Dual extruder 3D printers are changing how things are made. They let you print with two materials or colors at once. This makes your designs more useful and creative. You can create detailed models, mix hard and soft parts, or use supports that dissolve for tricky shapes.

If you want faster printing and better designs, try a dual extruder 3D printer. Whether you're testing ideas, making crafts, or inventing, this tool helps bring your ideas to life.

Key Takeaways

Dual extruder 3D printers can print with two colors or materials at the same time. This boosts creativity and makes designs more useful.

Dissolvable supports make tricky prints easier. They help create detailed shapes without harming the final model.

These printers save time by skipping filament changes. This makes them great for big projects or making many items at once.

Picking the right materials is important. Filaments that melt at similar temperatures stick better and print nicely.

Taking care of the printer is key. Clean the nozzles and adjust the printer often to keep it working well and lasting longer.

Advantages of Dual Extruder 3D Printers

Multi-material printing capabilities

Dual extruder 3D printers let you print with two materials or colors at the same time. This is helpful for making objects that need different properties, like being soft and hard. For example, you can print a phone case with a tough outside and a soft inside in one go.

Using more than one material makes your prints stronger and more useful. You can mix materials to make parts that are light but strong. This is important for industries like cars and airplanes, where materials need to work well and be efficient.

Feature | Benefit |

|---|---|

Dissolvable Supports | Helps print tricky shapes and removes supports without damage. |

Stronger Parts | Combines materials for better strength and impact resistance. |

Multi-color Printing | Prints colorful designs without needing to paint later. |

Faster Production | Mirror and repeat modes save time and boost efficiency. |

Dual extruder printers make multi-material printing easier and better. They allow you to create things single extruder printers can't.

Faster and more efficient production

Dual extruder 3D printers speed up printing by skipping filament changes. Two extruders work separately, so you can print faster and with fewer stops. This is great for big projects or making many copies of the same item.

Special modes like mirror mode and duplication mode make printing even quicker. Mirror mode prints two opposite parts at once, while duplication mode makes identical parts at the same time. These features save time and help you get more done, whether you're a hobbyist or a professional.

Advantage/Disadvantage | Explanation |

|---|---|

Speed | Saves time by skipping filament changes. |

Prints with different plastics needing unique temperatures. | |

Less Waste | Uses less extra material, reducing waste. |

Calibration Issues | Needs careful setup to avoid problems with idle extruders. |

Dual extrusion makes printing faster and uses less material. It’s a smart choice for saving time and money in 3D printing.

Creating complex designs with support materials

Dual extruder 3D printers can use dissolvable supports for tricky designs. These supports hold up overhangs and bridges while printing. After finishing, you can dissolve them in water or a special liquid, leaving a clean model.

This feature is great for prototypes, art pieces, and detailed parts. You can make moving parts or delicate sculptures easily. Support materials keep your designs strong and looking good during printing.

Industries and hobbyists need reliable extruders for high-quality prints. Better extruder designs and materials make it easier to create complex parts. Dual extruder printers let you explore new ideas in 3D printing and make amazing designs.

Comparison with single extruder 3D printers

Choosing between a dual extruder 3D printer and a single extruder one depends on your needs. Both printers build 3D objects layer by layer, but they work differently and offer unique features.

Functionality and Features

Single extruder printers use one nozzle for all tasks. This means you can only print with one material or color at a time. To switch materials or colors, you must stop the printer and change the filament by hand. This process can slow you down and limit your creativity.

Dual extruder printers have two nozzles. These let you print with two materials or colors at once. For example, you can mix hard and soft materials in one print or use dissolvable supports for tricky designs. This makes it easier to create complex and useful objects.

Print Quality and Precision

Single extruder printers work well for simple designs. But they may struggle with complex models needing supports or multiple materials. Using one nozzle for both the main material and supports can cause rough surfaces or make it hard to remove supports without damage.

Dual extruder printers solve this problem. One nozzle handles the main material, while the other uses support material. This setup creates cleaner and smoother prints. Dissolvable supports make it even easier to get perfect finishes. This is especially helpful for professionals making prototypes or detailed products.

Efficiency and Time-Saving

Single extruder printers need frequent filament changes for different materials or colors. This takes time and can cause problems like jams or misalignments.

Dual extruder printers avoid these issues by printing continuously. They also have special modes like mirror mode and duplication mode. Mirror mode prints two opposite parts at once, while duplication mode makes identical copies. These features save time and help with big projects or batch printing.

Cost Considerations

Single extruder printers cost less, making them great for beginners or hobbyists. They are easy to use and maintain, which is good if you're new to 3D printing. However, they have limits in what they can do.

Dual extruder printers cost more but offer better features for advanced users. They handle complex designs, improve print quality, and save time. If you need multi-material printing or high precision, the extra cost is worth it.

Tip: Unsure which printer to pick? Think about your project needs. For simple designs, a single extruder printer works fine. For advanced designs, a dual extruder printer gives you more options and better results.

Applications of Dual Extruder 3D Printers

Prototyping and product development

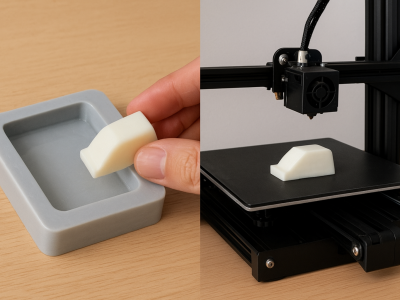

Dual extruder 3D printers are changing how prototypes are made. You can use different materials, like hard plastics for structure and soft ones for flexible parts. This helps test designs better before making them on a large scale. For example, a wearable device prototype can have a tough outer shell and soft, skin-friendly parts in one print.

These printers also save time by skipping assembly steps. Instead of printing parts separately and putting them together, you can print the whole prototype at once. This faster process makes it easier to create new products quickly and bring them to market.

Medical and dental applications

Dual extruder 3D printers are helping in healthcare. They can make custom medical devices like prosthetics and braces for each person. By using different materials, these devices can be strong and comfortable. For example, a prosthetic leg can have a sturdy frame and a soft, cushioned inside.

Dentists also use these printers to make accurate models for crowns, bridges, and aligners. This improves patient care and speeds up treatments. Printing with safe materials for the body makes these printers even more useful in medicine and dentistry.

Artistic and consumer goods production

Artists and designers use dual extruder 3D printers to make creative projects. You can print detailed sculptures, colorful designs, and useful art pieces easily. Using dissolvable supports lets you create shapes that are hard to make with other methods.

In making consumer goods, these printers combine looks and usefulness. For example, you can print a phone case that is both stylish and protective. This makes dual extruder 3D printers great for creating unique, high-quality items.

Did you know? Dual extruder 3D printers are used in car and airplane industries. They make lightweight parts with multiple materials, saving time and effort in production.

Aerospace and automotive innovations

Dual extruder 3D printers are changing how planes and cars are made. These printers help create parts that are light, strong, and complex. By using two materials in one print, you can make designs that were hard to do before.

Lightweight Components for Efficiency

Planes need to be light to save fuel. Dual extruder printers mix tough materials with lighter ones. For example, you can print a part with a strong outside and a light inside. This makes parts weigh less but stay strong. Lighter parts help planes and rockets use less fuel and cost less to run.

Prototyping and Customization

Dual extruder printers make testing new designs faster. Car engineers use them to try out parts before making many copies. For example, you can print a car grille with hard and soft sections at the same time. This speeds up testing and makes sure the design works well.

Tip: Use dissolvable supports for tricky designs. They save time and make smoother models.

Heat-Resistant and Functional Parts

Planes and cars need parts that handle heat and stress. Dual extruder printers can mix heat-proof materials with flexible ones. This is great for making engine parts or shapes that cut through air easily.

Feature | Benefit for Planes/Cars |

|---|---|

Multi-material printing | Makes parts strong and bendable. |

Lightweight designs | Saves fuel and money. |

Rapid prototyping | Helps test ideas faster. |

Dual extruder 3D printers help invent better parts for planes and cars. Whether for flying or driving, these printers make new ideas possible.

Best Dual Extruder 3D Printers on the Market

Top models and their standout features

When picking a dual extruder 3D printer, look for reliable and flexible options. Here are some great choices:

Flashforge Creator 3: This printer uses two extruders that work separately. It can print with two materials at once. Its extruder heats up to 300 °C, handling tough filaments. It also prints fine details with a 50-micron layer height.

CreatBot F430: This printer has a big build space (400 x 300 x 300 mm). It includes a heated bed (120 °C) and works with many materials. Features like filament detection and print resume make it easy to use.

Fusion3 F410: Built for tough jobs, it has a strong metal frame. Its heated bed has multiple zones, and it uses special heads for abrasive filaments. This makes it perfect for hard projects.

Raise3D E2: This printer heats up to 300 °C and prints very thin layers (20 microns). Its dual extruders work independently, making prints clean and accurate.

These printers are great for tricky designs and advanced materials. They work well for both experts and beginners.

Choosing the right printer for your needs

The best dual extruder 3D printer depends on what you need. If you want detailed prints, choose one with high resolution and filament options. For bigger projects, pick a printer with a large build area.

Look for extras like filament sensors and heated beds. These features make printing easier and reduce mistakes. Beginners should pick simple models with easy controls. Professionals might prefer advanced printers for complex tasks.

Price ranges and value considerations

Dual extruder 3D printers come in different price ranges. Basic models for small businesses cost $200 to $1,000. These are affordable for beginners. High-end printers cost more but last longer and perform better.

Think about material costs and ease of use when deciding. A printer that works with many filaments can save money over time. Balancing the price with features helps you get the most value.

Recommendations for beginners and professionals

Picking the best dual extruder 3D printer depends on your skills and needs. Beginners and experts require different features, so choose wisely.

For Beginners

If you're just starting, pick a printer that's easy to use. Look for simple controls and settings already set up for you. These make learning easier and let you focus on printing.

Here are some helpful beginner features:

Automatic Bed Leveling: Keeps prints smooth without needing manual fixes.

Filament Sensors: Warns you when filament is low to avoid mistakes.

Affordable Price: Start with a model under $1,000 to save money.

Tip: Try the Flashforge Creator Pro. It’s beginner-friendly and has dual extrusion.

For Professionals

Experts need advanced tools for detailed and high-quality prints. Look for printers with bigger build areas, better resolution, and more filament options.

Important features for professionals include:

Independent Dual Extruders: Prints two materials at once for complex designs.

High-Temperature Nozzles: Works with strong filaments like nylon and carbon fiber.

Precision and Speed: Choose printers with thin layers and faster speeds.

Feature | Why It’s Useful |

|---|---|

Large Build Volume | Makes bigger parts and prototypes. |

Advanced Filament Support | Prints strong, durable materials. |

Customizable Settings | Gives control over every detail. |

Note: The Raise3D E2 is great for experts. It’s fast, precise, and flexible for tough projects.

No matter your skill level, the right printer helps you create better designs. Match the features to your experience and project needs.

How Dual Extruder 3D Printers Work

Overview of dual extrusion mechanics

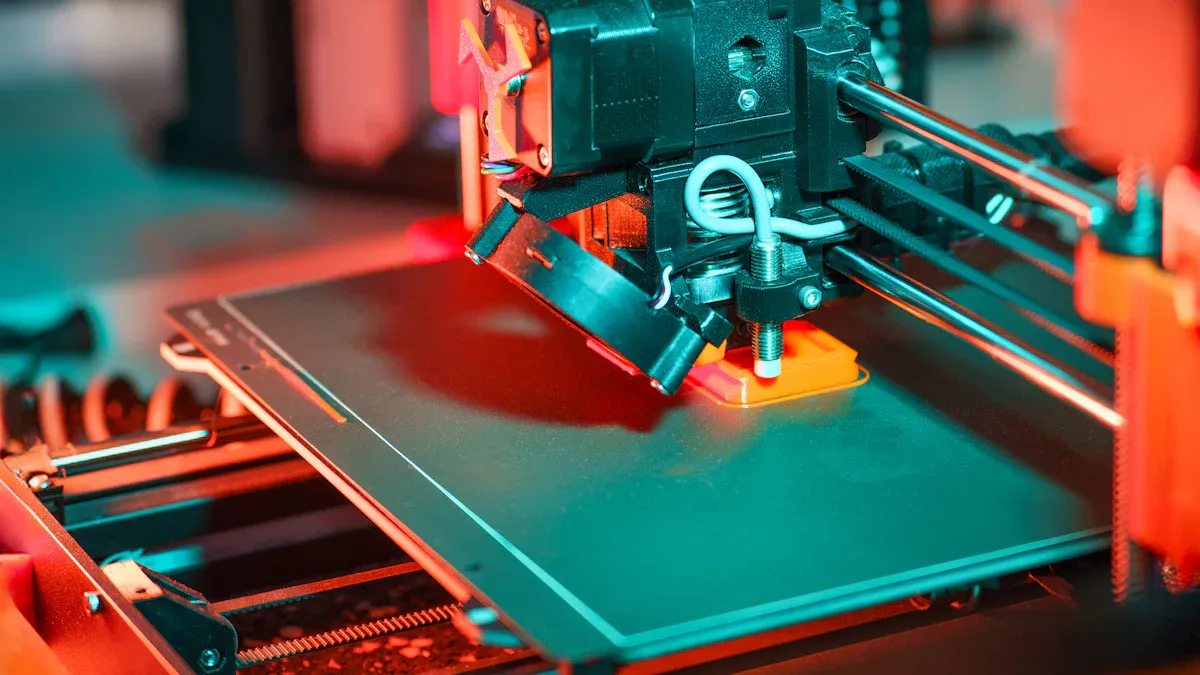

Dual extrusion lets you print with two materials or colors at once. It uses two nozzles or extruders that work together. This helps you make detailed designs, mix materials, or add bright colors. The printer carefully coordinates the extruders for smooth and neat results.

Each extruder feeds its own filament into its nozzle. This keeps the materials separate and avoids mixing problems. Some advanced printers use special systems to handle different materials better. For example, they can combine plastics that need unique handling methods. These features make dual extrusion great for creating multi-material objects.

Aspect | Description |

|---|---|

Temperature Needs | Filaments melt at different temperatures, so settings must match. |

Adhesion | Materials must stick to the bed and each other for strong prints. |

Shrinkage Issues | Cooling can cause warping if materials shrink differently. |

Strength | Material choice affects how strong or flexible the print is. |

Appearance | Different materials can change how the final print looks. |

Print Settings | Adjust temperature and speed to avoid problems like stringing. |

Common Problems | Issues like jamming or oozing need careful setup to fix. |

Dual extrusion opens up new ways to make strong, useful, and good-looking designs.

Filament types and compatibility

Picking the right filaments is key for dual extrusion printing. Each filament has its own melting point, strength, and stickiness. Choosing compatible filaments ensures your prints work well and look great.

Here are some popular filament types for dual extrusion:

PLA (Polylactic Acid): Easy to use and eco-friendly, great for beginners. Works well with PVA for dissolvable supports.

ABS (Acrylonitrile Butadiene Styrene): Strong and durable, ideal for tough parts. Needs a heated bed and good ventilation.

TPU (Thermoplastic Polyurethane): Flexible and bendable, perfect for soft parts. Pairs well with rigid materials like PLA or ABS.

Nylon: Tough and wear-resistant, great for industrial use. Needs high heat and controlled conditions.

PVA: Water-soluble, used for supports in complex designs.

When choosing filaments, check their melting points and how well they stick together. For example, PLA and TPU work well because they have similar temperature ranges and good adhesion. Mixing materials with very different cooling rates can cause problems like warping.

Tip: Always read the filament maker's instructions to avoid printing issues.

Optimizing print settings for dual extrusion

To get the best results, adjust your printer settings for each filament. Every material has specific needs, so fine-tuning is important.

Here are some tips for better dual extrusion printing:

Set Correct Temperatures: Match each extruder's temperature to its filament. For example, PLA prints at 190–220°C, while ABS needs 230–250°C.

Align Nozzles Properly: Misaligned nozzles can ruin prints. Use your printer's tools to fix alignment.

Adjust Retraction: Retraction stops oozing by pulling filament back during pauses. Test different settings to find the best one.

Use Wipe Towers: These clean the nozzles between material changes to prevent mixing.

Heat the Bed: A heated bed helps materials stick and reduces warping, especially for ABS and nylon.

Slow Down for Details: Lower speeds improve accuracy for tricky designs or multi-material prints.

Note: Dual extrusion printers need more care than single extruders. Clean the nozzles often and check for clogs to keep them working well.

By fine-tuning your settings, you can make the most of dual extrusion and create amazing 3D prints.

Maintenance and Calibration Tips

Taking care of your dual extruder 3D printer keeps it working well. Regular maintenance stops problems like jams, uneven layers, or misaligned parts. Follow these simple tips to keep your printer in great shape.

Keep the Build Plate Clean

A clean build plate helps your printer work properly. Dust or leftover filament can mess up bed leveling. Before printing, wipe the plate with a cloth or alcohol cleaner. This helps prints stick better and avoids warping.

Do Calibration Tests

Test prints check if your printer is working right. Use small models to see if layers are even. If layers look uneven, adjust the bed or nozzle height. Regular tests help you fix problems early and keep prints accurate.

Check Bed Springs

Bed springs keep the plate steady. Over time, they can wear out or loosen. Check them often and replace worn springs. Strong springs keep the plate level and improve print quality.

Tighten the Belts

Belts move the printer’s parts. Loose belts can cause slipping and bad prints. Check belts for wear and tighten them if needed. Proper belt tension makes prints smoother and extends the printer’s life.

Recalibrate After Changes

If you replace parts like nozzles or belts, recalibrate the printer. New parts can change alignment. Recalibrating ensures everything works together correctly. This is especially important for dual extrusion printing.

Tip: Set a schedule for maintenance. Weekly or monthly care keeps your printer running smoothly and avoids downtime.

Fix Common Calibration Problems

Even with care, problems can happen. Here are some common issues and fixes:

Uneven Layers: Adjust the bed and nozzle height for even layers.

Filament Jams: Clean the extruders and check for blockages.

Nozzle Misalignment: Use tools to align the nozzles correctly.

Problem | Fix |

|---|---|

Uneven Layers | Adjust bed and nozzle height. |

Filament Jams | Clean extruders and check the path. |

Nozzle Misalignment | Align nozzles with proper tools. |

Fixing these problems quickly avoids failed prints and keeps quality high.

Taking time to maintain and calibrate your printer is worth it. A cared-for printer makes better prints, lasts longer, and saves money on repairs.

Challenges of Using Dual Extruder 3D Printers

Common problems like leaks and filament clogs

Dual extruder 3D printers are powerful but can have issues. One common problem is leaking, where an idle nozzle drips filament onto the print. This can ruin the print and make extra cleanup necessary. Adjusting retraction settings can help stop leaks by pulling filament back during pauses. However, finding the right settings takes practice and testing.

Filament clogs are another issue. These happen when filament gets stuck in the nozzle or extruder. Clogs can stop printing and might harm the printer if not fixed quickly. Cleaning nozzles often and using good-quality filament can help prevent this. Also, check the filament path for blockages before starting a print.

Tip: Use cleaning tools like wipe towers to clear nozzles during material changes. This keeps prints smooth and improves efficiency.

Handling material compatibility

Picking the right materials is key for dual extrusion printing. Some materials don’t work well together and can make weak prints. For example, mixing PLA with TPU or PET can cause poor bonding. Studies show that PLA-TPU prints are much weaker than pure PLA. This shows why choosing compatible materials is so important.

To avoid problems, use materials with similar melting points and cooling needs. For instance, PLA and PVA work well together because they stick easily and share temperature ranges. But combining PLA with nylon or ABS can cause warping due to different cooling rates.

Note: Test material combinations on small prints first. This helps spot problems early and improves print quality.

Fixing problems and useful tips

Fixing dual extruder printer issues takes patience and care. Start by figuring out what’s wrong. For leaks, adjust retraction settings and use wipe towers to clean nozzles. If clogs happen, check the nozzle and extruder for blockages. Regular cleaning keeps the printer working well.

For material issues, pick filaments that match in temperature and cooling needs. If they still don’t stick, try using glue or primers to improve bonding.

Tip: Keep a notebook to track settings and changes for different materials. This helps you learn what works best and avoid repeating mistakes.

By solving these problems, you can use dual extrusion printers to make amazing, high-quality designs.

Long-term maintenance best practices

Taking care of your dual extruder 3D printer keeps it working well. Regular upkeep avoids expensive repairs and keeps prints looking great. Follow these simple tips to make your printer last longer.

1. Clean the Nozzles Often

Filament leftovers can block nozzles and cause uneven printing. Use a cleaning needle or special tools to clear out debris. For tough clogs, heat the nozzle and use cleaning filament to remove stuck material.

Tip: Clean the nozzles after every 10–15 prints to prevent clogs.

2. Lubricate Moving Parts

Parts like rods and bearings need oil to move smoothly. Use a good-quality lubricant suggested by the maker. Apply only a little to avoid dust sticking to it.

3. Check and Tighten Belts

Loose belts can mess up prints and lower accuracy. Look at the belts often and tighten them if they feel loose. Replace worn belts to keep the printer running smoothly.

4. Keep the Build Plate Clean

A clean, flat build plate helps prints stick and stops warping. Wipe it with rubbing alcohol before printing. If the plate is removable, check for scratches or damage and replace it if needed.

5. Update Firmware and Software

Printer makers release updates to fix bugs and improve performance. Check for updates regularly and install them to keep your printer working its best.

Maintenance Task | How Often | Tools You Need |

|---|---|---|

Nozzle Cleaning | Every 10–15 prints | Cleaning needle, filament |

Belt Check | Monthly | Allen wrench |

Lubrication | Every 3 months | Good-quality lubricant |

Note: Always follow the maker’s instructions for care. Proper maintenance keeps your printer reliable for a long time.

By following these steps, you can avoid problems and enjoy better printing. A well-cared-for printer makes high-quality prints every time.

Creative Uses for Dual Extruder 3D Printers

Multi-material functional prototypes

Dual extruder 3D printers let you make useful prototypes easily. You can mix hard and soft materials in one print. This is great for testing designs needing strength and flexibility. For example, using PLA with TPU makes strong parts with bendable sections. This works well for wearable gadgets or moving mechanical parts.

Water-soluble supports like PVA help with tricky designs. These supports dissolve in water, leaving clean models behind. This is helpful for designs with overhangs or hidden spaces. Dual extrusion simplifies prototyping and gives better results.

Examples of multi-material prototypes:

A phone case with a hard shell and soft inside.

Hinges or joints mixing tough plastic with flexible parts.

Complex machines with moving pieces inside.

Artistic and decorative projects

Dual extruder 3D printers make creative designs easier to print. You can use different filaments for bright colors or cool textures. Artists use these printers for sculptures, decorations, or even useful art. Dissolvable supports allow for detailed and delicate designs.

For instance, you can print a colorful vase with fancy patterns. Or, make a sculpture with tiny details that are hard to carve by hand. These printers help you try new ideas and expand your creativity. Whether you're an artist or hobbyist, dual extrusion offers endless possibilities.

Combining rigid and flexible materials

Dual extruder 3D printers can mix hard and soft materials in one print. This is useful for making parts that need to be strong but also flexible. For example, you can print a shoe sole with a tough bottom and soft top. This saves time by skipping assembly steps.

Using PLA for hard parts and TPU for soft parts works well. These materials stick together because they need similar heat levels. This feature helps create new products for healthcare, cars, and everyday items.

Tip: Test materials on small prints first. This avoids problems like warping or bad sticking.

Using soluble supports for detailed designs

Soluble supports help make detailed 3D designs possible. These supports act like temporary helpers, holding up tricky parts like overhangs or bridges while printing. Once the print is done, you can dissolve them in water or a special liquid. This leaves your model clean and smooth.

These supports let you print designs that are hard to make otherwise. For example, think about printing a hollow ball with tiny details inside. Without supports, the ball might fall apart during printing. Materials like PVA (Polyvinyl Alcohol) or BVOH (Butenediol Vinyl Alcohol) make such designs possible.

Why Use Soluble Supports?

Easy Cleanup: They dissolve fully, leaving no scratches or marks.

Complex Shapes: Print moving parts or hidden spaces with ease.

Saves Time: No need to remove supports by hand anymore.

Tip: Warm water dissolves PVA faster. For BVOH, check the maker’s instructions for best results.

Picking the Right Filament Match

Choosing the right materials is key for good prints. Soluble supports work well with filaments like PLA, ABS, or PETG. These materials stick to PVA or BVOH, making strong and stable models.

Filament Type | Best Soluble Support | Common Uses |

|---|---|---|

PLA | PVA | Art pieces, prototypes |

ABS | BVOH | Strong parts, industrial use |

PETG | PVA | Long-lasting products |

Soluble supports make it easier to create detailed and professional-looking designs. They open up new ways to explore creativity and improve your prints.

Future Trends in Dual Extruder 3D Printing

New Ideas in Multi-Material Printing

The future of dual extruder 3D printers is exciting. Better slicing software and easier controls are coming soon. These updates will make it simpler to create tricky designs, even for beginners.

AI and machine learning are also being added. Future printers might adjust settings on their own to avoid mistakes. This will make prints look better and save time. Modular printers are another trend. You can upgrade parts to keep your printer up-to-date as technology improves.

Sustainability is becoming important too. Companies are making printers that use less energy and eco-friendly materials. This helps the planet and saves money over time.

Better Filaments for Printing

Filaments are key to 3D printing, and they’re improving fast. New materials are being made to work well with dual extrusion. Some filaments are both strong and flexible, great for tough projects.

Water-soluble filaments like PVA are getting better. They dissolve faster and leave no mess, perfect for detailed designs. Heat-resistant and conductive filaments are also growing in use. These let you print parts that handle heat or carry electricity.

Manufacturers are making filaments that match dual extruder printers perfectly. This means you can try more materials without worrying about problems like sticking or melting.

Dual Extrusion in Big Industries

Dual extrusion is changing how industries make things. In aerospace and cars, these printers create light but strong parts. For example, you can print a tough outer layer with a light inside to save material and keep strength.

Healthcare is also using dual extrusion. It’s now easier to make custom prosthetics, dental tools, and surgical items. Using safe materials ensures these products work well for patients.

In everyday products, dual extrusion helps make cool and useful items. Think of colorful phone cases or handy kitchen tools. As technology gets better, more industries will start using dual extrusion for their needs.

Accessibility for hobbyists and enthusiasts

Dual extruder 3D printers are now easier for hobbyists to use. They used to be for professionals, but now anyone can try them. Affordable models with simple features make it easy for beginners to start multi-material printing.

Affordable Options for Beginners

Some dual extruder printers cost as little as $300. These cheaper models have basic features that are easy to understand. For example, the Flashforge Creator Pro is a good choice. It lets you try multi-material designs without spending too much money.

Simplified User Interfaces

Modern printers are simple to use. They have touchscreens and pre-set options to help you get started. You don’t need to be an expert to use them. Features like automatic bed leveling and filament sensors reduce mistakes during printing.

Tip: Pick a printer with pre-set profiles for common filaments. This saves time and makes printing easier.

Growing Community Support

The 3D printing community is growing fast. Online groups, videos, and forums give helpful advice. You can learn new tips, fix problems, and share your projects. Many companies also offer guides and support for beginners.

Feature | Benefit for Hobbyists |

|---|---|

Easy way to start dual extrusion. | |

Simple Interfaces | Makes printing less confusing. |

Community Resources | Learn and improve with others. |

Dual extruder 3D printers help you turn creative ideas into real objects. With low-cost models, easy controls, and community help, anyone can try multi-material printing.

Dual extruder 3D printers are changing how things are made. They let you build objects using two materials with great accuracy. These printers are useful for both creative and professional projects, like prototypes or detailed art pieces. The future of 3D printing is exciting, with better materials, smarter technology, and greener methods on the way. As these tools improve, they will become easier to use, faster, and better for the environment. This is a great time to discover what dual extruder 3D printers can do!

FAQ

What is the main advantage of a dual extruder 3D printer?

A dual extruder 3D printer can print with two materials or colors at once. This makes it easier to create detailed designs, combine different materials, or use dissolvable supports for smooth results.

Can beginners use dual extruder 3D printers?

Yes, beginners can use dual extruder printers. Many models are easy to use with features like automatic bed leveling and pre-set filament options. A good beginner choice is the Flashforge Creator Pro, which helps you learn step by step.

Tip: Choose a printer with simple controls to make learning fun.

What materials work best with dual extrusion?

Popular materials include PLA, ABS, TPU, and PVA. PLA works well with PVA for dissolvable supports, while TPU is great for flexible parts. Always check if the materials and temperatures match before printing.

Material | Best Use |

|---|---|

PLA | Models, art projects |

TPU | Bendable parts, gadgets |

PVA | Supports that dissolve |

How do you stop filament oozing during dual extrusion?

To stop oozing, adjust retraction settings and use wipe towers. Retraction pulls back filament during pauses, and wipe towers clean nozzles when switching materials. These tricks keep your prints clean and tidy.

Are dual extruder 3D printers worth the price?

If you need to print with multiple materials, save time, or make complex designs, a dual extruder printer is worth it. They cost more than single extruder printers but improve quality and speed, making them a smart buy for advanced projects.

Note: Think about your project needs before spending money.

Start your project with LKprototype

LKprototype company simplifies procurement for custom manufacturing, Suitable for making your products or prototypes with a variety of materials, such as metal or plastic, silicone rubber, from 3D Printing to CNC Machined Parts and Urethane Casting Service , with a focus on speed and efficiency. Our platform provides instant quotes. With LKprototype, You can connect with the team to communicate your project to ensure quality and on-time delivery.

Start with an instant quote and experience how our technology and expertise can make custom part procurement faster and easier.

LKprototype

LKprototype