You might wonder, is bronze magnetic? Generally, bronze, along with brass and copper, is not magnetic. These metals don’t exhibit a strong pull or push on magnets. However, certain bronze alloys containing iron can be slightly magnetic. Similarly, metals like aluminum, titanium, and brass are also not magnetic. Key Takeaways Bronze, brass, and copper are not magnetic. This makes them great for tools and art. Some bronze and brass alloys may be slightly magnetic. This happens if they have iron or nickel, but it is uncommon. Knowing what these metals are made of helps pick the right one. This is…

Image Source: pexels Choosing the right aluminium extruded profiles is key to your project's success. These profiles are very flexible and meet both design and strength needs. Aluminium extruded profiles are popular in many industries because they are light and strong. Good-quality profiles are tough, resist rust, and look great, lasting a long time. The rising demand shows their value: The global market for aluminium extruded profiles has grown steadily since 2019. Earnings from 2019 to 2024 show they are used more in different fields. Modern buildings often use aluminium extruded profiles in their designs. Picking the right aluminium extruded…

Image Source: unsplash Accuracy and speed are very important when working with bronze. This metal is strong, resists rust, and conducts heat well. These traits make it great for making tough parts. However, cutting bronze requires careful work to achieve good results. CNC machining bronze helps cut this material with high accuracy and detail. It utilizes automated steps and smart cutting settings to save material and maintain consistent quality. Whether creating machine parts or art pieces, CNC machining bronze is a dependable method for working with this versatile metal. Key Takeaways Pick the right bronze type for your project. Each…

Have you ever thought about making aluminum shiny again? To do this, you must remove anodizing. Anodizing is a strong protective layer on aluminum. It can be removed with the right method. This will show the bare aluminum underneath. Whether fixing a part or getting it ready to paint, the steps are simple if done correctly. Tip: Be gentle with aluminum to prevent scratches or harm. Key Takeaways Get the right tools and materials first. Use a soft brush, fine sandpaper, and a plastic container for chemicals. Always stay safe. Wear rubber gloves, safety goggles, and a face mask when…

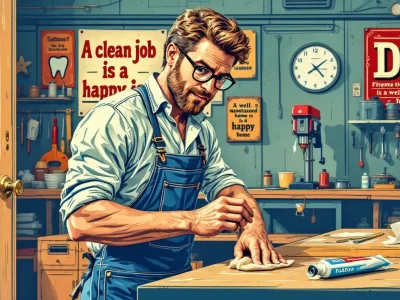

Looking to restore your brass to its original shine quickly and effectively? This guide will show you how to polish brass metal using common household items and simple techniques. Get ready to make your brass shine again. Key Takeaways Identify whether your brass item is solid or plated before cleaning to choose the right method.Effective cleaning methods include natural solutions like lemon juice and baking soda, toothpaste, and even ketchup, each with specific techniques for application and rinsing.Regular maintenance is key; high-use brass items should be cleaned monthly, while decorative pieces can be cleaned annually. Determine if Your Brass is…

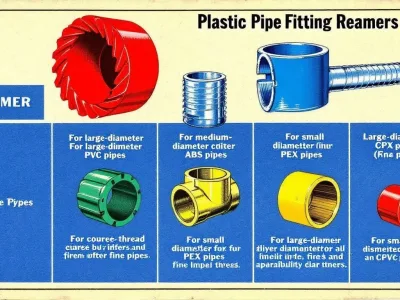

A plastic pipe reamer is a tool used to remove old fittings from plastic pipes, ensuring a clean surface for new connections. It’s essential for plumbing repairs and installations. In this article, we’ll explore how plastic pipe reamers work, different types available, key features to look for, and maintenance tips. Key Takeaways Plastic pipe reamers are essential for removing fittings and preparing pipes for new installations, enhancing efficiency in plumbing tasks.The Clean Ream Extreme® reamer is notable for its ability to clean and reuse fittings, which minimizes material costs and waste.High-quality reamers feature durable designs with carbide cutting inserts and…

Selecting the right silicone rubber for mold-making is key to successful projects. Silicone rubber is flexible, durable, and easy to use, making it ideal for detailed molds. This guide details everything you need to know to make the best choice. Key Takeaways Selecting the right silicone rubber enhances mold quality. It emphasizes factors like flexibility, tear strength, and curing time for successful applications. A 1:1 mix ratio of silicone components simplifies the preparation process. It ensures consistent results while minimizing bubbles and imperfections. Fast-curing silicones facilitate quick production cycles. Their versatility allows for casting across various surfaces, making them essential…

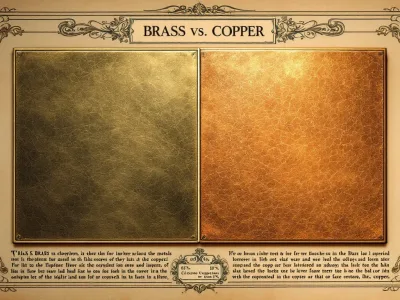

Brass versus copper: what’s the difference and which metal is right for your project? In this article, we’ll compare their composition, visual appeal, mechanical properties, corrosion resistance, conductivity, and common applications. By the end, you’ll understand which metal suits your needs best. Key Takeaways Brass is an alloy primarily made of copper and zinc, offering high strength and corrosion resistance, while pure copper is known for its superior conductivity and malleability. Copper’s reddish-brown hue and patina provide aesthetic appeal, making it suitable for artistic applications, whereas brass’s yellowish-gold color is preferred for decorative and functional items. Cost and application considerations…

Bronze machining is the process of cutting and shaping bronze alloys, crucial for its corrosion resistance and machinability. This guide covers why bronze is preferred over other materials, the main types of bronze alloys, and key machining techniques for high-quality results. Key Takeaways Bronze machining offers high corrosion resistance, wear resistance, and strength, making it ideal for precision components in various industries. Selecting the appropriate bronze alloy and machining technique is crucial for optimizing performance and achieving desired outcomes in CNC machining. Implementing best practices and rigorous quality control measures enhances the efficiency and reliability of bronze machining projects. Understanding…

Is stainless magnetic? It can be, but it depends on the type. In this article, you’ll learn why some stainless steels are magnetic and others aren’t, and how this affects their uses. Key Takeaways Stainless steel’s magnetic properties are influenced by its crystal structure and chemical composition, with martensitic and ferritic types being magnetic, while austenitic types are typically non-magnetic. Understanding the magnetic characteristics of different stainless steel types—like austenitic, ferritic, martensitic, and duplex—is crucial for selecting the right material for specific applications such as manufacturing and food processing. Testing for magnetism using a simple magnet can indicate magnetic properties,…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.