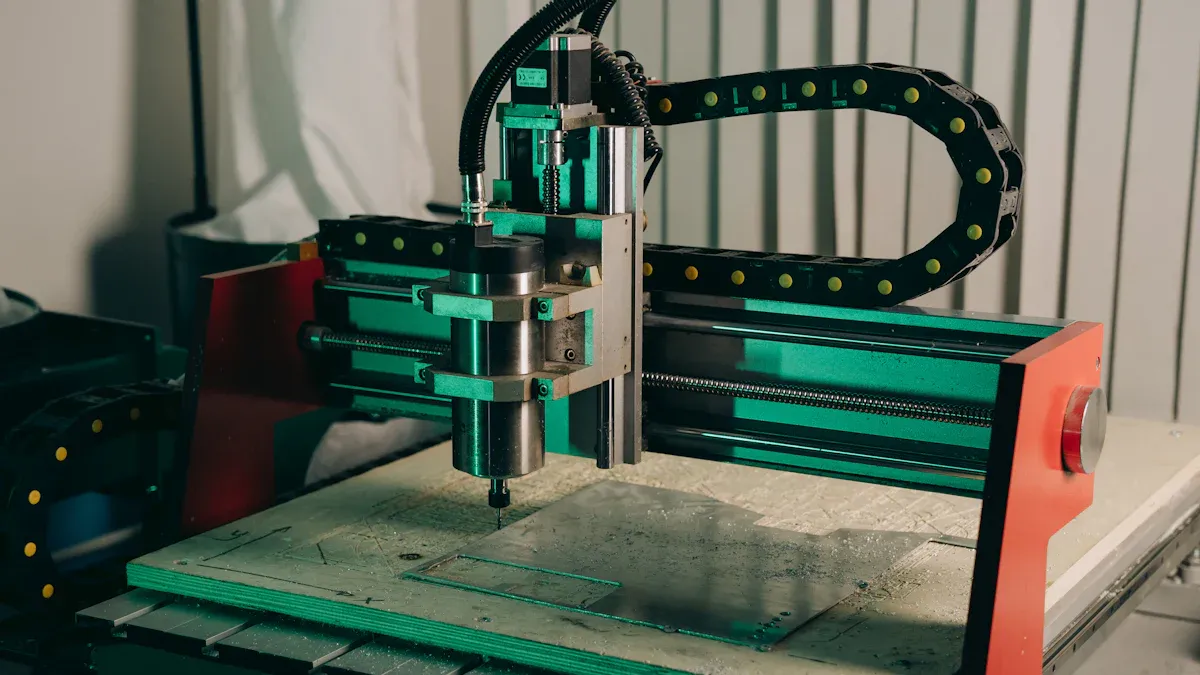

Finding the right CNC router CNC is very important for work. The right machine can help you work faster and waste less. You need a machine that fits your materials and goals. It should also meet your accuracy needs. Picking the best CNC router CNC helps your business grow now and later. Whether you use wood, metal, or other materials, CNC machines provide great accuracy and steady results. By understanding what you need, you can choose the best CNC machine and utilise it effectively.

Key Takeaways

Know your materials. Pick a CNC router that suits the type and thickness of what you use for better results.

Think about how much you produce. Get a machine that fits your current work and can grow with your needs.

Focus on precision. Make sure the CNC router cuts accurately and matches your designs.

Check long-term costs. Include maintenance, tool changes, and savings when planning your budget.

Ask for expert help. Talk to professionals and try machines before buying to make a smart choice.

Assessing Business Needs for CNC Machining

Materials and their compatibility with CNC routers

Knowing your materials is key when picking a CNC router. Different machines work best with certain materials like wood, metal, or plastic. For example, cutting hardwood or aluminium needs strong spindles and high torque. Softer materials like foam or acrylic need less power but faster cutting speeds.

Think about the thickness and hardness of your materials too. Machines with adjustable speeds and tool choices are more flexible. Matching the CNC router to your materials gives better results and keeps the machine lasting longer.

Production volume and scalability considerations

How much you produce affects your CNC router choice. For big jobs, you need a machine with a large workspace and smart controls. These machines can handle many parts at once, saving time. Scalability is also important. As your business grows, your needs may change. A machine that does many tasks helps you adjust to future demands.

Feature | Description |

|---|---|

Bigger machines suit large projects and allow for growth. | |

Advanced Control Features | Smart features improve speed and help with bigger tasks. |

Variety of Tasks Handling | Machines that do different jobs are good for scaling up. |

A scalable CNC router helps your business grow without losing quality.

Precision and accuracy requirements for your projects

Precision and accuracy are very important for your projects. Precision means cuts are consistent, while accuracy ensures the design is correct. For instance, if you cut a 10-inch circle, accuracy makes sure it’s exactly 10 inches. Both are needed for high-quality work.

Several things affect precision and accuracy:

Machine Calibration: Aligns the machine with the design file.

Maintenance: Stops problems that could ruin precision.

Setup: Correctly fixing materials and tools improves accuracy.

Environmental Factors: Heat and moisture can change materials.

Operator Expertise: Skilled workers make the machine perform better.

Focusing on these points ensures your CNC router gives great results every time.

Planning for future business growth

Buying a CNC router is not only about today’s needs. You should think about how it can help as your business grows. A machine with features that can expand lets you handle more work later without losing quality.

The global market for CNC machining is growing fast. By 2025, it could be worth $1.5 billion, growing at 8% each year. By 2033, this value might reach $2.8 billion. This shows more industries are using CNC routers, making them a smart choice for staying competitive.

Year | Market Value (in billion USD) | Growth Rate (%) |

|---|---|---|

2025 | 1.5 | 8 |

2033 | 2.8 |

When planning for growth, check if the machine can do many tasks. A flexible CNC router lets you make new products and enter new markets. Machines with smart controls and changeable parts are better. They let you upgrade as your needs change.

Tip: Pick a CNC router with a bigger cutting area and strong spindle power. These features handle larger jobs and tougher materials, keeping the machine useful as your business grows.

Also, think about how the machine works with new technology. CNC routers that connect with modern software and automation make work faster and easier. This helps your business use future tools and stay efficient.

Choosing a CNC router that fits your growth plan ensures success and good returns on your investment.

Understanding CNC Machine Routers Types and Features

Types of CNC routers (e.g., gantry, moving table)

There are different types of CNC routers for various tasks. Each type has its own benefits. Gantry CNC routers have a moving gantry. They are great for large items like aircraft parts. These machines are strong and precise, even for tough jobs. Moving table CNC routers have a fixed gantry and a moving table. This design makes setup easier. They are good for medium projects like car moulds.

Other types include desktop CNC routers, which are small and good for prototypes. Industrial CNC routers are made for heavy work and high production. For detailed designs, 5-axis CNC routers can cut in many directions. ATC CNC routers switch tools automatically, saving time on big jobs. Nested-based CNC routers reduce waste by using materials efficiently.

Type of CNC Router | Applications and Characteristics |

|---|---|

Industrial CNC Routers | Built for heavy work, high output, and precision. |

Desktop CNC Routers | Small size, ideal for prototypes and small tasks. |

Hobby CNC Routers | Affordable and versatile for personal crafts. |

3-Axis CNC Routers | Common type, good for flat surfaces like signs. |

4-Axis CNC Routers | Adds rotation, useful for complex shapes. |

5-Axis CNC Routers | Advanced for detailed designs and smooth finishes. |

ATC CNC Routers | Switches tools automatically for faster work. |

Nested-Based CNC Routers | Saves material and reduces waste during cuts. |

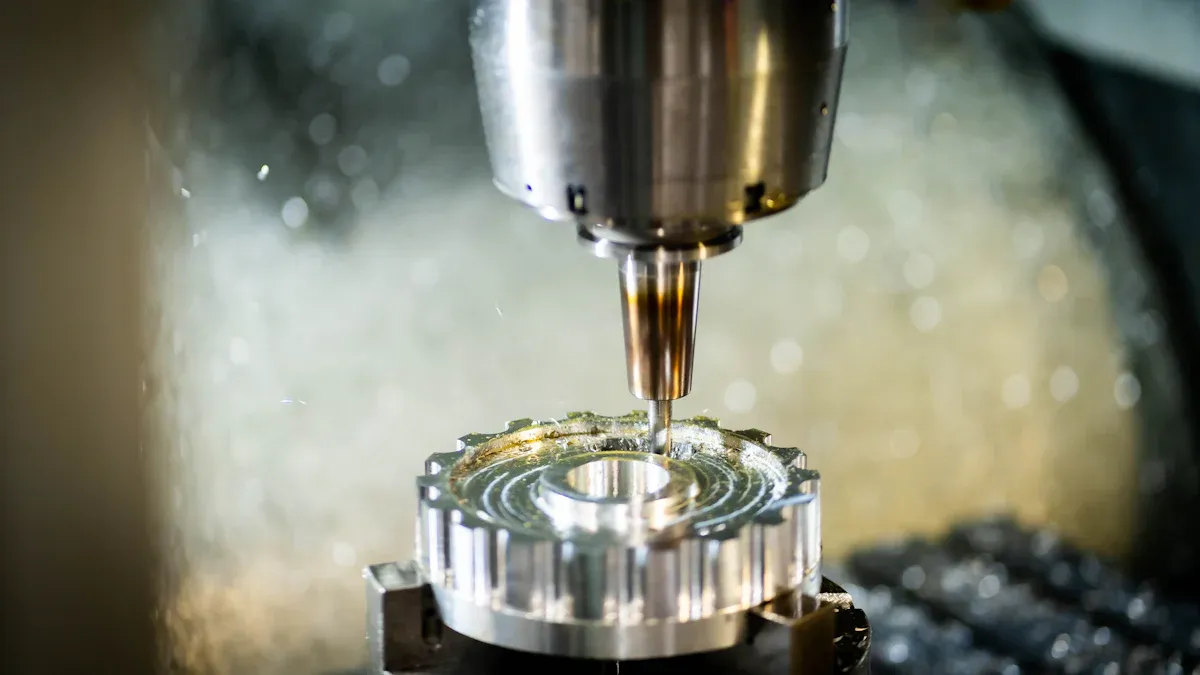

Key features like spindles, motors, and controls

The features of a CNC router affect how it works. Spindles are important for cutting. Faster spindles are better for soft materials. Stronger spindles handle hard materials like metal. Motors move the machine and keep it steady. Servo motors are more accurate than stepper motors. They are better for detailed work.

Controls are also key. Modern CNC routers have easy-to-use controls. These make programming cutting paths simple. Some machines use software for automation. This reduces manual work and boosts productivity. Picking a good tooling supplier ensures you get quality tools. This improves the machine’s performance.

Choosing the right size and cutting area for your needs

The size of the CNC router affects what it can do. Bigger cutting areas are good for large items like wood panels. They save time by avoiding material repositioning. Smaller machines fit small spaces and are good for small tasks.

Think about spindle speed when choosing a machine. Faster spindles cut harder materials smoothly. Check the machine’s size and capacity to match your needs. For example, if you work with large wood pieces, pick a machine with a big cutting area and strong spindle. Bigger machines are also more stable, which helps with precision.

Tip: Measure your workspace and think about your projects before buying a CNC router. This helps you pick the right machine for your needs.

Software compatibility and ease of use

Picking a CNC router isn’t just about the machine. The software and controls are very important too. Good software makes the machine easier to use and saves time.

Users have different skill levels. Beginners need simple software to learn quickly. Experts may want advanced tools with more features. Choosing software that fits your skills makes work smoother and less stressful.

The software should also work well with other programmes. Many businesses use CAD or CAM to design projects. A CNC router that connects easily with these programmes avoids mistakes and speeds up work. This also helps teams share files and work together better.

Easy-to-use software is very helpful. Simple menus and clear options make it easier to learn. You can focus on your tasks instead of struggling with the system. Modern CNC routers often have drag-and-drop tools or ready-made templates. These features are great for beginners.

Feature | Benefit |

|---|---|

User Skill Level | Beginners need simple tools; experts may prefer advanced features. |

Compatibility with Other Software | Smooth file sharing saves time and avoids errors. |

Easy Interface | Simple controls help users learn faster and work efficiently. |

When choosing a CNC router, think about how the software fits your needs. Look for systems with updates and good support. These keep your machine useful as technology changes. By focusing on software compatibility and ease of use, you can work faster and avoid delays.

Evaluating Costs and Long-Term Value

Budgeting for a CNC router

Planning your budget is key when buying a CNC router. Start by checking the price range for the machine you need. This helps you avoid spending too much and ensures good value. For example, custom CNC routers can cost $50,000 to $250,000. However, they can boost production efficiency by up to 40%. This makes them a smart choice for improving your business.

Compare prices from different sellers to make a better choice. This helps you find a machine that fits your budget. Think about long-term benefits too. A high-quality CNC router may cost more at first. But it can save money and improve work efficiency over time.

Tip: Custom CNC routers often cut setup times and lower running costs. They can pay for themselves in 8 to 24 months.

New vs used CNC machines: Pros and cons

Choosing between new and used CNC routers depends on your needs and budget. New machines cost $100,000 to $300,000. They perform better, need less maintenance, and have modern features. Used machines are cheaper, costing $70,000 to $90,000. But they might need repairs and updates, which can add costs.

Type of CNC Router | Cost Range | Long-term Value Considerations |

|---|---|---|

New | $100,000 - $300,000 | Costs more upfront but offers better performance and lower maintenance. |

Used | $70,000 - $90,000 | Cheaper initially but may need repairs and updates. |

If you choose a used machine, check its condition and service history. Think about upgrade costs too. New machines are pricier but often come with warranties and the latest technology. This makes them a safer long-term option.

Maintenance and operational cost considerations

Maintenance and running costs are important when owning a CNC router. Regular care keeps the machine working well and avoids big repair bills. Main costs include electricity, tool replacements, and software fees. For instance, tools wear out, so plan for replacements.

Cost Factor | Description |

|---|---|

Electricity Costs | Power use depends on machine size and activity; check local rates. |

Tool Replacements | Tools wear out; plan for replacements based on usage. |

Material Costs | Material prices vary; research helps plan expenses. |

Software Licences | Some setups need extra software, which adds ongoing costs. |

Maintenance and Repairs | Regular care is needed; costs depend on the machine and schedule. |

Training Costs | Training operators may cost extra but reduces future mistakes. |

Training workers is also important. Skilled operators can use the machine better, reducing errors and downtime. Working with a trusted CNC tool supplier ensures you get quality tools, improving performance.

Note: Good maintenance and support extend your CNC router's life and lower surprise costs.

Calculating ROI for CNC machining investments

Knowing the ROI of a CNC router helps you decide wisely. ROI shows how much profit you make compared to the cost. This calculation ensures your purchase matches your business goals.

To find ROI, follow these steps:

Find Total Investment Cost: Add the machine price, setup, training, and tools.

Estimate Yearly Savings: Think about how it cuts labour, waste, and time.

Predict Revenue Growth: See how it boosts work speed and new opportunities.

Calculate ROI: Use this formula:

ROI (%) = [(Yearly Savings + Revenue Growth) - Total Cost] ÷ Total Cost × 100

For example, a company spent ₹2 Crores on a CNC router. At first, slow work and tool wear caused problems. By improving tool paths, doing regular maintenance, and using live monitoring, they achieved:

25% faster cycle times.

18% less material waste.

30% higher productivity.

These changes helped them recover their money in three years, not five.

Metric | Before Changes | After Changes | Improvement (%) |

|---|---|---|---|

Cycle Time | Slow | Faster | 25% |

Scrap Rate | High | Lower | 18% |

Productivity | Low | Higher | 30% |

Tip: Keep up with maintenance and use tools wisely to improve ROI. Advanced features like live monitoring can give long-term benefits.

By working out ROI, you can see if a CNC router is worth it. This method helps you earn more and grow steadily.

Practical Considerations for CNC Router Selection

Power and space needs for setup

When setting up a CNC router, think about power and space. Most machines use 208 or 240 volts, which is cheaper than 480 volts. For running several machines, a 240-volt, 3-phase, 200-amp supply works well. If you plan to grow, 400 amps of 3-phase power is better for the future.

Space is also very important. A workshop of 24 feet by 36 feet (about 900 square feet) is good for one machine. Bigger setups may need 2,000 square feet for more equipment and better workflow. Leave extra room for storing materials and moving safely.

Tip: Plan your power and space for future growth. This saves money on upgrades later.

Securing materials and handling them properly

Holding materials firmly is key for accuracy and speed. Automated clamps or vacuum systems keep parts steady and reduce mistakes. These tools also lower vibrations, giving cleaner cuts and better results.

Know your material type too. Softer materials need different holding methods than harder ones. Robotic loaders can help by automating loading and unloading, saving time and effort.

Key Suggestions:

Use clamps or vacuum systems to hold materials tightly.

Pick holding methods based on your project’s needs.

Try automated systems to save time and reduce manual work.

Note: Good material handling improves accuracy and protects your CNC router from wear.

Moving, setting up, and installing the machine

Moving and installing a CNC router can be tricky. Use secure shipping to avoid damage. Larger machines may need special packaging. Plan the freight process, including booking and tracking deliveries, to ensure everything arrives on time.

If buying internationally, handle customs paperwork carefully. Insurance is important to cover any damage during shipping. Once delivered, you might need experts to unload and install the machine.

Step | What to Do |

|---|---|

Shipping | Pick trusted carriers for safe delivery. |

Packaging | Use strong or custom packaging to avoid damage. |

Freight Planning | Schedule pickup, tracking, and delivery times. |

Customs | Follow all rules for international shipping. |

Insurance | Get insurance to protect against loss or damage. |

Final Setup | Arrange professional help for unloading and installation. |

Tip: Use skilled logistics teams to make transport and setup easier.

By managing these steps well, you can install your CNC router smoothly and prepare your business for success.

Availability of technical support and training

When picking a CNC router, think about support and training. These services help you use the machine well and fix problems fast.

Why Technical Support is Important

Good technical support reduces delays and keeps work going. If the machine breaks, skilled help saves time and money. Look for suppliers that provide:

24/7 Support Services: Help anytime for urgent problems.

On-Site Repairs: Experts who visit to fix tough issues.

Remote Troubleshooting: Quick fixes via phone or video calls.

Tip: Ask if the supplier offers a warranty with free support at first.

Why Training is Needed

Training helps you and your team use the CNC router properly. Trained workers make fewer mistakes, work faster, and keep the machine in good shape. Training usually includes:

Basic Operations: How to set up and use the machine.

Software Usage: Learning to program and design with the software.

Maintenance Practices: Cleaning and checking the machine regularly.

Some suppliers give hands-on training, while others offer online lessons or videos. Pick what works best for your team.

Training Type | Benefits |

|---|---|

In-Person Training | Practical learning with expert guidance. |

Online Courses | Learn anytime at your own speed. |

Video Tutorials | Easy-to-follow guides for daily tasks. |

Note: Spending on training boosts your team’s skills and avoids costly errors.

By focusing on support and training, you can get the most from your CNC router and keep your business running smoothly.

Making the Final Decision on a CNC Router

Summarising your business requirements

Before picking the right CNC router, list your project needs. Write down the materials you use and the tools required for your tasks. Think about how much you produce and the accuracy your work needs. For example, if you make many items, you’ll need a machine with strong controls and good software for efficiency.

Choose a CNC machine that matches your business goals. A bigger cutting area is better for large projects. Smaller machines are great for detailed designs. Always pick tools and accessories that fit your needs to avoid wasting money.

Researching and comparing CNC router options

Research is key to finding the best CNC machine. Start by looking at different machines in the market. Compare features like spindle strength, cutting speed, and control systems. Pick a machine that is flexible and suits your projects.

Check manufacturers’ websites and read reviews to learn about machine performance. Look at the tools and extras included with each model. A good CNC tooling setup with quality tools will improve your work.

Make a table to compare options. Include costs, maintenance, and software compatibility. This helps you choose the best CNC system for your business.

Consulting industry experts for advice

Talking to experts can make your choice easier. They can suggest the right tools and trusted suppliers. Experts also explain the control systems and software you’ll need for your work.

Visit trade shows or join online groups to meet people with CNC machine experience. Their advice can help you find the best CNC router for your needs. Some suppliers also offer consultations to guide your decision.

Tip: Get advice from reliable sources to ensure your choice supports your long-term goals.

Testing and checking CNC machines before buying

Before buying a CNC router, testing ensures it’s the right choice. Careful checks help you see if the machine fits your needs. Following simple steps can show any problems and confirm it works well.

Start with a visual check. Look at the machine’s parts for damage or wear. Check for loose screws or bent pieces that might cause issues. A good machine should look strong and move smoothly.

Then, test the accuracy of the machine. Cut a few shapes and measure them. Compare the sizes to what you expected. This shows if the machine can make precise cuts for your projects.

Check the surface quality of the cuts. Feel the edges to see if they are smooth and even. A good CNC router should cut cleanly without rough spots. This test shows if it can handle your materials well.

Test the machine’s speed and feed settings. Try cutting at different speeds to find the best one. This helps you know how fast the machine can work without losing quality.

Lastly, check the tool wear after cutting. Look at the tools to see if they wear out too quickly. Uneven wear might mean the machine isn’t set up properly.

Tip: Ask the seller for a report about the machine’s tests. It should include details about accuracy, surface quality, and tool wear. This report helps you understand how well the machine works.

By doing these tests, you can pick a CNC router that works well for your business and gives great results.

Choosing the right CNC router is very important for your business. You need to understand your materials, production needs, and future goals. By checking CNC machines carefully, you can pick one that fits your work and plans. Also, think about costs, growth options, and support to make a smart choice.

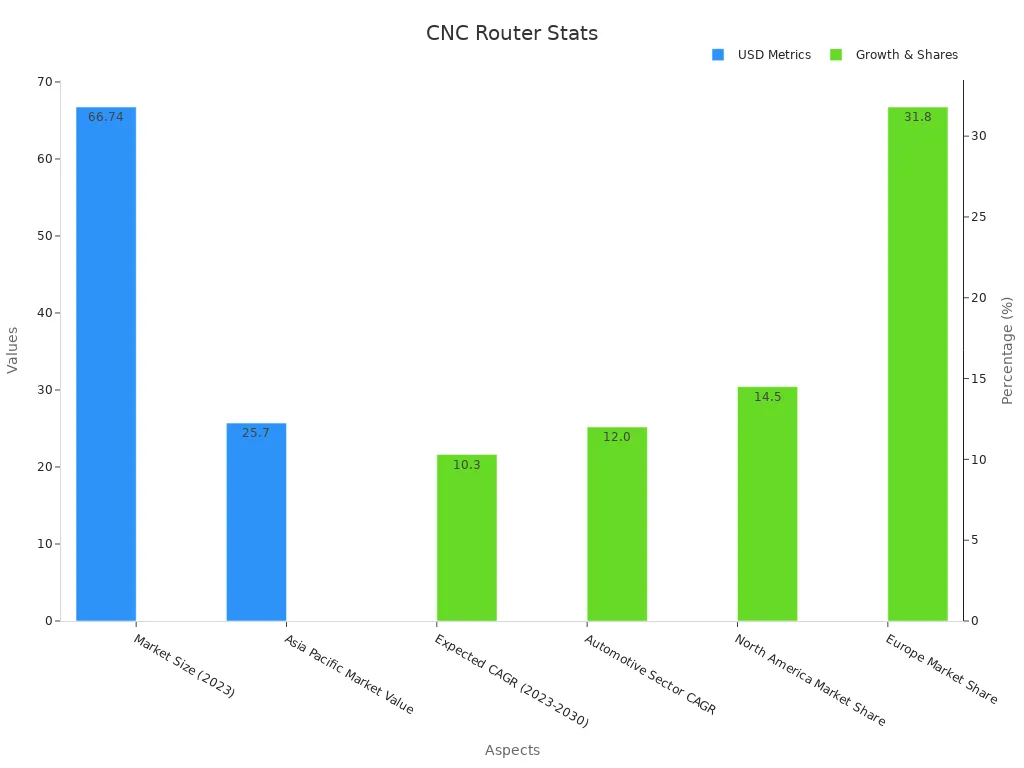

The CNC router market is growing fast and helping many industries. The table below shows key facts:

Aspect | Value/Trend |

|---|---|

Market Size (2023) | |

Expected CAGR (2023-2030) | 10.3% |

Automotive Sector CAGR | Nearly 12.0% |

North America Market Share | 14.5% in 2023 |

Europe Market Share | 31.8% in 2023 |

Asia Pacific Market Value | USD 25.7 billion in 2023 |

Take time to learn, test, and ask experts before buying. A good CNC router with the right tools can boost your work and grow your business.

FAQ

What makes a 3-axis CNC router different from a 5-axis one?

A 3-axis CNC router moves in three ways: left-right, forward-backward, and up-down. A 5-axis router can also tilt and rotate, making it better for detailed designs. It creates smoother and more complex shapes.

How can I keep my CNC router working well?

Clean your CNC router often to remove dust and dirt. Oil the moving parts to stop them from wearing out. Check tools for damage and replace them if needed. Follow the care guide from the maker to keep it running smoothly.

Can one CNC router work with different materials?

Yes, many CNC routers can cut wood, metal, and plastic. Make sure the spindle is strong enough for your materials. Change the speed and settings to match the material for the best results.

How do I pick the right software for my CNC router?

Choose software that fits your skills and projects. Beginners should use simple programs with ready-made designs. Experts might want software with more advanced options. Make sure it works with your CNC router and other design tools.

Should I buy a new or used CNC router?

New CNC routers have the latest features, warranties, and need less fixing. Used ones cost less but might need repairs. Think about your budget and future needs before choosing. Always check used machines carefully to avoid problems.

Tip: Test a used CNC router before buying to ensure it works well for your needs.

Start your project with LKprototype

LKprototype company simplifies procurement for custom manufacturing, Suitable for making your products or prototypes with a variety of materials, such as metal or plastic, silicone rubber, from 3D Printing to CNC Machined Parts and Vacuum Casting , with a focus on speed and efficiency. Our platform provides instant quotes. With LKprototype, You can connect with the team to communicate your project to ensure quality and on-time delivery.

Start with an instant quote and experience how our technology and expertise can make custom part procurement faster and easier.

LKprototype

LKprototype