A CNC router, or to answer the question "what is a CNC router," is a machine operated by a computer that cuts and shapes materials with exceptional precision. It automates tasks that would otherwise require manual effort, making the process both faster and more accurate. Unlike traditional tools, CNC routers optimise material usage, helping to minimise waste and reduce costs. They ensure that every product is consistent in appearance and of high quality. Additionally, CNC routers significantly cut down production time, enabling quicker delivery and the effortless creation of intricate designs. These versatile machines can be used on materials such as wood, metal, plastic, or glass, revolutionising the way items are manufactured.

Key Takeaways

CNC routers cut and shape materials quickly and precisely, reducing waste.

These machines are flexible and can work with wood, metal, plastic, and glass. They are important in many industries.

CNC routers improve product quality and make items consistent. They are great for mass production and detailed designs.

How Does a CNC Router Work?

Overview of the CNC Routing Process

The CNC routing process turns digital designs into real objects. It starts with creating a design using CAD (Computer-Aided Design) software. This design is changed into G-code, a language the CNC router understands. The router follows this code to cut materials with great accuracy. Automating the cutting ensures consistent results and fewer mistakes.

Modern CNC routers are very precise and reliable. They can make the same part many times without losing quality. This is perfect for industries needing mass production or detailed designs. The process also reduces waste by using materials efficiently, saving money and helping the environment.

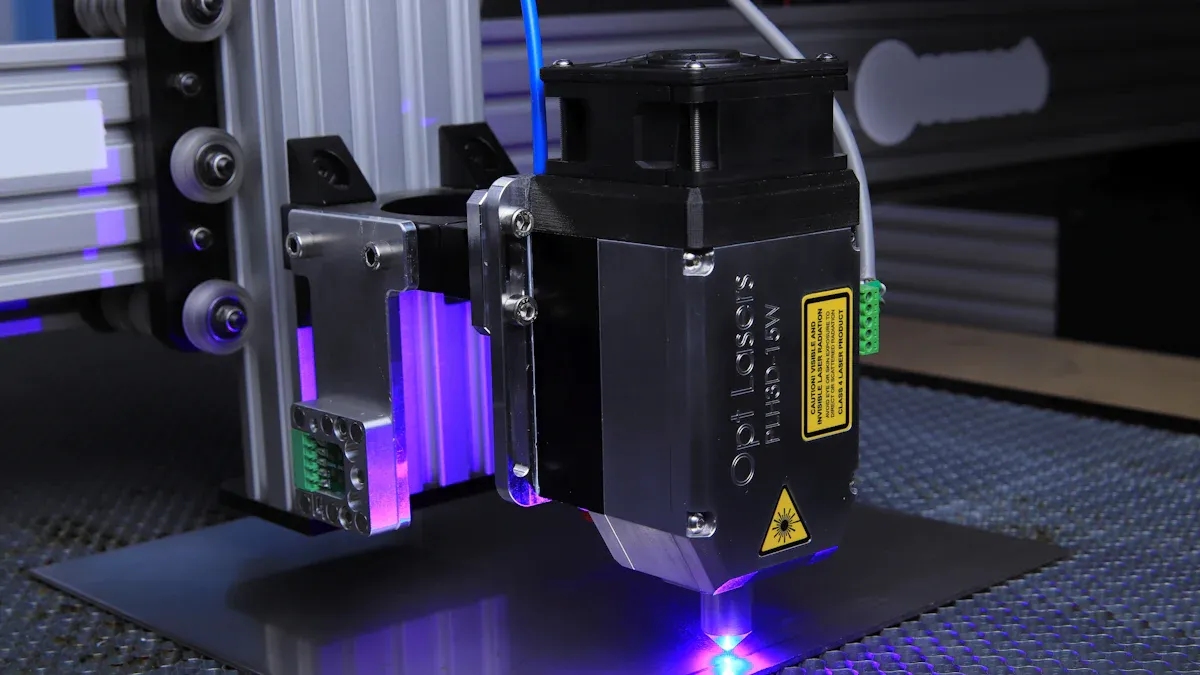

Key Components of a CNC Router

A CNC router has important parts that work together smoothly. The table below shows these parts and their roles:

Component | Description |

|---|---|

Cutting bed | A flat surface that holds the material steady during cutting. |

Spindle | A spinning blade that cuts materials at different speeds. |

Drive system | Moves the router in three directions (x, y, z) for cutting. |

Controller | A computer that uses G-code to guide the cutting process. |

These parts help the machine work well and produce great results. For example, the spindle's strength decides how well it cuts different materials. The cutting bed keeps the material stable while cutting.

Step-by-Step Explanation of CNC Router Operation

Using a CNC router involves several steps to ensure good results. Here’s a simple guide:

Design Creation: Make a detailed design using CAD software.

G-code Generation: Change the design into G-code with CAM software.

Machine Setup: Get the CNC router ready with the right tools and settings.

Zero-Positioning: Place the router bit at the starting point for accurate cutting.

Machining: The router cuts or shapes the material by following the program.

Post-Operation Quality Control: Check the finished product for accuracy and smooth the surface if needed.

To get the best results, keep the tools in good condition. Make sure the material is firmly attached to the cutting bed. Testing the tool paths before starting can also help avoid mistakes.

Applications of CNC Routers Across Industries

Woodworking and Furniture Design

CNC routers have changed how furniture is made. They can create detailed patterns and carvings with great accuracy. The machine keeps quality consistent, whether for one item or many. For example, CNC routers cut walnut and ash wood smoothly at speeds up to 18,000 rpm. This saves time and gives a polished finish.

Parameter | Findings |

|---|---|

Machined Materials | Walnut and ash wood were tested. |

Spindle Speeds | Speeds of 12,000, 15,000, and 18,000 rpm were tested. |

Surface Quality | Tests showed smooth and wettable surfaces under ideal conditions. |

Online shopping has increased demand for custom furniture. This has made CNC routers even more popular in this field.

Metalworking and Fabrication

CNC routers are important in metalworking. They are great for cutting metals like aluminium and brass. These machines waste less material and improve surface quality by 15%. They also cut faster, increasing speed by 25%. This makes them essential for car and plane industries.

Metric | Improvement/Effectiveness |

|---|---|

Surface finish quality | 15% better surface finish quality |

Material waste | 15% less material wasted |

Cutting speed | 25% faster cutting speed |

Prototyping and Product Design

CNC routers make prototyping easier and faster. They help create accurate models without needing moulds or special tools. Designs can be quickly updated using CAD files. This makes CNC routers perfect for industries like cars and consumer goods.

Sign-Making and Engraving

Sign-making and engraving are easier with CNC routers. They carve detailed designs into wood, metal, or plastic. This creates professional signs. A survey showed 88% of sign shop owners value CNC routers highly. Shops earning over $1,000,000 credit their success to these machines.

Specialised Uses in Plastics, Composites, and Glass

CNC routers also work with plastics, composites, and glass. Hybrid CNC machines handle many materials and are becoming popular. These machines are vital for industries needing precision, like medical devices and electronics. Countries like India and China are using more CNC routers due to growing industries and automation.

CNC routers have changed manufacturing by adding accuracy, speed, and automation. These machines are trusted to make reliable, high-quality items in many industries. They are useful in areas like woodworking, metalworking, and creating prototypes.

The CNC machine market is expected to grow from USD 86.83 billion in 2022 to USD 140.78 billion by 2029.

Automation lowers costs, boosts efficiency, and reduces mistakes, making CNC routers essential for modern production.

As industries need more accuracy, CNC routers remain key to improving manufacturing's future.

FAQ

What materials can a CNC router cut?

A CNC router can cut wood, metal, plastic, and glass. It also works with composites, making it useful for many industries.

How precise is a CNC router?

CNC routers are very precise, accurate to 0.001 inches. This makes them great for detailed designs and large-scale production.

Do you need training to use a CNC router?

You need basic training to use a CNC router properly. Learning CAD software, G-code, and setup helps you get the best results.

Start your project with LKprototype

LKprototype company simplifies procurement for custom manufacturing, Suitable for making your products or prototypes with a variety of materials, such as metal or plastic, silicone rubber, from 3D Printing to CNC Machined Parts and Vacuum Casting , with a focus on speed and efficiency. Our platform provides instant quotes. With LKprototype, You can connect with the team to communicate your project to ensure quality and on-time delivery.

Start with an instant quote and experience how our technology and expertise can make custom part procurement faster and easier.

LKprototype

LKprototype