CNC rapid prototyping is an innovative solution that is being adopted widely within different industries for product development. CNC machines helps to produce prototypes in a shortest possible time, with high precision and least cost. This article focuses on the basic principles, factors, and uses of CNC prototyping and its benefits for engineers, designers, and producers.

What is CNC Prototyping?

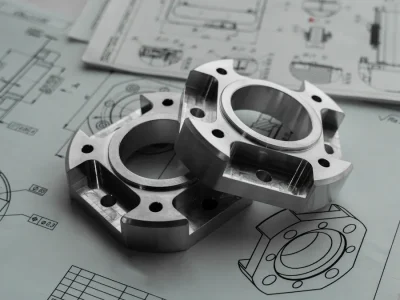

CNC rapid prototyping is a technique that engages the use of Computer Numerical Control machines to build prototypes of parts or products from a designed model. These prototypes help the designers and engineers to make quick modifications and thereby avoid expensive attempts gone awry.

Key Components of CNC Prototyping

· CNC machines

Computer numerically controlled machines are the core tool in rapid prototyping process. These machines employ a computer program that is used in cutting and shaping of materials and also assembling.

· CAD

CAD is used to draw part or product designs that require 3D modeling before they are manufactured. This model is a guide for the CNC machine so that it makes the correct move to replicate the intended prototype.

· CAM

CAM program changes the 3D CAD model to points of instructions to the CNC machine and guides to perform specific task. It allows for the integration optimization of the manufacturing processes like tool path generation, to improve on speed and accuracy.

Types of CNC Machines for Prototyping

· CNC Milling Machines

CNC Milling machines are versatile tools that are capable of making slots, cutting, drilling and shaping materials using a rotating cutter that is controlled along multiple axes. These machines are ideal for producing prototypes of difficult geometry, particularly such parts that require small tolerances.

· CNC Lathes

CNC lathes turn the material relative to a cutting tool in order to generate cylindrical parts. They are widely utilized for manufacturing of parts such as shafts, pins, round cross section components and so on, which generally demands a high degree of accuracy in addition to fine finishes.

· CNC Routers

CNC routers are employed in carving wood, plastics, and non-ferrous metals. They are especially suitable as large prototypes or designs that demand fine cutting and fine details especially in the furniture makers and sign makers.

· CNC EDM (Electrical Discharge Machining)

CNC EDM utilizes electrical discharge to cutting harder materials such as metals. It is mainly used to generate complex geometric tolerances and fine shapes that cannot be fabricated utilizing conventional machining processes. Therefore, appropriate for precision industries including aerospace and medical instruments.

CNC Rapid Prototyping Techniques

· Milling:

Milling is one of the most used CNC techniques used for prototyping. It is the process of employing a cutter that is rotate to produce a desired shape out of the work-piece out. Milling is versatile and can be done on a number of materials to create intricate shapes to fine detail.

· Turning:

Turning is one earning operation that involves the use of cutting tool to give shape and form a rotating work piece. It is mostly applied in building cylindrical or conical parts in applications such as shafts or tubes. This method is fast and efficient and therefore suitable for mass production of parts with cylindrical geometry.

· Drilling and Grinding:

Drilling and grinding are cutting operations performed on CNC that is used to produce holes or enhance the surface finish. Drilling is used where there is a need to make a particular hole, while grinding results to enhanced surface finish which are usually important where tight tolerances are needed in an application.

Advanced CNC Techniques in Prototyping

· 5-Axis CNC Machining:

5-axis CNC machining gives even greater precision possibility and mobility of the instrument as changing its position in five different axes simultaneously. It is ideal for the case when different areas of the prototype have varying angles and different features to be cut using the prototype.

· High-Speed Machining:

High-speed CNC machining concentrates on increasing the cutting speed, so that the amount of time taken to produce a product is reduced, with equal concern to the accuracy. This is particularly important to sectors with shortened production cycles and numerous prototypes, including automotive and aerospace industries.

· CNC Laser Cutting & Water Jet Cutting:

CNC laser cutting and water jet cutting are both non-contact processes which involve the use of concentrated energy on the material. Laser cutting delivers high accuracy and works well with thin materials, while water jet cutting is better for thick materials and leaves no heat affected area.

Automating the Prototyping Process

CNC machines make it possible to greatly minimize the lead time and costs associated with prototyping in production. Due to improved technology in the form of robotics, AI, and machine learning, many of today’s CNC machines are semiautonomous at best. This enables round-the-clock, shift manufacturing that shortens the cycle time and speeds up the prototyping phase. The use of automated systems also increase efficiency in terms of the performance of the machines hence bringing in reduced errors and increment in quality. In addition, automation allows for more challenging tasks to be performed, such as real-time trading and tool paths, to improve the development of prototypes, at a higher speed, with greater precision and at a lower cost.

Benefits of CNC Rapid Prototyping

· Speed and Efficiency:

The first advantage of CNC rapid prototyping is the short time that is taken during the development of models. Since CNC machines are fully automated, developing prototypes takes several hours or days which minimizing time taken in product development.

· Precision and Accuracy:

As usual CNC machines provide precision which means that prototypes can be built with high precision as required. This level of accuracy guarantees that the final prototype serves its purpose and meets all the intended design which is so vital in application such as aerospace or medical applications.

· Cost-Effectiveness:

CNC rapid prototyping costs less than conventional processes in terms of material utilization as well as its ability to eliminate the costs of tools or molds. The rapid and inexpensive manner that prototypes can be created also affords the opportunity to try out a design multiple times to make it a good one.

· Flexibility in Materials:

The flexibility of CNC machines is that they can be used in different sectors since it can work on different types of materials such as metals, plastics and composite material. This versatility helps manufacturers place prototypes made from different materials in various environments to evaluate performance once adopted.

· Improved Design Validation:

In its capacity, CNC prototyping provides rapid prototyping solutions for designers or engineers to facilitate design validation. It also allows teams to point out missing features, mistakes and errors right at the design stage, thus lowering the chances of having to spend a lot of money to reverse the mistake during mass manufacturing.

· Customization:

CNC prototyping is also flexible hence designers are able to make changes on a prototype whenever they want. With CNC prototyping designs can be easily adapted depending on the needs by adjusting the dimensions or adding features or changing the material type.

Applications of CNC Rapid Prototyping

· Automotive Industry:

In the automotive industry CNC rapid prototyping is crucial for developing functional parts and other automotive components like the engines, the dashboards and brackets. It allows manufacturers to create new vehicle designs slightly faster than their competitors, which can be hugely beneficial in terms of cutting down time to meet that perfect market.

· Aerospace & Aviation:

CNC prototyping is widely used in the aerospace and aviation industries where issues of safety and accuracy cannot be overemphasized. Parts and subassemblies including aircraft, turbines, cockpits and other aircraft structures, may be quickly fabricated and then immediately subjected to tests and regulatory evaluation.

· Medical Devices:

The field of medical devices also lodges much advantage from the CNC rapid prototyping where it leads to the manufacture of prototypes of tools for surgeries and diagnosis, implants among others. These prototypes are then useful in ascertaining fit, functionality as well as the safety of the patients before large scale production.

· Consumer Electronics:

Consumer electronics is one of the most prominent industries to adopt CNC prototyping to build various prototypes of smartphones, wearable technology gadgets, and home appliances. Rapid prototyping enables reduction in the time taken to develop and improve the design of a product therefore is an essential tool in a competitive market that relies on new products.

· Industrial and Commercial Products:

In industries that deal in manufacturing industrial equipment or commercial trinkets, the CNC rapid prototyping process enables testing of the prototypes under actual working conditions within a short time. This can be Machining parts, tools used in production as well as products that will be used at the customer’s end such as home use appliances.

· Product Development & Testing:

CNC rapid prototyping integrates with designs, development, to testing in that it has various cycles which includes designing, building real part model, assembling and testing. Creating mechanical models during the development process means that the company shall perform several tests to establish that the product meets all design requirements before the full-scale production process is initiated.

Conclusion

Rapid prototyping with CNC technology is one of the most effective tools of contemporary product creation. It offers speed, precision and flexibility providing industries with a way to introduce, prototype and develop designs across the board rapidly. From automotive and aerospace industries to the medical device sector, CNC prototypes have remained the future of manufacturing. Explore our Prototyping Services at LK Prototype to get more information about CNC rapid prototyping.

LKprototype

LKprototype