If you want to make silicone parts with vacuum casting in China, you should know the steps to do it well. This vacuum casting china guide shows why picking the right supplier and design is important. Vacuum casting lets you make a prototype or small batch fast and without spending a lot. You can make cheap prototypes and get good silicone parts quickly.

Tip: A simple guide helps you not make mistakes and get what you want.

Key Takeaways

Vacuum casting in China helps you save money. It costs less than in Europe or the USA. You can make prototypes without spending a lot.

This method works well for small batches. You can make 1 to 200 parts fast. It is good for testing designs before making many parts.

Picking the right supplier is very important. Make sure they have the right skills and tools. They should also have good quality checks for your project.

Use good design rules for silicone molds. Do not use sharp corners. Make sure the walls are thick enough. This helps the mold last longer and makes better parts.

Good communication and project management matter a lot. Set clear goals and talk often. This helps stop mistakes and makes sure you get your parts on time.

Why Pick Vacuum Casting in China? ⭐⭐⭐

Cost Advantages vs Europe & USA

You want to spend less money on silicone parts. Many companies pick vacuum casting in China because it costs less than in Europe or the USA. You get good quality for a lower price. This is a big reason people choose vacuum casting in China. You do not have to buy expensive tools or machines. You only pay for what you need. This guide shows why many buyers pick vacuum casting.

Note: Saving money lets you try new ideas and make changes without spending a lot.

Manufacturing Capacity and Speed

China has many factories that do vacuum casting. They can make small or big orders. You get your parts fast because Chinese suppliers work quickly. The time to finish silicone vacuum casting in China is shorter than in other places. Here is a table that shows how fast you can get your parts:

Source | Average Lead Time |

|---|---|

Top 10 Vacuum Mold Casting Manufacturers in China | 5–10 working days |

Vacuum Casting/Silicone Molding/Urethane Casting Services | 7-12 Business Days |

Vacuum Casting for Rapid Prototyping | 7 to 15 days |

You can see why vacuum casting is good for quick projects. Fast delivery is a big advantage, but you should check the quality.

Typical Industries Outsourcing to China

Many industries use vacuum casting for different needs. You see vacuum casting in cars, medical tools, electronics, and home appliances. These industries need quick samples and small batches. The advantages and disadvantages of vacuum casting make it a good choice for them. You can use vacuum casting for prototypes, testing, and even final products. More companies use vacuum casting as they want flexible ways to make things.

What Is Silicone Vacuum Casting? (Quick Overview)

Vacuum casting helps you make good prototypes and small batches. This technology uses silicone molds to make parts that look real. It works well for making samples and small amounts. You get parts with smooth surfaces and fine details.

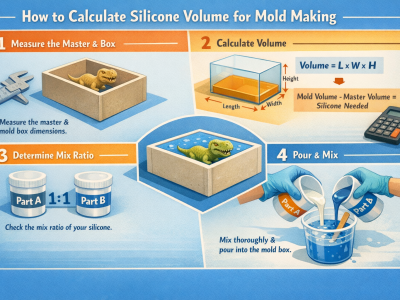

The process starts with a master pattern. You can use a 3D printed or machined part for this. The master pattern decides the shape and surface of your parts. Put the master pattern in a mold box. Pour liquid silicone around it. The silicone hardens and makes a soft mold.

Here are the main steps in vacuum casting:

Get the master pattern ready. Make sure it is smooth.

Put the master pattern in the mold box. Add gates and risers for resin flow.

Mix the two-part silicone. Remove air bubbles for better results.

Pour the silicone into the mold box. Use a vacuum to get rid of trapped air.

Let the silicone cure. Take out the master pattern from the mold.

Check the silicone mold for any problems.

Mix the casting resin. Remove air bubbles. Pour it into the silicone mold.

Cure the part in an oven. Take out the finished part and add any needed touches.

Vacuum casting has many good features. You can make prototypes with tricky shapes and undercuts. You get the same results each time. You can pick different materials and colors. Many industries use vacuum casting for testing and samples. You save time and money compared to old ways.

Tip: Vacuum casting lets you test your design before making lots of parts. You can change your design easily and see how it works.

Vacuum casting is fast and flexible. It makes high-quality prototypes. You can trust this process for samples and small batches when you need parts with fine details.

When Vacuum Casting Is the Right Choice

You want to know if vacuum casting fits your project. This process works best when you need high-quality parts quickly and do not want to spend a lot on tools. Vacuum casting gives you smooth surfaces and fine details. You can use it for prototypes or small batches before moving to large-scale manufacturing.

You should choose vacuum casting in these situations:

You need 1 to 200 parts for testing or showing to customers.

You want to check your design before making many parts.

You need parts with complex shapes or undercuts.

You want to use different colors or finishes for your samples.

You need parts fast for a trade show or meeting.

Vacuum casting helps you save time and money. You do not need to wait for steel molds or expensive machines. You can get your parts in days, not weeks. This makes vacuum casting a smart choice for rapid production and design changes.

Tip: If you want to test your idea before spending more on manufacturing, vacuum casting gives you a safe way to try.

You can use vacuum casting for many industries. Car makers use it for new parts. Medical companies use it for device covers. Electronics makers use it for cases and buttons. You can also use vacuum casting for home appliances and tools.

Here is a table that shows the best production volumes and part sizes for vacuum casting:

Production Volume | Part Size (Max) |

|---|---|

10–200 units | N/A |

1 – 100 units | 2500 × 2200 × 1800 mm |

This table helps you see if your project fits vacuum casting. If you need more than 200 parts, you may want to look at other manufacturing methods. If your part is very large, check the size limits with your supplier.

Vacuum casting works best when you want quality, speed, and flexibility. You can make changes without wasting money. You get parts that look and feel like the final product.

Vacuum Casting Design Guide

Design Principles for Silicone Molds

You want your vacuum casting project to succeed. You should follow some important design principles for silicone molds. Start with a high-quality master model. This model captures fine details and helps you get accurate parts. Silicone molds work best when you avoid sharp corners and deep undercuts. These features can cause stress and shorten mold life. Add a draft angle of 1 to 2 degrees to your design. This makes it easier to remove parts from the mold without damage.

Here are some key design tips for vacuum casting:

Use smooth surfaces on your master pattern.

Avoid thin walls and sharp internal corners.

Plan for easy part removal with draft angles.

Understand the material and technician’s skill for better mold production.

Note: The design of your part affects how long your mold will last.

Wall Thickness, Undercuts & Detail Limits

Wall thickness is very important in vacuum casting design. If you make walls too thin, they can tear or break. If you make them too thick, parts may cool slowly and become brittle. Most experts recommend a minimum wall thickness of 0.75 mm. For best results, use 1.5 mm. Some projects work well with walls up to 4 mm.

Source | Recommended Wall Thickness |

|---|---|

Nice Rapid | At least 0.75mm (1.5mm recommended) |

Xometry | At least 0.75-1.0 mm |

ARRK | 1.5 mm to 4 mm (minimum 1 mm) |

You should avoid deep undercuts and sharp corners. These features can damage the mold and reduce its life. Always balance wall thickness for strength and durability. This vacuum casting design guide helps you make better choices for your parts.

Common Design Mistakes to Avoid

Many people make mistakes in vacuum casting design. You can avoid problems by following these steps:

Prepare your pattern well. Make sure it is smooth, clean, and sealed.

Mix silicone and resin in the correct ratio. Use accurate measurements.

Mix materials thoroughly. This prevents soft or sticky spots.

Clean the mold before each use. This gives you smooth surfaces.

Allow enough time for curing. Do not rush this step.

Tip: Careful preparation and patience lead to better results in vacuum casting.

This vacuum casting design guide gives you the main design tips for vacuum casting. You can use these ideas to avoid common errors and get high-quality parts every time.

How to Outsource Vacuum Casting in China (Step-by-Step) ⭐⭐⭐

Defining Your Project Requirements

Start by knowing what you want for your project. Decide how many parts you need. Think about what you will use them for. Vacuum casting is good for prototypes or small batches. Write down the size and shape of your parts. Say what you want your parts to do. Pick the material you want. Most suppliers use polyurethane. You can also ask for nylon if you need it. Make a list of special needs. This can be color, texture, or how hard the part is. Tell your supplier if your part must handle heat or cold.

Tip: When you share clear project needs, you get the right service and avoid mistakes.

Preparing Drawings & Specifications

Give your supplier good drawings and details. You can use 3D files or simple sketches. Add all the important sizes and shapes. Tell the supplier what material, color, and finish you want. Here is a table to help you check your details:

Specification | Details |

|---|---|

Minimum Wall Thickness | At least 0.75 mm (1.5 mm recommended) |

Maximum Part Dimensions | 1900 x 900 x 750 mm, max volume: 10 liters |

Typical Quantities | Up to 25 copies per mold |

Color & Finishing | Customizable colors and textures |

Say if you want your part to look like the final product. If you need printing or special textures, add this in your guide.

Requesting and Comparing Quotes

Ask for quotes from different vacuum casting suppliers in China. Give each supplier the same details. This makes it easy to compare prices and services. When you get quotes, look at more than just the price. Use this table to help you compare:

Criteria | Description |

|---|---|

Request Physical Samples | Check the surface, size, and material of real samples. |

Review Production Metrics | Ask about delivery times and how often clients return. |

Inspect Equipment Capabilities | Make sure the factory has modern machines and tools. |

Verify Material Compliance | Check if materials meet safety rules for your market. |

Assess Communication Speed | Fast replies (under 4 hours) show good support. |

Value-Added Services | See if the supplier helps improve your design for better manufacturing. |

This vacuum casting china guide helps you make smart choices. Good planning helps you get the best service for your needs.

How to Choose a Reliable Vacuum Casting Supplier in China ⭐⭐⭐

Factory vs Trading Company

When you look for a vacuum casting supplier in China, you need to know the difference between a factory and a trading company. Factories make the products themselves. Trading companies help connect buyers and sellers. Here is a simple list to show the differences:

Factories have their own machines and workers. Trading companies do not make anything.

Factories register as manufacturers. Trading companies register for buying and selling.

Factories can show you their work areas and equipment. Trading companies may not have any machines.

If you want more control and help, pick a factory for your vacuum casting job.

Evaluating Technical Capabilities

You should check if the supplier has good skills and tools. A strong team and good machines help you get better vacuum casting parts. Use this table to compare what suppliers can do:

Capability | Description |

|---|---|

Experienced Team | Engineers with over 20 years in rapid prototyping and vacuum casting. |

Advanced Equipment | Multiple vacuum casting machines, CNC, and SLA for master models. |

Stable Quality | Every batch gets checked for size, look, and material. |

Flexible Volume | Can make a few prototypes or hundreds of parts with the same quality. |

Fast & Cost-Effective | Quick delivery and smart processes to save money. |

Molds | Silicone molds made from CNC or SLA master models. |

Material Range | Polyurethane resins like ABS, PC, PP, POM, PA, rubber-like, and clear grades. |

Common Grades | PX5210, PX223, UP 8150, UP 8260, UP 4280, UP 5290, and more. |

Finish Options | Painting, polishing, texture, logos, and simple assembly. |

A good supplier gives you low-cost molds, fast service, and steady quality. You can also ask for special finishes and thin-wall casting.

Tip: Always ask about the supplier’s skills and machines before you start your vacuum casting project.

Certifications, Quality Systems & Experience

You should check if the supplier has the right certificates and follows quality rules. Look for ISO certificates and proof of careful checks. A good supplier uses new technology and strong quality steps. They hire skilled engineers and mold experts. This helps you get vacuum casting parts that meet your needs every time.

Sample Orders and Trial Runs

Before you order a lot, ask for sample parts or a test run. This lets you see how well the supplier does vacuum casting and how fast they work. You can check the surface, size, and finish of the parts. If you like what you get, you can trust the supplier for bigger jobs. This guide helps you avoid problems and pick the best partner for your needs.

Material Options for Vacuum Casting

When you pick vacuum casting, you should learn about materials. The right material helps your parts work well. It also makes them look and feel good. You can choose from different silicone molds and resins. You can ask for special colors and finishes too.

Silicone Mold Types and Properties

There are three main silicone mold types in vacuum casting. Each type is best for certain shapes and needs. The table below shows the types and what they do:

Type of Mold | Description |

|---|---|

One-Part Molds | Good for flat objects with no undercuts. |

Two-Part Molds | Used for tricky shapes, made of two halves. |

Multi-Part Molds | Best for detailed designs, often used in factories. |

Pick the mold type that fits your part’s shape. This helps you get a smooth surface. It also makes it easy to take out your part.

Polyurethane Resin Options

Vacuum casting uses many polyurethane resins. Each resin has special features for different jobs. Here is a table to help you compare the most common options:

Material | Properties | Applications |

|---|---|---|

UPX8400 | Stretches well and flows easily. | Molds that come out easily. |

T0387 | See-through, stretches well, sets fast in 5-6 minutes. | Fast jobs that need quick curing. |

Pros | Absorbs shocks, feels nice to hold, good for seals. | Used for protection and products. |

Cons | Does not work well in high heat, not very strong. | Not good for hot places. |

Talk to your supplier about which resin is best for you. Picking the right resin is important for your project.

Color Matching & Custom Finishes

You can make your vacuum casting parts look special with colors and finishes. Here are some ways to change your parts:

Mix color into resin for solid colors.

Use special colors for clear or see-through parts.

Ask for colors that match your brand.

Add color before casting with dyes or pigments.

Mix colors or paint for custom looks.

Try UV printing for many colors or vacuum plating for shiny parts.

Pick smooth, satin, or matte surfaces.

Ask for polishing or special finishes when you order.

You can use customization vacuum casting to get the look you want. This helps your parts match your brand or style. You can always ask your supplier for help with choices.

Vacuum casting gives you lots of choices for molds, resins, and finishes. You can get strong, bendy, or clear parts. You can also pick the color and texture you need for your design.

Quality Control and Inspection Process

Setting Quality Standards

You need to set clear quality rules before you start. These rules help you get parts that fit your needs. In China, suppliers use different ways to check each part. The table below shows the main ways they check quality:

Inspection Method | Description |

|---|---|

Dimensional Accuracy Testing | Using calipers, CMM (Coordinate Measuring Machines), or 3D scanning. |

Material Property Testing | Tensile strength, hardness, and impact resistance tests. |

Surface Finish Inspection | Checking for defects like bubbles, warping, or incomplete fills. |

You should talk with your supplier about which tests are most important. This helps you stop problems before they happen.

First Article & Sample Approval

You want to make sure the first part is right before making more. The first article and sample approval process helps you do this. Here are the main steps you should follow:

Look at all drawings and details for your vacuum casting part.

Pick and get the first sample ready.

Check and measure every part of the sample.

Write down and share all results.

Find and fix any mistakes or problems.

Get everyone to agree and sign off.

This process helps you feel sure your supplier knows what you want. You can ask for changes before making lots of parts.

In-Process and Final Inspection

You should check quality while making and after making the parts. In-process inspection means checking parts as they are made. This helps you find mistakes early. Final inspection happens when all parts are done. You or your supplier should look for size, shape, and surface problems. You can ask for photos or reports to see the results. Good checks help you get the right parts every time.

Tip: Clear checks and reports help protect your project from big mistakes.

You can trust the vacuum casting process more when you set strong quality rules and follow them at every step.

Cost Factors and Pricing Transparency

Main Cost Drivers

When you start a vacuum casting project in China, you should know what makes the price go up or down. Each step in the process adds to the total cost. Here is a table that lists the main things that affect the price:

Cost Component | Description |

|---|---|

Material Costs | Includes resin material cost per part. |

Labor | Covers labor for mold preparation, de-molding, and post-processing. |

Tooling | Refers to the master pattern cost or mold cost for the first run. |

Overheads | Supplier's overheads and profit margin. |

Energy | Equipment running costs associated with the casting process. |

Order Volume | Larger orders can reduce per-unit costs. |

Supplier Reliability | Affects pricing and availability of materials. |

Material and labor are two big parts of the cost. Tooling is paid only once for the first batch. If you order more parts, each one costs less. A good supplier helps you avoid waiting and extra spending.

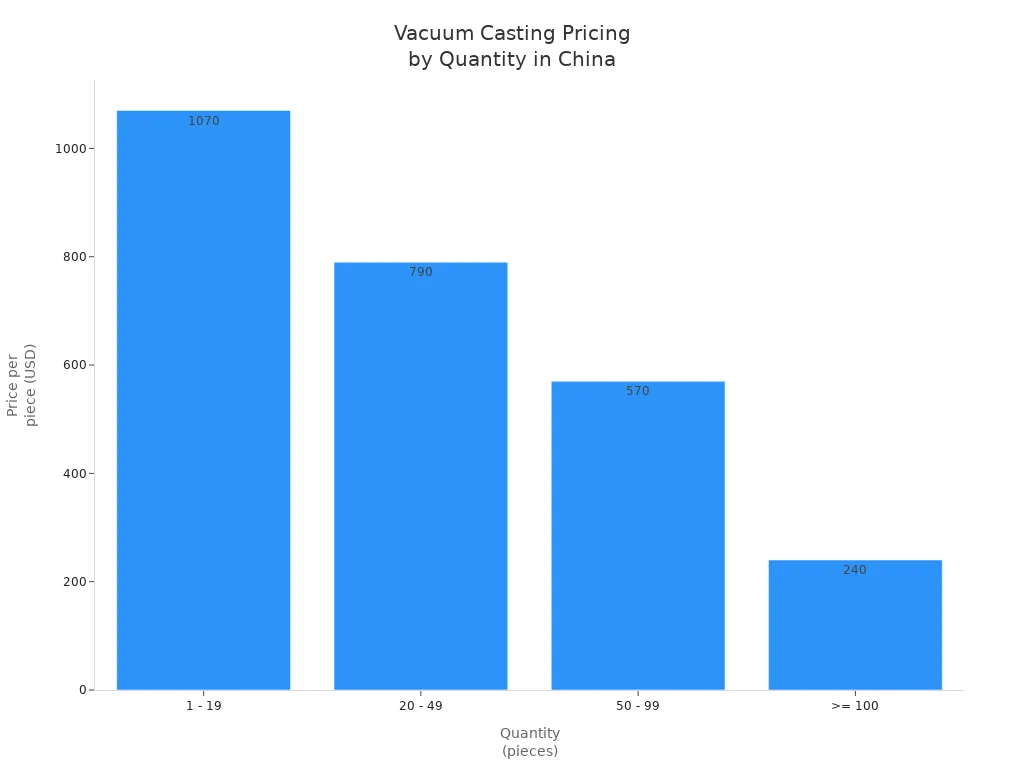

Typical Pricing Structure in China

The price for vacuum casting in China depends on how many parts you buy. Small orders cost more for each part. Big orders make each part cheaper. Here is a table that shows the usual price for each amount:

Quantity (pieces) | Price per piece |

|---|---|

1 - 19 | $1070 |

20 - 49 | $790 |

50 - 99 | $570 |

>= 100 | $240 |

You can see that buying more parts saves money. This is why vacuum casting is good for small batches. The chart below shows how the price goes down when you order more:

You can pick from different polyurethane types. Rigid polyurethane is strong and used for car parts and samples. Flexible polyurethane bends and is good for seals. These choices help you get the right part for your needs.

How to Balance Cost and Quality

You want to spend less but still get good parts. You can do this by following some easy steps. The table below gives you a plan to help:

Step | Strategy Description |

|---|---|

1 | Identify suitable suppliers through thorough research and due diligence. |

2 | Evaluate the technical capabilities of the supplier, including quality assurance processes. |

3 | Discuss and finalize project details, including specifications and costs. |

4 | Request sample production for quality assessment before full production. |

Always check if the supplier has experience and ask for samples. Talk clearly to avoid mistakes. Good planning helps you save time and get the best results from vacuum casting. If you follow these steps, you get good parts for a fair price.

Communication and Project Management Tips

Overcoming Language and Time Zone Barriers

If you work with a company in China, you might have trouble with language and time zones. You can fix these problems by using smart tools and planning well. Many buyers use different ways to keep their projects running smoothly. The table below shows some good ways to talk with your team:

Method | Description |

|---|---|

Create a Communication Schedule | Pick times and dates for updates and meetings. |

Use World Clock Tools | Check time differences to plan calls and emails. |

Overlap Hours | Find times when both teams are working to talk live. |

Online Scheduling Tools | Use apps to set up meetings in different time zones. |

You can also use special translation tools like Gleen AI for live chats. These tools help you understand hard words in vacuum casting. Giving your team language lessons can make talks easier. If you plan ahead, you will not get confused or have delays.

Tip: Always check meeting times in both time zones so no one misses a call.

Tracking Production Progress

You need to know how your vacuum casting project is going. Good tracking helps you find problems early and keeps things on time. Ask your supplier to send updates with photos or videos of each step. Many buyers use project tools to watch tasks and deadlines. You can ask your supplier for a simple checklist. This list should show each step, like mold making, casting, and checking parts.

Make clear goals for each part of the vacuum casting job.

Ask for weekly reports about progress.

Use shared online folders for files and feedback.

Plan short calls to talk about any problems.

When you watch progress closely, you get better results from your vacuum casting supplier. You can fix small problems before they get bigger. This way saves you time and money.

Common Risks and How to Avoid Them ⭐⭐⭐

Specification and Communication Errors

Problems can happen if you do not give clear details. In vacuum casting, mistakes often come from missing information or unclear drawings. You can stop these errors by doing a few things. Share full drawings and clear part details. Work with a team that answers fast. Set up regular updates to check progress. This helps you solve problems early. Use checks like CMM or laser scanning to match your master model. Check resin thickness and mix ratios during production. Build strong quality control steps for every part of the job.

Tip: Talking clearly helps you get the vacuum casting parts you want.

Quality Consistency Issues

You want every vacuum casting part to look and work the same way. Sometimes, parts may change in color, shape, or finish. These problems happen if the supplier skips steps or does not check well. Ask for checks during and after making the parts. Make sure the supplier tests each batch for size and surface finish. Ask for photos or reports to see results. You can also ask for a sample before making many parts. This helps you find mistakes early and keep quality steady.

Step | Action |

|---|---|

In-process checks | Inspect resin mix and curing |

Dimensional checks | Use CMM or laser scanning |

Final inspection | Review surface and details |

Payment Terms and Shipping Risks

You need to know payment and shipping rules before you order. Most suppliers use a 30/70 TT payment plan. You pay 30% before making starts and 70% before shipping. This can be risky if you do not check quality before the last payment. Ask for sample approval and inspection reports before sending the final payment. Shipping can take longer because of distance and customs checks. Delays may happen if paperwork is wrong or customs holds your shipment. Plan for extra time and ask your supplier for tracking updates.

Shipping takes longer because it is far away.

Customs can slow down delivery.

It is hard to check quality from far away.

Note: Careful planning and clear payment rules help you avoid problems with vacuum casting orders from China.

Conclusion – Is Outsourcing Vacuum Casting to China Right for You?

You have learned a lot about vacuum casting in this vacuum casting china guide. Now, you need to decide if this process fits your project. Vacuum casting gives you fast results and high-quality parts. You can use it for prototypes or small batches. Many industries trust vacuum casting for its speed and cost savings.

Think about your needs. If you want to test a new design or show a sample to customers, vacuum casting works well. You do not need to spend much money on tools. You can get parts with smooth surfaces and fine details. You can also choose from many materials and colors.

Here is a quick checklist to help you decide:

Do you need 1 to 200 parts quickly?

Do you want to save money on prototypes?

Do you need parts with complex shapes?

Do you want to test your design before mass production?

Do you need flexible material choices?

If you answered yes to most questions, vacuum casting is a smart choice for you.

Note: Always follow the steps in this guide to avoid mistakes and get the best results.

You should also check your supplier’s skills and quality control. Good planning helps you avoid risks. Use this guide to make smart choices and get the parts you need.

Decision Point | Yes | No |

|---|---|---|

Need fast prototypes? | ✅ | |

Small batch needed? | ✅ | |

Cost is important? | ✅ |

Vacuum casting can help you reach your goals. Use the tips in this guide to make your project a success.

FAQ – Vacuum Casting in China

1. What is vacuum casting and why do companies use it?

Vacuum casting is a process that uses silicone molds to make plastic or rubber parts. You can use it for prototypes or small batches. Companies choose vacuum casting because it gives smooth surfaces and fine details. You do not need to buy expensive tools.

2. How many parts can you make with one silicone mold?

You can usually make 15 to 25 parts from one silicone mold. The number depends on the part shape and the material you use.

3. How long does vacuum casting take in China?

Most suppliers finish vacuum casting in 7 to 15 days. You get your parts faster if you send clear drawings and details.

4. What materials can you use for vacuum casting?

You can pick from many polyurethane resins. Some resins are hard, some are soft, and some are clear. You can also ask for special colors or finishes.

5. How do you make sure the quality is good?

You should ask for sample parts before full production. You can check the size, surface, and color. Good suppliers use tests like CMM or 3D scanning to check each part.

Tip: Always use the vacuum casting china guide to help you plan your project and avoid mistakes.

6. Is vacuum casting good for large orders?

Vacuum casting works best for small batches. If you need more than 200 parts, you should look at other methods like injection molding.

7. Can you use vacuum casting for final products?

Yes, you can use vacuum casting for end-use parts. Many companies use it for covers, buttons, and test samples.

Question | Short Answer |

|---|---|

Lead time | 7–15 days |

Mold life | 15–25 parts |

Best for | Prototypes, small batches |

If you have more questions about vacuum casting, talk to your supplier. You can get better results when you ask for details and check every step.

You can do well with vacuum casting in China if you follow easy steps. First, think about what you need for your project. Next, make sure your designs and drawings are good. Pick suppliers you trust and check if they have the right skills. Make rules for quality and look at every part to see if it is made well.

Use the vacuum casting china guide to help you make good choices. This guide helps you not make mistakes and get the best results from vacuum casting.

LKprototype

LKprototype