Choosing the right prototype tooling plastics is essential for efficient and cost-effective prototype production. This guide covers the top methods and materials to help you create high-quality prototypes quickly, including 3D printing, CNC machining, and injection molding. Key Takeaways Prototype tooling plastics enable rapid and cost-effective production of prototypes, facilitating early design validation and testing.Key methods for creating prototype tooling include 3D printing, CNC machining, and injection molding, each offering unique benefits for different prototyping needs.The benefits of using prototype tooling plastics include faster time to market, significant cost savings, and improved design validation, making them essential in various industries.…

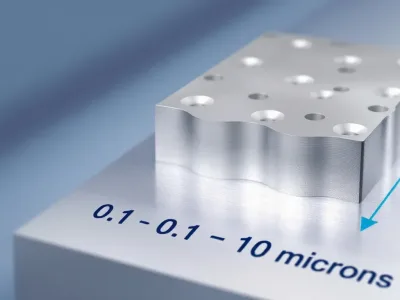

RMS surface finish quantifies the smoothness of a surface’s microscopic peaks and valleys. A lower RMS value indicates a smoother and higher-quality surface. This article explains what RMS surface finish is, its importance, and how to measure it. Key Takeaways RMS surface finish is a crucial measure of surface quality in manufacturing. It indicates smoother surfaces with lower roughness values compared to other metrics. Calculating RMS involves determining the square root of the average of the squared deviations from mean profile height. This offers a detailed analysis of surface texture. Various contact and non-contact methods exist for measuring RMS surface…

Precision CNC machined components are essential in creating parts with high accuracy and quality. Key industries such as automotive, aerospace, and medical rely on them. This article explores their importance, the machines and materials used, and their benefits and applications. Key Takeaways CNC precision machining transforms raw materials into high-quality components with exceptional accuracy, vital for industries like automotive, aerospace, and medical. Various specialized CNC machines, including milling machines, lathes, and EDMs, are used to achieve tighter tolerances and meet diverse manufacturing needs. Precision CNC machining offers multiple advantages, including enhanced accuracy, cost efficiency, and flexibility, making it a preferred…

Bronze machining is the process of cutting and shaping bronze alloys, crucial for its corrosion resistance and machinability. This guide covers why bronze is preferred over other materials, the main types of bronze alloys, and key machining techniques for high-quality results. Key Takeaways Bronze machining offers high corrosion resistance, wear resistance, and strength, making it ideal for precision components in various industries. Selecting the appropriate bronze alloy and machining technique is crucial for optimizing performance and achieving desired outcomes in CNC machining. Implementing best practices and rigorous quality control measures enhances the efficiency and reliability of bronze machining projects. Understanding…

CNC machining products are essential in automotive, aerospace, electronics, and healthcare industries. They are also crucial in the defense industry for producing weapons, ammunition, and military vehicles, as well as in the marine industry for creating durable, corrosion-resistant parts for vessels. These parts offer unparalleled precision and consistency. This article explores the key CNC machined components and their diverse applications. Key Takeaways CNC machining enhances efficiency, precision, and consistency in producing critical components across industries such as automotive, aerospace, electronics, healthcare, defense industry, and marine industry. The technology supports a wide range of materials, including metals and plastics, allowing manufacturers…

Medical device prototyping involves creating early models of medical devices to test, refine, and perfect designs before mass production. By quickly identifying and resolving design flaws, prototyping ensures that the final product is safe, effective, and meets regulatory standards. In this article, we will explore the key stages and advanced techniques of medical device prototyping, offering insights for anyone involved in the development of innovative medical technologies. Key Takeaways Medical device prototyping is essential for transforming concepts into functional products, allowing for early design validation and risk reduction.The prototyping process involves key stages such as conceptualization, material selection, and iterative…

Before electronic devices enter mass production, innovators develop prototypes as initial models to examine and improve their concepts. This crucial stage allows for the testing and perfecting of design details. It helps to confirm functionality, reduce potential risks, and certify that product standards are met. By having the devices prototyped, it becomes possible to determine cost-efficiency and identify potential defects early. Consequently, this helps prevent higher expenses during manufacturing. We will delve into the fundamental phases of electronic prototyping in this article and provide valuable advice for efficiently advancing your projects. Key Takeaways Electronic prototyping validates design and functionality, minimizing…

Prototyping manufacturing helps you develop products efficiently. You create early test versions to spot and fix issues, saving time and money before mass production. This article explores best practices and techniques in prototyping manufacturing. Key Takeaways Prototyping manufacturing is essential for identifying design flaws early, reducing risks, and accelerating product development. The selection of the right prototyping method and materials significantly impacts the functionality, cost, speed of the product development process. Emerging trends, including advanced materials and automation, are enhancing prototyping efficiency and enabling the development of complex, high-quality prototypes. What is Prototypeing Manufacturing? Manufacturing prototypes involves the creation of…

Curious about how silicone prototypes can enhance your product development? Silicone prototypes provide a quick and precise way to test and refine designs. This article covers the main techniques for creating silicone prototypes and their benefits, helping you make informed decisions for your projects. Key Takeaways Silicone rapid prototyping accelerates product development, significantly reducing time to market with over 95% accuracy. Key techniques such as LSR molding, compression molding, and RTV silicone casting each offer unique advantages for various prototype needs. Selecting the appropriate silicone grade is essential for performance and safety, with factors like budget, application environment, and durability…

Curious about how iPhone prototypes shape the final product? This article gives you an exclusive look at rare iPhone prototypes, revealing how Apple’s secretive testing processes influence the features and design of their iconic devices, including the iPhone prototype. Key Takeaways Apple’s iPhone prototypes have evolved significantly, reflecting a continuous pursuit of innovation that shapes the design and functionality of final products. The prototyping process involves meticulous stages of design, including the use of silicone molds and CNC technology, which ensure high precision and quality. Recent trends in iPhone prototyping include the use of advanced materials and the integration of…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.