Plastic injection molding is a manufacturing process that involves melting plastic pellets and injecting them into molds to create parts and products, making it a versatile method for manufacturing plastic parts. But what is plastic injection molding? It is widely used because it allows for high-volume production with consistent quality and minimal waste. This method is essential in various industries, including automotive, medical, and consumer goods. In this article, we will explore the steps involved in the process, the benefits of using plastic injection molding, and its common applications. Key Takeaways Plastic injection molding is a versatile manufacturing process that…

Plastic molders are essential for creating precise, high-quality plastic parts. In this article, you’ll learn about the advanced methods plastic molders use and the benefits of partnering with a top-tier plastic molder like LKprototype Plastic Molders. Discover how they can help turn your concepts into reliable, market-ready products. Key Takeaways LKprototype Plastic Molders specializes in high-quality plastic manufacturing with over 15 years of experience, offering personalized customer service for both small and large orders. The company utilizes advanced plastic injection molding techniques, including Water-Assisted and Microcellular Injection Molding, to enhance product quality and reduce production times. Their comprehensive design and…

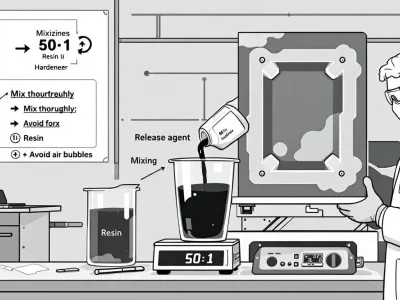

Curious about how to make hard plastic molds? Start with gathering your materials, then prepare your workspace, create a master model, apply a mold release agent, and pour the silicone. This guide takes you through every step for making durable, hard plastic molds. Key Takeaways Start by gathering key materials like silicone rubber, epoxy resin, and mold release agents for effective mold making. Creating a master model is essential, so use sculpting tools and materials like clay to achieve a precise design. After mixing and pouring, allow your silicone to cure properly before carefully removing the mold and adding finishing…

Wondering how to fabricate plastic parts? This guide covers the essentials from material selection to manufacturing techniques. Learn how to choose the right plastic, design your parts, and pick the best fabrication methods suited for your needs. Key Takeaways Understanding various types of plastic materials is crucial for selecting the appropriate resin that meets functional and budgetary requirements in manufacturing. Designing plastic parts necessitates careful planning and the use of specialized tools to ensure structural integrity and efficient manufacturing processes. Choosing the right manufacturing technique, such as injection molding or extrusion, significantly influences the quality and cost-effectiveness of plastic products.…

If you’re involved in plastic injection moulding, you know that choosing the right raw materials is crucial. Different raw materials offer various properties, affecting the performance, cost, and applications of the final product. This article will guide you through the most commonly used plastic injection moulding raw materials, their unique attributes, and how to select the best material for your needs. Key Takeaways Successful plastic injection molding relies on selecting suitable raw materials, which must meet specific performance, durability, and cost criteria. Commonly used materials such as polyethylene, polypropylene, and ABS each have unique properties catering to diverse applications across…

Wondering how to make a mold for silicone parts? This guide breaks down the process into simple steps. Learn how to pick the right silicone, gather your tools, design your mold, and go through the mixing, curing, and demolding phases. Get ready to create your own professional-grade silicone molds. Key Takeaways Select the appropriate silicone type (tin-cure for beginners and platinum-cure for high durability) based on project needs for successful mold making. Essential tools, materials, and a well-designed mold box are critical for creating precise and effective silicone molds. Proper mixing, curing, and maintenance techniques significantly enhance the quality and…

Die casting vs injection moulding: which is right for your project? This article breaks down the key differences in materials, precision, and production volumes. These insights will guide you in making the best choice. Key Takeaways Die casting is a high-pressure metal casting process. It is ideal for producing intricate parts with excellent dimensional accuracy. This method mainly uses nonferrous metals like aluminum and zinc. Injection moulding is a versatile plastic manufacturing method. It allows for rapid production of complex shapes but has higher initial tooling costs. It also has limited design flexibility. When selecting between die casting and injection…

Plastic moulding techniques create the diverse plastic products we use daily. This article covers the main methods: injection, blow, compression, extrusion, rotational, and thermoforming. Learn about each method’s benefits and ideal applications to choose the best fit for your project, utilizing the plastic moulding technique that suits your needs. Key Takeaways Plastic molding encompasses several techniques, including injection, blow, compression, extrusion, rotational molding, and thermoforming, each suited for specific applications and materials. Injection molding is the most versatile method, allowing for high precision, consistent quality, and cost-effectiveness in mass production, while blow molding is ideal for creating hollow and thin-walled…

Looking for plastic molders? These specialists transform raw plastics into precise components used in industries like automotive, electronics, and healthcare. This guide will help you understand the types of plastic molding, key materials, and what to look for when choosing a plastic molder. Key Takeaways Plastic molding is a versatile manufacturing process essential for producing a wide array of products across multiple industries, utilizing various specific techniques. Injection molding is a key process characterized by its cost-effectiveness, ability to produce intricate designs with high precision, and efficient mass production capabilities. Sustainability and technological advancements in plastic molding, such as bioplastics…

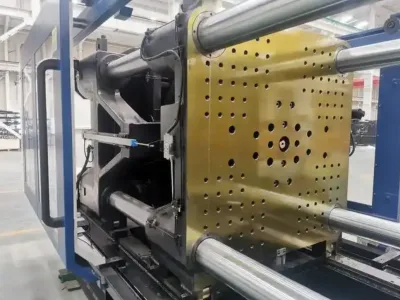

Often used manufacturing process to make high quality, precision engineered components is injection molding. A main progression point of injection molding involves the injection molding tools. These are vital components because these molds shape raw material to construct products in the best and shortest way. What is Injection Molding? A process used to manufacture parts is Injection molding where molten material is injected in a mold. This is a universal process employed across the automotive, electronics, medical device and consumer goods industries to create complex and precise components. The reason injection molding is the perfect manufacturing method is that it…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.