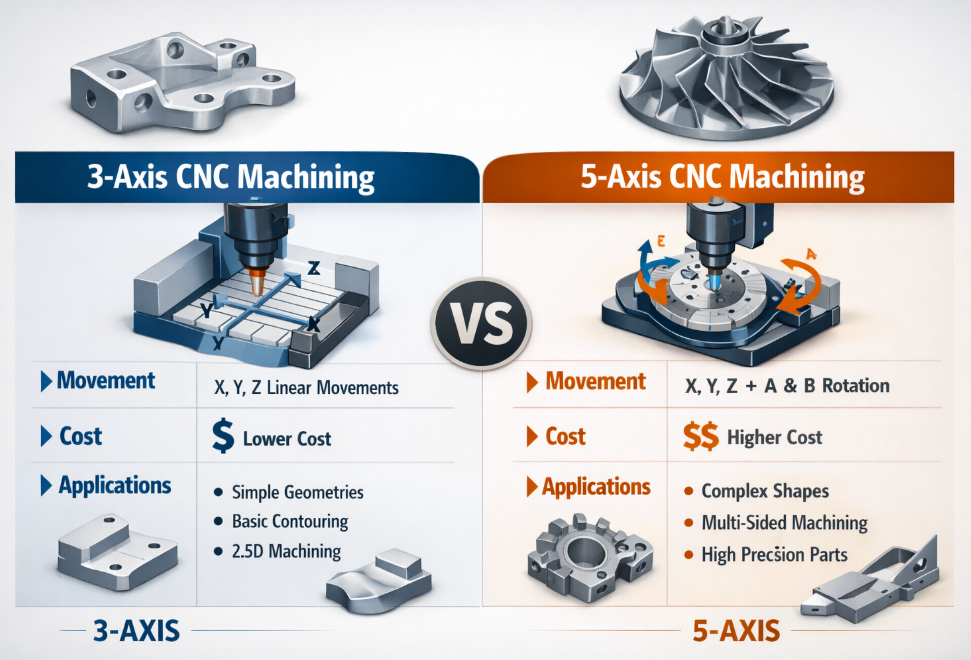

When you compare 3 axis vs 5 axis cnc machining for complex parts, you can see they operate differently in terms of shapes and speed. You might choose 3-axis cnc for simpler shapes. However, more challenging parts often require the additional movement capabilities of 5-axis cnc. Many companies now prefer 5-axis cnc because it can complete multiple sides in a single setup. This efficiency allows for faster workflows and time savings. If you are concerned about setup time and cost, 3-axis cnc may initially appear to be the more economical option. However, if your project demands numerous setups, it can become expensive and time-consuming.

As Mike Cope states, “The biggest benefit of 5-axis machining is making hard shapes in one setup… The ‘done-in-one’ idea is where you really save money.”

Engineers and buyers should consider how quickly they want to work and their budget before deciding on the best cnc process, whether it be 3 axis vs 5 axis cnc machining for complex parts.

Key Takeaways

3-axis CNC machining works well for simple shapes. It costs less, so it is good for basic parts like plates and brackets.

5-axis CNC machining is great for making complex parts. It can make curves and undercuts. It gives better accuracy and smoother finishes. It needs fewer setups.

Think about your project's difficulty and budget before you choose. 5-axis may save time and money for tricky designs.

Setup time and machine costs are very different. 3-axis machines cost less at first. But 5-axis machines can lower total costs for hard parts.

Working with a CNC machining partner helps your project. They give engineering support and advanced equipment. They also check quality for better results.

Quick Comparison: 3 Axis vs 5 Axis CNC for Complex Parts

Key Differences at a Glance

Axes and Motion Type

With 3-axis cnc, you control three directions. The machine moves left and right, forward and backward, and up and down. 5-axis cnc adds two more movements. These let you tilt and spin the part or tool. You can reach more spots without stopping the machine.

Complexity Capability

3-axis cnc works well for easy shapes and flat parts. If you need to make parts with curves or tricky sides, 5-axis cnc helps more. You can finish hard shapes in one setup.

Typical Tolerances

3-axis cnc can be accurate, but moving the part can lower precision. 5-axis cnc keeps the part still, so you get better accuracy for tough jobs.

Surface Finish Quality

3-axis cnc can make smooth surfaces, but tool angles are limited. Sometimes, you see more marks from the tool. 5-axis cnc lets you use the best angle, so surfaces look smoother.

Setup Time

With 3-axis cnc, you often stop and move the part. This takes extra time. 5-axis cnc can work on five sides at once, so you save time.

Cost per Part

3-axis cnc costs less at first. If your part is simple, you spend less money. For hard parts, 5-axis cnc can lower the total cost because you need fewer setups and finish faster.

Summary Table Overview

3 Axis CNC Machining Summary

Feature | 3-Axis CNC Machining |

|---|---|

Part Complexity | Best for easy, boxy parts |

Number of Setups | Needs more setups |

Accuracy & Precision | Good, but drops with extra setups |

Surface Finish | Good, but tool angle limits smoothness |

Lead Time | Fast for easy parts, slower for hard ones |

Cost | Cheaper to start |

Suitability | Flat parts, lots of pieces |

5 Axis CNC Machining Summary

Feature | 5-Axis CNC Machining |

|---|---|

Part Complexity | Great for tricky shapes and undercuts |

Number of Setups | Can work on five sides in one setup |

Accuracy & Precision | Very high because of single setup |

Surface Finish | Better, tool uses best angle |

Lead Time | Quicker for hard parts |

Cost | |

Suitability | Hard shapes, needs high accuracy |

Tip: When you look at 3 axis vs 5 axis cnc machining for complex parts, think about the shape, finish, and how many setups you need. This helps you choose the best process for your project.

What Makes a Part “Complex” in CNC Machining?

When you look at parts for cnc machining, you might ask why some are harder to make. Many things can turn a simple part into a complex one. These things include the shape, how exact it must be, and how strong it needs to be.

Geometric Complexity

Multiple Faces and Orientations

Some parts have lots of sides that need work from different angles. If you need to move or turn the part many times, it gets harder to make. This can cause mistakes and slow down the job.

Undercuts and Internal Features

Parts with undercuts or hidden spots need special tools and plans. You must think ahead to reach these places without hurting the part.

Freeform and Curved Surfaces

Curved shapes and freeform surfaces make things tougher. These shapes need smart computer programs and careful tool moves. You must control the machine closely to get the right shape.

Note: Shapes like steep angles, curved profiles, and mixed features such as tiny holes or text often need multi-axis machining.

Feature Type | Description |

|---|---|

Geometry | Curved surfaces, undercuts, steep angles, and shaped profiles |

Tolerances | Needs tighter than ±0.02 mm |

Thin Walls | Walls under 1 mm can shake or bend |

Deep Features | Deep pockets, thin channels, or tall cavities |

Multiple Setups | Parts needing many positions or rotary axes |

Hybrid Features | Threads, text, tiny holes, or mixed milling/turning |

Precision and Quality Requirements

Tight Tolerances

Some parts need very tight tolerances. This means the part must match the plan almost exactly, sometimes less than ±0.02 mm. Getting this right takes good planning and top machines.

Surface Finish Expectations

Some jobs want smooth surfaces with no tool marks. You must pick the best tools and settings to get these smooth finishes.

Complex parts often need tricky shapes and many details.

Fine finishes and tight tolerances make the job harder.

Use strict tolerances only on important spots to save money and work.

Structural Challenges

Deep Pockets

Deep pockets and thin channels make it hard to clear chips and reach with tools. You need smart ways to stop tools from breaking and keep things accurate.

Thin Walls

Thin walls can shake or bend while you work. You must use special tools and holders to keep the part steady.

Challenge Type | Description |

|---|---|

Ultra-Tight CNC Machining Tolerances | Getting tolerances in the ±0.0005” (±0.012 mm) range needs advanced holders and tools. |

Multi-Axis Simultaneous Milling | Hard parts often need 5-axis machining to avoid mistakes and save time. |

Exotic Material Machining | Materials like titanium and Inconel wear out tools and need heat control. |

Complex Thin-Wall Structures | Walls under 0.5 mm can shake and bend, so you need special tools. |

Intricate Internal Cavities | Deep pockets and hidden spots are hard to program because tools can't reach and chips get stuck. |

Multi-Step Fixtures and Workholding | Complex holders can cause mistakes if not lined up and checked well. |

Tip: Big parts and cuts that stop and start also make things harder. Tight tolerances and special materials like titanium or Inconel can make the job take longer and cost more.

You should always check these things before starting a cnc job. This helps you pick the best way and avoid expensive mistakes.

How 3-Axis CNC Machining Works

Axis Movement and Capabilities

A 3-axis cnc machine moves in three straight lines. You control the tool or the workpiece along the X, Y, and Z axes. Each axis gives you a different direction for cutting.

X-Axis Function

The X-axis moves the tool or table left and right. You use this movement to cut across the width of your part.

Y-Axis Function

The Y-axis moves the tool or table forward and backward. This direction lets you shape the length of your part.

Z-Axis Function

The Z-axis moves the tool up and down. You use this axis to control the depth of your cuts.

Here is a table to help you see how each axis works:

Axis Movement | Description |

|---|---|

X-axis | Left and right |

Y-axis | Forward and backward |

Z-axis | Up and down |

Limitations | Cannot create intricate shapes or features requiring multi-directional access. You need multiple setups for different sides. |

Note: 3-axis cnc cannot rotate the tool or part. You must reposition the material to reach other sides. This adds time and can cause mistakes.

Typical Part Complexity Level

Suitable Geometries

You can use 3-axis cnc for simple, flat shapes. It works best for prismatic parts, like brackets and plates. You can easily cut features that are open and easy to reach from the top.

3-axis cnc machining is best for planar parts.

You can make parts with holes, slots, and pockets on one side.

Design Limitations

You cannot make complex geometries or undercuts in one setup. If your part has features on many sides, you must stop and turn the material. This increases labor and the chance of errors. You also get a rougher surface finish compared to machines with more axes.

You cannot reach hidden features or organic curves without extra setups.

Each new setup can lower accuracy.

Cost and Maintenance

Machine Investment

You will find that 3-axis cnc machines cost less than advanced models. Most machines range from $25,000 to $50,000. This makes them a good choice for shops with a smaller budget.

Operating Cost

You spend less on maintenance and repairs. These machines have fewer moving parts, so they break down less often. You also use less energy and fewer tools.

3-axis cnc has lower operating costs.

You save money on upkeep and training.

Best Applications for 3-Axis Machining

Simple Prismatic Parts

You can make simple, boxy parts quickly. These include blocks, spacers, and basic housings.

Fixtures and Jigs

You can use 3-axis cnc to create fixtures and jigs for holding other parts. Many general manufacturing shops and prototyping labs use these machines for this purpose.

Plates and Brackets

You can cut plates, brackets, and panels with holes or slots. Job shops often use 3-axis cnc for these tasks.

Tip: If you need to make simple parts with features on one side, 3-axis cnc machining gives you a fast and affordable solution.

How 5-Axis CNC Machining Works

Axis Movement and Capabilities

A 5-axis cnc machine can move in more ways. It moves in three straight directions like a 3-axis cnc. It also has two rotary axes. These let you tilt and spin the tool or part. You can reach almost any spot without stopping the machine.

Rotary Axis A

The rotary axis A tilts the part or tool side to side. You can cut at an angle. This helps you make hard shapes. It is useful for deep pockets or curved surfaces.

Rotary Axis B or C

The rotary axis B or C spins the part or tool. You can turn the workpiece to see different sides. This makes it easier to work on many faces in one setup. You save time and keep your part accurate.

The design of a 5-axis cnc machine lets you work from many directions. You can make tough shapes and finish jobs faster.

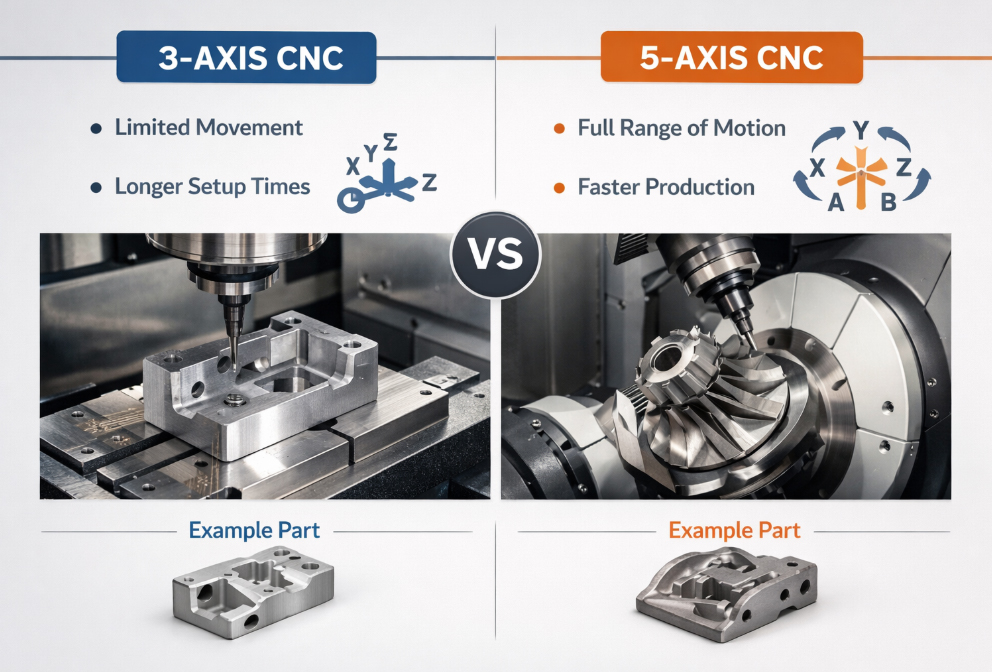

Simultaneous 5-Axis vs 3+2 Machining

You can use a 5-axis cnc in two main ways. Simultaneous machining moves all five axes at once. 3+2 machining sets the rotary axes first, then uses the three straight axes to cut.

Simultaneous Machining Characteristics

Simultaneous 5-axis machining works best for parts with curves. You get a smooth finish and tight tolerances. The machine keeps the tool at the best angle. You see fewer tool marks.

Positional Machining Characteristics

3+2 machining works well for parts with features on different faces. You set the angles, then cut with three axes. This way is easier to program. You may see blend lines between setups.

Feature | 3+2 Axis Machining | Simultaneous 5-Axis Machining |

|---|---|---|

Movement | Positions workpiece, then does 3-axis cutting. | All five axes move at once. |

Programming | Easier; like 3-axis programming. | Harder; needs special software. |

Best For | Parts with features on angled faces. | Parts with tricky shapes and curves. |

Accuracy | Good, but can lose accuracy from re-clamping. | Great; single setup avoids errors. |

Surface Finish | Can show blend lines. | Smooth finish without tool marks. |

Limitations | Cannot make true curved surfaces. | Costs more for machine and programming. |

Simultaneous 5-axis machining lets you finish all sides in one setup. You get better accuracy and smoother surfaces.

Flexibility and Surface Finish

Improved Tool Access

You can move the cutting tool to almost any angle. This helps you reach hard spots and keep the tool steady. You get smoother surfaces and tighter tolerances.

You keep the tool at the best angle for each cut.

You do not need extra grinding or polishing.

You can make detailed shapes for medical and aerospace parts.

Reduced Tool Length

You use shorter tools with a 5-axis cnc machine. Short tools vibrate less and cut better. You finish jobs faster and get better results.

You reach deep pockets and thin walls without bending the tool.

You reduce setup time and mistakes.

You make complex parts in one piece, which helps accuracy.

Best Applications for Complex Parts

Multi-Face Machining

You can work on many sides of a part in one setup. This is important for turbine blades, engine blocks, and transmission parts. You save time and keep your parts precise.

Organic and Sculptured Shapes

You can make curved surfaces and freeform shapes with a multi-axis cnc machine. This helps you create medical implants, molds, and special energy parts.

Aerospace: Turbine blades and engine parts with tough shapes.

Automotive: Valve bodies and housing parts.

Medical: Implants and surgical tools.

Mold and Die: Molds with cooling channels.

Energy: Wind turbine and nuclear equipment parts.

Defense: Precision weapons and radar systems.

Use 5-axis cnc machining when you need to make complex parts with many faces or curved shapes. You get better accuracy, faster production, and smoother finishes than with a 3-axis cnc.

3 Axis vs 5 Axis CNC Machining: Technical Comparison

Precision and Tolerances

Repeatability

You want your parts to look the same every time. With 3-axis cnc, you often need to move the part for each side. This can make it hard to repeat the same results. A 5-axis cnc machine keeps the part in one place, so you get better repeatability. You avoid mistakes from moving and clamping the part again.

Accuracy

Machining accuracy matters when you need tight tolerances. The table below shows how 3 axis vs 5 axis cnc machining for complex parts compares:

Factor | 3-Axis | 5-Axis |

|---|---|---|

Accuracy | Good | Excellent |

Tool changes | Multiple setups | Minimal setups |

Capabilities | Limited | Intricate shapes |

Efficiency | Good | Excellent |

You get higher machining accuracy with a 5-axis cnc machine. You can cut deep features and complex shapes without moving the part.

Surface Finish Quality

Tool Orientation Impact

Tool orientation changes how smooth your part feels. With 3-axis cnc, the tool only moves up, down, left, and right. You cannot always point the tool at the best angle. A 5-axis cnc lets you tilt and rotate the tool for each surface. This gives you a better finish.

Aspect | 3-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

Tool Orientation | Limited angles | Any angle for best finish |

Surface Finish Quality | Lower, more marks | Smoother, fewer marks |

Cutting Forces | Higher | Lower, less tool wear |

Tool Life | Shorter | Longer, better chip removal |

Reduced Tool Marks

You see more tool marks with 3-axis cnc because you need extra setups. A 5-axis cnc machine keeps the tool at the right angle, so you get fewer marks and a cleaner look.

Setup Time and Fixturing

Number of Setups

You spend more time setting up with 3-axis cnc. You must stop and move the part for each side. A 5-axis cnc can work on five sides in one setup. This saves you time and lowers the chance of mistakes.

Aspect | 3-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

Number of Setups | Many | One |

Fixture Complexity

You need simple fixtures for 3-axis cnc, but you use more complex fixtures for 5-axis cnc. One customer used a 5-axis fixture to finish a water pump housing in just one clamping. This cut setup time by 70%. You also reduce scrap and rework.

5-axis cnc machining lets you machine more sides in one setup, which streamlines your process and lowers risks.

Tool Accessibility and Reach

Collision Risk

You face predictable collision risks with 3-axis cnc. You know where the tool will go. With 5-axis cnc, you get more moving parts, so you must watch for collisions. You need advanced software to help you avoid crashes.

Challenge Type | 3-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

Collision Risk | Predictable | Increased |

Short vs Long Tools

You use longer tools with 3-axis cnc to reach deep spots. These tools can bend or vibrate. A 5-axis cnc machine lets you use shorter tools. Short tools stay steady and cut better. You get better results and longer tool life.

You get better access to hard-to-reach areas with a 5-axis cnc machine. This helps you make complex parts faster and with fewer mistakes.

Cost Comparison: 3 Axis vs 5 Axis CNC Machining

When you compare the costs of 3-axis cnc and 5-axis cnc, you need to look at more than just the price of the machine. You should think about machine hour rates, programming and setup costs, and how the cost per part changes with different production volumes.

Machine Hour Rates

The machine hour rate tells you how much it costs to run a cnc machine for one hour. This rate includes the cost of the machine, the operator, and the shop overhead. You will see big differences between 3-axis cnc and 5-axis cnc, especially in different regions.

Typical 3-Axis Rates

You can expect lower machine hour rates for 3-axis cnc. In places with lower labor costs, the rate usually falls between $20 and $50 per hour. In areas with higher labor costs, like North America or Western Europe, the rate can go from $50 up to $100 per hour.

Typical 5-Axis Rates

The machine hour rate for 5-axis cnc is much higher. In North America and Western Europe, you might pay between $100 and $250 per hour. In Eastern Europe, the rate drops to $75–$150 per hour. In Asia, you may see rates from $50 to $125 per hour.

Here is a table to help you compare:

CNC Machining Type | Low-Labor-Cost Regions | High-Labor-Cost Regions |

|---|---|---|

3-axis cnc | $20 - $50/hour | $50 - $100/hour |

5-axis cnc | $80 - $180/hour | $100 - $250/hour |

Tip: The higher rate for 5-axis cnc comes from the advanced technology, more expensive machines, and the need for skilled operators.

Programming and Setup Costs

Programming and setup costs can make a big difference in your total project cost. These costs depend on how hard it is to program the machine and how much time your engineers spend getting ready.

CAM Programming Complexity

Programming a 3-axis cnc is much simpler. You use basic linear moves, and most operators can learn the process quickly. For 5-axis cnc, you need to program complex tool paths that move in many directions at once. This takes more skill and better software.

Engineering Time

You will spend less time programming a 3-axis cnc. The process is quick, and you do not need to check for tool collisions as much. For 5-axis cnc, you need more time to debug and verify the tool paths. Sometimes, programming and checking a single part can take over a day. For example, a mold factory once spent 36 hours just to debug the tool path for a high-gloss mobile phone shell mold. The extra time comes from checking for tool collisions and making sure the machine moves the right way.

Here is a table that shows the main differences:

Aspect | 3-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

Programming Complexity | Simpler, linear moves | Complex, multi-axis paths |

Engineering Time | Shorter, quick setup | Longer, needs more debugging |

Operator Expertise | Basic CNC knowledge | Advanced skills needed |

Software Requirements | Standard CAM software | Advanced, special software |

Debugging Time | Minimal | Can take many hours |

Note: 3-axis cnc programming is easier to learn and faster to finish. 5-axis cnc programming needs more time, better software, and skilled engineers.

Cost per Part at Different Volumes

The cost for each part changes when you make more parts at once. You need to think about setup costs, batch size, and how complex your part is.

Prototyping

When you make just one or two parts, setup costs have a big impact. For both 3-axis cnc and 5-axis cnc, the first parts cost more because you cannot spread the setup cost over many pieces. If your part is complex, you may also need extra finishing steps, which adds to the cost.

Low-Volume Production

If you make a small batch, like 5 or 10 parts, the cost per part is still high. The setup cost does not change, so each part carries a big share of that cost. For complex shapes, you may need more inspection and cleaning, which also raises the price.

Medium-Volume Production

When you make more parts, like 50 or 100, the cost per part drops. You spread the setup cost over more pieces. This makes both 3-axis cnc and 5-axis cnc more affordable for bigger batches. If you use 5-axis cnc for complex parts, you can save time and money because you need fewer setups and less manual work.

Here are some key points to remember:

Setup costs matter most for small batches.

Making more parts lowers the cost per part.

Complex parts need more finishing, which costs more for small runs.

If you plan to make many parts, 5-axis cnc can save you money on complex jobs. For simple shapes or small batches, 3-axis cnc may be the better choice.

Efficiency and Production Volume Considerations

Cycle Time Differences

Tool Path Efficiency

You want to make parts fast and right. Cycle time means how long one part takes. With 3-axis cnc, you stop and move the part a lot. This makes the job slower. 5-axis cnc cuts from many angles in one go. You save time because you do not move the part. The table below shows how cycle time and setups are different:

Feature | 3-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

Cycle Time | Slower due to repositioning | Faster due to simultaneous machining |

Complexity Handling | Limited to simpler geometries | Capable of complex geometries |

Setup Time | Multiple setups needed | Single setup for multi-surface parts |

5-axis cnc helps you finish hard parts faster. You get better results for shapes like cam lobes and helical profiles.

Automation Potential

Pallet Systems

Pallet systems help you load and unload parts quickly. You can get the next part ready while the machine works. This keeps the machine busy and saves time. You swap pallets fast, so the machine does not stop.

Robotic Loading

Robots can put in raw materials and take out finished parts. They also help with jobs like cleaning and checking parts. Robots work all day and night. You can run your shop without people there. Software makes it easy to use robots with your machines.

Tip: Using pallet systems and robots helps you make more parts and keep quality high.

Lead Time Impact

Quotation to Delivery

Lead time is how long it takes from getting a quote to sending the finished part. 3-axis cnc jobs take longer because you need more setups. 5-axis cnc needs less setup and cuts faster. Here is a table showing typical lead times:

CNC Machining Type | Quote | Setup | Material | Machining | Secondary | Inspection | Finishing |

|---|---|---|---|---|---|---|---|

3-Axis | 1-3 | 1-5 | 1-7 | 1-10 | 1-7 | 1-2 | 1-3 |

5-Axis | 1-3 | 1-1 | 1-7 | 1-5 | 1-7 | 1-2 | 1-3 |

5-axis cnc gives you faster delivery, especially for hard parts. This helps you meet deadlines and keep customers happy.

Industry Applications

You can find 3-axis cnc and 5-axis cnc machines in many places. These machines help make parts for planes, hospitals, cars, and robots. Each group uses cnc machines to make better parts faster.

Aerospace Components

Planes need parts that are strong but not heavy. A 5-axis cnc machine makes things like turbine blades and engine pieces. These machines reach small spaces and make smooth surfaces.

Impellers

Impellers are used in jet engines and pumps. A 5-axis cnc machine cuts curved blades and deep pockets. You finish the part in one setup and keep it accurate.

Structural Brackets

Planes use brackets to hold wings and engines. You use 3-axis cnc for easy brackets. For brackets with many sides or curves, you use 5-axis cnc. This helps you avoid extra setups and get better results.

Tip: Plane parts need tight tolerances and smooth surfaces. You save time and make fewer mistakes with 5-axis cnc.

Industry Sector | Key Applications |

|---|---|

Aerospace | Turbine blades, Engine components, Structural aircraft parts, Satellite components |

Industry | Common Complex Parts |

|---|---|

Aerospace | Turbine blades, engine components, structural components (bulkheads, wing ribs, landing gear brackets) |

Medical Devices

Hospitals need safe and exact tools. Cnc machines help make smooth and precise implants and instruments.

Implants

A 5-axis cnc machine makes hip and knee implants. These parts have curved surfaces and need to be very accurate. You finish them in one setup and avoid tool marks.

Surgical Instruments

Doctors use tools made from strong metals. You use 3-axis cnc for simple handles. For tricky shapes, you pick 5-axis cnc. You get smoother finishes and strong tools.

Industry Sector | Key Applications |

|---|---|

Medical Device | Orthopedic implants, Dental prosthetics, Surgical instruments, Medical imaging equipment components |

Industry | Common Complex Parts |

|---|---|

Medical | Orthopedic implants (hip and knee), surgical instruments (medical-grade titanium or stainless steel) |

Automotive Parts

Car makers want fast and good machining. You use 3-axis cnc for basic engine blocks. For parts with deep channels or curves, you use 5-axis cnc.

Engine Components

Engine heads and blocks are made with cnc machines. A 5-axis cnc machine helps you reach all sides and keep tight tolerances.

Transmission Parts

Transmissions have gears and cases with hard shapes. You use 5-axis cnc to cut these parts with fewer setups. You save time and make better parts.

Industry Sector | Key Applications |

|---|---|

Automotive | Engine blocks, Transmission components, Brake rotors, Custom aftermarket parts |

Robotics and Industrial Equipment

Robots need special parts to move and work. Cnc machines make end effectors and custom mechanisms.

End Effectors

Robots use end effectors to grab and move things. You use 5-axis cnc to make these parts with tricky shapes. You get smooth surfaces and strong parts.

Custom Mechanisms

Factories use custom mechanisms for automation. You use 3-axis cnc for simple plates. For moving parts with curves, you use 5-axis cnc. You finish jobs faster and keep machines working well.

Note: You pick 3-axis cnc or 5-axis cnc based on part shape, finish, and accuracy. Every industry uses these machines to make complex parts quickly and precisely.

Which Should You Choose for Your Complex Parts?

Picking between 3 axis and 5 axis cnc machining depends on your part’s shape, how exact it must be, and what you want to make. You need to use the right machine to get good results and save time.

Choose 3-Axis CNC If

Simple Geometry

Pick a 3-axis cnc machine if your part is not complicated. Flat plates, brackets, and blocks are easy for this machine. It moves in three straight lines, so it can cut simple shapes fast.

Moderate Tolerance

If your part does not need to be super exact, 3-axis cnc is good enough. You spend less money on setup and running the machine. This is best for test parts or small batches when cost is important.

Tip: 3-axis cnc is great for easy jobs that do not need perfect accuracy.

Choose 5-Axis CNC If

High Complexity

Use a 5-axis cnc machine for parts with curves, undercuts, or many sides. This machine can tilt and spin the part, so it reaches hard spots without stopping. You do not need to move the part as much, so everything stays lined up.

Tight Tolerance and Finish

If you need your part to be very exact and smooth, 5-axis cnc is best. It works on all sides at once, so you do not make mistakes by moving the part. You get a better finish and all the features line up right.

Here is a table to help you pick:

Criteria | 3-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

Part Complexity | Good for simple parts with basic shapes | Best for tricky parts with detailed shapes |

Production Volume | Cheaper for making a few simple parts | Better for making lots of hard parts |

Accuracy Requirements | Fine for jobs that do not need to be perfect | Needed for very exact and smooth parts |

Operational Costs | Costs less to run | Costs more at first but saves money on big jobs |

5-axis cnc can work on many sides at once, so you make fewer mistakes.

You get better results when your part needs to line up on different faces.

5-axis cnc is best for hard parts in planes, hospitals, and cars.

Note: 3-axis cnc is best for easy parts. 5-axis cnc gives you more options and better accuracy for tough jobs.

Decision Checklist Before Choosing a CNC Process

When you pick between 3-axis cnc and 5-axis cnc, you should think about a few key things. This checklist helps you find the best process for your part and project.

Geometry Factors

Number of Faces

Count how many sides need machining. If your part has features on one or two sides, 3-axis cnc works well. If your part has features on many sides or angles, 5-axis cnc is better. You can reach more surfaces in one setup.

Undercuts

See if your part has undercuts or hidden spots. 3-axis cnc cannot reach these places easily. 5-axis cnc can handle undercuts and tricky shapes without extra setups. You save time and get better accuracy.

Quality Factors

Tolerance

Think about how exact your part must be. If you need tight tolerances, pick 5-axis cnc. The machine keeps the part still, so results stay the same. 3-axis cnc is fine for moderate tolerances, but moving the part can lower accuracy.

Surface Finish

Check your surface finish needs. 5-axis cnc lets you use the best tool angles, so surfaces look smoother. If your part does not need a perfect finish, 3-axis cnc may be enough.

Production Factors

Quantity

Decide how many parts you want. For lots of simple parts, 3-axis cnc costs less. If you need fewer complex parts, 5-axis cnc saves time and lowers mistakes.

Budget

Look at your budget. 5-axis cnc costs more to buy and run. You also spend more time programming. 3-axis cnc has lower costs and is easier to set up.

Lead Time

Check your delivery dates. 5-axis cnc can finish hard parts faster if the machine is ready. If you need quick jobs for easy parts, 3-axis cnc is a good choice.

Tip: Use this checklist to match your part’s shape, quality, and production needs with the right cnc process. You will work faster and avoid expensive mistakes.

Factor | 3-Axis CNC | 5-Axis CNC |

|---|---|---|

Faces | 1-2 | Multiple |

Undercuts | Limited | Excellent |

Tolerance | Moderate | Tight |

Surface Finish | Good | Superior |

Quantity | High for simple | Low/medium for complex |

Budget | Lower | Higher |

Lead Time | Fast for simple | Fast for complex |

Work with a CNC Machining Partner for Complex Parts

Choosing the right CNC machining partner can make your job easier and your parts better. When you work with a team that offers engineering support, advanced equipment, and strong quality checks, you get more than just parts—you get peace of mind.

Engineering Support

You need help to turn your ideas into real parts. A good partner gives you engineering support from the start. They look at your designs and give you DFM feedback. This means they check if your part can be made easily and suggest changes to save time and money. You can avoid mistakes before production begins.

DFM Feedback

With DFM feedback, you learn how to make your part stronger and easier to machine. Your partner will point out features that may cause problems on a 3-axis cnc or a 5-axis cnc. They help you pick the best process for your part. This support leads to better quality and lower costs.

Tip: Working with a CNC machining partner who gives DFM feedback helps you improve your design and finish your project faster.

Manufacturing Capability

You want a shop that can handle any part you need. A partner with both 3-axis cnc and 5-axis cnc machines can make simple and complex shapes. Multi-axis equipment lets you create parts with deep pockets, curves, and undercuts. You get high accuracy and repeatability, even for tricky jobs.

Multi-Axis Equipment

A multi-axis cnc machine gives you advanced tool control. You can make parts that would be impossible on a basic machine. This means you can trust your partner to handle any challenge, from a simple bracket to a complex aerospace part.

Quality Assurance

You need every part to meet your standards. A strong partner checks each part for size, shape, and finish. They use inspection tools and testing to make sure your parts are right every time.

Inspection and Testing

Your partner will inspect parts made on both 3-axis cnc and 5-axis cnc machines. They test for accuracy and surface finish. This process helps you avoid delays and costly mistakes.

High accuracy and repeatability for complex parts

Consistent quality from design to delivery

Note: A CNC machining partner with engineering support, multi-axis equipment, and quality checks helps you get the best results for your complex parts.

When you compare 3 axis vs 5 axis cnc machining for complex parts, you see clear differences. You use 3-axis cnc for simple shapes and lower costs. You choose 5-axis cnc when you need to make complex parts with tight tolerances and smooth finishes. You get faster production and fewer setups with 5-axis cnc. If you want the best results, review your part’s geometry and quality needs. Ask a cnc expert for advice before you decide.

Tip: You can save time and money by matching your part to the right machine.

Review your design.

Check your budget.

Contact a trusted shop for help.

FAQ

What is the main difference between 3-axis and 5-axis cnc machining?

You control three directions with 3-axis machines. You get two extra movements with 5-axis machines. This lets you reach more surfaces and make complex shapes in fewer setups.

When should you choose 5-axis cnc machining?

You should pick 5-axis machining for parts with curves, undercuts, or features on many sides. You save time and get better accuracy for complex jobs.

Does 5-axis cnc machining cost more than 3-axis?

You pay more for 5-axis machines and skilled operators. You spend less time on setups and finishing, which can lower your total cost for complex parts.

Can you use 3-axis cnc for all parts?

You can use 3-axis machines for simple shapes like plates and brackets. You need 5-axis machines for parts with tricky angles or many faces.

How does cnc machining improve part quality?

You get better accuracy and smoother surfaces with cnc machining. You use computer controls to follow exact designs and reduce mistakes.

LKprototype

LKprototype