CNC machining allows you to create parts with very tricky shapes and small size limits, especially when it comes to cnc machining complex geometries. You must follow simple design rules to ensure your parts are easy to make, accurate, and cost-effective. New technology enhances CNC machining's ability to work with hard shapes. You can see significant advancements with multi-axis machines and CAM software:

5-axis machining enables you to produce turbine blades or medical implants in just one setup, effectively handling cnc machining complex geometries.

These machines can reduce machining time by up to 84% compared to traditional methods.

Hybrid manufacturing conserves 40% of material and accelerates production by 30%.

Tiny details, such as internal cooling channels, can be precisely crafted.

This guide provides you with valuable tips for designing high-precision parts.

Key Takeaways

CNC machining is great for making hard shapes. It can make parts very exact. This helps in fields like aerospace and medical.

Multi-axis machines can save time. They also make parts more accurate. These machines let you make detailed designs in one go.

Picking good materials and making designs simple helps a lot. It makes parts easier to make. It also lowers costs and makes products better.

Working with CNC machining partners early is smart. They can spot problems in designs. This makes production faster and results better.

Good toolpath planning helps the process go smoothly. Not making deep cavities also helps. This leads to better parts and easier machining.

Quick Overview of CNC Machining Complex Geometries

What CNC Can Achieve with Complex Shapes

CNC machining helps you make parts with shapes that are too hard to make by hand. You can use cnc milling to create parts with many angles. CNC turning is good for making round shapes and special outlines. Wire EDM cuts tiny details and tricky shapes very accurately. Multi-axis machines let you work with cnc machining complex geometries better. Special cutting tools help you get exact sizes in tough designs.

Multi-Surface Machining Capability

You can work on many surfaces at once. Multi-axis cnc machines turn and tilt the part. This lets you reach every side. You do not need extra setups. Your part stays accurate. You save time and make things faster.

High-Accuracy Contouring

CNC machining follows hard curves and shapes. Advanced CAM software helps you plan tool paths. The tool matches the shape closely. You get smooth surfaces and exact sizes. Your parts fit and work as they should.

Key Challenges and How CNC Solves Them

Making hard parts is not easy. You must think about how tools reach the part and how heat builds up. CNC technology helps you fix these problems.

Tool Accessibility

It can be hard to reach deep spots or inside features. CNC machines use special software to check tool paths before cutting. This helps you find problems early and change your design.

Challenge | Solution |

|---|---|

Making hard shapes like undercuts or inside features is tough because CNC tools cannot always reach or move easily. | Using advanced CAD/CAM software to test and change designs before making the part helps you find problems early. |

Heat and Tool Wear

Cutting makes heat and wears out tools. You can use cooling systems and pick the best cutting tools. This keeps parts exact and helps tools last longer. You avoid mistakes and stop delays.

Tip: Always check your tools and cooling when using cnc machining. This helps you keep parts exact and avoid expensive errors.

When Multi-Axis Machining Is Required

You need multi-axis cnc machining for parts with hard shapes or very exact sizes. Some jobs need high accuracy and special features.

Geometry-Driven Requirements

You must use multi-axis machines if your part has features on many sides or needs angled cuts. Multi-axis cnc milling lets you reach every surface without moving the part. This is needed for impellers, turbine blades, and other hard parts.

Tolerance-Driven Requirements

Some jobs need very exact sizes. You need multi-axis cnc machining to meet these needs.

Industry | |

|---|---|

Automotive | Exact size control for parts like powertrains and brakes to keep things safe. |

Aerospace | Very tight sizes to keep things lined up in tough conditions, making sure everything works safely. |

Robotics | Exact fits and shapes to stop things from moving wrong and keep machines working smoothly. |

Medical Devices | Very exact sizes and fits for safety and to make sure medical parts work well for patients. |

If you want to make hard parts fast, you can use LKprototype. They work quickly and give you good results. You can learn more about their CNC machining services for advanced manufacturing.

What Are Complex Geometries in CNC Machining?

Definition of Complex Geometry

People talk about complex geometries in cnc machining. These shapes are not just blocks or cylinders. They have many faces, curves, and angles. Engineers use CAD/CAM software to look at surfaces. They check for spots that are hard to reach. Algorithms like Gaussian curvature help find tricky areas. You sort parts by how curved they are. You also check if tools can reach those spots.

Multi-Face Features

Multi-face features mean a part has many surfaces. These surfaces connect at different angles. You must plan how to cut each face. Sometimes, advanced cnc milling is needed. This helps you reach every side. Multi-face parts need more setups. Careful toolpath planning is important.

Freeform Surfaces

Freeform surfaces are smooth and curved. They look like waves or natural shapes. You see these in aerospace and medical devices. These surfaces need high precision. CNC milling follows the curves closely. Surface analysis helps pick the right tools and machines.

Tip: Always check your design for hidden curves. Look for faces that are hard to reach. This helps you avoid mistakes when making the part.

Common Examples of Complex CNC Parts

Complex parts are used in many industries. Here are some examples:

Aerospace: Turbine blades, fuel injectors, and structural parts use strong metals.

Medical Devices: Hip implants and surgical tools need to be precise. They use safe materials like titanium and stainless steel.

Automotive: Engine parts like pistons and crankshafts use tough metals.

Impellers and Turbine Blades

Impellers and turbine blades have twisted shapes. They have many faces. Advanced cnc machines are needed to make them. These parts must be strong and exact.

Medical Implants

Medical implants have curved surfaces. They need tight tolerances. CNC machining complex geometries helps them fit patients well. Precision is important for safety and comfort.

If you want fast prototyping for complex parts, LKprototype can help. They offer advanced manufacturing and cnc machining services. Learn more about their CNC machining services.

Why Complexity Affects Machining Strategy

Complex shapes change how you plan machining. You must think about toolpaths and setups.

Toolpath Planning

You need to plan toolpaths for tricky shapes. Advanced cnc milling helps you cut better. You use methods like adaptive clearing and trochoidal milling. Z-level machining is also used. These ways keep the tool safe and improve accuracy.

Setup Planning

Setup planning means choosing how to hold the part. You also decide how to move it. Complex parts need more setups. You must pick the right cnc machine. Sometimes you need a 4-axis or 5-axis machine. This helps reduce mistakes and keeps parts accurate.

Note: Good toolpath and setup planning saves time. It reduces machine wear and improves results. Always plan ahead for complex geometries.

CNC Machining Capabilities for Complex Geometries

Precision and Repeatability in CNC Machining

Machine Accuracy

You need parts that are very exact. Modern CNC machines can make parts with tiny errors, as small as ±0.01 mm. Some machines are even more precise, reaching micron-level tolerances. This means you can trust cnc machining to make high-quality parts. These parts work well for aerospace, medical, and automotive uses. These industries need parts that fit perfectly and work every time.

Precision machining makes parts with errors of ±0.01 mm or less.

Advanced CNC machines can be even more exact.

Every part comes out the same.

Process Stability

You want every part to match your design. CNC machines help you do this by repeating the same steps each time. This means you get many parts that look and work the same. Stable processes help you avoid mistakes and save materials. Reliable cnc machining keeps your work moving smoothly.

Tip: Always check your machine and tools before you start. This helps you make sure your parts are exact and you do not waste money.

Multi-Axis Machining for Complex Parts

You can pick different CNC machines for hard shapes. Each type has special benefits for cnc milling and making parts.

Type of CNC Machine | Axes of Movement | Complexity of Parts | Setup Requirements | Cost Efficiency |

|---|---|---|---|---|

3-axis | X, Y, Z | Simple shapes | Move part to reach all sides | Least expensive |

4-axis | X, Y, Z, A | Harder shapes | One setup for most sides | Medium cost |

5-axis | X, Y, Z, A, B/C | Very hard shapes | Reach all sides in one setup | Most expensive |

3-Axis Machining

You use 3-axis cnc milling for easy shapes. The machine moves in three ways. You might need to turn the part to reach other sides. This way is good for simple designs and saves money.

4-Axis Machining

You use 4-axis cnc milling for more details. The machine adds a spinning part. You can make harder shapes without moving the part. This saves time and helps you be more exact.

5-Axis Machining

You use 5-axis cnc machining for the hardest shapes. The machine moves in five ways. You can reach almost every side in one go. This is best for tricky designs and tight fits.

Note: If you want fast samples of hard parts, LKprototype can help. They use multi-axis machines to make good parts quickly. Learn more about their CNC machining services.

Design Guidelines for CNC Machining Complex Parts

When you make complex parts with cnc machining, you should follow simple rules. These rules help you get good parts that are easy to make and not too expensive. If you use good design rules, you can stop mistakes and keep your project on time.

Material Selection for Complex Geometries

Picking the right material is very important. It helps your part work well and be easy to make. You need to think about how easy it is to machine, how much it costs, and what your part needs to do.

Machinability Ratings

Some materials are easier to cut than others. If you pick a material with a high machinability rating, you can make parts faster. The surface will look better too. Here is a table to help you choose the best material:

Use Case | Recommended Material | Why |

|---|---|---|

High strength-to-weight ratio | Aluminium 7075, Titanium | Great balance of strength and weight |

Low-cost prototyping | Delrin (POM), Aluminium 6061 | Cheap and easy to machine |

Excellent surface finish | Brass, Aluminium, Acrylic | Shiny finish, less work needed after machining |

Wear resistance | Nylon, PEEK, Hardened Steel | Good for moving or rubbing parts |

Corrosion resistance | Stainless Steel 316, Titanium | Stays strong in wet or harsh places |

Tight tolerances / low expansion | Stainless Steel, Acetal, Aluminium | Stays the same size in heat or wet places; good for exact parts |

Fast turnaround / high availability | Aluminium 6061, Stainless Steel 304, POM | Easy to find and buy |

High heat resistance | PEEK, PPS, PEI | Works well in hot places |

Chemical resistance | PEEK, PTFE, PVDF | Stays strong with chemicals |

UV stability (outdoor use) | PEEK, UV-stabilized Polycarbonate | Good for sunlight |

Impact resistance | Polycarbonate, ABS | Does not break easily |

Tip: If you want fast samples and good cnc machining, LKprototype can help. They have many materials and advanced cnc milling for hard jobs. Learn more about their CNC machining services.

Hard-to-Machine Materials

Some materials, like hardened steel or titanium, are tough to cut. You need special tools and must go slow. Only use these if you really need them. Always check if an easier material will work for your part.

Tool Access and Feature Orientation

How you hold your part and where you put features matters. It changes how easy it is for tools to reach and how smooth the surface will be.

Optimal Part Orientation

You should hold your part so tools can reach everything. This means fewer setups and better accuracy. Five-axis cnc milling lets you reach more places in one go. This helps you get exact parts and smooth surfaces.

Aspect | Three-Axis Machining | Five-Axis Machining |

|---|---|---|

Tool Access | Only from above | From many angles |

Setup Complexity | Easier setups | More setups needed |

Quality of Features | May not be perfect | Very good quality |

Surface Finish | May need extra steps | Smooth in one try |

Five-axis machining works best for angled and tricky shapes.

How you hold your part changes tool access and quality.

Avoiding Shadowed Areas

Shadowed areas are places tools cannot reach. Try not to use deep holes, overhangs, or blocked spots. If you must use these, pick advanced cnc machines or change your design for better access.

Note: Five-axis cnc machining complex geometries means fewer setups and better parts.

Internal Features and Cavity Design

Making inside shapes and holes needs extra care. This helps you make your part right.

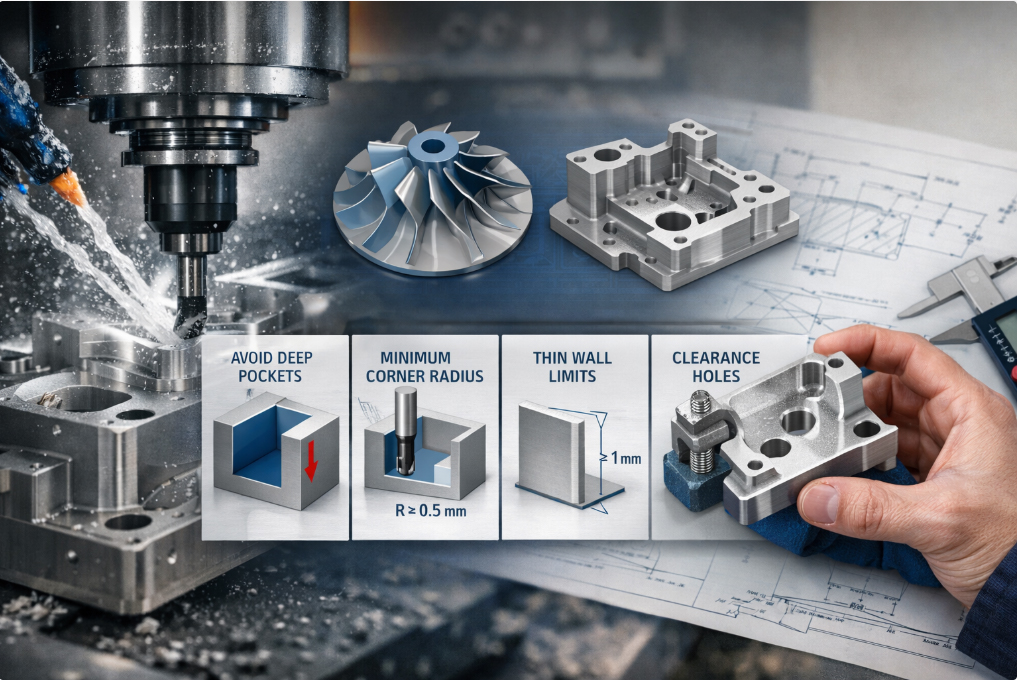

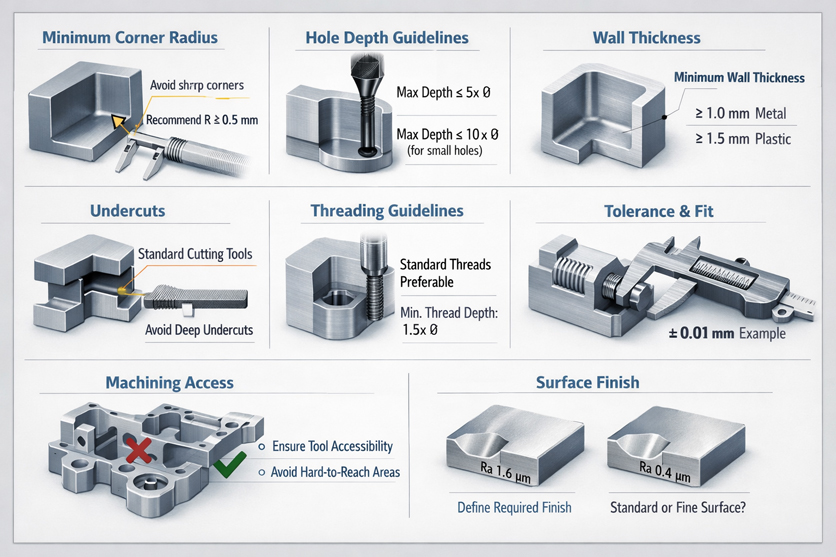

Pocket Depth-to-Width Ratio

Deep pockets are hard to cut. Keep them as shallow as you can. Shallow pockets are easier and cheaper. If you need deep pockets, use bigger corners and do not use thin walls.

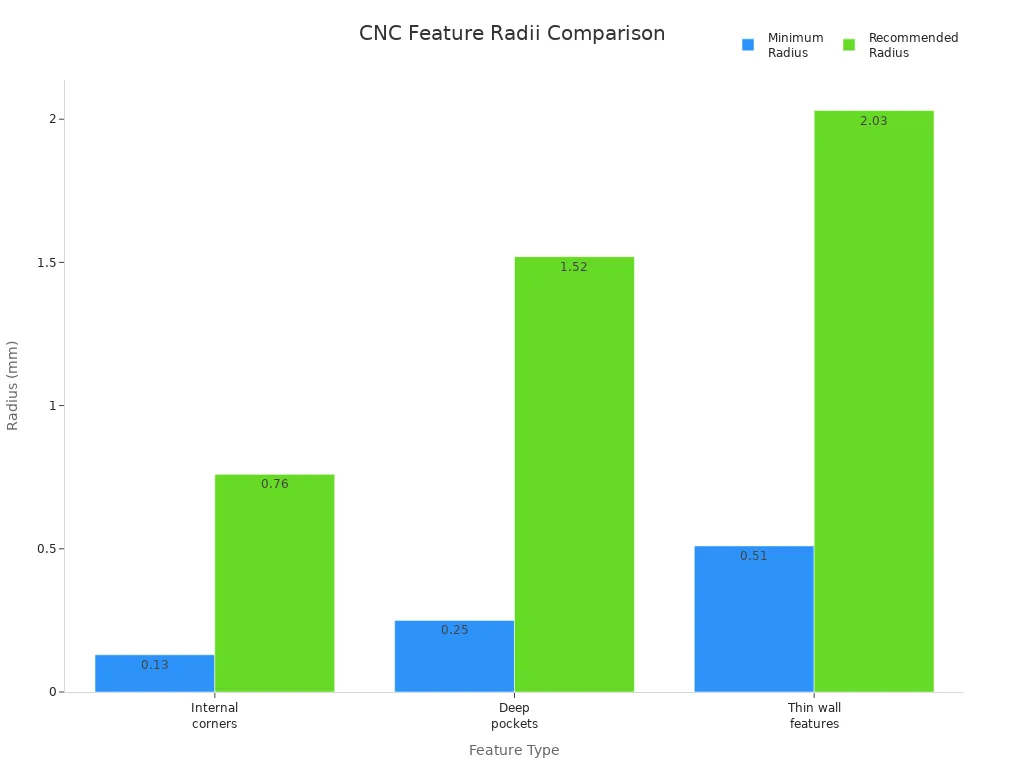

Corner Radius Recommendations

CNC tools are round, so they cannot make sharp inside corners. Add rounded corners or reliefs to your design. This lets you use stronger tools and makes the surface smoother.

Feature Type | Minimum Radius | Recommended Radius | Manufacturing Benefit |

|---|---|---|---|

Internal corners | 0.005" (0.13mm) | 0.030" (0.76mm) | Works with standard tools |

Deep pockets | 0.010" (0.25mm) | 0.060" (1.52mm) | Stops tools from bending |

Thin wall features | 0.020" (0.51mm) | 0.080" (2.03mm) | Makes cutting easier |

Make tool access easy by not blocking shapes.

Use rounded corners to stop tools from breaking.

Do not use big outside corners to save time.

Tolerances and Surface Quality

Picking the right tolerances and surface finish is important. It helps you make your part well and not spend too much.

Functional vs Non-Functional Surfaces

Only use tight tolerances where you need them. Important surfaces, like bearing seats, need to be exact. Other surfaces can be less exact, which saves time and money.

Different parts need different tolerances.

Some industries, like aerospace and medical, need very exact parts.

Surface Finish Targets

Surface finish changes how your part looks and works. Finer finishes take more time and special tools. Only ask for a fine finish where you need it. This saves money and makes things faster.

Tip: Pick tolerances and finishes that make sense. This helps you avoid mistakes and waste.

Manufacturability and Cost Factors

How hard your part is to make changes the price and speed.

Geometry Complexity vs Cost

Hard shapes need better machines and more time.

Sharp corners, thin walls, and deep holes cost more.

Tough designs need more checks and work.

Volume vs Unit Price

Making lots of parts makes each one cheaper.

Small batches of hard parts cost more for each piece.

The cnc machine you pick also changes the price.

Remember: Good design rules help you balance making, cost, and quality. Reliable cnc machining gives you the best parts for your needs.

Advanced CNC Machining Strategies for Complex Geometries

CAM Techniques for Complex Shapes

You can use special CAM techniques to make toolpaths for hard shapes. These methods help you get smooth surfaces and exact sizes. When you work with complex parts, you must pick the best way to machine them. Here is a table that shows some common CAM techniques and what they are good for:

Technique | Key Benefits | Ideal Use Case |

|---|---|---|

Cuts down machining time and tool wear. Keeps the tool working evenly. Changes cutting settings for each material and shape. | Good for roughing out complex shapes | |

High-Speed Machining | Makes surfaces smoother and sizes more exact. Lowers heat while cutting. Needs special CAM software and machines. | Great for fast cuts that still need accuracy |

Spiral Machining | Keeps the tool moving the same way all the time. Helps tools last longer and saves time. Works well for deep holes and round shapes. | Best for fast cutting of deep holes |

Rest Machining | Removes leftover material better. Helps tools last longer by making smart cutting paths. Needed for small details in tight spots. | Used for finishing details after roughing |

Toolpath Smoothing

Toolpath smoothing helps you avoid sharp turns and stops. This makes the tool move smoothly. The surface looks better and the tool lasts longer. Smooth toolpaths also help keep the cnc milling process steady.

Adaptive Clearing and Rest Machining

Adaptive clearing uses toolpaths that change as you cut. The tool stays busy and the chip load stays the same. This method helps you:

Make tools last longer and stop them from breaking.

Remove lots of material quickly to save money.

Work faster when making complex shapes.

Cut tough materials without problems.

Rest machining lets you finish small details after roughing. You use smaller tools to reach tight places. This step makes the cnc milling process better and gives you a nice finish.

High-Efficiency Roughing

High-efficiency roughing takes away most of the material fast. You use adaptive clearing to keep the cutting force even. This saves time and keeps your tools safe.

Semi-Finishing and Finishing

Semi-finishing gets the part ready for the last cut. You take away leftover material and get close to the final shape. Finishing uses fine tools to make the surface smooth and exact.

Reducing Setups and Tolerance Stack-Up

You can use five-axis machines to cut down on setups. These machines can reach almost every side in one go. You keep the same zero point, which makes parts more accurate. Here is a table that shows the benefits:

Benefit | Description |

|---|---|

Five-axis machines can reach most surfaces, so you do not need to set up the part many times. | |

Relational Accuracy | Using the same zero spot makes features line up better and lowers errors from moving the part. |

Single-Setup Machining

Single-setup machining helps you keep sizes exact. You do not move the part, so mistakes do not add up.

Modular Fixturing

Modular fixturing lets you hold parts in different ways. You can change how you hold the part quickly. This saves time and keeps the cnc machining process running well.

Tip: LKprototype uses smart machines and fixtures for fast samples. You can get good parts quickly. Learn more about their CNC machining services.

Practical Tips and Common Mistakes

Optimizing Geometry for CNC

You can make parts easier to machine by changing their shape. When you design for cnc milling, pick shapes that help the process. Try not to use shapes that make things hard. Many engineers try to balance how a part works and how easy it is to make.

Simplifying Features

Keep your design simple. Extra features make machining harder and cost more. Focus on what your part really needs to do. Use fillets instead of sharp corners. Fillets spread out stress and help tools last longer. Too many big outside curves take more time to program and cut.

Here is a table with good ways to make part shapes better:

Strategy | Description |

|---|---|

Material Selection | Pick materials that are easy to cut and not too expensive. |

Features and Geometry | Make shapes simple to lower cost and make machining easier. |

Tolerances and Surface Finish | Only use tight tolerances if you really need them. |

Make parts easy to hold and cut by planning the shape and how it sits in the machine. | |

Optimize for Tool Access | Make sure tools can reach all the spots they need to. |

Minimize Sharp Internal Corners | Use fillets so tools do not break and the finish is better. |

Avoid Excessive External Radii | Do not use too many big outside curves to save time. |

Consider Material Grain Orientation | Show which way the grain goes to make the part stronger and easier to cut. |

Plan for Workholding | Add spots that are easy to grip so you do not need special holders. |

Use Standard Features | Use common sizes to make production faster and need fewer tools. |

Watch Feature Size and Aspect Ratios | Keep sizes right so you do not have problems when cutting. |

Specify Appropriate Tolerances | Work with machinists to pick tolerances that work but are not too tight. |

Design for Prototyping and Iteration | Keep designs simple so you can change them easily when testing. |

Tip: Always focus on the most important features. Do not add details that do not help the part work better.

Using Standard Tool Sizes

Use standard tool sizes in your design. Standard sizes make cnc milling faster and cheaper. Custom tools take longer to set up and cost more money. If you use standard holes, slots, and curves, machinists can work faster. This also helps stop mistakes from happening.

Avoiding Deep Cavities and Undercuts

Deep holes and undercuts are hard for cnc machines. Spinning tools cannot reach into small, deep spaces. This makes machining take longer and tools can break. You will also spend more money making the part.

Alternative Feature Designs

Instead of deep holes or undercuts, change your part’s shape. Try using outside shapes or open areas. These are easier to cut and cost less. You can still get the same job done without making things harder.

Note: Turning tricky inside shapes into outside shapes on different pieces makes parts easier to make and faster to finish.

Split-Part Strategies

You can split your part into two or more pieces. Each piece can have simple shapes. After cutting, you put the pieces together. This way, you avoid hard inside shapes and make cnc milling easier. You also get better quality and save money.

Collaboration with CNC Machining Partners

Work with your cnc machining partner early in the design. This makes parts easier to make and helps you finish faster. You get advice about your design, materials, and sizes. Working together helps you avoid mistakes and keeps your project moving.

Early DFM Review

Share your design with your partner before you finish it. Early checks help find shapes that take too long or waste material. Your partner can suggest changes that make the part easier to put together and work better.

Video calls help you talk about goals and pick materials.

Good planning sets what is most important and keeps things on track.

Use skilled workers and better ways to set up to save time.

Pick materials that are easy to buy for faster making.

Check if your design is too hard or if the CAD file is good for a correct price.

Tip: Working together early stops mistakes and helps you finish faster.

Clear Technical Drawings

Give clear drawings that show all the important parts. Drawings should show features, sizes, and which way the grain goes. If you use standard sizes and clear notes, machinists can understand your design. This lowers mistakes and makes better parts.

Note: LKprototype gives fast samples and good advice. Their team helps you make your design better for cnc milling and making parts. You can learn more about their CNC machining services.

Do not add extra features you do not need.

Focus on what the part must do.

Make sure the part is strong.

Think about what the machine can do.

Add fillets to sharp corners.

Plan how the tool will move.

Pick materials that are easy to cut.

Remember: Simple shapes, standard features, and working together early help you get the best results from cnc machining.

Why Work with an Experienced CNC Partner for Complex Parts

Engineering Support

You get helpful engineering support from an experienced CNC partner. The Design for Manufacturability (DFM) process helps you improve your design early. This lowers the chance of expensive changes or delays later. Skilled teams help match your design ideas with the right materials. They think about tolerances and how parts are made. Early choices affect cost, time, and how well your part works.

Design for Manufacturability Feedback

Complex machined parts need advanced ways to make them, like 5-axis CNC, mill-turn systems, and additive manufacturing. These methods help you get precise and repeatable results.

You get advice that makes your design better and easier to produce. Your partner helps you pick the best way to make your part.

Advanced Equipment Capability

Experienced CNC partners use modern machines. Multi-axis CNC centers change how you make tricky parts. Five-axis machines move in five directions at once. This helps you make complex shapes with great accuracy. Automation and new control systems bring more innovation and flexibility.

Multi-Axis CNC Centers

Five-axis machining helps you make detailed shapes.

Tilting and turning the cutting tool helps with multi-dimensional work.

New CNC machines use smart ways to manage materials.

Quality Assurance System

Quality checks are important for tricky parts. Your partner uses systems like CMM inspection to make sure parts are accurate.

CMM Inspection

CMMs measure inside cooling channels in aerospace turbine parts.

They check the shape of surgical-grade parts.

Non-contact CMM systems test soft materials like plastics and ceramics.

Rapid Prototyping and Production

Rapid prototyping helps you develop products faster. CNC machining quickly turns your designs into good prototypes. You can test and improve your products early.

Short Lead Times

For example, a car company made an engine block prototype in only three days. Rapid prototyping helps you go from design to finished product quickly. LKprototype offers fast prototyping and production for tricky parts. You can learn more about their CNC machining services.

You can use CNC machining to make hard shapes very accurately. Multi-axis machines let you make parts like impellers and turbine blades in one go. If you follow design rules and use smart methods, you make parts easier and save money. Talking early with machinists helps you match your design with how it is made.

LKprototype gives quick samples and expert help for tough parts. Check out their CNC machining services for more ideas.

Find out about CNC rapid prototyping.

Get tips for making part shapes, picking materials, and setting tolerances.

FAQ

What makes CNC machining good for complex shapes?

CNC machining can make parts with lots of curves and angles. The machine follows your design very closely. This gives you high accuracy every time. Advanced software helps plan tool paths for hard features.

How do you choose the right material for CNC machining?

Pick materials that are easy to cut and fit your part’s job. Aluminum and plastics are good for most projects. Hard metals need special tools to cut. Always ask your machinist for help before you pick.

Why do you need multi-axis CNC machines for some parts?

Multi-axis machines let you reach more sides in one setup. This saves time and makes parts more exact. Five-axis machines help make turbine blades and medical implants.

How can you avoid mistakes when designing for CNC machining?

Keep your design simple and easy to make. Use standard tool sizes and do not use deep holes or sharp corners. Work with your CNC partner early. Clear drawings help machinists know what you want.

What are the advantages of prototyping with LKprototype?

LKprototype gives you fast samples and expert advice. Their advanced CNC machines can make hard shapes easily. You can test your design quickly. Learn more about their CNC machining services.

LKprototype

LKprototype