Share a little biographical information to fill out your profile. This may be shown publicly.

When designing boxes for electronics, you face unique challenges. CNC machining electronics enclosures offers a reliable solution for creating durable and high-performance enclosures. This method is excellent for EMI shielding, achieving tight tolerances, and delivering attractive finishes. By choosing cnc machining electronics enclosures, you gain several advantages, including the use of conductive materials, precise machining, and innovative design strategies. Conductive materials such as aluminum and copper are ideal for cnc machining electronics enclosures, providing effective heat dissipation and EMI shielding. Precision machining ensures that cnc machining electronics enclosures are consistently accurate and fit perfectly every time. Advanced surface finishes enhance…

CNC machining tolerances for assembly fit are important. They help parts line up and work well. They also make sure parts last a long time. When you set tolerances, you pick the size range that is okay. This keeps parts steady and accurate. Bad tolerances can cause parts to not fit right. They can make parts wear out too fast. Parts may shake or even break during assembly. Tolerances help stop things from breaking or being unsafe. Wrong tolerances can mess up the whole assembly. This can make products not last as long. If you ignore tolerances, you may spend…

CNC machining medical prototypes help you get very exact parts. These parts have tight tolerances for making medical devices. You can turn your design ideas into real models fast. This makes the process quicker and lets you test early. Rapid prototyping helps you change designs quickly and test them for safety. You can also check how well they work. Customization lets you make implants and prosthetics that fit each patient. This helps patients get better results. Scalable production gives you the same parts every time for tools and devices. This lowers mistakes and makes things work better. Key Takeaways CNC…

CNC machining allows you to create parts with very tricky shapes and small size limits, especially when it comes to cnc machining complex geometries. You must follow simple design rules to ensure your parts are easy to make, accurate, and cost-effective. New technology enhances CNC machining's ability to work with hard shapes. You can see significant advancements with multi-axis machines and CAM software: 5-axis machining enables you to produce turbine blades or medical implants in just one setup, effectively handling cnc machining complex geometries. These machines can reduce machining time by up to 84% compared to traditional methods. Hybrid manufacturing…

Estimated reading time: 22 分钟 You use the vacuum casting process to make exact parts from a master model. This method lets you change your design and use cheap tools. It is great for making prototypes and small batches. You get high-quality prototypes with smooth surfaces and tricky shapes. This happens because there are fewer air bubbles and you can use more materials. AdvantageDescriptionReduced Porosity and DefectsGets rid of air pockets so parts are stronger.Superior Surface FinishMakes smoother surfaces, so you do not need much extra work.Complex GeometriesLets you make detailed designs that other ways cannot do.Material VersatilityWorks with many…

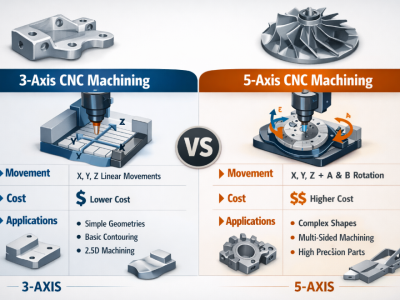

When you compare 3 axis vs 5 axis cnc machining for complex parts, you can see they operate differently in terms of shapes and speed. You might choose 3-axis cnc for simpler shapes. However, more challenging parts often require the additional movement capabilities of 5-axis cnc. Many companies now prefer 5-axis cnc because it can complete multiple sides in a single setup. This efficiency allows for faster workflows and time savings. If you are concerned about setup time and cost, 3-axis cnc may initially appear to be the more economical option. However, if your project demands numerous setups, it can…

When you want custom CNC parts, it's essential to consider quality, cost, and time. Many engineers face challenges with how to choose a CNC machining service, especially when it comes to early communication, collaborating on design, and selecting materials. Steel CNC machining can be particularly difficult because strong cutting and heat can lead to mistakes. Before you choose a CNC machining service, make sure you understand your project's needs and set clear goals. Early communication is crucial Material characteristics can affect results Establishing tolerance is very important Selecting the right partner helps prevent issues Key Takeaways Talk early and clearly…

You figure out cnc machining cost by looking at many things. These include material, machining time, complexity, and machine type. If you know about cnc costing, you can control your project’s budget. You can also avoid extra charges that you did not expect. Knowing each cost part helps you pick the best supplier. It also helps you plan production better. Cnc costs are different in each country: CountryAverage Hourly CostUSA$75–$200Canada$70–$180UK$60–$150Germany$70–$160China$30–$90 You should always use a detailed cnc costing report or tool. This helps you keep cnc costing correct. Key Takeaways Learn what things change CNC machining costs, like the material…

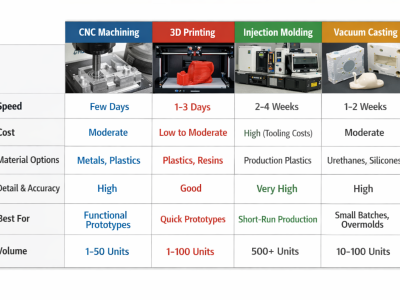

You need to know how to choose the best prototyping method for your project. Your goals, materials, how many you need, budget, and time all matter. Matching the method to your needs helps users get better feedback. Picking the right way lets users see ideas come to life. It helps users agree on choices. It also lets users spot problems early. Manufacturing MethodCost EffectivenessLead TimeMaterial Compatibility3D PrintingCost changes with amount; cost stays the same for small numbersQuick setup, slower for big batchesWorks with many materials, good for tricky shapesCNC MachiningNot great for very small batches; better for bigger batchesFast after…

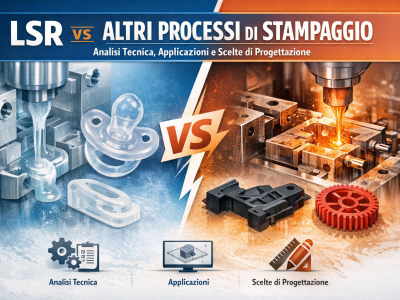

When deciding on a molding process, you should opt for liquid silicone rubber (LSR) molding over other methods if your product demands high precision, exceptional clarity, or complex shapes. Many engineers choose LSR for these specific reasons: It offers precise control for tight burr management. It provides exceptional clarity, ideal for medical components. It can produce intricate and detailed parts. It has faster cycle times compared to traditional thermoplastic molding. Understanding the differences between liquid silicone molding vs other processes is crucial in selecting the most suitable molding process for your design and manufacturing needs. Key Takeaways Pick liquid silicone…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.