Selecting the right silicone rapid prototyping manufacturers is crucial for the success of your project. Reliable manufacturers not only save time and money but also ensure top-notch quality. For instance, rapid prototyping can complete tasks in just 6 hours compared to the 14 hours traditional methods might take. Additionally, it is more cost-effective, as older vacuum molds can be four times more expensive. Beyond cost savings, trusted silicone rapid prototyping manufacturers focus on accuracy and material strength by thoroughly measuring errors and testing durability. Choosing the right manufacturer is key to achieving your project's goals.

Key Takeaways

Pick manufacturers with a good reputation. This shows they are reliable.

Look at their past work and reviews. Experienced makers solve problems better.

Check for certifications like ISO 9001. These prove high-quality standards.

Ask about their tools and machines. Better tools make faster and accurate products.

Make sure they communicate well. Updates and feedback keep your project on track.

Choose a flexible manufacturer. They can adjust to your needs and save money.

Confirm they have quality checks. This ensures good prototypes and protects your money.

Talk about silicone materials with them. The right material makes stronger and better products.

Reputation and Experience

Why Reputation Matters for Silicone Rapid Prototyping Manufacturers

When picking silicone rapid prototyping manufacturers, their reputation is very important. A good reputation shows they care about quality and customer service. Well-known manufacturers often have more clients because they are trusted. Their focus on making great prototypes can help your project succeed.

Tip: Choosing a trusted manufacturer gives steady results and avoids delays.

Checking Industry Experience and Past Work

Experience shows how well a manufacturer can handle tough projects. Skilled manufacturers have solved many problems over the years. This makes them ready to meet your needs. Their history often includes working with many industries, proving their skills.

To check a manufacturer’s experience, look at these:

Past Projects: Find examples like what you need.

Client Reviews: Happy clients show they are dependable.

Years in Business: Long-time companies are often reliable and skilled.

How to Check a Manufacturer’s Reputation

Research is key to knowing if a manufacturer is trustworthy. Look into their certifications, skills, and customer reviews. The table below shows ways to check their credibility:

Method/Metrics | Description |

|---|---|

Quality Certifications | Check for ISO 9001 or ISO 13485 to ensure high standards. |

Production Skills | See if they can meet your needs and handle big orders. |

Technical Knowledge | Make sure they’ve made similar products with good results. |

Customer Support | Test how well they solve problems and help clients. |

Research and Reviews | Study their reputation and how they treat customers. |

Client Feedback and Stories | Read reviews to see if they deliver great products. |

By following these tips, you can find a manufacturer that fits your project. Good silicone rapid prototyping manufacturers help your product succeed and meet your goals.

Technical Expertise and Equipment

Why Advanced Tools Are Important in Silicone Prototyping

Modern tools are key for making silicone prototypes. They help with accuracy, speed, and saving money. Old methods took longer and cost more. New rapid prototyping tools make parts faster and better.

Why advanced tools are helpful:

You can test and fix designs quickly.

It shortens project time and lowers costs.

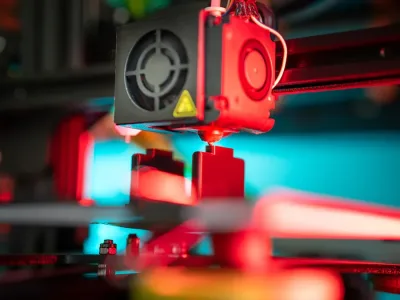

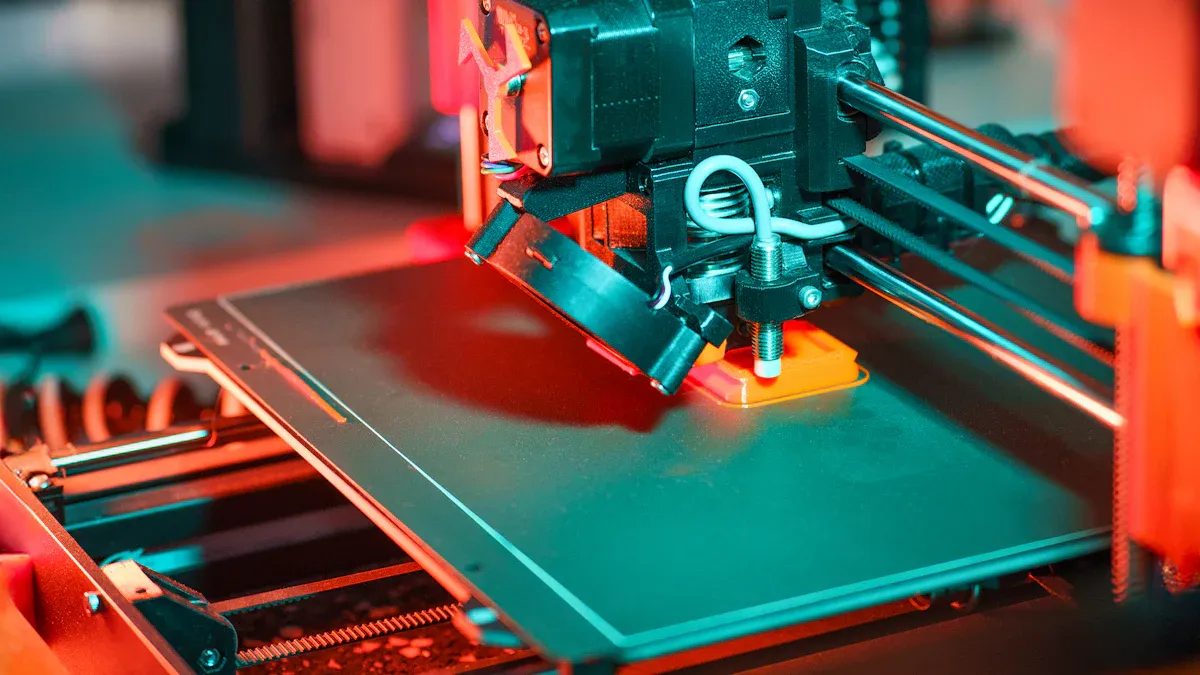

Tools like SLA, SLS, and PµSL make detailed parts easily.

For example, 3D printers now use soft materials to make detailed shapes. These printers don’t need molds, so they can create hollow or textured parts. Picking manufacturers with modern tools gives you these benefits. Your prototypes will be high-quality and meet your needs.

Tip: Always ask what tools a manufacturer uses. Better tools mean better results.

How to Check a Manufacturer’s Knowledge

A manufacturer’s skills affect how good your prototypes are. You need someone who knows silicone prototyping well and keeps up with new trends. Look for experience with FDM, SLA, and silicone molding. These skills show they can handle tough designs.

Here’s how to check their knowledge:

Ask about their methods: Learn how they solve problems during prototyping.

Look at past work: See if they’ve made similar products before.

Talk about materials: Make sure they know silicone and can suggest the best type for you.

Working with skilled manufacturers means your prototypes will work well and last long.

Keeping Up with New Prototyping Ideas

Prototyping changes fast with new tools and materials. Manufacturers using these updates can give you better results. For example, new materials like heat-conductive ones improve electronics. Flexible composites work well in aerospace projects.

New Idea | What It Does | How It Helps Production |

|---|---|---|

Moves heat away quickly for better cooling | Great for electronics, making them more reliable | |

Flexible Composites | Changes shape based on conditions | Useful for planes in different environments |

Robots and Automation | Handles hard tasks without human help | Speeds up work and keeps quality high |

Machine Learning | Uses data to improve how things are made | Makes work faster and reduces waste |

Sensors for Monitoring | Checks quality during production | Catches mistakes early and improves reliability |

Choosing manufacturers who use these ideas keeps you ahead. They’ll help you make prototypes that meet today’s needs and prepare for the future.

Note: Pick a manufacturer who values new ideas. It shows they aim for the best results for your project.

Communication and Collaboration

Clear Communication Practices to Look For

Good communication is key to working well with silicone prototyping manufacturers. It helps match your ideas with what they can do. This lowers mistakes and keeps the project on schedule. Clear communication makes teamwork better and avoids confusion.

They keep everyone focused on the same goal.

Talking openly prevents mistakes and makes projects run smoothly.

When manufacturers give updates often, you feel more confident in them. Meetings and reports keep you updated. Open feedback helps you make changes without wasting money. These habits build trust and ensure good prototypes are delivered on time.

Tip: Pick a manufacturer who shares updates and involves you in every step.

Aligning Manufacturer Services with Your Business Needs

Every business has different needs, and good manufacturers adjust their services to fit. This makes sure your prototypes work well and are ready for the market. Working closely with manufacturers, like in Joint Development Manufacturing (JDM), helps meet your goals. This teamwork creates better products.

Here’s why matching services to your needs is important:

Good parts lower the chance of problems or recalls.

On-time delivery avoids delays that cost money.

A steady supply chain keeps your work running smoothly.

For example, JDM builds strong partnerships by aligning with your goals. This teamwork reduces mistakes, speeds up production, and creates custom solutions. By choosing a manufacturer who understands your needs, you can work faster and stay ahead of others.

Responsiveness and Problem-Solving in Prototyping Projects

Quick responses are very important in prototyping. A manufacturer who solves problems fast keeps your project moving. For example, STAND+, a medical shoe company, cut costs by five times with a quick-acting manufacturer. This helped them save money and meet market needs with great prototypes.

Fast problem-solving also earns trust from others. Good prototypes impress investors, and fixing issues quickly improves designs. In STAND+’s case, rapid prototyping helped them get funding and grow in a tough market.

Note: Choose a manufacturer who solves problems quickly and focuses on your success.

Quality Assurance and Testing

Why Quality Assurance is Important for Silicone Prototypes

Quality assurance (QA) makes sure silicone prototypes are top quality. Without it, problems like delays and defects can happen. Good silicone prototyping manufacturers focus on QA to give reliable results. They check durability, function, and accuracy to ensure prototypes work well in real life.

QA also builds trust. When prototypes meet strict rules, you know they’re reliable. This is very important in industries like healthcare and aerospace. Small mistakes in these fields can cause big problems. Picking a manufacturer with strong QA protects your money and reputation.

Tip: Ask about a manufacturer’s QA process. It shows their dedication to quality.

Testing Methods Used by Trusted Manufacturers

Trusted manufacturers test prototypes carefully to ensure strength and performance. These tests include:

Checking strength to make sure it holds up.

Testing how well it works with the design.

Seeing if it resists wear, heat, and chemicals.

For example, new silicone materials are now 50% stronger. This makes them great for tough jobs. Manufacturers also improve flexibility and heat resistance through research. These upgrades make prototypes last longer and work better.

In-process checks catch problems early, saving time and money. Calibrating tools ensures accuracy, and trained workers keep standards high. These steps make sure every prototype meets your needs.

Note: Work with manufacturers who value testing and new ideas. This ensures your prototypes succeed.

Certifications and Standards to Check

Certifications prove a manufacturer follows global quality rules. Look for these certifications:

Certification | What It Means |

|---|---|

Ensures quality systems meet customer and legal needs. | |

Importance | Focuses on customer happiness and constant improvement. |

These certifications show a manufacturer cares about quality and safety. They also give worldwide recognition, proving their skills. Checking these ensures you’re working with a reliable partner.

Tip: Always confirm certifications before choosing a manufacturer. It avoids costly mistakes.

Flexibility and Scalability

Adjusting to Different Project Sizes and Needs

A good silicone prototyping manufacturer should handle projects of any size. Whether you need one prototype or many, being flexible keeps things smooth. Manufacturers who adjust their methods to fit your needs save time and money while keeping quality high.

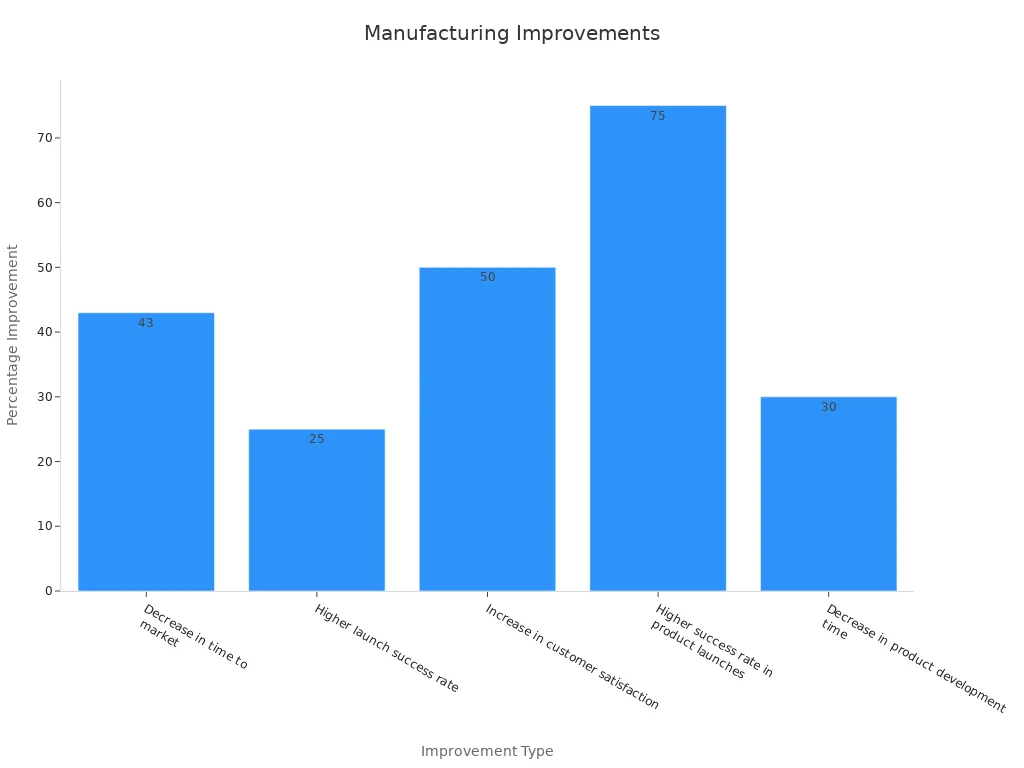

Being adaptable brings big benefits. For example, companies that change their production methods see a 43% faster market launch and a 30% shorter development time, says the Product Development and Management Association (PDMA). These improvements help you release products quicker and more efficiently.

Some manufacturers, like Makelab, show this flexibility in action. For instance, Another Room worked with Makelab to grow production without losing quality. Similarly, STAND+ used creative prototyping to cut costs and speed up healthcare product development. The table below shows these success stories:

Case Study | Description | Benefits |

|---|---|---|

Another Room | Partnered with Makelab to expand production | Flexible methods, detailed support, growth without quality loss |

STAND+ | Used Makelab and Inkbit for advanced prototyping | Lower costs, faster development, better materials for healthcare |

Picking a manufacturer that adjusts to your project size ensures a smooth process from start to finish.

Scalable Solutions for Expanding Businesses

As your business grows, your prototyping needs will change. A manufacturer with scalable solutions can grow with you while keeping quality steady. Scalable production helps meet higher demand without losing consistency.

Scalability also lowers risks during fast growth. Manufacturers with modern tools and methods can handle big orders without delays. This dependability lets you focus on creating new ideas and growing your business. Studies show companies using scalable prototyping have a 25% better launch success rate and a 50% boost in customer satisfaction.

When you work with a manufacturer that values scalability, you gain an advantage. They help you meet market needs while keeping prototypes high-quality and affordable.

Customization Choices for Special Prototyping Needs

Every project is different, so customization is important to meet specific goals. Manufacturers offering custom solutions can improve designs, use versatile materials, and create prototypes that match your vision perfectly.

Customization options include rapid tooling, which makes functional prototypes quickly. This allows for fast testing and changes, saving time and money. Plus, improving designs during prototyping leads to better final products.

Customization makes silicone materials more versatile.

Rapid tooling speeds up testing and design changes.

Improved prototypes lead to better final products.

Choosing a manufacturer with strong customization options helps bring your ideas to life with accuracy and speed. This ensures your prototypes stand out in a competitive market.

Tip: Always ask about customization when picking a manufacturer. Tailored solutions can help you reach your project goals.

Materials and Durability

Why Choosing the Right Material Matters in Silicone Prototyping

Picking the right material is crucial for silicone prototyping. Good silicone improves how your product works and lasts longer. It also saves money and meets industry rules. For example, the right silicone can handle heat, bend easily, and resist chemicals. This makes your prototypes stronger and more dependable.

The material you choose also affects how well your product sells. Using the wrong material can cause it to fail tests or work poorly. By picking the best silicone, you can make a better design. This helps your prototype stand out in the market.

Tip: Talk to your manufacturer about materials to match your needs.

How to Check Silicone Prototype Durability

Durability shows how well a prototype will last over time. Good manufacturers test their prototypes to ensure they handle real-world use. These tests check strength, tear resistance, and how much they can stretch. For instance, silicone with high tear strength and stretchability works better for tough jobs.

Here’s a simple look at key durability features:

Property | Test Method | Value |

|---|---|---|

ISO 7619-1 | 35, 50, 60 | |

Density | ISO 1183-1 A | 2.10 lb/in³, 2.15 lb/in³, 2.19 lb/in³ |

Tensile Strength | ISO 37 Type 4 | 1,450 psi, 1,233 psi, 1,160 psi |

Elongation at Break | ISO 37 Type 4 | 950%, 550%, 320% |

Tear Strength | ASTM D624 Type C | 60 lbf/in., 51.4 lbf/in., 80 lbf/in. |

Manufacturers also cure silicone carefully to get the right strength. If curing is done wrong, prototypes might break or wear out quickly. Proper curing and testing ensure your prototypes last longer and work well.

Note: Ask your manufacturer about their tests to confirm durability.

Questions to Ask About Silicone Quality

To make sure your prototypes are great, ask your manufacturer these questions:

What silicone material fits my project best?

How do you test for strength and performance?

Can you show certifications for the materials?

How long will the prototype last under normal use?

These questions help you see if the manufacturer knows their stuff. Testing and careful planning make sure your product works well. For example, well-made silicone prototypes can last over 25 years with proper care.

By focusing on material quality early, you avoid problems later. This helps you create prototypes that perform better than expected.

Tip: Always ask detailed questions. A good manufacturer will give clear answers.

Picking the best silicone prototyping manufacturer is very important. Look for companies with good reviews, strong skills, and modern tools. Clear communication and quality checks make teamwork easy and results reliable. Flexible services help you adjust to changes, and choosing the right materials ensures long-lasting prototypes.

Do your homework before deciding. Check their experience, location, and customer feedback. Know what you need and explain it clearly. These steps will help you find a manufacturer who meets your needs and creates great prototypes.

FAQ

1. Why pick silicone for prototyping?

Silicone is strong, flexible, and handles heat well. It’s great for making prototypes that act like finished products. Its adaptability helps meet standards and saves money.

2. How can you check a manufacturer’s skill?

Ask about their certifications, tools, and past work. Good manufacturers share their experience and show examples of successful projects.

3. Which industries use silicone prototypes the most?

Healthcare, automotive, and electronics depend on silicone prototypes. They ensure accuracy, strength, and follow strict rules.

4. Can silicone prototypes survive tough conditions?

Yes! Silicone resists heat, chemicals, and damage. It works well for prototypes used in harsh environments.

5. How do manufacturers check prototype quality?

They test strength, flexibility, and resistance to tearing. Quality checks make sure prototypes meet your needs.

6. How fast can silicone prototypes be made?

It depends on the project. Rapid prototyping often finishes in just a few days.

7. Are custom silicone prototypes costly?

Not always. Custom designs reduce mistakes and save money by avoiding extra fixes.

8. How can a manufacturer handle growing needs?

Pick one with modern tools and flexible methods. They should adjust to your needs while keeping quality high.

Tip: Share your project goals clearly. This helps manufacturers match their services to your needs.

Start Your Next Project with LKprototype

LKprototype company simplifies procurement for custom manufacturing, Suitable for making your products or prototypes with a variety of materials, such as metal or plastic, silicone rubber, from 3D Printing to CNC Machined Parts and Vacuum Casting , with a focus on speed and efficiency. Our platform provides instant quotes. With LKprototype, You can connect with the team to communicate your project to ensure quality and on-time delivery.

Start with an instant quote and experience how our technology and expertise can make custom part procurement faster and easier.

LKprototype

LKprototype