You can lower your rapid prototype machining cost by picking China for your projects. Manufacturers in China pay less for raw materials and labor. They also have many skilled workers. These things make rapid prototyping cheaper than in other places. Machining companies in China use new technology like CNC and 3D printing. This helps them make prototypes faster and for less money. They work quickly and can handle different order sizes. This saves you time and money. Many companies say they pay up to 61% less for rapid prototype machining in China because of these benefits.

Key Takeaways

Picking China for rapid prototype machining can help you save money. You can save up to 61% because labor and materials cost less. - China uses advanced CNC machines and 3D printing. These tools make things faster and help finish your project sooner. - If you order more parts at once, each part costs less. This is because setup and material costs are shared over more pieces. - Choose suppliers who have good quality control and clear prices. They should also know your industry well. This helps you avoid extra costs and delays. - Keep your designs safe by using NDAs and registering patents. Work with suppliers who respect intellectual property.

Rapid Prototype Machining Cost in China

Material and Labor Cost

You can save a lot on rapid prototype machining cost in China. Factories pay less for raw materials because they have good supply chains and local sources. This helps you keep your project budget low.

Labor costs in China are much lower than in the West. Skilled machining work usually costs $8 to $30 per hour. If your project is very complex, it can go up to $50 per hour. In the USA or Europe, these rates are much higher. Lower labor costs mean you spend less at every step.

Here is a quick comparison:

Aspect | Details |

|---|---|

Average Hourly Labor Rates | $8 to $30 per hour (typical), up to $50 for complex work |

Influencing Factors | Material type, project complexity, machine type, skill level, production volume |

Comparison to Global Averages | Much lower than USA/Europe due to lower labor and overhead costs |

Quality and Lead Time | May vary; Western countries often have stricter quality control and longer lead times |

Competitive Advantage | China offers cost-effective pricing, especially for bulk and complex projects |

Tip: To save money, pick Chinese suppliers who know your material and project type. This helps you avoid extra costs and delays.

Machine and Technology Cost

China uses advanced CNC machines and rapid prototyping technology. These machines work fast and are very accurate. This lowers your machining cost. You can find many types of CNC machines in China. Some are basic 3-axis mills, while others are advanced 5-axis systems. The cost depends on your project’s type and how hard it is.

CNC Machine Type | Hourly Cost Range (USD) | Starting Cost for Rapid Prototyping (USD) |

|---|---|---|

3-axis CNC Milling | 20 - 30 | As low as 100 |

3-axis CNC Turning | Around 20 | As low as 100 |

4-axis or 5-axis CNC Milling | 35 - 50 or higher | As low as 100 |

New technology in China, like 3D printing and advanced CNC machining, has changed rapid prototype manufacturing. These technologies help you make prototypes faster and cheaper. You do not need expensive tools. You can get working parts in days, not weeks. This makes rapid prototyping cheaper and helps you launch products faster.

CNC machining cost in China stays low because factories use automation and skilled workers. They make their work steps better, so you pay less for each prototype. When you use rapid prototype manufacturing in China, you get both good technology and experience.

Order Size Impact

Order size changes rapid prototype machining cost a lot. If you order only one or two prototypes, the price for each part is high. This is because setup and programming costs stay the same, no matter how many parts you make. If you order more, these costs are shared, so the price per part goes down.

Batch Size | Cost per Square Meter (USD) | Minimum Cost (USD) | Assembly Labor Cost (RMB/hour) | Packaging Labor Cost (RMB/hour) | Scrap Material Cost (% of material) |

|---|---|---|---|---|---|

Large Batch | 1.5 | 0.1 | 10 | 13 | 2% - 5% |

Medium Batch | 2.0 | 0.15 | 15 | 15 | N/A |

Small Batch | 2.5 | 0.3 | 18 | 18 | N/A |

Most rapid prototyping orders in China are small, usually between 1 and 20 pieces. There is no strict minimum order, but small orders mean higher costs for each part. This is because you pay for setup, special materials, and extra labor for each part. If you order more units, your average machining cost drops a lot.

Small orders: Each part costs more because of setup and material waste.

Large orders: Each part costs less because fixed costs are shared.

When you plan your rapid prototype manufacturing project, think about how many parts you need. Ordering more can help you save money and get better value from your supplier.

Cost Comparison: China vs. Other Regions

If you want to save money, you should compare rapid prototype machining costs in China and other places. A price comparison helps you see how much you can save. Many companies look at these numbers before picking where to make their prototypes. This information helps you make good choices for your project.

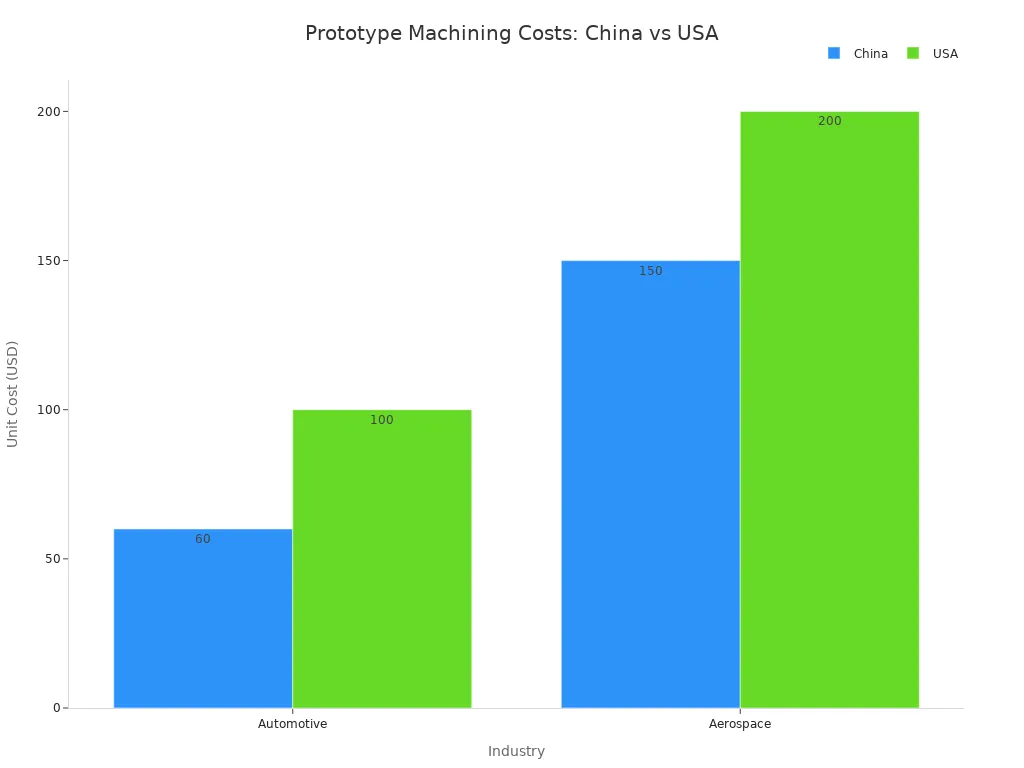

Cost Table

The table below shows how much it costs in China and the USA. You can see the unit cost, lead time, and quality certifications for different industries. This makes it easy to compare rapid prototype machining in each place.

Industry | Location | Unit Cost (USD) | Lead Time | Quality Certifications |

|---|---|---|---|---|

Automotive | China | $60 | 3 weeks | IATF 16949, ISO 9001 |

Automotive | USA | $100 | 6 weeks | High quality control |

Aerospace | China | $150 | 5 weeks | Advanced 5-axis equipment |

Aerospace | USA | $200 | 8 weeks | Leading aerospace technology |

Medical Device | China | 50% lower cost than US (exact $ N/A) | 1 week | FDA certified |

Medical Device | USA | High cost (exact $ N/A) | 3 weeks | High quality, reputable |

You can also look at the chart. It shows the unit cost for automotive and aerospace machining in China and the USA.

When you check the numbers, you see that China’s machining cost is about 25% to 50% of the USA’s cost. This means you can save a lot by picking Chinese suppliers. The savings are even bigger for big orders or hard CNC parts.

Key Differences

It is important to know why the prices are so different. The main reason is the cost structure in each country. Labor is much cheaper in China. Skilled CNC machinists in China get about $5–7 per hour. In the USA, machinists get over $25 per hour. This big difference in pay changes the final machining cost.

Factories in China also pay less for raw materials. They have strong supply chains and buy a lot at once. This keeps CNC machining prices low. In the USA, raw materials cost more, and factories are smaller. They cannot get the same discounts as big Chinese factories.

CNC machine costs matter too. In the USA, a basic CNC machine like a Haas costs at least $30,000. Factories add this cost to every part they make. In China, machines and maintenance cost less. This helps keep your machining cost down.

Here is a table that shows the main cost differences:

Cost Factor | China CNC Machining | US CNC Machining |

|---|---|---|

Labor Costs | Significantly lower (up to 70% less); skilled machinists at $5–7/hour | Much higher labor costs (often > $25/hour) |

Economies of Scale | Large-scale factories improve cost efficiency | Smaller scale, less bulk purchasing power |

Raw Material Sourcing | Abundant, competitively priced raw materials | Higher raw material costs |

Equipment and Machinery | Lower equipment amortization costs | Higher equipment costs (e.g., Haas machines start at $30,000) and maintenance costs |

Quality Control | Potentially less stringent tolerance controls | Strict quality control and professionalism |

Intellectual Property (IP) Protection | Less robust IP protection | Strong IP protection due to legal framework |

Compliance and Certification | Less strict regulatory compliance | Adheres to strict industry certifications and standards |

Turnaround Time | Fast production cycles and timely delivery | Longer lead times but higher precision |

Transportation Costs | Higher for overseas clients | Lower for North American customers |

Rapid prototype machining in China is also 30-50% cheaper than in Europe. Many companies say their CNC machining cost in China is about half the price of the USA or Europe. This is true for both simple and complex CNC projects.

Note: China has lower prices, but you should check quality, communication, and intellectual property protection. Always check your supplier’s certifications and ask for samples before making a big order.

This cost comparison shows why many companies pick China for rapid prototype machining. You get lower prices, faster delivery, and advanced CNC technology. When you use this information, you can make the best choice for your project and budget.

Rapid Prototyping Lead Time in China

Production Speed

If you want your prototypes fast, China is a good choice. Factories in China work quickly because they use advanced machines. Skilled workers help keep projects moving. Most projects start just a few days after you approve the design.

Many things can change how fast you get your prototypes:

Skilled workers in China help make parts quickly and correctly.

Quality control checks take extra time but make sure your prototypes are good.

The material you pick matters. Some materials are easy to find in China, so you get them fast. Special materials can take longer to get.

If your design is simple, it moves through rapid prototyping faster. Complex parts need more setup and checking, so they take longer.

The number of parts you order also changes how long it takes. Small orders are finished faster. Large orders need more time.

Here is a table that shows how long each step usually takes in China:

Stage | Average Time Needed |

|---|---|

Sourcing & Negotiation | About 3 weeks |

Tooling | Around 45 days |

Sampling | Few weeks to months |

Production & QC | Varies by project |

Shipping | 10 to 40 days |

Some suppliers in China can make your prototypes even faster if you pay more. This rush service can help you get your parts sooner, but it costs extra.

Tip: Pick a supplier that does both fabrication and assembly in-house. This can make your rapid prototyping project go faster and help you finish on time.

Shipping and Logistics

After your prototypes are made, you need them delivered fast. China has many shipping choices for rapid prototyping. Air freight is the quickest way. You can get your prototypes from China to Europe in 3-4 days. It takes 4-5 days to North America. This helps you test and fix your designs without waiting too long.

You should know some common shipping terms:

Ex Works (EXW): You take care of shipping and customs after the prototypes leave the factory.

Delivered Duty Unpaid (DDU): You pay import duties when the prototypes arrive.

Shipping times can change if it is a busy season or if something big happens in the world. Always plan for possible delays. Most rapid prototyping suppliers in China know how to ship worldwide. They can help you pick the best shipping for your time and budget.

Note: Fast shipping from China helps you move ahead in product development. Quick delivery lets you test, change, and launch your products before others.

Maximize Cost Savings

Supplier Selection

You can save money if you pick the right supplier in China. Look for companies that check quality during production. Good suppliers use special machines to measure parts and check for mistakes. They also use process control to keep things running smoothly. These steps help stop defects and extra costs. Pick suppliers who have worked in your industry before. They understand your needs and fix problems fast. Always ask for a clear price quote. A good supplier will show you the cost for material, cnc machine time, labor, and overhead. This makes it easy to compare prices and spot hidden fees.

Here are some key things to look for:

Quality checks during production

Experience and a good name in your industry

Clear prices and detailed quotes

Fast work and enough machines for your order

Helpful customer service and easy communication

Knowledge about picking the right materials

Suppliers in China who do these things can help you get good prices and quality for your rapid prototyping project.

Design Optimization

You can pay less for cnc machining if you design smart parts. Simple shapes need fewer steps to make. This means each part costs less. Use standard parts when you can. This stops you from needing special tools and keeps costs low. Pick materials that are easy to machine but still strong enough. Try to design parts that need fewer setups on the cnc machine. This saves both time and money.

Follow these tips to make your design better:

Make shapes simple and less complex.

Use standard sizes and parts.

Pick materials that cost less but work well.

Cut down on the number of cnc machine setups.

Use bigger fillets so cutting is faster.

Only set tight tolerances if you really need them.

Plan to make more parts at once if you can.

Talk with your supplier in China early. They can help you find more ways to save money on rapid prototyping.

Bulk Orders

Ordering more prototypes at once can make each part cheaper. In China, buying more raw materials at once can lower the cost per part by 10-15%. This works best if raw materials are a big part of your total cost. But rapid prototyping often uses small batches, so savings from bulk orders may not be huge. Still, if you want to test many designs or need several prototypes, ask your supplier in China about bulk discounts. This can help you get a better price and make your project cost less.

Tip: Always check prices for different order sizes. Sometimes, ordering just a few more parts can save you a lot on cnc machining and rapid prototyping.

Quality and Risk in Rapid Prototyping

Quality Control

You want your rapid prototyping project to be high quality. In China, suppliers use many steps to make sure of this. They follow rules like ISO 9001:2015 and IATF 16949:2016. There are strict checks at every step. Factories in China check all materials before they start making parts. They use First Article Inspection and In-Process Quality Control to find problems early. Before shipping, they do Final Quality Control and Outgoing Quality Control.

Factories use special tools like Coordinate Measuring Machines, XRF analyzers, and micrometers. They keep their machines and tools checked and working well. You get inspection reports and certificates with your order. If something is wrong, many suppliers in China will fix it or give you a refund.

Some common problems are using the wrong material or machine errors. To fix these, suppliers in China test materials, train workers, and check machines often. They also check parts at many steps and give you detailed reports.

Communication

Good communication helps stop mistakes in rapid prototyping. Many suppliers in China now have project managers who speak English. This makes it easier to share your needs and get updates. Some big companies in China even have offices in the USA to help you.

You should pick suppliers who reply fast and give updates often. You can send clear drawings to avoid mistakes in translation. Building a good relationship with your supplier in China helps your project go well.

Here are some tips for better communication:

Pick suppliers who speak English well.

Send clear technical drawings.

Talk about shipping and payment early.

Sign NDAs to keep your ideas safe.

IP Protection

It is important to protect your ideas in rapid prototyping, especially with suppliers in China. You should register your designs and patents in your country and in China before sharing them. Make strong NDAs in both English and Chinese. Good suppliers in China will sign these and follow the rules.

You can also register trademarks and copyrights in China to protect your brand. Many companies in the USA use law firms in China to help with patents and design rights. You should ask your supplier about their IP rules and make sure all workers sign IP papers.

China’s laws now help protect IP, but you must act early. Use contracts, NDAs, and check often to keep your ideas safe during prototyping.

Tip: Always work with suppliers in China who have a good record of protecting customer IP. This helps you avoid problems and lets you focus on getting the best quality from your rapid prototyping project.

You can save time and money by picking rapid prototype machining in China. Labor and material cost less there. China uses new technology and has good supply chains. This makes it a great place for prototyping.

Many companies save a lot, like paying $6,800 for a mold in China instead of $19,000 somewhere else.

One-stop services and quick delivery help you get your product out fast.

Factories in China have many materials and check quality well.

To get the best results:

Look at quotes from different suppliers in China.

Give clear design files and needs.

Check if the supplier has good experience and reviews.

Use contracts to keep your ideas safe.

Reach out to trusted suppliers in China for quotes and lead times. Careful planning and smart choices help you avoid problems and make your project a success.

FAQ

What is the typical lead time for rapid prototype machining in China?

Most prototypes from China are finished in 1 to 3 weeks. If your part is complex or needs special materials, it might take longer. Always ask your supplier for a clear schedule before starting.

How do you ensure quality when working with Chinese suppliers?

Check if your supplier has ISO certifications. Ask them for inspection reports and sample parts. Good suppliers will explain their quality checks and give you updates during production.

Are there hidden costs in rapid prototype machining quotes?

Sometimes, quotes do not include shipping, taxes, or extra finishing. Always ask for a full price list. This helps you avoid surprise costs and plan your budget better.

Can you protect your design and intellectual property in China?

You can keep your ideas safe by signing NDAs and registering your designs in China. Pick suppliers who have a good record of IP protection. Always keep your documents safe and easy to find.

LKprototype

LKprototype