The injection molding industry is changing fast, offering cool injection molding jobs near me. New technology and automation are improving how things are made. These changes need workers with skills and flexibility. Around the world, this field is growing. In 2024, Asia-Pacific will make 40% of the money because of more need for medical tools and eco-friendly materials. If you want a job in injection molding, learn the skills and get certified to succeed in this exciting field.

Key Takeaways

The injection molding industry is growing fast. It may reach $511.7 billion by 2031. This growth means more jobs for skilled workers.

Knowing tools, reading drawings, and using software are key skills. Learning these makes you a valuable worker in this field.

Communication, teamwork, and being flexible are also very important. These skills help you work well with others and handle changes.

Certifications and training programs help you grow in your career. Beginner certifications teach basics, while advanced ones improve your skills and job chances.

Meeting people and joining groups can lead to new jobs. Talking to others helps you learn, share ideas, and stay updated on trends.

Overview of the Injection Molding Industry

What is Injection Molding?

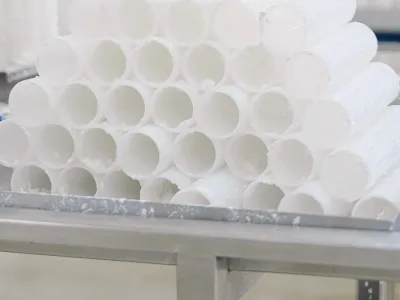

Injection molding is a way to make plastic parts. It works by pushing melted plastic into a mold. The mold shapes the plastic, which cools and hardens into the final part. This method is great for making many parts that look the same. It follows strict ISO standards to ensure accuracy and quality.

There are two main steps in this process. First, a mold is made from steel or aluminum. This mold has the opposite shape of the part you want. Next, plastic pellets are melted and pushed into the mold. After cooling, the part is removed and ready to use.

Key Sectors and Applications

The injection molding industry helps many industries:

Packaging: This is the biggest sector, making 32% of revenue in 2023. It creates strong and lasting packaging for food and other items.

Electronics: Plastic parts are used in devices like coffee makers and hair dryers because they are light and cheap.

Medical: Medical tools are in high demand because they are safe and clear.

Automotive: Cars use plastic parts to be lighter and more fuel-efficient.

Construction: Plastic is used in floors, roofs, insulation, and windows to save money.

Why Injection Molding Jobs Are in Demand

The injection molding industry is growing fast. In 2022, it was worth $337.8 billion. By 2031, it could reach $511.7 billion, growing 4.7% each year. The plastic injection molding market alone might hit $235.7 billion by 2029.

This growth comes from more demand in healthcare, cars, and packaging. For example, healthcare needs lightweight and strong medical tools. Cars use plastic parts to weigh less and save fuel.

The injection molding industry has many job options for skilled workers. It’s an exciting field to join!

Skills Needed for Injection Molding Jobs Near Me

Technical Skills for Injection Molding Operators

To do well in injection molding jobs, you need technical skills. Employers want workers who know about tools, materials, and suppliers. You should also understand how to read technical drawings. These skills help you follow instructions and make quality parts.

Knowing how to use software like ERP or MRP (like SAP) is important too. These programs help manage schedules and inventory. Problem-solving is another key skill. You’ll need to fix problems and improve processes to keep things running smoothly.

Here’s a simple list of important skills:

Skill Type | Description |

|---|---|

Technical Skills | Know about tools, materials, and supplier management. |

Software Proficiency | Use ERP/MRP systems (like SAP). |

Technical Reading | Read technical drawings and instructions well. |

Soft Skills | Be good at talking, teamwork, and thinking critically. |

Work Environment | Handle fast-paced and team-based work settings. |

Problem-Solving | Solve problems and improve processes. |

Language Proficiency | Speak and write English well; other languages are a bonus. |

Travel Requirement | Be okay with traveling (10-25%). |

Learning these skills will make you valuable in this field.

Soft Skills for Career Success

Technical skills are important, but soft skills matter too. Good communication helps you work with others and explain ideas clearly. Teamwork is needed because you’ll often work with a group to meet goals.

Being flexible is also important. The industry changes quickly, so you must learn new tools and methods. Paying attention to details helps you catch mistakes early, saving time and money. These soft skills make you a better worker and teammate.

Here are the top soft skills you’ll need:

Communication

Teamwork

Flexibility

Attention to detail

Building these skills will help you grow and find more job opportunities.

Emerging Skills in Advanced Manufacturing

New technology in manufacturing means learning new skills. Smart factories now use IoT and data tools. You’ll need to watch systems in real-time and fix problems before they happen.

Sustainability is also important now. Knowing about bioplastics and recycled materials is a big plus. New methods like micro injection molding need special training to use advanced machines.

Training is key to keeping up with these changes. Experts like Karen Paulson say training should happen often, not just once. This helps you understand processes better and solve problems faster. Murphy Forsyth adds that training improves production, making it worth your time.

By learning these new skills, you’ll stay ahead in the injection molding industry.

Certifications and Training for Injection Molding Careers

Certifications and training are important for success in injection molding. They teach you the skills and knowledge needed to do well. Whether you're starting out or want to grow, there are programs for everyone.

Entry-Level Certifications and Training Programs

If you're new, entry-level certifications help you learn the basics. These programs teach safety, how to use machines, and handle materials. They also explain industry rules to ensure good product quality.

One example is the Injection Molding Certificate Program by the University of Akron and ConxusNEO. It focuses on skills employers want, preparing you for molding jobs.

Here are some common entry-level certifications:

Certification Name | Description |

|---|---|

Injection Molding Professional | Shows knowledge of safety, machines, tools, and materials. Great for many roles. |

Certification for Injection Mold Setters | Teaches die setting, robotics, and processing steps. Perfect for setup jobs. |

Certification for Injection Molding Maintenance | Covers maintenance skills to keep machines running smoothly. |

These certifications build your confidence and make you stand out to employers.

Advanced Certifications for Career Growth

With experience, advanced certifications help you move up. These programs teach special skills like Scientific Molding and AI mold flow simulation. Employers value these skills as technology advances.

Surveys show 68% of manufacturers want workers with AI and maintenance skills. Certified workers are 15% more efficient and have 22% fewer accidents. Advanced certifications improve your skills and workplace safety.

Some advanced certifications include:

Advanced Certification for Scientific Processors: Teaches advanced molding methods for engineers and technicians.

Certification for Injection Molding Quality: Focuses on quality checks, great for inspectors and managers.

Getting these certifications boosts your skills and helps you get better-paying jobs.

Specialized Training in Mold Design and Quality Assurance

Specialized training focuses on areas like mold design and quality checks. These programs are great if you want to be a mold technician or quality manager. They teach you to design molds and ensure products meet standards.

Mold design training includes CAD software, material choices, and mold flow studies. Quality assurance training covers inspections, fixing defects, and meeting industry rules.

Why specialized training matters:

It gives you unique skills that are in demand.

It prepares you for leadership roles in design and quality.

It keeps you updated with new tools and methods.

Specialized training makes you an expert and helps you grow your career long-term.

Career Growth Opportunities in Injection Molding

Starting Jobs: Injection Molding Operator and More

When you start in injection molding, you’ll likely take an entry-level job. As an injection molding operator, you’ll run machines and check parts for quality. This job teaches you important skills and shows you how factories work.

Other beginner jobs include material handlers and quality helpers. These roles let you work with materials and learn about processes. You’ll also see how different teams work together. Entry-level jobs help you figure out what career path fits you best.

Moving Up: Mid-Level and Supervisor Jobs

With experience, you can get mid-level jobs like mold technician or team leader. Mold technicians set up and fix molds, which is key for smooth production. Team leaders guide small groups to finish tasks on time.

Supervisor jobs let you grow leadership skills. You might plan schedules, train workers, or solve problems. These roles prepare you for bigger responsibilities and career growth.

Here’s a simple look at career paths:

Job Path | What You’ll Do |

|---|---|

Skilled Operator | Teach new workers and handle advanced tasks like mold programming. |

Mold Technician | Learn to set up and repair molds with extra training. |

Manager | Use leadership skills to become a production manager and oversee operations. |

Advanced Jobs and Leadership Roles

Advanced jobs and leadership roles offer great chances to grow. With more training, you could become a mold designer, quality manager, or production manager. These jobs need skills like using CAD software and fixing defects.

Many companies help workers become leaders. For example, Hoffer University gives training guides and certifications for production teams. Leadership programs help workers at all levels improve their skills.

Some companies also let you try different jobs. After six months, you might get help paying for college classes. This support can help you study at community colleges, universities, or even graduate schools.

Advanced jobs and leadership roles not only improve your skills but also lead to better pay. They let you make a big difference in your company’s success.

Networking and Professional Development in Injection Molding

Making Connections in the Industry

Making connections in injection molding can lead to new chances. Networking helps you share ideas, learn, and follow industry changes. You can meet others by going to trade shows, conferences, or local events.

For instance, companies like Project DIAMOnD and Tucker Induction System gained success through teamwork. They used 3D printing to create new ideas and cut costs. Networking helps you work with others, find creative solutions, and improve processes.

Company | Success Story | Benefits |

|---|---|---|

Project DIAMOnD | Created new ideas and saved money while helping others. | |

Tucker Induction System | Used 3D printing to make strong parts. | Lowered costs, saved time, and boosted creativity. |

Champion Plastics | Added 3D printing to check quality faster. | Cut costs and made manufacturing more efficient. |

By meeting others, you can learn from their successes and use those lessons to grow your career.

Joining Industry Groups

Joining industry groups can help your career a lot. These groups give you resources, training, and chances to meet others. Being a member can help you get noticed, learn from others, and find new ideas.

More people are joining these groups every year. Members say they learn better work methods and see fewer workers leaving jobs. Companies that support these groups often work better and earn more.

Get recognized for great work

Learn from others in the industry

Find new ideas to improve your work

These groups also focus on safety, which is very important. By joining, you can stay updated on safety rules and help make workplaces safer.

Keeping Up with Trends and Technology

Learning about new technology is key to doing well in injection molding. In 2023, the injection molding machine market was worth $10.1 billion. It is expected to grow 4.8% each year until 2032. This growth comes from high demand in cars and packaging.

New trends like automation and IoT are changing the industry. These tools make machines work faster and more accurately. Sustainability is also a big focus, with companies using energy-saving and eco-friendly machines. Electric and hybrid machines are popular because they save energy and work better.

Keeping up with these changes helps you stay competitive. Learning new skills and staying informed will prepare you for future challenges and help you succeed.

The injection molding industry has many job options, from beginner roles to top leadership jobs. Programs like Moldmakers Pathways and AIM Coursework help workers learn important skills. These programs make sure the industry has a strong future.

Program/Initiative | What It Teaches | Why It’s Important |

|---|---|---|

Moldmakers Pathways | Teaches workforce skills | Helps the industry stay strong |

AIM Coursework | Covers plastics, mold design, and processing | Prepares students for many job types |

Certifications are also important for growing your career. Certifications like the AAS-AT Degree in Plastics Injection Molding or Autodesk Moldflow Associate Certification teach special skills for mold design and processing.

Certification | What You Learn |

|---|---|

AAS-AT Degree | Focuses on Plastics Injection Molding |

Autodesk Moldflow Associate Certification | Teaches mold design using simulation software |

OSHA-30 Certification | Provides workplace safety training |

To do well, keep learning and improving your skills. Look for local training, join industry groups, and follow new trends. By working on your skills, you can have a great career in this exciting field.

FAQ

How can I start working in injection molding?

Start with beginner certifications and training. These teach safety, using machines, and handling materials. Check for local classes or online courses to practice skills.

Is a college degree needed for injection molding jobs?

No, most jobs need only certifications or technical training. But higher roles like mold designer or manager might need an engineering degree.

How do I keep up with industry changes?

Join groups, go to trade shows, and read industry news. Talk to others and join training programs to learn about new tools and methods.

Are there work-from-home jobs in injection molding?

Most jobs need you to work on-site because they are hands-on. But some roles in design, quality checks, or management might allow remote or mixed work.

Can I grow my career in this field?

Yes, injection molding has clear career steps. Start as an operator and move up to mold technician, quality manager, or production manager. Special training and certifications help you reach leadership roles.

💡 Tip: Keep learning new skills and tools to stay ahead in this growing field.

LKprototype

LKprototype