

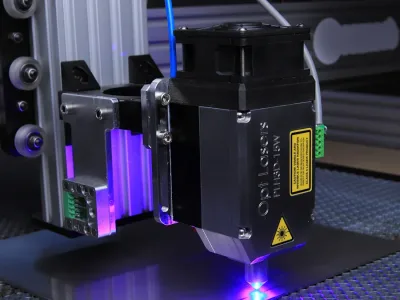

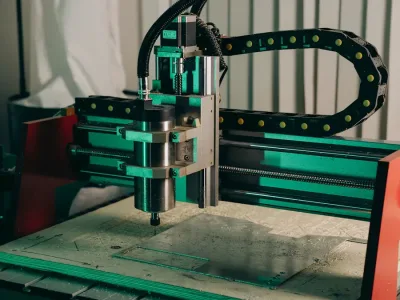

Industries

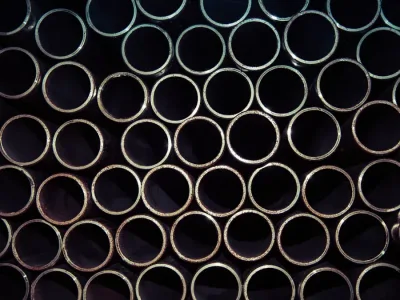

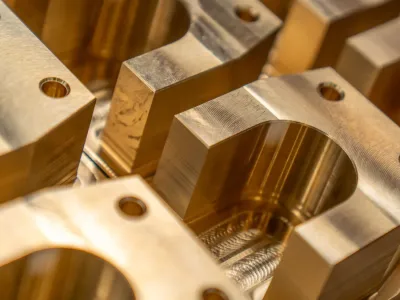

Materials

About

Resources

LKprototype

LKprototype