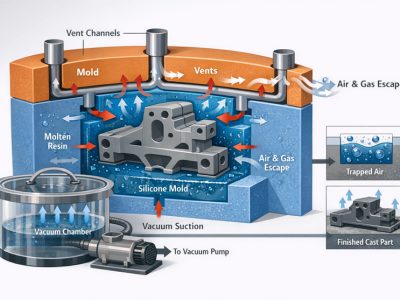

You can stop air bubbles and air traps in vacuum casting gate design by using simple steps that make mold setup and airflow better. These steps are: Mix the materials well so air does not get trapped. Use enough vacuuming to remove all the air. Make the mold with good gate placement and venting. Keep the casting temperature steady for smooth resin flow. If you follow these methods, you will have fewer air problems and get better results. For expert help, visit vacuum casting service. Key Takeaways Mix resin slowly and evenly. This helps stop air bubbles from forming when…

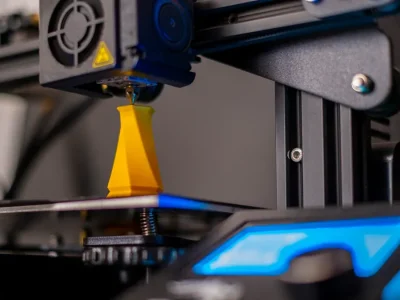

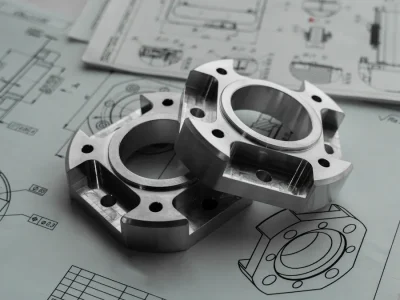

When comparing cnc machining vs casting vs 3d printing, you'll find that cnc machining offers the best material strength and superior mechanical properties for most projects. The method you choose for manufacturing can significantly impact the performance and reliability of your part. As you examine cnc machining, casting, and 3d printing, you'll notice substantial differences in precision, cost, and speed. The table below illustrates how each method serves different needs: Manufacturing MethodBest Use CaseKey BenefitsCNC MachiningMedium to high volumesPrecision, tight tolerances, strong materials3D PrintingLow volumes, prototypesFast turnaround, complex shapes Key Takeaways CNC machining gives the most strength and accuracy. It…

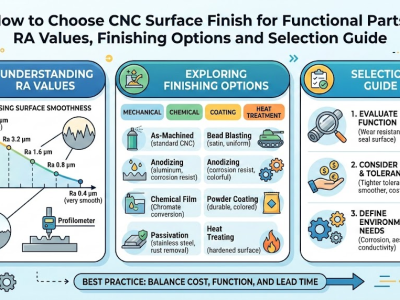

When you ask how to choose CNC surface finish for parts, you should consider how well the parts function and their overall quality. The right CNC finish can reduce friction, minimize wear, and extend the lifespan of the components. If you aim for the best quality, it's essential to understand how to choose CNC surface finish that meets your specific requirements. Smoother CNC surfaces facilitate better fitting of parts and prevent leaks or misalignment. Conversely, rough CNC surfaces can lead to rapid wear and even failure of the components. You enhance the performance and durability of parts when you know…

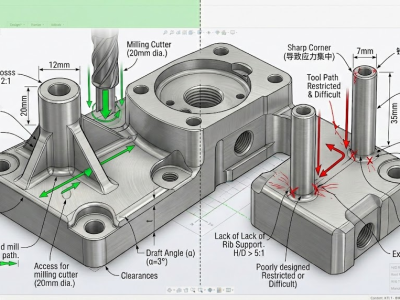

When you design bosses for CNC machining, ensure that tools can access all necessary areas. It's important to maintain optimal wall thickness when you design bosses for CNC machining, as this strengthens parts and simplifies manufacturing. Applying good design for manufacturability principles when you design bosses for CNC machining reduces waste and speeds up the machining process, making your parts more cost-effective. By following CNC machining DFM guidelines as you design bosses, you achieve higher quality parts and streamline the manufacturing workflow. Focusing on the DFM process while you design bosses for CNC machining improves production efficiency and consistently delivers…

You can enhance your CNC shop's efficiency by implementing smart CNC machining chip control and cooling strategies. Research indicates that chipbreakers, high-pressure coolant, and process modifications contribute to longer tool life. These techniques also ensure that machines operate effectively. The right CNC machining chip control strategies lead to smoother surfaces, reduced heat, and prevention of tool damage. StrategyBenefitsImplement ChipbreakersExtends tool life and prevents the formation of long, stringy chips.Use High-Pressure CoolantAids in CNC machining chip control and reduces heat, improving overall machining performance.Apply Process ChangesSaves costs by prolonging tool life and maintaining consistent machining operations. Key Takeaways Use chipbreakers to…

When you're looking for the best method to produce your parts, it's essential to consider vacuum casting vs CNC machining accuracy. CNC machining is generally more accurate than vacuum casting, making it a superior choice for small spaces and complex shapes. Precision is crucial in manufacturing, as it enhances quality, reduces errors, and saves time. Mistakes can occur on assembly lines, contributing to approximately 23% of all quality issues, which can be costly for companies each year. By evaluating vacuum casting and CNC machining accuracy, you can choose the most effective method, ultimately saving money and gaining a competitive edge.…

You have many cnc machining cost factors that change your project’s price. These are material selection, part complexity, machining time, quantity, machine type and accuracy, surface preparation, and post-processing. Material types and machinability matter a lot. Skilled labor and machine setup also change costs. If you know these factors, you can make better choices and work faster. Each section will show you useful ways to control costs. Key Takeaways Know the main things that change cost: material choice, part shape, how long it takes to make, and how many you order all change CNC machining prices. Pick common materials like…

You need good materials, finishes, and design steps to make strong electronics enclosures with CNC machining. This process is fast, accurate, and flexible. Manufacturers use aluminum alloys, copper, stainless steel, titanium, and engineering plastics because each has special features and uses. Material CategoryTypical GradesKey PropertiesTypical ApplicationsAluminum Alloys6061, 7075, 5052Light, conducts heat wellCases, frames, heat sinksCopper / BrassC110, C101, H59Conducts electricity wellTerminals, connectors, shieldsStainless Steel304, 316, 303Resists rustFasteners, precise partsTitanium AlloyTi-6Al-4VStrong but lightMedical, aerospace electronicsGeneral Engineering PlasticsABS, PC, PMMALight, easy to shapeEnclosures, light coversMechanical Performance PlasticsPOM, PA6, PETTough, resists wearGears, sliding parts CNC machining for electronics enclosures lets you pick the…

You want each part to fit and work right. That is why cnc machining geometric accuracy is important. When you control accuracy, parts fit better. They move well and last longer. Tight tolerances make assemblies safe and reliable. The table below shows how different industries need precision tolerances to keep things working and safe: IndustryImpact of Tolerances on Reliability and FunctionalityAutomotiveMakes sure things are safe and move rightAerospaceKeeps seals working wellRoboticsMakes sure things repeat and are exactMedical DevicesVery important for working well and being safe If you set the right tolerances, you help parts line up. You also control friction…

You want your complex parts to work well and not cost too much. Making the geometry better for manufacturability and efficiency is very important in design for CNC machining. Many industry surveys show common mistakes that make costs go up and cause problems with machining. Thin walls can break or bend, especially if they are less than 0.020 inches. Internal 90-degree corners are hard to make and may need extra tool changes. Small text and deep holes make machining slower and can break tools. Tight tolerances should only be used when you really need them. Curved holes and very tall…

When you design cnc machining threaded features, you must think about thread type, inserts, CAD display, and how easy it is to make. Modeling external threads the right way helps the software use your design. Thread milling uses less power and makes tools last longer, so it works better.Good planning makes threads strong and reliable. Key Takeaways Pick the correct thread type for your material. This helps make strong connections and stops things from breaking. Set thread depth and wall thickness based on material rules. This makes parts stronger and more reliable. Use threaded inserts in soft materials or places…

When utilizing CNC machining, you should consider the importance of CNC machining heat treatment for your metal parts. CNC machining heat treatment alters the behavior of metal during the machining process and after the part is completed. Research indicates that CNC machining heat treatment can enhance machining speed and facilitate the removal of more material. Additionally, it strengthens parts and increases their reliability. If you neglect or improperly apply CNC machining heat treatment, your parts may not achieve the correct dimensions, may exhibit more defects, or could even fail. Therefore, it is crucial to select the most effective CNC machining…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.