CNC Machined Nylon Parts: Strength, Precision, and Versatility

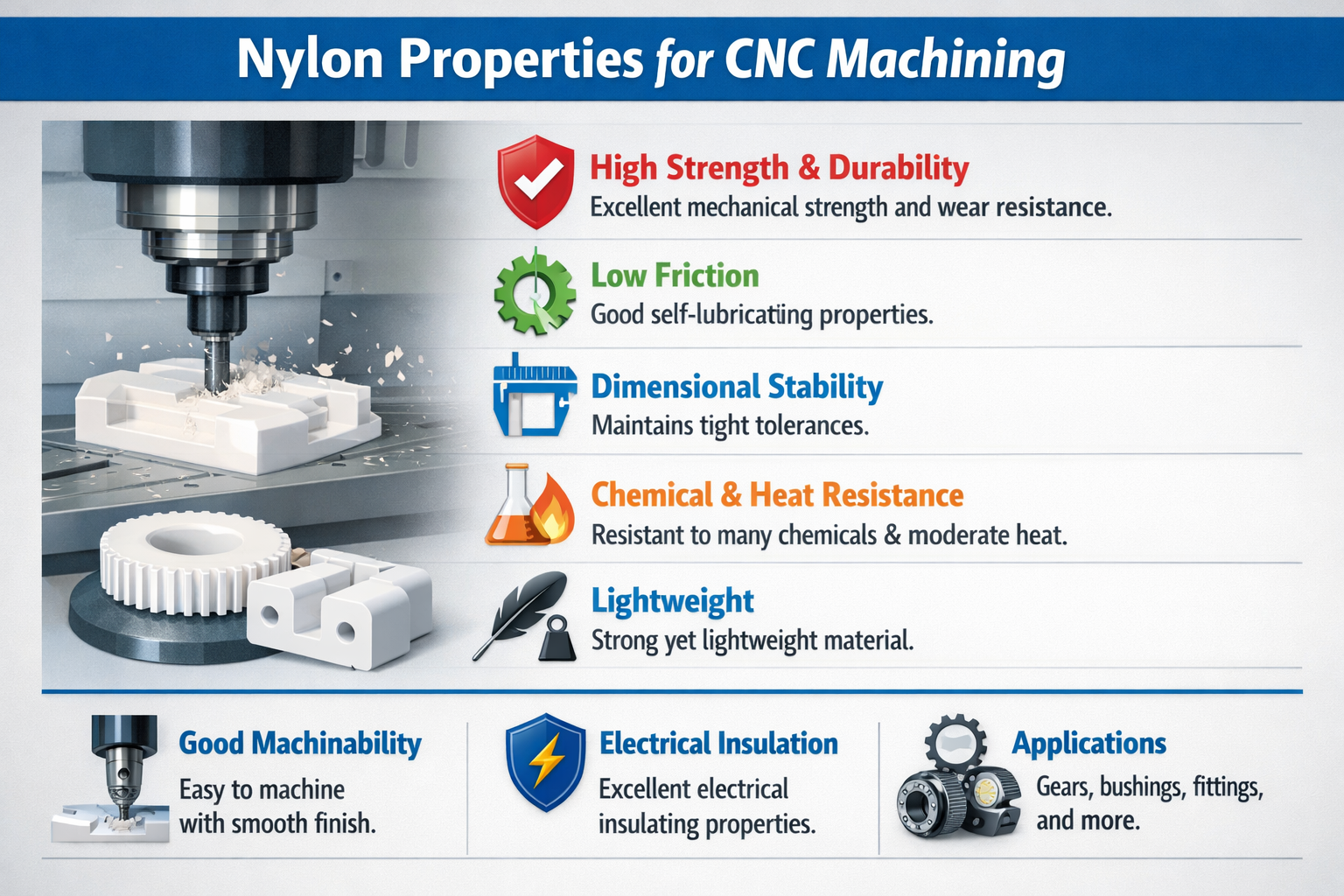

CNC machined nylon parts have become a top choice for industries requiring durable, lightweight, and chemically resistant components. Nylon’s unique combination of mechanical strength, wear resistance, and low friction makes it ideal for applications where precision and longevity are critical. From automotive gears and bushings to electrical housings and industrial machinery components, machined nylon components deliver reliable performance under demanding conditions.

One of the key advantages of nylon in CNC machining is its flexibility and toughness. Unlike metals, nylon can absorb impacts without cracking, while maintaining dimensional stability when exposed to moderate heat and chemical environments. Glass-filled or oil-filled nylon variants enhance strength, wear resistance, and self-lubricating properties, providing superior performance for high-load or high-wear applications.

Manufacturers also value nylon CNC components for their ease of machining. With proper cutting tools, feed rates, and cooling techniques, machinists can produce complex geometries with smooth finishes and tight tolerances. This makes nylon suitable for precision gears, conveyor parts, custom mechanical components, and even medical or food-grade applications where compliance with FDA or EU standards is essential.

Whether for one-off prototypes or low- to medium-volume production, CNC machined nylon parts offer a cost-effective, high-performance solution. Their combination of durability, chemical resistance, and lightweight properties ensures that engineers can rely on nylon components for both functional and structural needs across diverse industries.

You often see manufacturers pick nylon CNC machined parts for tough jobs. Nylon is special because it is strong, tough, and can resist chemicals. Many industries use nylon because it can handle rubbing and wearing out. The table below shows why nylon is a top pick for CNC machining:

Property | Description |

|---|---|

Durability and wear resistance | Nylon is very tough and does not wear out easily. It works well in places with lots of stress and rubbing. |

Lightweight yet strong | Nylon is light but also very strong. It lets you make lighter parts that are still hard to break. |

Chemical resistance | Nylon can stand up to many chemicals. This makes it good for rough places. |

Low coefficient of friction | Nylon helps parts slide easily and not wear out fast. This is good for parts that move. |

Thermal stability | Nylon can handle heat up to a certain point. It is good for things that get warm. |

Key Takeaways

Nylon is tough and light. It does not wear out easily. This makes it good for hard CNC machining jobs.

Nylon parts can handle chemicals and heat. This helps them last long in many industries.

Glass-filled nylon is even stronger and steadier. But it can cost more and break easier.

Using sharp tools and cooling helps make nylon parts better. These steps help nylon parts last longer.

Nylon can be used in many areas. It works well in cars, medicine, and food factories because it has great features.

Why Nylon Is Ideal for CNC Machined Parts

Key Benefits of Nylon

Nylon is a great choice for CNC machining. It has many good points. Nylon parts last a long time and work well in hard places. Here are some reasons why nylon is special:

Nylon is strong and tough. It can hold heavy things.

It does not get damaged by oils or weak acids.

Nylon slides easily and does not wear out fast.

It is good for electrical parts because it insulates.

Nylon is light but still strong.

You can shape nylon into many forms.

Nylon stays strong even when it is wet.

Nylon is not just strong. It is also flexible and works well in many places.

Tip: Nylon slides well, so moving parts last longer and work better.

Comparison with Other Plastics

You may ask how nylon is different from plastics like POM. Nylon often costs less than POM. The table below shows a simple cost check:

Aspect | Nylon Cost | POM Cost |

|---|---|---|

Raw Material Cost | $1.50 - $2.50/lb | $2.50 - $3.50/lb |

Cost per 1,000 lbs | $1,500 - $2,500 | $2,250 - $3,500 |

Processing Cost Advantage | Higher | Lower (5-15% savings) |

Nylon is cheaper than POM, especially if you buy a lot. Nylon also lasts longer and stands up to chemicals. This makes nylon a smart pick for CNC jobs.

Nylon Properties for CNC Machining

Mechanical Strength and Wear Resistance

Nylon is strong and does not wear out fast. It works well for tough jobs. There are different types of nylon. Each type has its own strength and wear resistance. The table below shows how strong each nylon grade is and how well it resists wearing out:

Nylon Grade | Tensile Strength (MPa) | Wear Resistance |

|---|---|---|

Nylon 6 | 60-85 | Good |

Nylon 6/6 | 75-100 | Better |

Nylon 4/6 | 80-110 | Better |

Nylon 12 | 45-70 | Good |

Glass-Filled Nylon (30% GF) | 150-250 | Better |

Nylon can make parts last longer because it is self-lubricating. This means moving parts do not need extra oil. Gears, bushings, and bearings work better with nylon. Nylon helps parts slide easily and not wear out quickly.

Tip: Pick glass-filled nylon if you need very strong parts that last longer.

Chemical and Thermal Stability

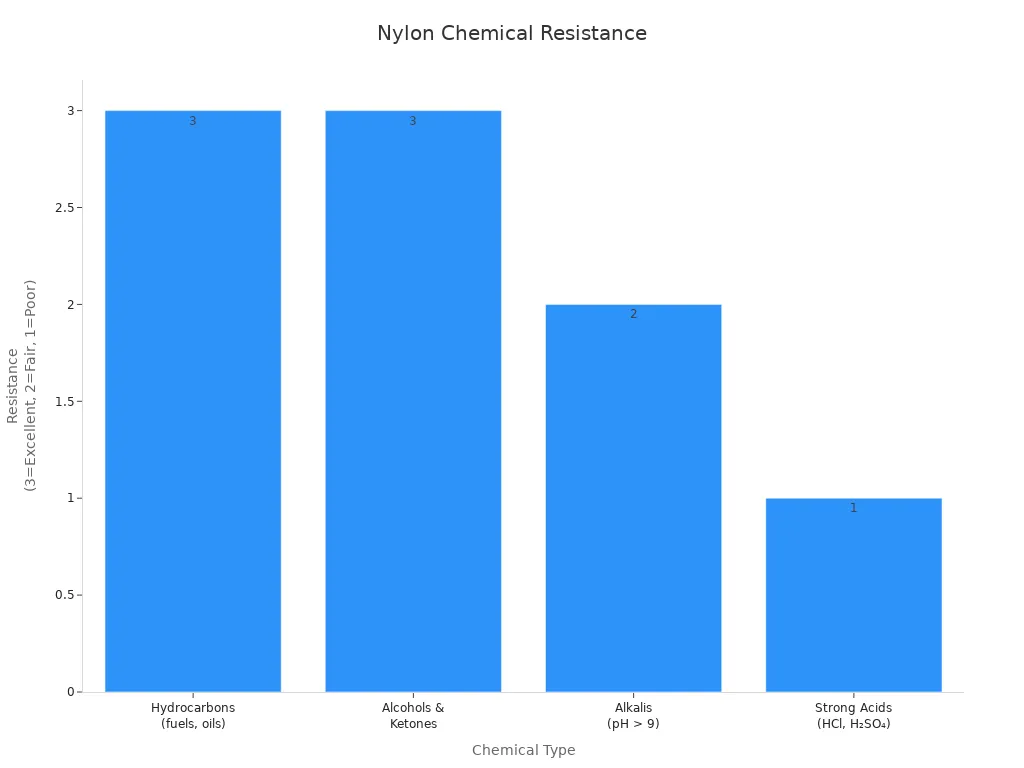

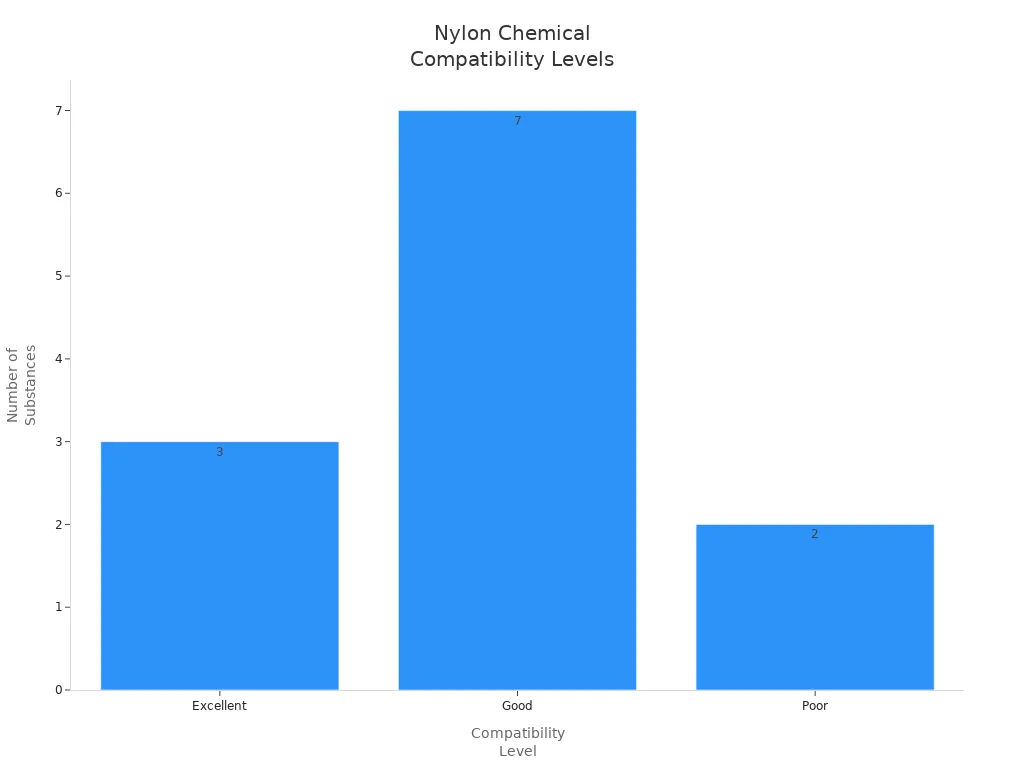

Nylon can handle tough places with lots of chemicals. It does not get damaged by oils, greases, or fuels. Nylon 11 is good for places with many chemicals. The table below shows how nylon reacts to different chemicals:

Chemical Type | Resistance | Effect |

|---|---|---|

Hydrocarbons (fuels, oils) | Excellent | Minimal swelling; ideal for automotive |

Alcohols & Ketones | Excellent | Stable in cleaning agents |

Alkalis (pH > 9) | Fair | Possible surface whitening |

Strong Acids (HCl, H₂SO₄) | Poor | Chain scission & embrittlement |

Nylon can also handle heat well. Most nylon types can be used at temperatures between 100°C and 150°C. Some special nylons work even above 250°C. Nylon keeps its shape and strength when it gets warm.

Moisture Absorption and Dimensional Stability

Nylon takes in water from the air. This can change the size and shape of parts. Nylon can absorb 1.5-2% water in normal air. If soaked in water, it can take in up to 8%. When nylon gets wet, it can grow by 2% in length and 8.8% in mass. Even small changes can affect how well parts fit.

Nylon can expand by 0.2-0.3% in all directions indoors.

Parts may not fit right if nylon gets too wet.

Complicated shapes might bend or twist.

You can stop these problems by drying nylon before you machine it. Use sharp tools and cut slowly. Cooling and using oil helps keep parts the right size. Nylon is a good material, but you must watch out for moisture.

Note: Always dry nylon before machining so your parts stay accurate.

Machining Nylon: Key Factors

Types of Nylon for CNC Machining

There are many types of nylon you can use. Each type has special features that help you get good results. Here are some common types for cnc nylon machining:

Nylon PA6 is strong and resists impacts. It also stands up to chemicals.

Nylon PA9 is used for special jobs in cnc machining.

Nylon PA12 bends easily and is simple to machine.

Nylon PA11 has unique features for certain uses.

Nylon 6/6 lasts longer and is less bendy than Nylon 12.

Polyamideimide (PAI) stays strong in heat, but needs higher machining temperatures.

Nylon 6

Nylon 6 is easy to machine. You can use it for many jobs. It works well for parts that need to be strong and tough.

Nylon 66

Nylon 66 is easier to machine than Nylon 6. It lasts longer when parts rub together. This type is good for gears and bushings.

Material | Machinability |

|---|---|

Nylon 6 | Good |

Nylon 66 | Better |

Glass-Filled Nylon

Glass-filled nylon has glass fibers inside. This makes it stronger and stiffer. It is good for parts that carry heavy loads.

Oil-Filled Nylon

Oil-filled nylon has oil inside. It helps moving parts slide better. It also cuts down on rubbing and wearing out.

Machining Practices and Techniques

You need the right tools and settings for cnc nylon machining. Here are some tips to help you do a good job:

Use high-speed steel or carbide tools. These last longer and cut well.

Keep your cutting edge sharp. Try an angle between 10 and 15 degrees.

Set cutting speeds from 200 to 300 feet per minute. Use feed rates from 0.002 to 0.008 inches per tooth.

Hold your workpiece steady with clamps or a vacuum chuck.

Use water-based coolants to keep things cool and stop bending.

Finish your parts by removing rough edges, sanding, or polishing.

You can use different ways to machine nylon:

CNC Milling: Use sharp cutters with one or two flutes. Keep the feed rate steady.

CNC Turning: Hold the rod tight. Use a sharp carbide tool and spindle speeds from 1500 to 3000 RPM.

CNC Drilling: Pick drills with special shapes. Use air cooling so nylon does not melt.

Tool Selection for Nylon Machining

Pick high-speed steel or carbide tools for cnc nylon machining. Sharp tools help you get smooth cuts.

Cutting Parameters and Speeds

Use medium cutting speeds and feed rates. This stops nylon from melting and keeps parts smooth.

Cooling and Chip Control

Use water-based coolants or air cooling. This keeps nylon cool and stops it from bending.

Common Challenges and Solutions

You might have problems when machining nylon. Here is a table that shows some issues and how to fix them:

Challenge | Impact on Machined Parts | Possible Solutions |

|---|---|---|

Dimensional Instability Over Time | Nylon takes in water and can swell. This changes size and fit. | Use the right tolerance; dry nylon before machining |

Heat Sensitivity | Nylon gets soft or bends above 100°C. | Use slower speeds and coolants; keep heat low |

Grade Confusion | Using the wrong type can cause bad finishes or broken parts. | Check with suppliers; change tools and settings |

Managing Heat Buildup

Control your speeds and use coolants. This keeps nylon from getting too hot and changing shape.

Preventing Material Deformation

Hold your workpiece tight. Use the right coolant. Dry nylon before machining to keep it steady.

Controlling Tolerances

Plan for nylon taking in water. Set your tolerances carefully. Dry your material before you start machining.

Achieving Excellent Surface Finish

You want your nylon parts to look and work well. Here are tips for a smooth finish:

Parameter | Effect on Surface Finish Quality | Recommended Practice |

|---|---|---|

Tool Geometry | Makes cleaner cuts | Use a 20–25° angle and smooth edges |

Cutting Speed | Too fast melts nylon; too slow tears it | Use medium speeds and fine feeds |

Coolant Use | Cuts down on rubbing and smearing | Use mist cooling or air |

Depth of Cut | Big cuts can make noise | Use a thin finishing pass |

Tool Material | Stops rubbing and wearing out | Use carbide tools with smooth edges |

Machining Strategy | Stops tools from bending | Use climb milling for thin nylon parts |

Finishing Methods for Nylon CNC Parts

Remove rough edges after machining. Sand and polish for a smooth finish. Use climb milling for thin nylon parts.

Post-Processing Options

You can polish, sand, or coat your nylon parts. These steps help your parts look better and work well.

Tip: LKprototype uses smart machines and skilled workers to make great nylon parts. You get accurate results and quick service for your cnc machining needs.

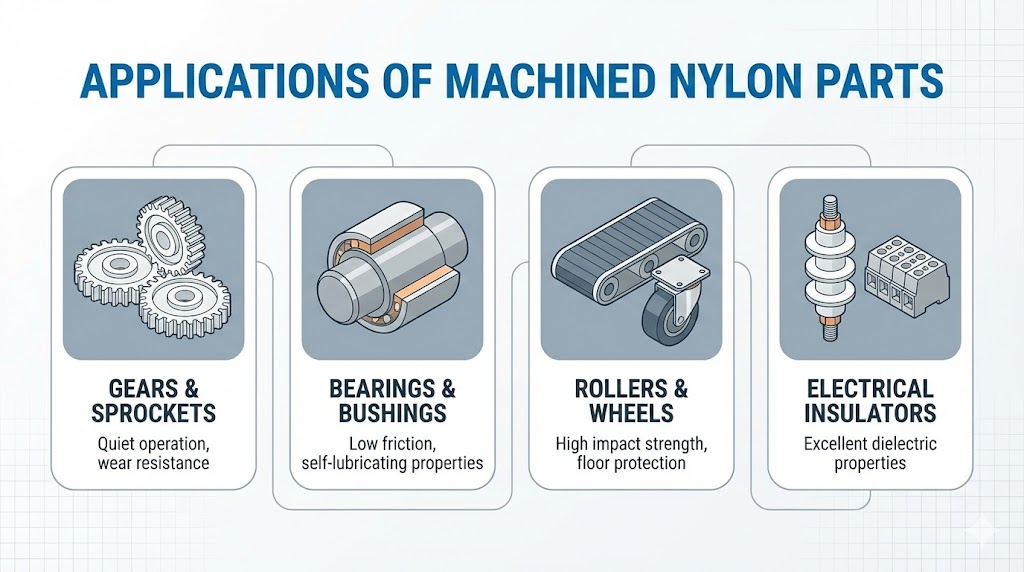

Applications of Machined Nylon Parts

Nylon is used in many different industries. This is because it is strong, lasts a long time, and can be used in many ways. The table below shows where nylon parts are used the most:

Industry | Applications |

|---|---|

Aerospace | Bearing cages, Cable guides, Spacers and bushings, Interior cabin components |

Automotive | Gear Systems, Bearings, Bushings, Brackets |

Medical Devices | Surgical instruments, Diagnostic equipment components, Laboratory equipment parts, Medical device housings |

Food Processing | Conveyor Parts, Processing Equipment, Storage Solutions |

Industrial Machinery | Conveyor systems, Material handling equipment, Packaging machinery, Assembly line components |

Electronics | Insulation components, Cable management systems, Housing components, Protective covers |

Marine | Bearing materials for propeller shafts, Deck hardware components, Navigation equipment housing, Cable routing systems |

Automotive Components

Nylon is important for car parts. It is found in gears, bushings, and other parts that wear out. These nylon parts help cars work better and last longer.

Bushings and Bearings

Nylon bushings are very tough. They work well even when pressed hard. You do not need to add grease often because they are self-lubricating. The table below shows how nylon bushings do their job:

Performance Aspect | Description |

|---|---|

Wear Resistance | Nylon bushings are designed to withstand high-frequency vibrations and continuous friction. |

Self-Lubricating Properties | They typically do not require external grease, reducing maintenance needs and costs. |

Structural Stability | Maintains controlled deformation under repeated friction and high-load cycles. |

Thermal Cycling Tolerance | Maintains geometric precision during long-term thermal alternation. |

Load Response | Fatigue life remains stable under localized high-load environments. |

Nylon bushings last longer because they resist wearing out.

They do not need much oil, so you do not have to fix them often.

They stay strong even when the temperature changes a lot.

Gears and Wear Parts

Nylon gears are used in cars because they are light and do not wear out fast. They also make less noise. Nylon rollers and guide rails help parts move smoothly. These features make cars work better and last longer.

Nylon gears: Light, tough, and quiet.

Other parts: Bushings, rollers, and guide rails slide easily and do not need much oil.

Electronics and Electrical Uses

Nylon is a good choice for electrical parts. It helps keep things safe and works as an insulator.

Insulating Components

Nylon parts stop electricity from causing problems. They keep wires and cables safe. You see nylon ties, clips, and holders in many devices.

Nylon is good at stopping electricity from passing through.

It does not let electricity flow, so it stops short circuits.

Used in power lines and connectors to keep things safe.

Structural Housings

Nylon covers protect electronic parts inside. They are strong and do not catch fire easily. You use nylon for boxes, cable ends, and couplings to keep electronics safe.

Industrial Equipment and Machinery

Nylon is found in many moving machine parts. It helps parts move smoothly and last longer.

Low-Friction Moving Parts

Nylon bearings and blocks slide easily. They do not need much oil and last a long time. Nylon does not rust or break down in wet or chemical places.

Nylon bearings help machines move without much rubbing.

They last longer because they do not wear out fast.

Nylon is great for parts that touch each other all the time.

Custom Machine Components

Nylon is used for gears, bushings, pump blades, nuts, screws, and spacers. It fits well in cars, planes, big machines, and conveyor belts.

Consumer Product Applications

Nylon makes many products stronger and better. You see it in lots of things at home and in sports.

Durable Plastic Enclosures

Nylon is strong and does not wear out fast. It is used for phone cases, grips, and sports gear. Nylon gives a smooth look and detailed shapes for device covers and kitchen tools.

Functional Mechanical Parts

Nylon gears and moving parts last longer than metal ones. They make less noise and work smoothly. You do not have to fix them as much.

Consumer Products | Benefits |

|---|---|

Automotive Parts | High strength, excellent wear resistance, lightweight properties |

Aerospace Components | High strength, chemical resistance, suitable for high-stress applications |

Electrical Housings | Low friction, chemical resistance, reducing maintenance costs |

Mechanical Transmission Parts | Wear resistance, noise reduction, self-lubricating properties |

Medical Device Uses

Nylon is safe and works well in medical tools.

Non-Implant Medical Components

You find nylon in tools for surgery and testing. Nylon does not get damaged by chemicals, so these parts last longer and need less fixing.

Laboratory Equipment Parts

Nylon can handle strong chemicals in labs. The chart below shows how nylon stands up to chemicals:

Nylon helps lab tools work well, even in tough places.

Specialized Machined Nylon Applications

Nylon is used for food and high-wear jobs.

Food-Grade Nylon Parts

Food-grade nylon is used in conveyor belts and machines for food. These nylon parts follow rules from the FDA, USDA, and EU.

Certification/Standard | Description |

|---|---|

FDA | Ensures materials are safe for food contact. |

USDA | Regulates materials used in food processing. |

EU Regulations | Sets standards for food safety in the European Union. |

High-Wear and High-Load Applications

Nylon works better than other materials in tough jobs. It does not rust, is light, and needs less fixing. These features make nylon a smart pick for hard jobs.

Tip: If you pick nylon, your products will last longer and work better in many industries. Nylon is being used in more ways as technology gets better.

You can make parts work better by using nylon for CNC machining. Nylon is strong and does not get damaged by chemicals. It also lets parts slide easily. These features help in many industries. Glass-filled nylon is even harder and more stable. But it costs more and can break easier. The table below shows what is good and bad about glass-filled nylon:

Advantages of Glass-Filled Nylon | Limitations of Glass-Filled Nylon |

|---|---|

Higher hardness | Higher cost |

Superior tensile strength | More brittle |

Greater stiffness | Abrasive to tooling |

Lower thermal expansion | Can abrade mating parts |

Increased stability under temperature fluctuation | Heavier than standard nylon |

Lower creep rate | Weaker weld lines |

Good fatigue strength | Anisotropic properties and shrinkage |

Pick the right nylon type for your part and job. This helps your parts work their best. If you have tricky needs, ask CNC experts for help.

FAQ

What makes machined nylon parts suitable for cnc applications?

Machined nylon parts are strong and light. They do not wear out fast. These parts can stand up to chemicals. Machining nylon makes surfaces smooth and sizes exact. You can use these parts in cars, electronics, and machines.

How does moisture affect cnc machined nylon parts?

Water can change the size of nylon parts. Parts might swell or bend a little. Dry nylon before you machine it to keep it the right size. Store nylon in a dry place if you need it for important jobs.

Can you use machined nylon parts for food-grade application?

Yes, you can use machined nylon parts for food jobs. These parts follow FDA and EU rules. You see them in food machines and conveyor belts. Machining keeps these parts safe for touching food.

What are the best practices for cnc machining nylon parts?

Use sharp carbide tools and medium speeds. Water coolants help keep nylon cool. Hold your parts tight while you work. Pick glass-filled nylon for stronger parts. These steps help parts last longer and look better.

Why do machined nylon parts offer high durability?

Machined nylon parts do not wear out fast. They can take hits and rubbing. Nylon parts last a long time in tough places. The way nylon is made helps parts stay strong. You can use these parts again and again in machines.

LKprototype

LKprototype