Understanding Prototypes and Their Importance

A prototype is a model or early version of your invention that helps you test and refine your idea. Creating basic prototypes using everyday materials is an essential step in refining designs before moving into mass production. Prototypes are essential for identifying and fixing design flaws, understanding user needs, and gathering feedback. The prototype development process can save time and money in the long run by ironing out production issues and rectifying problems before mass production. Creating a proof of concept can further validate the feasibility of your invention before moving to more advanced prototyping stages. Working with professional prototype makers can help address complexities and ensure all aspects of the invention are properly addressed.

Market Research and Inspiration

Conduct market research to understand your target audience, their needs, and preferences.

Gather inspiration from existing products, competitors, and industry trends.

Identify gaps in the market and opportunities for innovation.

Conduct a competitive analysis to understand the strengths and weaknesses of existing products in the market.

The Prototype Development Process

The prototype development process involves creating a series of prototypes, each refining and improving the previous one.

The process includes market research, creating an initial sketch as a fundamental step in the product design process, digital prototyping, physical prototyping, and testing. This initial sketch aids in balancing aesthetics and functionality, provides a tangible representation of ideas, and helps identify flaws before moving on to prototyping and production. Design validation is a crucial step to ensure that the prototype meets all design specifications and user requirements.

The goal of the prototype development process is to create a functional prototype that meets user needs and is ready for mass production.

Creating an Initial Prototype

Start by creating an initial prototype, also known as a basic prototype or rough prototype.

Use computer-aided design (CAD) software or sketching tools to create a digital prototype.

Create a physical prototype using materials such as cardboard, foam, or 3D printing.

Develop a concept prototype to visualize and test the basic idea of your invention.

Prototyping Methods and Costs

There are various prototyping methods, including rapid prototyping, 3D printing, and CNC machining.UrethaneVacuum Casting

Prototype costs vary depending on the method, materials, and complexity of the design. Accurate cost estimation is essential to ensure that the prototyping process stays within budget.

Consider working with a skilled prototype maker to reduce costs and improve efficiency. For example, LKprototype, we have 15 years of experience in prototyping, providing inventors with the fastest and highest quality service, helping engineers to successfully bring their products to market. Professional prototype makers bring expertise to the prototyping process, guiding inventors through the complexities of development. Selecting the right manufacturer is crucial, as they ensure all aspects of the invention are properly addressed, alleviating the burdens of DIY prototyping.

Material Selection for Prototyping

When it comes to selecting materials for prototyping, there are several factors to consider. The choice of material will depend on the specific requirements of your project, including the desired properties of the final product, the manufacturing process, and the budget. Understanding the material properties is crucial for selecting the right materials for your prototype.

Here are some common materials used in prototyping:

Plastics: Plastics are a popular choice for prototyping due to their versatility, durability, and affordability. Common types of plastics used in prototyping include ABS, PVC, and polycarbonate. These materials are ideal for creating detailed and intricate designs using methods like 3D printing and injection molding.

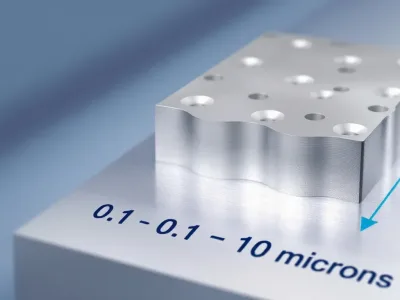

Metals: Metals are often used in prototyping for their strength, durability, and conductivity. Common types of metals used in prototyping include aluminum, steel, and copper. Metal prototypes are typically created using CNC machining or metal casting, making them suitable for parts that require high strength and precision.

Wood: Wood is a natural, renewable resource that can be used for prototyping. It is often used for creating mockups and models, as well as for testing the aesthetic and tactile properties of a product. Wood is easy to work with and can be shaped using traditional woodworking tools.

Foams: Foams are lightweight, flexible materials that can be used for prototyping. They are often used for creating models and mockups, as well as for testing the ergonomic and comfort properties of a product. Foam prototypes can be quickly shaped and modified, making them ideal for iterative design processes.

Composites: Composites are materials made from a combination of two or more materials. They are often used in prototyping for their unique properties, such as high strength-to-weight ratios and resistance to corrosion. Common composites include fiberglass and carbon fiber, which are used in applications requiring high performance and durability.

When selecting materials for prototyping, it’s essential to consider the following factors:

Cost: The cost of the material will impact the overall budget of the project. It’s important to balance material quality with affordability to stay within budget.

Availability: The material should be readily available and easily sourced to avoid delays in the prototype development process.

Properties: The material should have the desired properties for the final product, such as strength, durability, and conductivity. This ensures the prototype accurately represents the final product.

Manufacturability: The material should be easy to work with and manufacture. This includes considering the compatibility of the material with the chosen manufacturing process.

Sustainability: The material should be sustainable and environmentally friendly, aligning with modern standards for eco-friendly product development.

By considering these factors and selecting the right materials for prototyping, you can create a functional and effective prototype that meets your project’s requirements.

Budgeting for Prototyping

Budgeting for prototyping is an essential part of the prototype development process. The cost of prototyping can vary widely depending on the type of prototype, the materials used, and the complexity of the design. Effective financial planning can help you allocate resources efficiently and avoid overspending.

Here are some tips for budgeting for prototyping:

Estimate Costs: Start by estimating the costs of materials, labor, and equipment needed for prototyping. This will give you a clear picture of the financial requirements and help you plan accordingly.

Prioritize: Prioritize the features and functionalities of the prototype based on their importance and cost. Focus on the most critical aspects first to ensure the prototype meets its primary objectives.

Use Cost-Effective Materials: Use cost-effective materials and manufacturing processes to reduce costs. For example, consider using plastics instead of metals for initial prototypes or opting for rapid prototyping methods like 3D printing.

Outsource: Consider outsourcing prototyping to a third-party company or freelancer to reduce costs. Prototype companies and prototyping services often have the expertise and equipment to create high-quality prototypes more efficiently.

Plan for Contingencies: Plan for contingencies and unexpected expenses. Allocate a portion of your budget for unforeseen costs to avoid financial strain during the prototype development process.

The cost of prototyping can be broken down into several categories, including:

Material Costs: The cost of materials used for prototyping, such as plastics, metals, and woods. Material selection can significantly impact the overall budget, so choose wisely based on your project’s needs.

Labor Costs: The cost of labor required for prototyping, including design, manufacturing, and testing. Skilled labor can be expensive, so consider the complexity of the prototype and the expertise required.

Equipment Costs: The cost of equipment and tools needed for prototyping, such as 3D printers and CNC machines. Investing in or renting the right equipment can streamline the prototyping stage and improve efficiency.

Software Costs: The cost of software and computer-aided design (CAD) tools used for prototyping. CAD software is essential for creating digital prototypes and refining designs before physical production.

Testing and Validation Costs: The cost of testing and validating the prototype, including usability testing and performance testing. Ensuring the prototype functions as intended is crucial before moving to mass production.

By budgeting for prototyping and considering the costs involved, you can create a functional and effective prototype that meets your project’s requirements and stays within budget. Proper budgeting ensures that you can navigate the prototype development process smoothly and bring your invention to life without financial hurdles.

Iterative Design and Testing

Iterative design and testing are crucial steps in the prototype development process. This involves creating a series of prototypes, each with incremental improvements, to refine the design and functionality of the product. The goal is to test and validate assumptions about the product’s performance, usability, and market demand. Incorporating user feedback is essential for refining the design and ensuring the product meets user needs.

Design optimization and validation are crucial steps to ensure that the prototype meets all design specifications and user requirements.

During the iterative design and testing phase, it’s essential to:

Gather feedback from potential users and stakeholders

Analyze data and test results to identify areas for improvement

Refine the design and functionality of the product

Create new prototypes to test and validate changes

Repeat the process until the desired outcome is achieved

Iterative design and testing help to reduce the risk of launching a product that may not meet market demands or user expectations. By continuously refining and improving the design, you can increase the chances of success and create a product that meets the needs of your target audience.

Collaboration with Engineers and Designers

Collaboration with engineers and designers is critical in the prototype development process. Engineers can provide valuable insights into the technical feasibility of the product, while designers can help to refine the user experience and aesthetics.

When working with engineers and designers, it’s essential to:

Clearly communicate the product’s requirements and specifications

Establish a collaborative workflow to ensure seamless communication and feedback

Define roles and responsibilities to avoid confusion and overlapping work

Encourage open communication and feedback to ensure that all stakeholders are aligned

Foster a culture of innovation and experimentation to drive creativity and problem-solving

By collaborating with engineers and designers, you can create a product that is both functional and visually appealing, meeting the needs of both technical and non-technical stakeholders.

Working with a Prototyping Service

Consider collaborating with prototyping companies to streamline the manufacturing process and reduce costs when creating your prototype. Selecting the right prototype makers is crucial, as their expertise can streamline the manufacturing process and ensure high-quality prototypes. Outsourcing prototyping can save time and resources, allowing you to focus on other aspects of product development.

Look for companies that offer a range of prototyping services, including digital prototyping, physical prototyping, and testing.

Ensure that the company has experience in your industry and can provide high-quality prototypes.

DIY Prototyping

DIY prototyping involves creating your own prototype using materials and tools.

Use online resources and tutorials to learn about prototyping techniques and tools.

Consider using 3D printing or CNC machining to create a physical prototype.

Virtual Prototyping

Virtual prototyping involves creating a digital prototype using software such as CAD or simulation tools.

Virtual prototypes can be used to test and refine your design before creating a physical prototype.

Virtual prototyping can save time and money by reducing the need for physical prototypes.

Physical Prototyping

Physical prototyping involves creating a physical prototype using materials such as plastic, metal, or wood.

Physical prototypes can be used to test and refine your design, as well as to gather feedback from users.

Consider using 3D printing or CNC machining to create a physical prototype.

Create a mockup to test the physical appearance and functionality of your design.

Prototype Presentation and Feedback

Presenting your prototype to stakeholders, including investors, customers, and partners, is a critical step in the prototype development process. This is an opportunity to showcase your product, gather feedback, and validate assumptions about market demand. Effective stakeholder engagement is crucial for gathering valuable feedback and securing support for your project.

When presenting your prototype, it’s essential to:

Clearly articulate the product’s value proposition and unique selling points

Demonstrate the product’s features and functionality

Gather feedback and questions from stakeholders

Address concerns and provide solutions to potential issues

Use the feedback to refine and improve the product

Effective prototype presentation and feedback can help to:

Validate market demand and interest in the product

Identify areas for improvement and refinement

Build credibility and trust with stakeholders

Secure funding and support for further development

Sustainability in Prototyping

Sustainability is an increasingly important consideration in the prototype development process. As consumers become more environmentally conscious, companies must prioritize sustainability in their product design and development.

When it comes to sustainability in prototyping, it’s essential to:

Consider the environmental impact of materials and manufacturing processes

Design for recyclability and reusability

Minimize waste and energy consumption during the prototyping process

Use sustainable materials and suppliers whenever possible

Incorporate sustainable design principles into the product’s design and functionality

By prioritizing sustainability in prototyping, you can:

Reduce the environmental impact of your product

Appeal to environmentally conscious consumers

Differentiate your product from competitors

Contribute to a more sustainable future

Legal Considerations in Prototyping

When it comes to prototyping, it’s essential to consider the legal implications of your actions. Here are some key legal considerations to keep in mind:

Intellectual Property Protection: Before sharing your prototype with anyone, ensure your intellectual property is protected. This can include filing for patents, trademarks, or copyrights. Working with an intellectual property lawyer can help you navigate this process and ensure your rights are safeguarded.

Non-Disclosure Agreements (NDAs): When collaborating with prototype developers, manufacturers, or even potential investors, use NDAs to protect your design and ideas. An NDA legally binds the parties involved to confidentiality, preventing them from disclosing or using your invention without permission.

Compliance with Regulations: Depending on your invention, there may be specific industry regulations and standards you need to comply with. This can include safety standards, environmental regulations, and industry-specific guidelines. Ensure your prototype meets these requirements to avoid legal issues down the line.

Contractual Agreements: When working with prototyping companies or freelance prototype makers, have clear contractual agreements in place. These contracts should outline the scope of work, payment terms, timelines, and ownership of the prototype. This helps prevent misunderstandings and ensures all parties are on the same page.

Documentation and Record Keeping: Keep detailed records of your prototype development process, including design iterations, testing results, and feedback. This documentation can be crucial in protecting your intellectual property and proving the originality of your invention if disputes arise.

By considering these legal aspects, you can protect your invention and navigate the prototype development process with confidence.

Launching a Minimum Viable Product (MVP)

An MVP is a basic version of your product that meets user needs and is ready for market testing. Product iteration allows you to make continuous improvements based on user feedback and market testing.

Launching an MVP can help you gather feedback and refine your design before investing in mass production.

Consider using crowdfunding or online marketplaces to launch your MVP.

Refining Your Prototype

Refine your prototype based on user feedback and testing results. Design optimization ensures that your prototype is as efficient and effective as possible before moving to mass production.

Make iterative improvements to your design, using the prototype development process to guide you.

Ensure that your prototype meets user needs and is ready for mass production.

Protecting Your Intellectual Property

Protect your intellectual property by filing patents, trademarks, and copyrights. Filing a patent application is a crucial step in protecting your invention from being copied or used without permission.

Consider working with an intellectual property lawyer to ensure that your rights are protected.

Use non-disclosure agreements (NDAs) to protect your design and intellectual property.

Common Prototyping Mistakes

Common prototyping mistakes include rushing the prototype development process, neglecting user feedback, and overcomplicating the design.

Avoid these mistakes by taking a iterative and user-centered approach to prototyping.

Ensure that your prototype is functional, user-friendly, and meets user needs.

Conclusion

Creating a prototype is an essential step in the product development process. Understanding the product lifecycle helps you plan for each stage of development, from initial concept to mass production.

By following the prototype development process and using the right tools and techniques, you can create a functional prototype that meets user needs and is ready for mass production.

Remember to protect your intellectual property and avoid common prototyping mistakes to ensure the success of your product.

LKprototype

LKprototype