When you design cnc machining threaded features, you must think about thread type, inserts, CAD display, and how easy it is to make.

Modeling external threads the right way helps the software use your design.

Thread milling uses less power and makes tools last longer, so it works better.

Good planning makes threads strong and reliable.

Key Takeaways

Pick the correct thread type for your material. This helps make strong connections and stops things from breaking.

Set thread depth and wall thickness based on material rules. This makes parts stronger and more reliable.

Use threaded inserts in soft materials or places with lots of stress. This makes threads last longer and easier to fix.

Understanding CNC Machining Threaded Features

What Are Threaded Features in CNC Machining?

Threaded features help connect parts or let you take them apart. There are two main types in cnc machining. These are internal threads and external threads.

Internal vs external threads

Internal threads are inside a hole, like in a nut. External threads are on the outside of a shaft, like on a bolt. You use internal threads to put a screw into a part. External threads let you screw a part into something else.

Functional role of threaded features in machined parts

Threaded features make strong and safe connections. They let you take things apart for fixing or changing. Many industries use different thread types for special jobs. Here is a table that shows common threads and where they are used:

Thread Type | Industry/Application | Key Characteristics |

|---|---|---|

UNC | Construction | Coarse pitch, good for soft materials, fast to install, hard to strip |

UNC | Automotive | Holds tight, easy to fix, used in engine mounts and chassis |

UNC | Agriculture | Tough, handles shaking, easy to adjust often |

UNF | Aerospace | Very strong, fits tightly, used in airplane parts |

UNF | Automotive | Holds tight, keeps joints safe, used in engines and fuel systems |

UNF | Electronics | Holds well, less likely to break, used in small devices |

Why Thread Design Matters in CNC Machining

Load-bearing and assembly reliability

When you design threads, think about how much force they need to hold. The shape and size of threads change how well they work. Thread pitch and profile help decide how much weight threads can handle.

Screw thread shape changes how force moves in a part.

Thread design helps parts stay together when stressed.

The right pitch and profile make threads stronger and last longer.

Common causes of thread failure in CNC parts

If you pick the wrong thread type or size, threads can break or strip. Using the wrong material or not following cnc machining steps can also cause problems. Always check your design and pick the best threads for your job.

Types of CNC Threads and International Standards

Common Thread Types Used in CNC Machining

When you design parts for cnc machining, you will see different thread types. The most common threads are metric threads and unified threads. Metric threads follow ISO or DIN rules. Unified threads include UNC and UNF types. Some jobs need custom thread shapes.

Metric threads (ISO, DIN)

Metric threads are measured in millimeters. They have a 60-degree angle. ISO and DIN standards help keep results consistent. Metric threads have a finer pitch. This gives you more precision.

Unified threads (UNC, UNF)

Unified threads use inches for measurement. UNC threads have a coarse pitch. UNF threads have a finer pitch. Both types use a 60-degree angle. Unified threads are common in American-made parts.

Custom and special thread profiles

Custom threads are needed for special jobs. These threads can have unique shapes or sizes. Always check if they fit before using them.

Tip: Standard threads make it easier to put parts together from different countries. They help lower costs and improve quality.

Aspect | Metric Threads | Unified Threads (Inch) |

|---|---|---|

Measurement Units | Measured in millimeters | Measured in inches |

Thread Form & Angle | Standardized 60-degree angle | 60 degrees (common), 55 degrees (Whitworth) |

Tolerance & Fit | Follows ISO standards | Uses Unified Thread Standard, may not match ISO |

Strength & Precision | Finer pitch for more precision | Pitch changes for flexibility |

Thread Standards and Tolerance Classes

You must pick the right tolerance class for threads in cnc machining. Tolerance changes how tight parts fit and how strong they are.

Internal vs external thread tolerances

Internal threads and external threads have different tolerance classes. You can choose loose, medium, or tight fits. Loose fits make assembly simple. Tight fits give more strength and precision.

Thread Class | Description |

|---|---|

1A/1B | Loose threads are easy to put together or use in dirty places. |

2A/2B | This is the most common class. It gives good strength for most jobs. |

3A/3B | Used for close tolerances. It makes sure parts fit exactly and work well. |

How tolerance affects fit and strength

The tolerance class you choose changes how threads work. Looser tolerances are good for quick assembly. Tighter tolerances help stop vibration and seal parts.

Functional Requirement | Typical Tolerance Goal |

|---|---|

Easy & Fast Assembly | |

Vibration Resistance | Tighter Tolerance (e.g., 4g6g/4H5H) |

High-Strength Fastening | Medium to Tight Tolerance |

Sealing Applications | Tighter Tolerance with sealant |

You can make parts more reliable by matching tolerance to your needs.

Designing Threaded Holes for CNC Machining

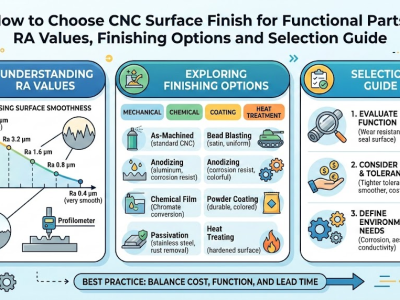

Material and Thread Suitability

When you design threads, pick the right thread type for the material. Every material acts differently when you cut threads.

Threads in aluminum CNC machining

Aluminum is easy to cut and thread. You get clean threads if you use fast speeds and coolant. Sometimes, aluminum feels sticky, so you need sharp tools. Threads in aluminum need more length to stop stripping.

Threads in plastics and soft materials

Plastics and soft metals can bend or strip if you do not follow rules. Use coarse threads for these materials. This makes it easier to put parts together and stops damage. Always check that threads are not too tight.

Threads in steel and high-strength alloys

Steel and hard alloys make strong threads. These materials get harder fast, so use sharp tools and slow speeds. Hardness helps threads last longer and resist wear. It also keeps threads accurate and safe from impacts.

Here is a table showing how materials act when you cut threads:

Material Type | Threading Characteristics |

|---|---|

Aluminum and Soft Metals | Easy to thread but can be sticky; needs fast speeds and coolant for clean threads. |

Stainless Steel and Hardened Alloys | Gets hard fast; needs sharp tools and slow speeds for good threads. |

Tip: Harder materials make threads last longer and stay accurate. They also resist damage better.

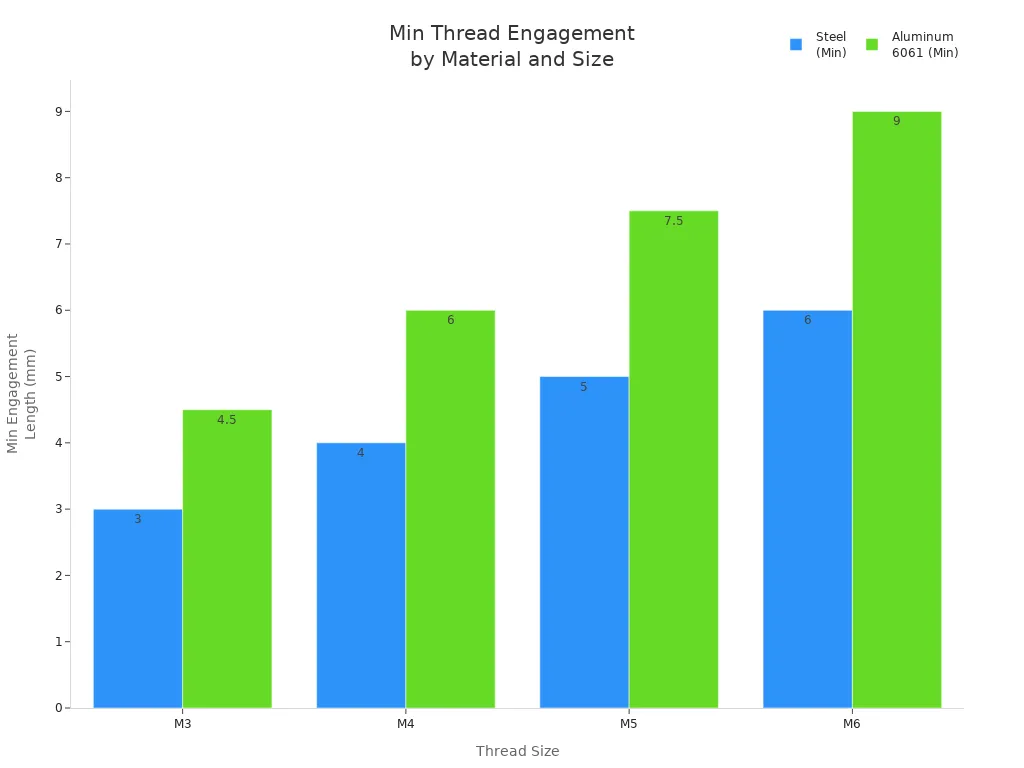

Thread Depth, Pitch, and Engagement Length

You must follow rules for thread depth, pitch, and length to make strong holes.

Minimum thread depth recommendations

The minimum length depends on the material. For steel, use at least the same as the diameter. For aluminum, use twice the diameter. This rule helps the screw break before the threads strip.

Thread Size | Steel (Min) | Aluminum 6061 (Min) |

|---|---|---|

M3 | 3 mm | 4.5 mm |

M4 | 4 mm | 6 mm |

M5 | 5 mm | 7.5 mm |

M6 | 6 mm | 9 mm |

The minimum thread length for a strong connection is about one times the diameter for steel and two times for aluminum.

Thread pitch selection guidelines

Thread pitch changes how strong threads are and how easy they are to use. Coarse threads are easier to start and less likely to cross-thread. Fine threads are stronger and resist loosening.

Thread Type | Mechanical Strength | Ease of Assembly | Resistance to Loosening | Engagement Length |

|---|---|---|---|---|

Coarse | Lower in brittle materials, higher for big sizes | Easier to use, less risk of cross-threading | More likely to loosen with vibration | Needs less length for same force |

Fine | Higher strength, less likely to strip in hard materials | Slower to assemble, higher risk of cross-threading | Better at resisting loosening | Needs more length for same strength |

Note: Use coarse threads for soft materials and fine threads for hard materials.

Avoiding over-threading and weak engagement

Do not make threads deeper than needed. Making threads too deep wastes time and can make the part weaker. If threads are too shallow, they can strip or break. Always follow rules for depth and pitch.

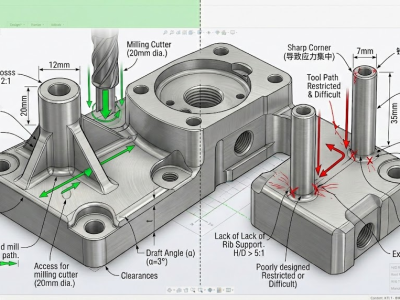

Minimum Wall Thickness and Edge Distance

You must keep enough material around holes to stop cracking and bending.

Preventing cracking and deformation

Thin walls can crack or bend when you cut threads. Keep wall thickness between 1.0mm and 2.0mm. This helps the part stay strong. If you need thin walls, add ribs or gussets for extra support.

Thin walls can crack or bend easily.

Use walls at least 1.0mm to 2.0mm thick.

Add ribs or gussets to make thin walls stronger.

Best practices for thin-wall CNC parts

Keep enough space from the edge of the part to the hole. The minimum distance from the tapped hole to the edge is important for strength. After you add the screw and countersink, keep at least 0.011 inches of wall thickness.

Keep enough material around the hole.

Do not put holes too close to the edge.

Follow rules for wall thickness and edge distance to avoid problems.

Tip: Good design threads follow these rules to make strong, reliable parts.

Threaded Inserts in CNC Machining: When and Why to Use Them

What Are Threaded Inserts?

Threaded inserts are special metal sleeves that you place inside a hole to create strong threads. You can use them to fix weak or damaged threads or to make new threads in soft materials. There are several types:

Helicoil vs press-fit vs molded inserts

Helicoil inserts look like coiled wires. You screw them into a tapped hole. They give you strong, wear-resistant threads.

Press-fit inserts have knurled or ribbed sides. You push them into a hole, and they stay in place because of friction.

Molded inserts go into a part during the molding process. You often see these in plastic parts.

When Threaded Inserts Are Necessary

You should use threaded inserts in certain situations to improve part performance:

High-cycle assembly and disassembly

If you need to take parts apart and put them back together many times, threaded inserts help. They stop threads from wearing out or stripping.

Soft materials and load-critical applications

Threaded inserts work well in soft materials like aluminum or plastic. They make the threads stronger and last longer. You also need them when your part must handle heavy loads or strong forces.

Threaded inserts boost connection strength.

They improve wear resistance, so threads last longer.

Inserts let you repair damaged holes instead of throwing away the part.

They give you stable, strong connections in high-stress jobs.

Threaded Inserts CNC Design Guidelines

Hole preparation and tolerances

You must drill the hole to the right size and shape. Follow the insert maker’s guide for the best fit. A hole that is too big or too small can cause the insert to fail.

Insert installation considerations

Choose the right installation method. Press-fit and Helicoil inserts need different tools. Make sure you install the insert straight and to the correct depth. This helps the insert hold tight and carry heavy loads. Inserts work best in materials that cannot handle high stress on their own.

CNC Threading Methods: Tapping vs Thread Milling

Tapping Threads in CNC Machining

Advantages and limitations

Tapping is used when you want to make threads fast. It works well for making lots of parts because it is quick and easy to set up. Each tap fits only one thread size and pitch. You need a new tap for every thread type. Tapping is good for most standard threads. It does not work well for custom threads or special sizes. Tapping needs a lot of force, especially in hard materials.

Aspect | CNC Thread Tapping | CNC Thread Milling |

|---|---|---|

Precision and Quality | Good enough for most jobs | Very precise with tight fits |

Tool Flexibility | One tap for each size | One tool can do many sizes |

Speed and Efficiency | Faster to use | Slower to use |

Tool Life and Cost | Cheaper tools, wear out faster | More expensive, last longer |

Setup and Programming | Easy to set up | Harder to set up, needs skill |

Risk of tap breakage

Tapping can break the tap inside the hole. This happens more in hard materials. If a tap breaks, you might have to throw away the part. Getting a broken tap out is very hard. Thread milling does not usually break tools like this. You can often fix the part if something goes wrong.

Aspect | Tap Breakage | Thread Milling Failures |

|---|---|---|

Risk Level | High, happens often and costs money | Lower, does not ruin the part |

Consequence of Failure | Usually means the part is wasted | You can often save the part |

Tool Removal Difficulty | Hard to get out of the hole | Does not get stuck in the part |

Thread Milling CNC Machining

Precision and flexibility benefits

Thread milling makes threads very accurate and smooth. You can use one cutter for many thread sizes. This helps you keep fewer tools. Thread milling is good for custom threads and tight fits. The tools last longer than tapping tools.

Cost and cycle time considerations

Thread milling takes more time because it needs more steps. The tools cost more at first but last longer. Tapping is faster for simple jobs with lots of parts. Thread milling is better for special designs or tough materials.

Process | |

|---|---|

Tapping | Faster for making many parts. |

Thread Milling | Slower, especially for big threads. |

Choosing the Right Threading Method

Prototype vs production decisions

When picking between tapping and thread milling, think about what your part needs. Tapping is best for making lots of standard threads fast. Thread milling is better for making prototypes, custom threads, or when you need very accurate threads. Think about how long tools last, how good the threads are, and how easy it is to clean chips. Always choose the method that fits your design and how you want to make your parts.

Best Practices for Reliable CNC Machined Threaded Features

Design Best Practices

Avoiding sharp internal corners

Do not use sharp corners inside threaded features. Sharp corners make parts weaker and can cause cracks. Rounded corners help tools move easily. They also lower the chance of breaking. Put a small radius at the bottom of blind holes. This keeps threads strong and safe.

Adding lead-ins and chamfers

Lead-ins and chamfers help start threading. They guide fasteners into holes. A chamfer at the hole entrance stops cross-threading. It also protects the hole from damage. Try these best practices for threaded holes:

Set thread depth as a minimum or maximum to avoid mistakes.

Keep thread depth at 1x diameter for steel and 2x for aluminum.

Do not set drill depth so machinists can adjust.

Use rolled threads if you want more strength.

Pick M6 or bigger threads to stop weak parts.

Leave enough space at the bottom of blind holes.

Tip: Check threads often for accuracy. Keep tools sharp and clean for good results.

Preventing Stripped or Damaged Threads

Assembly torque control

Use the right amount of force when putting parts together. Too much force can strip threads. Precision tools help control torque. They keep fasteners tight without breaking threads.

Practice | Benefit |

|---|---|

Proper torque application | Stops overtightening and lowers the risk of stripped threads |

Monitoring torque | Keeps force steady and avoids overload problems |

Surface finish considerations

Smooth threads lower friction and help parts fit well. Lubricants make putting parts together easier. They also protect threads from damage. Good surface finish and lubrication work together to keep threads safe.

Practice | Benefit |

|---|---|

Optimizing surface finish | Lowers friction and wear, gives a secure fit and less damage |

Makes assembly easier and keeps threads safe during installation |

Note: If you follow these steps, your threads will be strong and last a long time. They will work well in every job.

Thread Verification and Quality Control

CNC Thread Inspection Methods

You need to check threads to make sure they fit and work well. You can use different tools and machines to inspect threads in CNC parts.

Go / No-Go gauges

Go / No-Go gauges help you test if threads meet size and shape standards. You use the "Go" side to see if the thread accepts the gauge. The "No-Go" side should not fit if the thread is correct. This method gives you a quick answer. You can use it for fast checks in production.

Go / No-Go gauges are simple and fast.

You can use them for both internal and external threads.

They help you spot errors before parts leave the shop.

Optical and CMM inspection

Optical inspection uses cameras and lights to check thread shape and surface. You can see small defects that gauges might miss. CMM (Coordinate Measuring Machine) inspection uses probes to measure thread dimensions. You get detailed data about pitch, depth, and angle.

Inspection Method | What It Checks | When to Use |

|---|---|---|

Go / No-Go Gauge | Fit and size | Fast checks |

Optical | Surface flaws | Detailed checks |

CMM | Exact shape | High precision |

Tip: Use optical or CMM inspection for critical parts that need high accuracy.

Ensuring Thread Consistency in Production

Process control and repeatability

You must keep your process steady to make threads that match every time. Set up machines with the same settings. Check tools often for wear. Record inspection results to spot problems early. You can use thread verification to confirm that every batch meets your standards.

Keep machines clean and calibrated.

Train workers to follow the same steps.

Review inspection data to improve quality.

Consistent process control helps you avoid mistakes and keeps your parts reliable.

Common CNC Thread Design Mistakes to Avoid

Designing CNC threads is not always easy. You can stop many problems if you know what to look for. Here are some common mistakes and how they hurt your parts:

Mistake | Impact on Manufacturability and Reliability |

|---|---|

Thread Damage | Scratches or burrs make threads weak and short-lived. |

Thread Loosening | Loose threads make fasteners not work well. |

Thread Accuracy Issues | Bad design makes threads not fit right or swap easily. |

Heat Treatment Issues | Heat can bend threads and make them not fit. |

Overly tight tolerances

You might think tighter fits are always better. But this is not true. Tight fits make machining harder and cost more money. You may see more thread damage or mistakes. If you do not need a super tight fit, pick a normal one. This helps your parts fit well and last longer.

Tip: Only use the fit you need. This saves money and makes your threads work better.

Ignoring material behavior

Every material acts in its own way when you cut threads. If you forget this, your threads can get weak or break. Soft metals and plastics need coarse threads. Hard metals can use fine threads. If you pick the wrong type, threads can get loose or crack.

Always match the thread type to the material.

Test your design if you use a new material.

Skipping threaded inserts when needed

You might skip inserts to save time or money. This can make threads strip, especially in soft materials. Threaded inserts make threads stronger and last longer. If your part will be used a lot or hold heavy things, always use inserts.

Note: Inserts keep your threads safe and make fixing them easier if something breaks.

Conclusion: Designing Threaded Features That Work in CNC Machining

Key takeaways for engineers and designers

You can make strong threaded features if you follow simple rules. Always pick the right thread type for your material before you start. Check that your threads are deep enough and the walls are thick enough. Do not use sharp corners. Add chamfers so fasteners go in easily.

Use threaded inserts if your material is soft or will hold heavy things. Inserts help threads last longer and let you fix broken holes. Always check your threads with Go / No-Go gauges or CMM machines to keep quality high.

Here are some important things to remember:

Use standard threads for easy assembly and to save money.

Match the thread pitch to your material and the job.

Make thread depth fit how strong you need it to be.

Use the right amount of force so threads do not strip.

Leave enough space around holes to stop cracks.

Tip: You can make cnc machining better by checking your design and following good steps. This helps you avoid mistakes and keeps your parts working well.

Step | Why It Matters |

|---|---|

Choose thread type | Fits material and application |

Set depth and pitch | Gives strength and reliability |

Inspect threads | Ensures quality and fit |

You can finish your cnc machining projects well if you follow these steps. Always look over your design and use threading rules to get the best results.

You can design strong CNC threads by following these steps:

Choose the right thread type for your material.

Set clear specifications in your CAD files.

Check thread depth and wall thickness.

Inspect threads for quality.

Remember: Good planning and best practices help you get reliable, high-quality parts.

FAQ

What is the best way to show threads in a CAD model?

You should use a cosmetic thread feature in your CAD model. This helps machinists see thread size and type without slowing down the software.

When should you use a threaded insert?

Use a threaded insert when you work with soft materials or expect frequent assembly. Inserts make threads stronger and last longer.

How do you check if a CNC thread is correct?

You can use a Go / No-Go gauge. This tool quickly shows if your thread meets size and fit standards.

LKprototype

LKprototype