You might wonder, will AI replace CNC machining? The answer is no. Machinists remain crucial in the industry. While AI can enhance how you use CNC technology, it cannot fully replace what you do. Operators and programmers may notice some changes, as AI makes certain tasks easier, but your skills and adaptability are still essential. The future of CNC machining depends on humans and AI working together, not on the question of will AI replace CNC machining entirely.

Key Takeaways

AI will not take the place of CNC machinists. Your skills are still needed for hard jobs. Use AI tools to help you work faster and make fewer mistakes. Learn new CAM software and automation systems to keep up in the field. Work on your problem-solving and hands-on skills, because AI cannot copy human choices. The future of CNC machining needs people and AI to work together for better results.

The Short Answer: No — But the Job Will Change

Why CNC jobs are not disappearing

Some people ask if AI will take over CNC machining. The answer is no. CNC jobs are still needed. These jobs are just changing. AI helps you do your job better. You can use AI systems to make your work easier. For example, quality control with AI can lower mistakes by half. If you use these systems, you can also save money on repairs by a quarter. You do not need to worry about losing your job to AI. Instead, you will do harder tasks while AI does the boring ones. This makes your job more important.

Evidence Type | Description |

|---|---|

Defect Rate Reduction | AI-powered quality control systems can lower mistakes by up to 50%. |

Maintenance Cost Reduction | AI can save 25% on repairs when skilled workers use these systems. |

Job Transformation | Machinists do harder jobs while AI does easy ones, making their work matter more. |

Why traditional roles are evolving

Your job as a CNC operator or engineer is changing because new tools are coming. You see more robots and machines every day. These tools help you finish work faster and more accurately. New technology makes CNC machining better and more exact. AI can tell you when machines need fixing, so you do not get surprised by breakdowns. AI also helps you make your work better and your products higher quality. AI checks your work as you go, so you find problems early and waste less.

Robots and machines are changing how factories work.

New technology makes work faster and more exact.

AI can tell when machines need fixing and saves money.

AI looks at data to help you do your job better.

AI checks work in real time and helps you waste less.

You might wonder if AI will take over CNC jobs. Your skills are still very important. In the future, you will work with AI and use your knowledge to solve problems. CNC machining will always need people who know machines and materials. Operators and engineers who learn new things will stay important as things change.

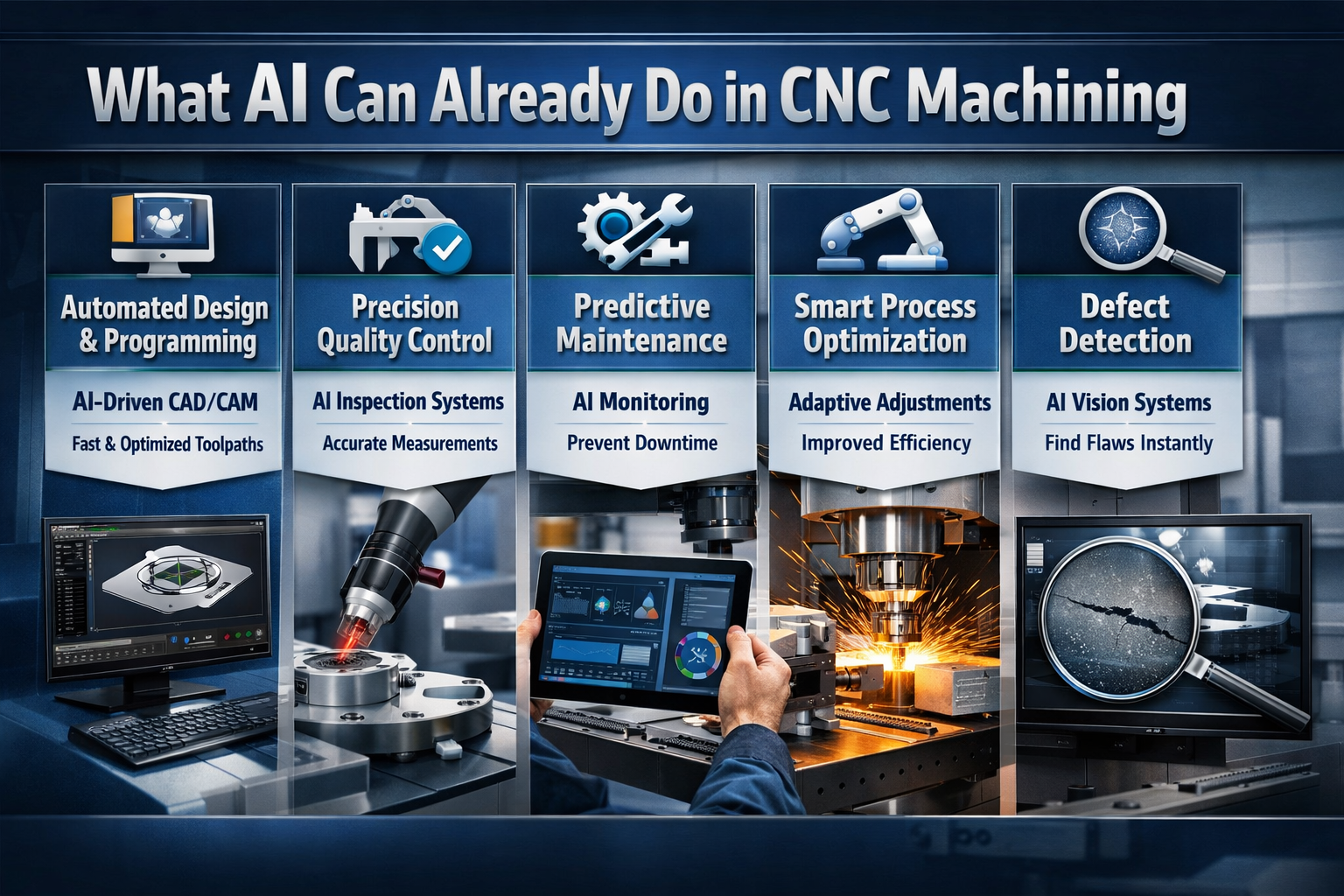

What AI Can Already Do in CNC Machining

AI in CAM Programming and Toolpath Optimization

Automatic toolpath generation

You can use AI to make CNC work easier. AI systems can create cutting paths for you. These systems use special features and smart code tips. This helps them finish jobs faster. You save time because AI can do tasks that took hours before. In the first week, toolpath automation saved four hours. This means you spend less time on manual programming. You get more time for important jobs.

Cutting paths get better.

Waste goes down.

Production is faster.

Costs are lower.

Cycle time optimization

AI helps you finish jobs quicker. AI systems cut cycle time by 28%. You change tools less often, about 40% less. Surface finish gets 15% better. Production costs drop by 22%. AI tools also make parts better, so you fix fewer mistakes. Workflows are smoother, so you finish tasks faster. AI makes CNC work more productive and flexible.

AI in CNC Process Monitoring

Tool wear detection

AI watches your machines all the time. Smart sensors and learning tools spot tool wear early. AI finds tool problems you might not see. Feedback helps you change tools at the right time. This means less scrap and fewer mistakes. AI works well in precision milling, where small changes matter.

Predictive maintenance

AI systems use predictive maintenance to keep machines working. You can cut maintenance costs by 12%. Uptime gets better by 9%. AI helps machines last 20% longer. Companies using AI have fewer breakdowns and better performance.

AI-Powered Quality Inspection

Vision systems

AI vision systems check parts for defects. These systems find mistakes with 97-99% accuracy. Common defect rates drop by 20-50%. AI vision finds errors that people miss.

Inspection Method | Detection Accuracy | Mistake Rate |

|---|---|---|

AI-Powered Vision | 97-99% | 1-3% |

Manual Inspection | 10-20% | 80-90% |

Automated defect detection

AI inspection cuts defects by up to 90%. Automated systems help you catch problems early. You waste less material and save money. AI in CNC work gives you better results with less effort.

What AI Still Cannot Replace in CNC Machining

Human Judgment in Complex Machining Decisions

Material behavior

You make choices in cnc machining that ai cannot do alone. Materials can act in ways that are hard to predict. You know how steel bends and how aluminum can twist when cut. Ai systems often miss these small details. You use your senses and what you learned before to spot problems early. Ai might pick a fast way to cut, but you notice if a part could crack or bend. Your judgment keeps things safe and makes sure parts are strong.

Real-world tolerance trade-offs

You decide about tolerances every day. Ai can follow numbers, but you know when a part needs a tighter fit or when a small mistake is okay. Sometimes, you must choose between speed and quality. Ai may care about being correct, but you think about what the customer wants and how the part will work. In emergencies, ai may not see the whole problem. You step in and use your judgment to fix things for people and machines.

Tip: Being a good leader matters in cnc machining. Ai helps you, but you guide the work when things get hard.

Problem-Solving on the Shop Floor

Unexpected machine behavior

Machines sometimes do things that ai cannot guess. You hear strange sounds or feel odd shakes. Ai may not notice these signs. You use your hands and eyes to find what is wrong. You fix problems before they stop the work. Your quick thinking keeps the shop moving.

Prototype and custom parts

You often work with new designs and custom parts. Ai has trouble with shapes or materials it has not seen before. You use your creativity to plan setups and solve problems. Machinists use their skills to make sure prototypes are made right. Ai helps with easy jobs, but you handle new and tricky ones.

Hands-on skill and what you know help your work.

Making fixtures for odd shapes needs human ideas.

Solving problems for new materials and shapes takes creativity.

Experience-Based Optimization

Setup intuition

You know how to set up cnc machines for the best results. Ai can give steps, but you see small things that matter. Your experience helps you avoid mistakes and save time.

Fixturing decisions

You pick the best way to hold parts while machining. Ai can give choices, but you know what works for each job. Your choices keep parts safe and make them better.

Task | AI Capability | Human Advantage |

|---|---|---|

Setup Planning | Good | Smart changes |

Fixturing | Basic | Custom answers |

Problem Solving | Limited | Creative ideas |

You and other machinists add value that ai cannot match. Your judgment, experience, and problem-solving skills keep cnc machining strong.

CNC Operators vs CNC Engineers: Who Is More at Risk?

CNC Operators: Tasks Most Likely to Be Automated

Repetitive loading/unloading

You might see more robots in the shop. These robots do simple jobs like loading and unloading parts. Automation makes these jobs quicker and more steady. Many factories use machines for this work now. You can spend time on harder jobs. Your skills are still needed. You should learn how to use these new systems.

Basic machine monitoring

AI tools now watch cnc machines for problems. They check things like temperature and tool wear. You do not have to stand by the machine all day. You can look at alerts and fix issues when needed. In top factories, half of these jobs use automation. This change lets you do work that needs your skill.

CNC programming automation includes:

Making code

Giving tool path ideas

Showing cutting plans

AI cnc programming tools look at part files and help with jobs that took lots of time before. You can work faster and make fewer mistakes.

CNC Engineers: Why Their Role Is Expanding

Process planning

Your job as a cnc engineer is changing. AI helps you plan better by using data from every job. You can use this to pick the best tools and speeds. In aerospace, AI changes toolpaths during milling to stop problems. You check these changes and make the process better each time.

AI tools make jobs faster and change toolpaths.

Smart changes based on cutting help tools last longer.

Engineers look at data to get better results.

Design-for-manufacturing decisions

You now use AI to help with design choices. AI cnc programming tools make programming faster and help you avoid mistakes. You can make sure every part is good. In car factories, AI checks sensor data and warns about problems before machines break. This keeps work going and saves money.

Using data can save 5-10% in costs.

AI helps you check quality and make smarter choices.

AI in cnc machining changes how you work. You become more important as you learn to use these tools. Machinists, operators, and engineers who learn new things will lead the future of manufacturing.

How CNC Professionals Can Stay Relevant in the AI Era

Skills CNC Machinists Should Learn

Advanced CAM

You should learn advanced CAM software to do well in CNC work. CAM tools help you make better tool paths and improve part quality. If you use advanced CAM, you become a more important team member. Companies want machinists who can use these tools with AI. More jobs will ask for CAM skills as AI and automation grow in factories.

Skill Requirement | Impact on Job Prospects |

|---|---|

Advanced CAM Software Proficiency | Makes your technical skills better and you more valuable |

AI Fluency | More jobs for people who check AI results |

Adaptability | Needed as companies want AI and big data skills |

Multi-axis machining

You should learn how to use multi-axis machining. This skill helps you work with hard parts and shapes. Multi-axis machines use AI to move better and make fewer mistakes. You will find more jobs if you know how to use these machines. Automation in multi-axis machining helps you finish work faster and with better accuracy.

Automation systems

You need to know about automation systems in today’s shops. These systems use AI to control robots and watch CNC machines. You will work with sensors, data, and machine learning. You should know how to fix AI systems and keep automation working well. Training now includes coding and finding defects for quality control.

Tip: Learning AI and automation helps you get better jobs. You will solve problems and keep production going.

Skill/Training Area | Description |

|---|---|

AI Integration | Use AI in CNC machining jobs |

Data Analytics | Work with and study data from CNC machines |

Machine Learning | Use machine learning to make machining better |

Troubleshooting AI Systems | Find and fix problems with AI in the shop |

Role-Specific Training | Get training for CNC programming or quality control work |

Skills CNC Engineers Should Develop

DFM/DFA

You should learn design-for-manufacturing and design-for-automation. These skills help you make parts that work well with CNC machines and AI. You will make better choices and waste less.

Simulation and digital twins

You need to learn about simulation and digital twins. These tools let you watch CNC machines in real time. AI digital twins help you find problems early and fix them before machines stop. You can use simulation to test new setups and make work better. This helps you get more done and make higher quality parts.

Digital twins help you see how machines are working and find problems.

Predictive maintenance lets you find failures early and keep machines running longer.

AI and machine learning help you make processes better and waste less.

AI-assisted manufacturing tools

You should use AI-assisted manufacturing tools. These tools help you with predictive maintenance, adaptive machining, and smarter CNC programming. You will work with robots and smart systems. AI-powered quality control helps you find mistakes fast and keep quality high.

Note: You will need to change as AI and automation change CNC engineering. Learning new tools keeps you ready for the future.

AI + CNC: The Future Is Collaboration, Not Replacement

Human-in-the-loop manufacturing

You are important when you work with AI and CNC machines. This way of working is called human-in-the-loop manufacturing. You use your skills to make smart choices. AI does the boring jobs and checks for mistakes. When you mix your experience with AI, you get better work and fewer errors.

Here are some teamwork benefits:

Benefit | Description |

|---|---|

Increased Output | You work on program improvement and quality, not just easy jobs. |

Reduced Overtime | AI helps you finish faster, so you work less extra hours. |

Energy Savings | AI makes CNC jobs use less energy. |

Improved Quality Assurance | AI checks parts as you work, so you find problems early. |

Strategic Human Role Shift | You spend more time on important jobs, not just watching machines. |

AI can find tiny defects while machining. You can fix problems right away and waste less material. AI helps you reject or fix bad parts before customers get them. The future is about working together. Your job becomes more important as you use these smart tools.

AI as a productivity multiplier

AI helps you do more in CNC machining. You get faster results and better quality with AI tools. For example, AI makes smarter toolpaths. This saves time and keeps tools from wearing out. You spend less time checking parts because AI uses vision systems to find defects.

AI Application | Benefit Description |

|---|---|

Smarter toolpaths | AI finds the best way to cut, saving time and tools. |

Predictive maintenance | AI tells you when machines need fixing, so you avoid sudden breakdowns. |

Adaptive machining | AI changes settings during work to keep parts good. |

Vision-based quality control | AI checks for defects fast, so you spend less time inspecting. |

You can focus on solving problems and making work better. AI does the easy jobs, so you finish more in less time. Working together helps you make better products and meet deadlines with less stress.

What This Means for Manufacturing Companies

When AI investment makes sense

You might wonder when it is smart to buy AI for your shop. Not every business needs AI right now. Some shops will get more from AI than others. If you make lots of parts, you have lots of data for AI to use. If your parts cost a lot, mistakes can be expensive. AI helps you save money by catching errors. If your work needs perfect quality, AI can check every detail. If you do not have enough skilled workers, AI can help fill in. If you need to work faster, AI can help you keep up. If your shop has strict rules, AI helps you keep good records.

Circumstance | Description |

|---|---|

High-volume production | Lots of data makes AI work better. |

Expensive parts | AI saves money by stopping costly mistakes. |

Tight tolerances | AI checks for perfect quality every time. |

Skilled labor shortages | AI helps when you need more skilled workers. |

Competitive pressure | AI helps you work faster and smarter. |

Regulated industries | AI helps you keep track of important records. |

Tip: Think about what your shop needs before you buy AI. If you see these signs, AI might help your shop grow.

Why skilled machinists remain critical

You may think machines can do everything, but machinists are still needed. You notice when a material is harder than usual. You hear odd sounds before sensors do. You see a tool that looks fine but does not work right. You set up jobs and know how heat can change things.

You find problems before machines break.

You use your senses to catch issues early.

You change setups when things go wrong.

You help keep work moving without trouble.

As machines do easy jobs, your judgment matters more. You fix problems that AI cannot see. You notice real-world changes and solve issues fast. Companies count on you to keep cnc machines working well.

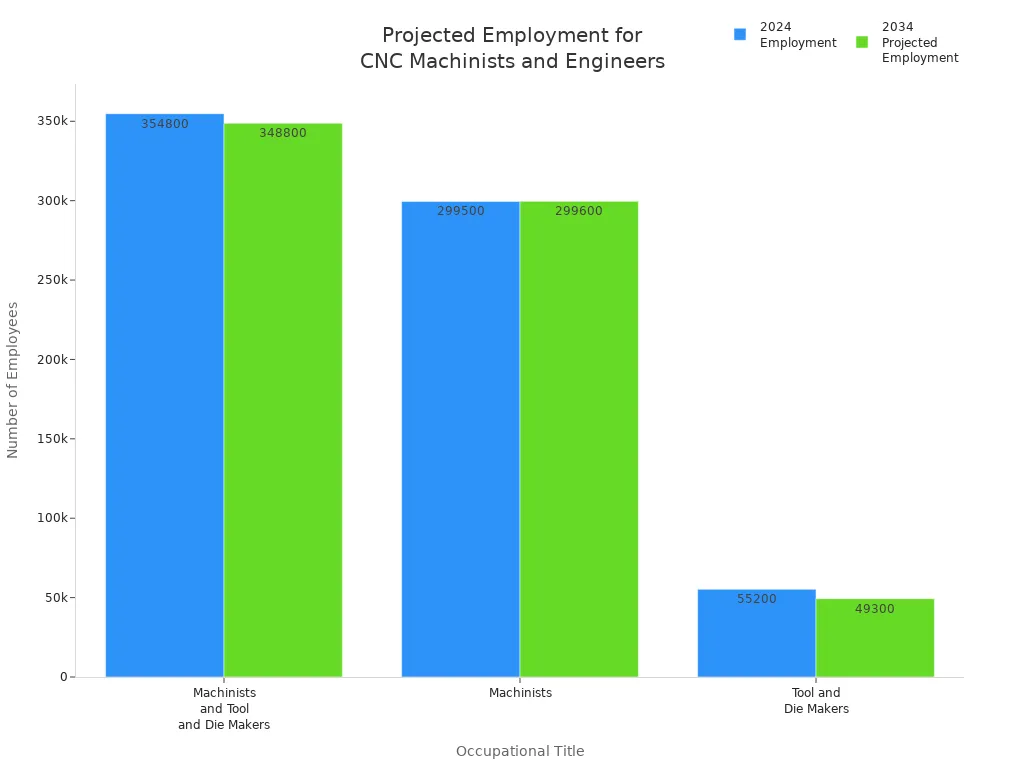

Conclusion: Will AI Replace CNC Machining Jobs?

Final balanced takeaway

You may ask, will ai replace cnc machining in the future? The answer is clear. You will see more ai in shops, but it will not replace machinists. Experts agree that cnc technology will change how you work, not take your job away. You will still need to operate machines, load designs, and manage processes. The idea that ai will fully replace machinists is far-fetched. The future will bring more collaboration between you and smart systems. You will use cnc technology to solve problems and improve quality. Ai will handle routine tasks, but you will make the important decisions.

Industry experts say ai will play a bigger role, but not fully replace machinists.

Specialized work in cnc machining needs your skills and judgment.

You will remain vital for operating machines and managing processes.

Career outlook summary

You may wonder about your career in cnc machining as ai grows. The numbers show a stable future for machinists. You will see small changes in job numbers, but demand for skilled workers stays strong. Tool and die makers may see a slight drop, but machinists will hold steady. CNC tool programmers will see more jobs and higher pay. You can earn a median wage of $70,580 as a programmer. Your core duties, like translating CAD into G-code and troubleshooting, cannot be fully automated.

Occupational Title | 2024 Employment | 2034 Projected Employment | Change (2024-34) |

|---|---|---|---|

Machinists and Tool and Die Makers | 354,800 | 348,800 | -2% |

Machinists | 299,500 | 299,600 | 0% |

Tool and Die Makers | 55,200 | 49,300 | -11% |

CNC tool programmers will see a 16% increase in demand from 2023-33.

You will find more opportunities if you learn advanced cnc technology.

The future will reward you for adapting and growing your skills.

Tip: You can secure your place in the future by learning new cnc technology and working with ai.

AI gives you strong tools to help with CNC machining, but your skills are still very important. You can make your career better by learning new things and changing with the times. The CNC market is growing all over the world, so jobs are safe. Look at the table below for important points about your future:

Key Takeaway | Description |

|---|---|

Adaptation to Technology | Learn new skills to keep up with CNC changes. |

Job Security | CNC jobs are wanted in many places. |

Career Advancement | Your skills help you move up in your job. |

Demand for Skills | Factories need people with new technical skills. |

Keep your job by getting more experience, learning programming, and using automation. Work with AI to fix hard problems and do better at work.

FAQ

Will AI take over all CNC machinist jobs?

You will not lose all CNC machinist jobs to AI. AI helps with simple and repetitive tasks. You still need to use your skills for setup, problem-solving, and quality checks. Your experience keeps you valuable.

What skills should I learn to stay ahead in CNC machining?

You should learn advanced CAM software, multi-axis machining, and automation systems. These skills help you work with AI tools. You will find more job opportunities if you keep learning.

Can AI make mistakes in CNC machining?

Yes, AI can make mistakes. AI may miss small details or struggle with new materials. You need to check AI’s work and fix problems. Your judgment keeps production safe.

How does AI help with quality control?

AI uses vision systems to check parts for defects. You get faster and more accurate inspections. AI finds tiny errors that you might miss. You still need to review results and make final decisions.

LKprototype

LKprototype