Choosing the right metal CNC machine is very important today. It helps make products the same every time with fewer mistakes. These machines use computers to follow exact instructions. They can work nonstop, making things faster and producing more items. They also save materials, which lowers costs and increases profits. Picking a machine that fits your needs gives better results. This choice improves work speed and helps you reach your goals easily.

Key Takeaways

Picking the right metal CNC machine makes work faster and better. It helps you reach your production goals easily.

CNC machines, like milling, lathes, or laser cutters, do different jobs. Know what you need to choose the right one.

Taking care of your CNC machine is very important. It stops big problems and keeps it working well.

Think about the machine's size, how much it can do, and its price. Make sure it fits your space and work needs.

Easy-to-use software and controls make work smoother. Check if the CNC machine works well with your current systems.

Types of Metal CNC Machines

Metal CNC machines come in different types. Each type is made for specific jobs and works with great accuracy. Knowing these types helps you pick the best one for your needs.

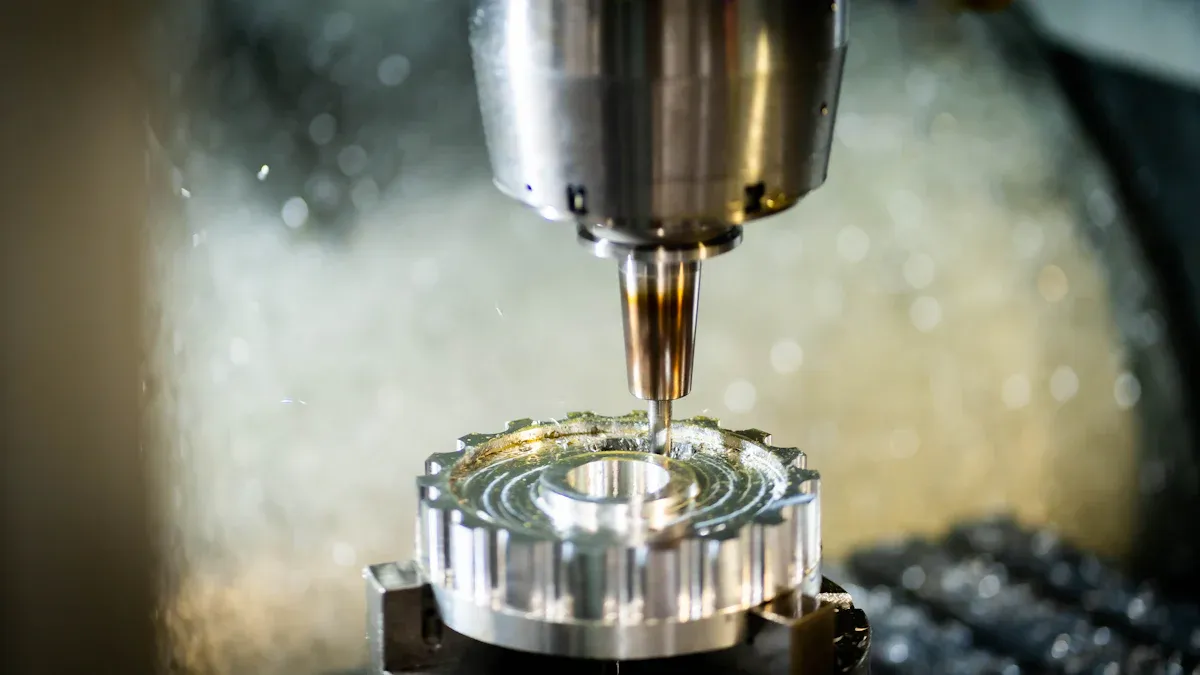

CNC Milling Machines

CNC milling machines are flexible tools. They cut and shape metal by spinning a cutting tool against a still workpiece. These machines are great for making detailed parts with high accuracy. You can use them for drilling, cutting slots, or shaping edges. Industries like aerospace and car-making depend on CNC milling machines for their precision.

🛠 Did You Know? CNC milling machines ensure exact results by following programmed paths.

What It Means | |

|---|---|

Geometric Accuracy | Checks how well the machine's parts are designed and aligned. |

Positioning Accuracy | Measures how correctly the tool is placed. |

Interpolation Accuracy | Tests how closely the machine follows the programmed design. |

Volumetric Accuracy | Looks at how much the tool's position varies in the workspace. |

These machines make sure every part looks the same. This is perfect for making many items quickly. They also save time by automating tasks and improving efficiency.

CNC Lathes

CNC lathes spin a workpiece while a cutting tool shapes it. They are great for making round parts like bolts, shafts, and bushings. These machines give smooth finishes and precise results, which are important for industries like car-making and medical tools.

Metric | Improvement |

|---|---|

Less unplanned downtime | |

Less time spent on-site | Up to 75% |

CNC lathes help reduce delays and boost productivity. Their automated systems make parts faster without losing accuracy. This makes them a smart choice for both small and big production needs.

CNC Plasma Cutters

CNC plasma cutters use super-hot plasma to cut metal. They are best for cutting thick metal sheets with precision. These machines are often used in construction and custom metal work.

Evidence Type | What It Does |

|---|---|

Precision | Keeps quality consistent and reduces wasted material. |

Efficiency | Cooling systems stop overheating and make machines last longer. |

Sustainability | Eco-friendly features lower harmful emissions. |

Metric | Benefit |

|---|---|

Cutting Speed | Faster cutting saves time and labor costs. |

Energy Consumption | Energy-saving models use less power but still perform well. |

Waste Reduction | Better cutting paths mean less wasted material. |

CNC plasma cutters are fast and eco-friendly. They save time, materials, and energy while meeting green standards. Regular care keeps them working well and lowers repair costs.

CNC Laser Cutters

CNC laser cutters use a strong laser beam to cut or engrave metal with great accuracy. These machines are perfect for making detailed designs. They are often used in industries like aerospace, medical, and custom metalwork. They are great for jobs needing high precision and less material waste.

💡 Tip: Laser cutting works best for thin materials and detailed designs.

Performance Indicator | Laser Cutting | CNC Cutting |

|---|---|---|

Speed | Up to 400 inches/min | |

Precision | ±0.001 inches | ±0.0005 inches |

Repeatability | ±0.0005 inches | ±0.0002 inches |

Laser cutting is very precise, with tolerances as small as 0.003mm to 0.006mm. This level of detail is important for things like medical tools and airplane parts. Even tiny mistakes can cause big problems in these fields. Laser cutters also reduce waste, making them a good eco-friendly option for manufacturers.

Advantages of CNC Laser Cutters:

Great for detailed designs and quick setups.

Cuts precisely, leaving little waste.

Best for thin materials and engraving.

If your project needs complex designs or tight accuracy, CNC laser cutters can deliver fast and reliable results.

CNC Grinding Machines

CNC grinding machines are used to make smooth surfaces and precise shapes in metalworking. They use grinding wheels to remove material, ensuring accuracy and a fine finish. These machines are common in industries like car-making and aerospace, where high-quality parts are needed.

Car and airplane industries use grinding machines for parts like engine casings and turbine blades. These parts need to be very accurate and smooth, which grinding machines can achieve. They also make rollers and cylinders with exact measurements, ensuring they work well in different uses.

🛠 Note: Grinding machines are important for industries needing smooth surfaces and tight accuracy.

CNC grinding machines are now essential because they meet the need for complex parts. They use advanced technology and special grinding features, making them a dependable choice for manufacturers aiming for high standards.

CNC Waterjet Cutters

CNC waterjet cutters use high-pressure water, sometimes mixed with abrasives, to cut metal and other materials. This process doesn’t use heat, so the material stays strong. Waterjet cutters are great for cutting thick metal and hard materials with clean, precise edges.

Metric | Value |

|---|---|

Material Waste Reduction | |

Production Time Decrease | 25% |

Post-Processing Reduction | 50% |

Precision Rate | 99.9% |

Accuracy | ±0.01 mm |

Kerf Width | As low as 0.2 mm |

Material Savings | Up to 35% reduction |

Production Speed | 40% faster than traditional methods |

Waterjet cutters are unique because they can cut many materials without causing heat damage. The water pressure can go up to 100,000 psi, allowing them to cut even the hardest metals. This makes them useful for industries like construction, aerospace, and custom metalwork.

Key Benefits of CNC Waterjet Cutters:

No heat damage, keeping materials strong.

Works well on thick and tough materials.

Cuts down post-processing time by 50%.

If you need a cutting tool that is precise, flexible, and protects materials, CNC waterjet cutters are a great option.

Applications of Metal CNC Machines

Aerospace Manufacturing

In aerospace, precision and trust are very important. Metal CNC machines help make parts like turbine blades and engine pieces. They do jobs like milling, drilling, and turning with great accuracy. These machines are key for making strong but lightweight parts.

✈️ Fact: CNC machining is more accurate and faster than hand tools. This is very important for making safe airplane parts.

The aerospace field uses CNC machines to avoid mistakes and improve safety. Even small errors can cause big problems in planes. By automating work, these machines save time and meet tight deadlines without losing quality.

Automotive Industry

The car industry uses many metal CNC machines. These machines make engine parts, body panels, and other key pieces. They ensure every part fits perfectly, improving car safety and performance. CNC machines also waste less material, which is helpful with costly metals.

🚗 Tip: CNC machines cut labor costs by working automatically. They need less watching, saving money for car makers.

CNC machines are flexible and can switch tasks quickly. This is useful when car production needs change fast. By working efficiently and reducing mistakes, they help make better cars that people trust.

Medical Device Production

In medicine, being exact can save lives. Metal CNC machines make prosthetics, implants, and tools with great care. They create custom implants that fit well and are safe for the body. These machines also make detailed surgical tools that work better.

🏥 Note: CNC machines make medical devices ready to use right away. No extra fixing is needed after production.

CNC machines are vital for making complex medical parts. They speed up production and keep high standards. This helps improve patient care and advance medical technology.

Custom Metal Fabrication

Custom metal fabrication helps make special, high-quality parts for specific needs. Metal CNC machines are important in this process because they are precise, consistent, and efficient. These machines can handle tricky designs and small details, making them great for industries like cars, medicine, and airplanes.

A top car company used CNC machines to save time and work faster. This made better parts with less wasted material.

A medical company made a detailed implant using CNC machines. The process was exact and steady, helping improve surgeries.

An airplane company made an important part with CNC machines. The part fit perfectly and passed all tests easily.

CNC machines let you try different materials, like aluminum or titanium. This makes it easier to meet the needs of different projects. Whether you need a unique prototype or a few custom parts, CNC machines give dependable results.

💡 Tip: Take care of your CNC machine regularly. This keeps it working well and lasting longer.

Mass Production vs. Prototyping

When choosing between mass production and prototyping, knowing their benefits helps you decide. CNC machining works well for both but is used differently based on your goals.

Production Method | Cost Type | Best For |

|---|---|---|

CNC Machining | Small-batch or single prototypes | |

Injection Molding | Lower cost per part | Large-scale production |

3D Printing | Lower cost per part | Small-batch or single prototypes |

CNC machining is great for making prototypes quickly. It skips the need for molds, saving time and money. But for making many items, injection molding is cheaper per piece. If you need just a few items or one prototype, CNC machining gives the best accuracy and speed.

🛠 Note: Use CNC machining for flexible and precise prototypes. For large amounts, pick injection molding to save money.

By knowing these differences, you can match the method to your project’s needs. This helps save time and money while staying efficient.

Key Features to Consider in a Metal CNC Machine

When picking a metal CNC machine, knowing its main features helps you choose the best one for your needs. These features affect how well the machine works, how fast it is, and the quality of the items it makes.

Precision and Accuracy

Precision and accuracy are very important for making good parts. A CNC machine must meet exact measurements so parts fit and work properly. Modern machines are great at this, offering excellent control over cutting and tool movements.

🛠 Fact: CNC machines can achieve super small tolerances, perfect for industries like aerospace and medical tools.

Aspect | What It Means |

|---|---|

Tolerances | CNC machines keep tighter tolerances than older methods, ensuring parts fit together perfectly. |

Repeatability | High repeatability means parts are made the same every time. |

Surface Finish | CNC machines create smooth surfaces that older methods can't match. |

Accuracy | Accuracy depends on material and design, with very tight tolerances possible. |

This level of precision reduces mistakes, saves materials, and ensures safety in important jobs. For example, in aerospace, even small errors can cause big problems. Choosing a CNC machine with advanced precision helps you get reliable results and meet high standards.

Spindle Speed and Power

The spindle speed and power decide how well a CNC machine cuts materials. Faster spindle speeds mean quicker cutting, while enough power ensures the machine handles tough materials easily.

Machines with the right spindle speed last longer. For example, the Omnitech Selexx CNC router cut over 200 sheets before needing a new cutter, compared to 60 sheets on another machine.

Faster speeds also save time, helping you meet deadlines without losing quality.

💡 Tip: Match the spindle speed and power to the material. Softer metals need less power, while harder ones need more.

Getting a machine with the right spindle specs improves productivity. It also reduces downtime from changing tools often, saving time and money.

Rigidity and Build Quality

Rigidity and build quality are key for a CNC machine's performance and durability. A strong structure reduces vibrations, making cuts more precise and helping the machine last longer.

Analysis Type | What Was Found | Details |

|---|---|---|

Static Structural Analysis | Machine Strength | Checked part movement and strength under a 5000 N load. |

Transient Structural Analysis | Tool Reaction | Measured tool response time of 0.5 seconds under load. |

Experimental Investigation | Static Stiffness | Found deformation values of 6.5 kg/μm for tool and spindle. |

A well-made machine handles daily use better. This is especially important for factories where machines run all the time. Picking a CNC machine with strong build quality ensures it works well for a long time.

🛠 Note: Regular care keeps your CNC machine working like new for years.

Tooling Options and Compatibility

Picking the right tools for your CNC machine is very important. The tools you choose affect how well the machine works with different jobs and materials. Knowing what fits and works best helps you get more done and succeed in the long run.

Fits Current Workflows: Make sure the tools match your current processes. This keeps work smooth and avoids problems.

Future Needs: Think about what you'll need later. Buying flexible tools now can save time and money later.

Workpiece Details: The size and type of material you use matter. Harder metals need strong tools, while softer ones need precise tools.

Custom Tools: Work with experts to create tools that fit your needs. Custom tools make your machine better and ready for future tasks.

💡 Tip: Test new tools on practice pieces first. This helps avoid mistakes and saves money.

Using the right tools also helps your machine last longer. Tools made for your machine reduce damage and wear. By focusing on good tools and custom options, you can keep up with changing needs and get great results.

Ease of Maintenance

Taking care of your CNC machine is key to keeping it working well. Regular maintenance helps it last longer and avoids costly breakdowns. A good care plan prevents problems and keeps production running smoothly.

Check the machine often to spot problems early.

Keep spare parts ready to fix issues quickly.

Use a system to organize spare parts for easy access.

Buy replacement parts from trusted sellers to avoid bad quality.

Learn tips from other machinists and suppliers to improve care.

🛠 Note: Clean your machine often to stop dirt from causing problems.

A clean and well-maintained machine works better and costs less to fix. For example, using good spare parts from reliable sellers keeps the machine safe from damage. Staying on top of maintenance avoids delays and keeps production steady.

🔧 Pro Tip: Make a checklist for daily, weekly, and monthly care tasks. This helps you track the machine's condition and keep it in great shape.

Spending time on maintenance improves how well your machine works and lowers repair costs. A clean, cared-for machine gives better results and helps you reach your manufacturing goals.

Size, Capacity, and Cost Factors

Machine Size and Workspace Needs

The size of a metal CNC machine is very important. It must fit in your workspace. Check the machine's size and make sure it matches your available area. Bigger machines may need their own space, while smaller ones can fit in tight spots.

The workspace also depends on what you plan to make. Machines for heavy tasks can hold bigger and heavier materials. If you work with large parts, pick machines with strong frames and big work areas.

🛠 Tip: Measure your workspace now and think about future needs. This helps you avoid running out of space as your work grows.

Production Amount and Capacity

Knowing how much you need to produce helps you choose the right machine. For high production, pick machines that work fast and last long. These machines can run smoothly without stopping often.

Machines with more capacity are great for making many items. They are perfect for industries like cars and airplanes. But if you do small custom jobs, choose machines that focus on being flexible and precise.

Think about the size and weight of the materials you use. Bigger machines can handle heavier items, which is important for meeting production goals.

💡 Fact: Machines with automation features save time and cut labor costs. They are great for high-volume production.

Cost and Budget Planning

Buying a metal CNC machine can be expensive, especially for small businesses. But the benefits over time often make it worth the cost.

Evidence Type | What It Means |

|---|---|

Demand Drivers | |

Government Policies | Tax breaks and funding help businesses buy CNC machines. |

Financial Barriers | High costs make it hard for smaller companies to afford these machines. |

To save money, compare the costs and benefits carefully. Look at how the machine improves speed, quality, and production. Advanced machines may cost more but save money later by reducing waste and boosting efficiency.

🔧 Pro Tip: Check for government programs or payment plans to help with the cost of buying a CNC machine.

Return on Investment Considerations

When buying a metal CNC machine, knowing its ROI is important. This helps you decide if it fits your budget and production needs. By looking at key points, you can make a smart choice.

1. Initial Costs vs. Long-Term Savings

CNC machines may cost a lot upfront, but they save money later. They lower labor costs and reduce wasted materials. For instance, CNC machines can cut mistakes by 50%, saving money on fixing errors and wasted parts.

💡 Tip: Think about how much time and money you’ll save by automating tasks. This can help explain the high starting cost.

2. Production Efficiency

CNC machines are faster and more accurate than doing work by hand. This means you can make more items in less time. Faster production increases profits, especially in industries like cars or airplanes.

Metric | Manual Work | CNC Work |

|---|---|---|

Time per Part | 30 minutes | 10 minutes |

Error Rate | 5% | 0.5% |

Output per Day | 50 parts | 150 parts |

3. Resale Value

Good CNC machines keep their value over time. If you upgrade, you can sell your old machine and get some money back. Machines from trusted brands usually sell for more.

🛠 Note: Take care of your machine to keep it in good shape. This helps it sell for a higher price.

4. Scalability

CNC machines let you grow your business. Whether you need to make one item or many, the machine can handle it. This flexibility helps you take on more work and expand your company.

By thinking about these points, you can get the most out of your CNC machine. It can become a valuable tool for your manufacturing success.

Software and Control Systems for Metal CNC Machines

CAD/CAM Software Compatibility

Having the right CAD/CAM software is very important. It helps your CNC machine work better and faster. This software connects design and production, saving time and cutting down mistakes. When CAD and CAM models work together, you can do everything in one place. This makes your work easier and more efficient.

Automation tools in CAD/CAM software make programming simple. Features like automatic programming reduce the need for manual work. This lets you focus on other important tasks. Also, keeping all CAD/CAM data in one file avoids errors. You get accurate designs and toolpaths every time.

Benefit | What It Does |

|---|---|

Combines CAD and CAM models for smooth design-to-production workflow. | |

Automation | Tools like auto-programming save time and reduce manual work. |

Data Management | Stores all data in one file, avoiding errors and keeping designs updated. |

Picking a CNC machine with good CAD/CAM software makes your work easier and improves your results.

User-Friendliness of the Control System

A simple control system makes using a CNC machine easier. Look for systems that are easy to understand and use. Clear instructions and simple menus help you avoid mistakes and learn faster.

Modern CNC machines often have touchscreens and visual displays. These features let you see how tools move and make changes easily. If you’re new to CNC machines, these tools can save you time and effort.

💡 Tip: Try out the control system before buying. Make sure it fits your skills and needs.

An easy-to-use control system helps you work faster and with fewer problems. It also makes training your team quicker, keeping your production running smoothly.

Software Updates and Support

Keeping your CNC machine’s software updated is very important. Updates improve how the machine works, fix problems, and add new features. With updated software, you can handle harder designs and meet industry needs.

Good support services are just as important. Trusted manufacturers offer help and training to get the most out of your machine. They also provide guides and spare parts to fix issues quickly.

🛠 Note: Pick a manufacturer with strong support. This ensures you get help when needed.

By focusing on updates and support, your CNC machine will last longer and keep producing high-quality work.

Integration with Existing Systems

Adding a new CNC machine to your setup needs careful planning. It should work well with your current systems to avoid problems.

1. Compatibility with Current Equipment

Check if the CNC machine matches your tools and machines. This saves money on upgrades or replacements. For example, see if it uses the same tools or connections as your other equipment.

💡 Tip: Write down your equipment details. Compare them with the CNC machine before buying.

2. Software and Data Integration

Modern CNC machines use CAD/CAM software to work. Make sure the machine fits with your current software. This avoids extra training or buying new programs. Machines that use common file types like DXF or STEP are easier to set up.

Software Feature | Why It’s Useful |

|---|---|

File Format Support | Works with your designs easily |

Cloud Connectivity | Lets you check progress remotely |

API Availability | Helps connect with other systems |

3. Networking and Automation

Some CNC machines can link to factory systems. This helps track work, plan better, and fix problems early. Machines with IoT features give helpful data to improve production.

🛠 Note: Ask your IT team to check if the machine’s network settings match your factory.

By ensuring compatibility, software fit, and network connection, your CNC machine will work smoothly with your systems. This reduces delays and makes your manufacturing process better.

Evaluating Manufacturers and Support Services

Reputation and Customer Reviews

Picking a metal CNC machine means checking the maker's reputation. Choose a company known for reliable machines and happy customers. Reading reviews and user stories helps you see how well they perform.

Haas Automation is famous for strong machines and great support. Many users say their CNC machines make work easier and smoother.

SYIL CNC Machines are praised for being precise and steady. Businesses often say SYIL machines improve product quality over time.

Customer feedback and success stories give helpful details. They show how a company solves problems and supports its buyers. Researching these can help you pick the right manufacturer.

Warranty and After-Sales Support

A good warranty and strong support keep your machine safe. Look for companies with clear warranty rules. These should cover fixing or replacing parts for a fair time.

After-sales support keeps your machine working well. Companies like Haas Automation offer training and help with problems. This lets you fix issues fast and avoid delays.

🛠 Tip: Check if technical help is easy to reach. A quick support team saves time and money.

Availability of Spare Parts and Training

Having spare parts and training is key for long-term use. You need quick access to parts to keep your machine running. Companies with stocked parts reduce repair wait times.

Training helps you and your team use the machine better. SYIL offers guides and workshops to teach you. These tools improve skills and make the machine work efficiently.

💡 Note: Pick a company that focuses on spare parts and training. This ensures smooth work and better results.

Long-Term Maintenance and Reliability

Taking care of your CNC machine is very important. Regular maintenance helps it last longer and work its best. Skipping maintenance can cause expensive repairs and stop production suddenly.

Key Maintenance Practices

Follow these simple steps to keep your CNC machine in good shape:

Daily Cleaning: Clean off metal bits and dirt after using the machine. This stops buildup that could harm parts.

Lubrication: Use the right oils on moving parts. This keeps them working smoothly and reduces wear.

Inspection: Look for loose screws, worn belts, or broken parts. Fixing small problems early avoids bigger issues later.

Calibration: Check and adjust the machine often to keep it accurate. Misaligned tools can ruin your cuts.

💡 Tip: Make a regular maintenance plan and follow it. This helps avoid sudden problems.

Benefits of Reliable Maintenance

Spending time on maintenance has many benefits:

Less Downtime: A cared-for machine works without stopping often.

Save Money: Preventing problems costs less than fixing big repairs.

Better Quality: Maintenance keeps the machine making accurate and good parts.

Maintenance Task | How Often | Why It’s Important |

|---|---|---|

Cleaning | Every day | Stops dirt from causing damage |

Lubrication | Once a week | Protects moving parts |

Full Inspection | Every month | Finds problems early |

Calibration | Every 3 months | Keeps cuts precise |

🛠 Note: Always use parts and tools approved by the manufacturer. This keeps your machine safe and working well.

By taking care of your CNC machine, you make sure it stays reliable for a long time. A well-maintained machine works better, saves money, and gives you peace of mind.

Picking the right metal CNC machine is very important. It helps you meet your manufacturing goals easily. Choose a machine that fits your needs for better results. Look at features, size, cost, and software compatibility. Good support from the manufacturer also helps the machine last longer.

Spend time researching before buying. Compare machines, read reviews, and ask experts for advice. This way, you can choose a machine that works well and gives reliable results for many years.

FAQ

What should you think about when picking a metal CNC machine?

Focus on what your work needs. Think about the materials, how much you need to make, and how exact the machine must be. These points help you pick the right machine for your tasks.

How often do you need to take care of a CNC machine?

Clean it every day and oil it weekly. Check it fully once a month and adjust it every three months. Regular care keeps the machine working well and lasting longer.

Can one CNC machine work with different materials?

Yes, most CNC machines can cut metals like aluminum, steel, and titanium. Look at the machine’s details to make sure it works with your materials.

Is CNC machining good for small businesses?

Yes, CNC machines are great for small businesses. They lower work costs, make things more exact, and help you get more done. Start with a machine that fits your budget and needs.

What kind of software do CNC machines need?

You need CAD/CAM software to design and program the machine. Make sure the software works with your CNC machine and the file types you use.

Start your project with LKprototype

LKprototype company simplifies procurement for custom manufacturing, Suitable for making your products or prototypes with a variety of materials, such as metal or plastic, silicone rubber, from 3D Printing to CNC Machined Parts and Vacuum Casting , with a focus on speed and efficiency. Our platform provides instant quotes. With LKprototype, You can connect with the team to communicate your project to ensure quality and on-time delivery.

Start with an instant quote and experience how our technology and expertise can make custom part procurement faster and easier.

LKprototype

LKprototype