Image Source: pexels Choosing the right CNC machining prototype service is very important. It can greatly affect how successful your prototyping process is. The global market for these services is growing fast. It is expected to increase from $10.5 billion in 2023 to $25.7 billion by 2032. This shows that more people want quick and reliable solutions. Working with a good CNC machining prototype service gives you access to accurate tools. You also get skilled workers who make high-quality prototypes. This helps save both time and money. Whether you need one prototype or many, a trusted CNC machining prototype service…

Image Source: unsplash Accuracy and speed are very important when working with bronze. This metal is strong, resists rust, and conducts heat well. These traits make it great for making tough parts. However, cutting bronze requires careful work to achieve good results. CNC machining bronze helps cut this material with high accuracy and detail. It utilizes automated steps and smart cutting settings to save material and maintain consistent quality. Whether creating machine parts or art pieces, CNC machining bronze is a dependable method for working with this versatile metal. Key Takeaways Pick the right bronze type for your project. Each…

Looking to restore your brass to its original shine quickly and effectively? This guide will show you how to polish brass metal using common household items and simple techniques. Get ready to make your brass shine again. Key Takeaways Identify whether your brass item is solid or plated before cleaning to choose the right method.Effective cleaning methods include natural solutions like lemon juice and baking soda, toothpaste, and even ketchup, each with specific techniques for application and rinsing.Regular maintenance is key; high-use brass items should be cleaned monthly, while decorative pieces can be cleaned annually. Determine if Your Brass is…

Searching for metal fab parts means you need information on how these parts are made, the materials used, and the different types available. This article covers the essential processes in metal fabrication, the most common types of metal fab parts, material options, and finishing techniques. Understanding these aspects will help you choose the right parts for your project. Key Takeaways Metal fabrication involves processes like cutting, bending, and welding to create durable and customized metal parts for various industries. Understanding the properties of materials like steel, aluminum, and specialty metals is crucial for selecting the right components to ensure optimal…

5-axis CNC machining services enable the creation of complex parts with high precision using advanced technology. This article explains what 5-axis machining is, why it’s beneficial, and what you should expect from these services. Key Takeaways 5-axis CNC machining offers superior precision and efficiency, enabling the production of intricate geometries and complex parts with fewer setups. The technology supports a wide variety of materials, including metals and plastics, making it versatile for applications across industries such as aerospace, automotive, and medical. Choosing a reliable 5-axis CNC machining service provider involves evaluating experience, customer satisfaction, and scalability to meet business production…

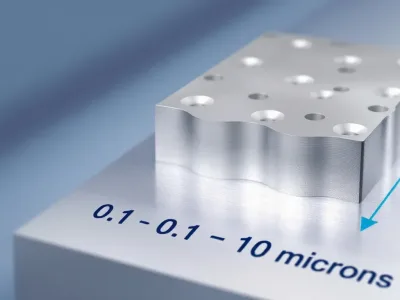

RMS surface finish quantifies the smoothness of a surface’s microscopic peaks and valleys. A lower RMS value indicates a smoother and higher-quality surface. This article explains what RMS surface finish is, its importance, and how to measure it. Key Takeaways RMS surface finish is a crucial measure of surface quality in manufacturing. It indicates smoother surfaces with lower roughness values compared to other metrics. Calculating RMS involves determining the square root of the average of the squared deviations from mean profile height. This offers a detailed analysis of surface texture. Various contact and non-contact methods exist for measuring RMS surface…

Precision CNC machined components are essential in creating parts with high accuracy and quality. Key industries such as automotive, aerospace, and medical rely on them. This article explores their importance, the machines and materials used, and their benefits and applications. Key Takeaways CNC precision machining transforms raw materials into high-quality components with exceptional accuracy, vital for industries like automotive, aerospace, and medical. Various specialized CNC machines, including milling machines, lathes, and EDMs, are used to achieve tighter tolerances and meet diverse manufacturing needs. Precision CNC machining offers multiple advantages, including enhanced accuracy, cost efficiency, and flexibility, making it a preferred…

Bronze machining is the process of cutting and shaping bronze alloys, crucial for its corrosion resistance and machinability. This guide covers why bronze is preferred over other materials, the main types of bronze alloys, and key machining techniques for high-quality results. Key Takeaways Bronze machining offers high corrosion resistance, wear resistance, and strength, making it ideal for precision components in various industries. Selecting the appropriate bronze alloy and machining technique is crucial for optimizing performance and achieving desired outcomes in CNC machining. Implementing best practices and rigorous quality control measures enhances the efficiency and reliability of bronze machining projects. Understanding…

Want to build a CNC machine? This guide to CNC DIY parts covers everything you need, including mechanical components, electronic systems, and more. Find out how to choose the best parts for a reliable and precise machine. Key Takeaways Mechanical components, including frames, axis drives, and ways, are essential for building a reliable and efficient CNC machine. The integration of electronic systems, such as CNC controllers and microcontrollers, is crucial for ensuring precise machine operation and performance. DIY CNC kits vary in complexity and customization, providing options for all skill levels, from beginners to experienced enthusiasts. need help? Contact Us: [email protected] Need…

Seeking a trustworthy manufacturer for CNC turned parts? This guide explores top industry players, showcasing their abilities, services, and distinctive features. It covers everything from custom machining to components of high precision, providing you with the finest selections tailored to your unique requirements. Key Takeaways Leading manufacturers in CNC turning, such as Yijin Hardware and Pioneer Service, prioritize quality and precision, establishing themselves in various industries. CNC turning offers benefits including high precision, consistency, and cost efficiency, making it essential for sectors like automotive, aerospace, and medical devices. The CNC turning process includes crucial steps like setup, machining operations, and…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.