China is the leading destination for prototype mold making China, producing more molds than any other country. With over a million skilled workers employed in this field, you benefit from advanced technology and expert craftsmanship. Additionally, China offers flexible manufacturing options at lower costs. Many international clients have concerns about IP protection, contract issues, and mold misuse. To address these concerns: Use contracts like NNN agreements. Register IP in China. Conduct regular audits.Following these steps helps safeguard your designs and ensures excellent results in prototype mold making China. Key Takeaways China is the top country for prototype mold making. It…

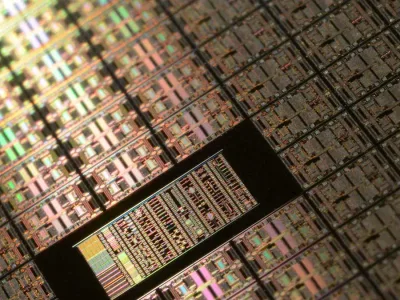

Imagine you order silicon molds for baking, thinking they are flexible trays, but you get hard, breakable blocks instead. This mistake can slow down your work and cost you money. Many people mix up silicon molds and silicone molds. You should know the difference if you make things or design products. Using the right word helps you avoid expensive mistakes and keeps your projects going well. Key Takeaways Silicon is a hard and breakable element. People use it in electronics. Silicone is soft and bends easily. People use it for baking and in medical items. Silicone molds are safe to…

Subtractive manufacturing involves using machines to remove material from a solid block, shaping metals, plastics, and other materials into precise parts. This subtractive manufacturing method is widely used by companies to create prototypes, quick models, and finished products. Thanks to its high accuracy, subtractive manufacturing supports industries in producing complex designs. In the United States, the smart manufacturing market reached $66.18 billion in 2023 and continues to grow rapidly. This market value highlights the significant role subtractive manufacturing plays across various industries. Market SegmentYearMarket Value (USD Billion)U.S. Smart Manufacturing202366.18 Key Takeaways Subtractive manufacturing makes parts by taking away material from…

Subtractive manufacturing vs additive manufacturing each have their own pros and cons. Subtractive manufacturing often provides better accuracy and smoother finishes, while additive manufacturing typically produces less waste and can create complex shapes. When comparing subtractive manufacturing vs additive manufacturing, subtractive methods tend to be more cost-effective for large production runs, whereas additive manufacturing is ideal for prototypes or small quantities. Considering factors like cost, accuracy, and waste is essential when deciding between subtractive manufacturing vs additive manufacturing. Ultimately, the best choice depends on the specific needs of the project. Key Takeaways Subtractive manufacturing takes away material to make smooth,…

Selecting the right machine parts manufacturer is crucial for your project's success. The choice of a machine parts manufacturer can significantly impact your results. You need a machine parts manufacturer that understands the importance of precision, with machining accuracy reaching as close as ±0.005mm. A reliable machine parts manufacturer ensures on-time delivery more than 95% of the time. Many teams face budget overruns in CNC projects, with up to 68% of cases caused by errors. Working with a knowledgeable machine parts manufacturer who offers rapid prototyping and expertise in materials like ABS or aluminum increases your chances of success. The…

When you ask, "How much does CNC machining cost?" expect a wide range. Simple parts often cost $10 to $100 each, while complex parts can reach $1,000 or more. Several factors shape the final price: Material selectionDesign complexityMachine typeBatch sizeLabor and setupTooling and finishingOverhead and profit margin Material TypeCost Range (per lb/part)Lead Time (days)Steel (Low Carbon)$4 – $153 – 7Aluminum (6061)$2 – $102 – 5Titanium (Grade 2)$20 – $505 – 12 Understanding the cost breakdown helps you plan your budget and see the true value in CNC machining. Market data shows that pricing and the right factors can make a…

A data-driven approach changes manufacturing by making it more efficient. You can use real-time data and analytics to find hidden problems fast. This helps you fix things quickly. Companies like Toyota and General Electric have made big improvements. They cut production defects by 45%. They also reduced inspection time by 75%.Data-driven manufacturing process optimization often gives a 5-6% boost in productivity. It also saves a lot of money. By tracking key metrics, you make sure every process change shows real results. Key Takeaways Real-time data lets factories spot problems quickly and fix them fast before they cause delays or mistakes.…

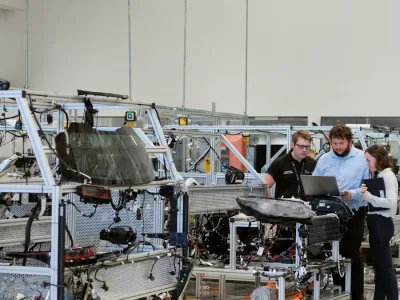

An automated manufacturing process uses machines and technology to do production work. Control systems help finish tasks with little help from people. This method tries to make work faster, more correct, and more productive. It also helps cut down on hard work and mistakes. In the past ten years, factories have used more robots and AI. This has made production reach new highs. The table below shows how automation helps make work better and more correct in factories: Benefit AreaStatistic / ImprovementConveyor systemsProductivity increase by 60%RFID technologyInventory accuracy improved to 99%Human-robot teams85% more productive than only humans or only robots…

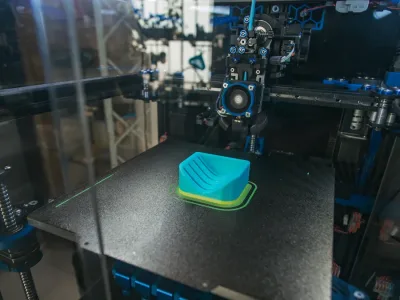

Additive manufacturing process involves creating objects by adding layers based on digital plans. Today, companies use this additive manufacturing process to produce car parts and medical tools. Imagine a designer with a new product idea—this additive manufacturing process allows them to quickly test models. They can begin mass production much sooner than before. Nearly 70% lower prototyping costs help companies save money. Lead times shrink from weeks to days, enabling faster responses. Up to 90% less wasted material benefits the environment. Every step in the additive manufacturing process is crucial. Designers select the best materials and settings to ensure parts…

You need to understand the contract manufacturing process to see how it works. Contract manufacturing is when you allow another company to produce your product. You provide your product design and requirements to the contract manufacturing company, and they handle the production for you. This contract manufacturing process helps many businesses save money and operate more efficiently. The table below shows that contract manufacturing is expanding worldwide. Metric/SegmentValue (2023/2024)Projected Growth/NotesGlobal contract manufacturing marketUSD 334.09 billion (2023)CAGR 9.32% (2024-2031), projected USD 676.76 billionPharmaceuticals & biopharmaceuticals32.35% market share (2023)Expected USD 225.24 billion by 2031End-to-end manufacturing segmentUSD 141.17 billion (2023)Highlights efficiency via integrated…

You can make your manufacturing work better by using five steps in the lean manufacturing process: Identify value Map the value stream Create flow Establish pull Pursue perfection Lean manufacturing is about getting rid of waste in the process. When you use lean principles, you remove waste, make more products, and work faster. Think about how each step helps you cut waste and get the most value in your work. Key Takeaways Lean manufacturing helps you get rid of waste. It lets you focus on what your customer wants most. Mapping your process helps you see slow or extra steps.…

The manufacturing process means changing raw materials into products people can use. Manufacturing is very important for all industries. Factories and workers take materials, make parts, and build things people need every day. Manufacturing turns simple things into complex items like cars, phones, and furniture. People need manufacturing for jobs, new ideas, and a strong economy. Each type of manufacturing has its own steps and tools. Learning about manufacturing helps people see how products get to stores. Today, technology gives new machines and ideas to manufacturing, making things faster and smarter. Key Takeaways Manufacturing turns raw materials into useful products…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.