Choosing the right CNC machining prototype service is very important. It can greatly affect how successful your prototyping process is. The global market for these services is growing fast. It is expected to increase from $10.5 billion in 2023 to $25.7 billion by 2032. This shows that more people want quick and reliable solutions. Working with a good CNC machining prototype service gives you access to accurate tools. You also get skilled workers who make high-quality prototypes. This helps save both time and money. Whether you need one prototype or many, a trusted CNC machining prototype service keeps your project on schedule.

CNC machining is very useful in industries like aerospace and cars. These fields need exact and repeatable results every time.

Key Takeaways

Understand your needs by setting goals, picking materials, and planning amounts.

Pick materials that fit your project; metals are strong, plastics are light and cheap.

Check CNC services for skill, tools, and reviews to ensure good work.

Ask for quotes from different providers to compare prices, including all costs.

Think about how fast they work and if they meet your deadlines.

Test with a small project first to check quality and communication.

Find a CNC service that can handle both small and big orders.

Pick a provider who shares updates and communicates clearly during the process.

Understanding Your Prototyping Needs

When using CNC machining for prototypes, know your needs first. Focus on three main things: setting project goals, picking materials, and planning for quantity.

Setting Project Goals

Before starting, decide what your prototype should do. Is it for testing how it works, showing how it looks, or both? Knowing this helps you design and produce better.

Why the Prototype Matters

Every prototype has its purpose. Electronic products often need smooth designs to look beautiful.

Precision and Detail Needed

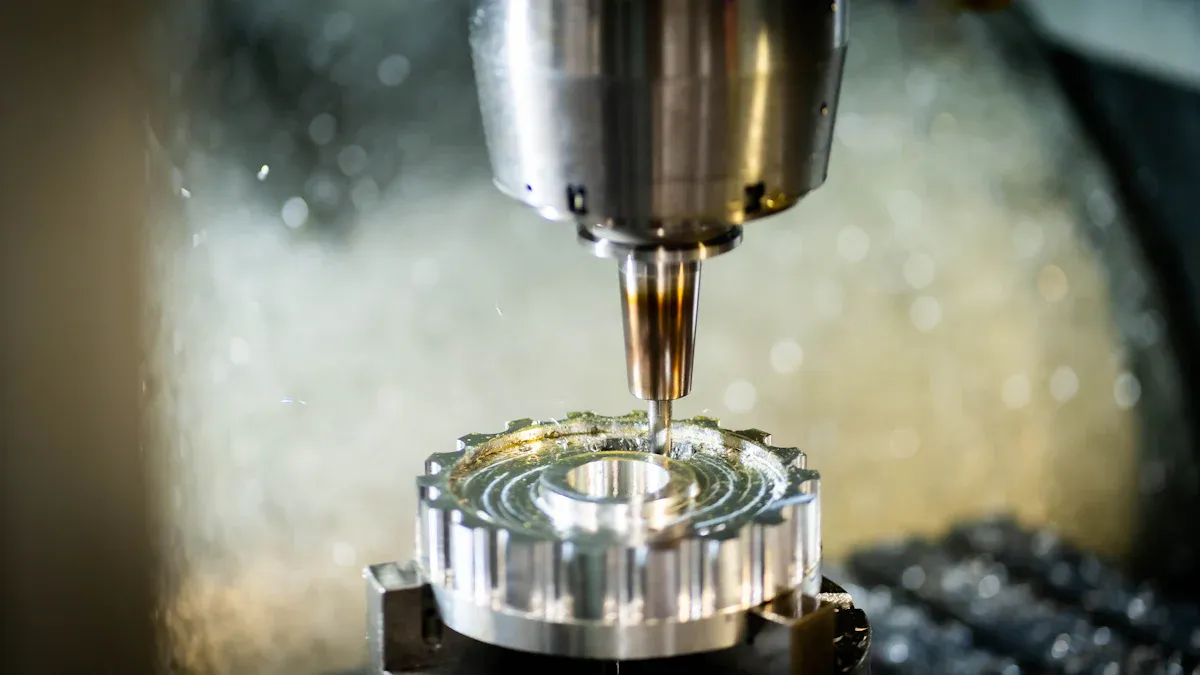

CNC machining is great for detailed designs. If your project needs exact measurements, pick a company with advanced tools. Reports show CNC machining is very accurate. This saves time, reduces mistakes, and cuts costs.

Benefit | What It Means |

|---|---|

High Precision and Accuracy | Makes exact parts quickly and efficiently. |

Consistency and Repeatability | Creates identical prototypes with little difference. |

Time-Saving | No molds needed, so changes are faster. |

Picking the Right Material

The material you use is as important as the design. CNC machining works with metals, plastics, and more, each for different uses.

Metals, Plastics, and Other Options

Metals like aluminum are strong and durable. Plastics are light and cheap. Composites mix both, giving strength and flexibility. For example:

Material Type | Use Cases | Features |

|---|---|---|

Plastics | Electronics, Medical Devices | Light and affordable. |

Metals | Cars, Planes | Strong and long-lasting. |

Composites | Special Projects | Strong, flexible, and lightweight. |

Matching Materials to Your Needs

Pick materials that fit your project. For aerospace, strong metals work best. For electronics, light plastics are better. CNC machining can handle many materials, making it flexible and efficient.

Planning for Quantity

Whether you need one prototype or many, plan ahead.

One Prototype or Many?

Start with one prototype to test your idea. CNC machining is great for single pieces. If you need more, it can scale up easily. This makes it useful for all stages of production.

Preparing for Future Needs

Think long-term. Choose a CNC service that can grow with your project. A supplier that handles small and large orders saves time later. This is key for industries like healthcare and electronics.

Tip: Making many items needs special tools, which cost more at first. But it’s cheaper over time if you make a lot. Make sure your design is final before spending on tools.

By knowing your needs, you can make smart choices. From setting goals to picking materials and planning for growth, every step matters for success.

Evaluating CNC Machining Services

When picking a CNC prototyping service, check their skills, tools, and reviews. These help ensure you get good-quality prototypes that meet your needs.

Expertise and Experience

Industry-specific experience and certifications

A CNC company with experience in your field is important. Certifications like ISO 9001 or AS9100D show they focus on quality and precision. For example, ISO 9001 ensures steady quality, while AS9100D is key for aerospace work. These prove the company follows strict rules and can handle tough jobs.

🛠️ Tip: Choose a CNC service with success in your industry. They will better understand your specific needs.

Proven track record with similar projects

Experience is key for CNC prototyping. Companies with successful past projects often deliver better results. Check if they’ve made similar prototypes before. For example, if you need metal parts, find a company skilled in working with aluminum or steel. Their past work shows they can meet your expectations.

Certification | What It Ensures |

|---|---|

ISO 9001 | Reliable and consistent quality. |

AS9100D | Designed for aerospace standards. |

Technology and Equipment

Use of advanced CNC machining tools and techniques

Modern tools are needed for precise prototypes. Advanced machines, like five-axis CNC systems, handle complex designs well. These machines can create detailed shapes and ensure tight tolerances, which are crucial for industries like healthcare and aerospace.

CNC machines can make parts with tiny tolerances.

Multi-axis tools create detailed and complex shapes.

Advanced machines ensure accuracy and repeatability.

Capability to handle complex designs and tight tolerances

Not all CNC services can manage tricky designs. Companies with top-notch equipment can make very precise parts. For example, five-axis machines are great for detailed designs, while three-axis machines work for simpler tasks. Always check if their tools fit your project’s needs.

CNC Machine Type | Features | Handles Complex Parts? |

|---|---|---|

CNC Lathe | Rotates for machining | No |

Three-axis CNC | Basic movements | Somewhat |

Five-axis CNC | Multi-directional machining | Yes |

Customer Feedback and Reviews

Online reviews and testimonials

Customer reviews are helpful when choosing a CNC service. They show the company’s strengths and reliability. Reviews often mention things like good communication, fast delivery, and high-quality work.

💬 Note: Look for reviews about precision, materials, or customer service. These details help you decide wisely.

References and case studies from the provider

Case studies show how a company solves problems and delivers results. For example, one might explain how they used plastic CNC techniques to make light but strong parts for electronics. These examples prove their skills and problem-solving abilities.

By checking expertise, tools, and reviews, you can pick the right CNC service. This ensures your prototypes are accurate, affordable, and delivered on time.

Cost Considerations for CNC Machining Prototype Service

Understanding costs early helps avoid surprises later. Let’s look at what affects pricing and how to make smart choices.

Pricing Transparency

Material, labor, and extra costs explained

CNC machining costs depend on many things. The material you pick matters a lot. Metals like aluminum or steel cost more than plastics but last longer. Complex designs also raise costs because they need special tools and take more time. Labor, setup, and finishing fees can add up too.

Here’s what to check in a price quote:

Material Costs: Type and amount of material used.

Labor Costs: Time workers spend programming and running machines.

Machining Time: Longer jobs cost more.

Setup Fees: Preparing the machine and programming it.

Post-Processing Fees: Finishing, assembly, or quality checks.

Shipping Costs: Delivering your prototypes to you.

💡 Tip: Ask for a detailed quote. This shows exactly what you’re paying for.

Comparing prices from different companies

Don’t pick the first quote you get. Ask several CNC services for prices and compare them. Make sure the quotes are for the same material and design. For example, a simple plastic part costs less than a detailed metal one. Also, check if extras like finishing or quality checks are included.

Steps to compare quotes:

Get detailed quotes from at least three companies.

Compare material, labor, and machining costs.

Look for extra services included in the price.

The cheapest option isn’t always best. A low-cost company might deliver poor-quality work, leading to fixes. A pricier company might provide better, more accurate prototypes.

Discounts and Hidden Fees

Savings for larger orders

If you need many prototypes, ask about discounts. Many CNC companies lower prices for bulk orders. This reduces the cost per piece. For example, making 50 parts costs less per item than making just one. But finalize your design first. Changes later can cost more.

🛠️ Note: Bulk discounts are helpful, but only if your design is final.

Spotting setup, shipping, or hidden charges

Hidden fees can increase your costs. Some companies charge extra for setup, special tools, or unique designs. Others add fees for surface treatments like anodizing. Shipping costs also vary based on size and weight.

Watch for these costs:

Setup Fees: Programming and machine prep costs.

Tooling Costs: Special tools needed for your design.

Surface Treatment Costs: Extra charges for finishing.

Shipping Fees: Ensure these are in the quote.

Factor | What to Know |

|---|---|

Total Price | Includes discounts and all extra fees. |

Material Costs | Special materials or bulk buys may add fees. |

Machining Time | Longer jobs can cost more even with discounts. |

Surface Treatment Costs | Often forgotten but can be expensive. |

Hidden Costs | Special tools or designs may lead to extra charges. |

Clear Pricing | Detailed quotes help avoid surprises and stay on budget. |

By asking questions early, you can avoid extra costs and keep your CNC project on track.

Timelines and Deadlines in CNC Machining

Turnaround Times

Provider's ability to meet deadlines

Meeting deadlines is very important in prototyping. A good CNC machining company should deliver projects on time. This keeps your prototype work on schedule and avoids delays. Many providers use advanced tools to speed up their processes. For example, online CNC services can give instant quotes and plan tool paths quickly.

To check if a provider meets deadlines, ask about their timelines. Do they share delivery dates and key steps? This shows if they can handle your needs. Companies that plan well and use machines efficiently often finish faster.

Metric Type | What It Shows |

|---|---|

OEE Performance Reporting | Tracks machine availability, performance, and quality. |

Machine Production Timeline | Shows machine events like faults and part cycles. |

Statistical Analysis | Finds issues in cycle times to improve accuracy. |

Lead times for different materials and processes

Lead times depend on the material and design complexity. Harder materials like aluminum take longer to machine than plastics. Detailed designs with tight measurements also need extra time for setup and checks. Providers use reports to track and improve lead times.

Ask about typical lead times for your material. Some companies can deliver simple prototypes in one day. Complex designs may take up to five days. Knowing this early helps you plan better.

🕒 Tip: Confirm lead times early to match your project schedule.

Communication and Updates

Regular updates on project progress

Good communication makes prototyping smoother. A reliable CNC service gives regular updates on your project. This keeps you informed about any delays or problems. Many companies assign one manager to handle your project. This makes it easy to get updates and solve issues fast.

Quick replies build trust. When providers answer questions quickly, it shows they care about your project. Regular updates and feedback ensure the final product meets your needs.

Quick Replies: Fast answers build trust.

One Manager: A single contact makes updates easier.

Feedback: Helps adjust services to fit your needs.

Clear communication channels for addressing concerns

Easy communication is as important as updates. You should have simple ways to contact your provider, like email or phone. This is helpful for solving problems or making changes. Companies with clear communication often have happier customers.

Some CNC companies use tools to keep clients updated. These tools let you track progress, check timelines, and approve designs. This transparency helps you stay informed and make decisions quickly.

💬 Note: Pick a provider with open communication. It ensures your project runs smoothly.

Making the Final Decision

Picking the right CNC machining service can seem hard. Breaking it into steps makes it simpler. Let’s see how to compare companies and why trying a small project first can save time and money.

Comparing Providers

Checking skills, price, and deadlines

When choosing a CNC machining company, focus on three things: skills, price, and deadlines. A company with experience in your industry and advanced tools will likely make better prototypes. Look for certifications like ISO 9001 to ensure quality and accuracy.

Price is also important. The cheapest option isn’t always the best. Spending a little more now can avoid costly mistakes later. Also, check if the company delivers on time. A reliable company with a good history of meeting deadlines will keep your project on track.

To make comparing easier, use tools like TOPSIS. This method helps you weigh things like cost, skills, and delivery times together. It’s a smart way to find the best fit for your needs.

Planning for bigger projects later

Think about the future. Can the company handle bigger orders if your project grows? A good CNC machining service should be flexible. Whether you need one part or many, they should maintain quality as your needs increase. Ask if they can handle large orders while keeping the same standards. This is key if you plan to scale up production.

Tip: Pick a company that can grow with you. It avoids switching services later.

Trial Runs

Testing with a small project first

Before fully committing, start with a small project. This lets you test their skills without spending too much. Check if the parts they make match your design. Are the sizes correct? Is the finish smooth? A good CNC machining company will deliver accurate and well-made prototypes.

Judging communication and service during the trial

A trial isn’t just about the product—it’s also about how they communicate. Do they update you regularly? Do they answer your questions quickly? Good communication makes the process easier. If the company does well in both quality and service during the trial, they’re likely a great choice for your project.

Note: A trial run is like a test drive—it helps you see if the company is the right fit.

By comparing companies carefully and starting with a trial, you can make a smart choice. This ensures your prototypes are high-quality, on time, and within budget.

Why LKprototype is the Best CNC for Rapid Prototyping

LKprototype company simplifies procurement for custom manufacturing, Suitable for making your products or prototypes with a variety of materials, such as metal or plastic, silicone rubber, from 3D Printing to CNC Machined Parts and Vacuum Casting , with a focus on speed and efficiency. Our platform provides instant quotes. With LKprototype, You can connect with the team to communicate your project to ensure quality and on-time delivery.

Start with an instant quote and experience how our technology and expertise can make custom part procurement faster and easier.

If you need a top CNC service for rapid prototyping, LKprototype is a great choice. They use advanced tools, offer many services, and focus on quality. This ensures your prototypes are made with high precision and care.

Full CNC Machining Services

Milling, turning, EDM, and gear hobbing options

LKprototype provides many CNC services like milling, turning, EDM, and gear hobbing. These allow them to handle both simple and complex designs. Whether you need metal or plastic prototypes, they can meet your needs.

LKprototype checks every part carefully for accuracy and reliability. They use machine inspections, technical reviews, and constant monitoring during production.

Over 65 certified materials for various uses

LKprototype works with more than 65 certified materials, including metals, plastics, and composites. This makes them suitable for industries like cars, healthcare, and electronics.

Certification | What It Ensures |

|---|---|

ISO 9001 | Quality management systems |

AS9100 | Aerospace quality management |

ISO 13485 | Medical devices quality management |

ISO 14001 | Environmental management systems |

IATF 16949 | Automotive quality management |

Fast Delivery and Quality Control

Parts ready in 1-5 business days

Speed matters in prototyping, and LKprototype delivers quickly. Simple parts can be ready in one day, and most projects finish within five days. This helps you stay ahead in competitive fields.

ISO-certified processes for accuracy

LKprototype follows ISO-certified processes to ensure quality. These standards guarantee precise and reliable results. Their CNC machining is perfect for industries needing exact measurements and high performance.

CNC machining speeds up production and keeps it consistent.

It reduces waste, saving money while keeping quality high.

Parts are made with tight tolerances for a perfect fit.

Custom Finishes and Solutions

Options like anodizing and nickel plating

LKprototype offers finishing options like anodizing and nickel plating. These improve how your prototypes look and work, meeting your specific needs.

Custom solutions for unique projects

Every project is different, and LKprototype understands this. They create custom solutions for your needs. Whether it’s detailed art pieces or precise engineering parts, they ensure your prototypes are functional and attractive.

Industry | What They Provide |

|---|---|

Design and Arts | Detailed sculptures, jewelry, and creative designs. |

Engineering | Complex, precise engineering parts. |

Energy | Strong parts for wind, solar, and oil equipment. |

Hardware Startups | Quick prototypes and custom hardware. |

Industrial | Durable machine parts and tools. |

Medical | Accurate surgical tools and medical device parts. |

Robotics | Complex parts for robots and automation. |

With advanced CNC tools, fast delivery, and custom finishes, LKprototype is the best choice for prototyping. Their focus on precision, flexibility, and quality ensures your prototypes are delivered on time and meet your needs.

Picking the right CNC machining service is very important. It can decide if your prototyping works well or fails. First, know what your project needs. Then, check providers carefully and plan costs and timelines. CNC machining is very precise. It makes fewer mistakes and saves time and money. As CNC technology grows fast worldwide, it’s changing how things are made.

Companies like LKprototype make sure your prototypes are top quality. They use advanced machines, deliver quickly, and focus on doing great work. Always choose clear communication and good quality to turn your ideas into real products with ease.

FAQ

1. What is CNC machining, and how does it work?

CNC machining uses computers to control tools that cut and shape materials into exact parts. You send a design file, and the machine follows it to make your prototype. It’s quick, precise, and great for complicated designs.

2. Which materials can I use for CNC prototypes?

You can use metals like aluminum or steel, plastics like ABS or nylon, and composites. Each material has special features. Metals are strong, plastics are light, and composites mix flexibility with strength.

3. How long does CNC machining take?

Simple prototypes can be done in one day. Complex designs might take up to five days. The time needed depends on the material, how complicated the design is, and how fast the provider works.

4. Can CNC machining handle intricate designs?

Yes! Advanced machines like five-axis CNC systems can make detailed shapes and tight fits. These tools are great for fields like aerospace, healthcare, and robotics.

5. Is CNC machining expensive?

Prices change based on material, design complexity, and how many you need. Metals usually cost more than plastics, but bulk orders often get discounts. Always ask for a clear quote to avoid surprises.

6. How do I choose the right CNC service?

Look for experience, certifications, and customer feedback. Check their tools and materials. Start with a small project to see their quality and communication.

7. What industries benefit from CNC machining?

CNC machining is used in cars, airplanes, healthcare, electronics, and industrial machines. It’s perfect for making precise, strong, and useful prototypes.

8. Does LKprototype offer custom finishes?

Yes! LKprototype has options like anodizing and nickel plating. These finishes enhance the look and function of your prototypes, making them great for special projects.

LKprototype

LKprototype