CNC, or computer numerical control, plays a transformative role in manufacturing. To understand the CNC meaning, it refers to the use of computers to control machines, enabling faster and more precise work. Unlike traditional methods, CNC relies on programmed software to operate machines, ensuring consistent results every time. This technology supports modern factories by reducing errors, saving time, and increasing production efficiency.

The impact of CNC on industries has been significant. For instance:

Projections suggest sales could grow to $162.16 billion by 2032, with an annual growth rate of 10.43%.

CNC also drives innovation by producing identical parts quickly while minimizing material waste. This not only saves money but also helps businesses meet growing demands effectively.

Key Takeaways

CNC tech helps make products faster and cuts labor costs.

CNC machines are very precise, crucial for aerospace and medical fields.

They waste less material, saving money and helping the planet.

CNC machines adjust to custom designs, handling different needs well.

Combining CNC with IoT and AI boosts efficiency and new ideas.

CNC Meaning and Core Functionality

What is CNC and how it works

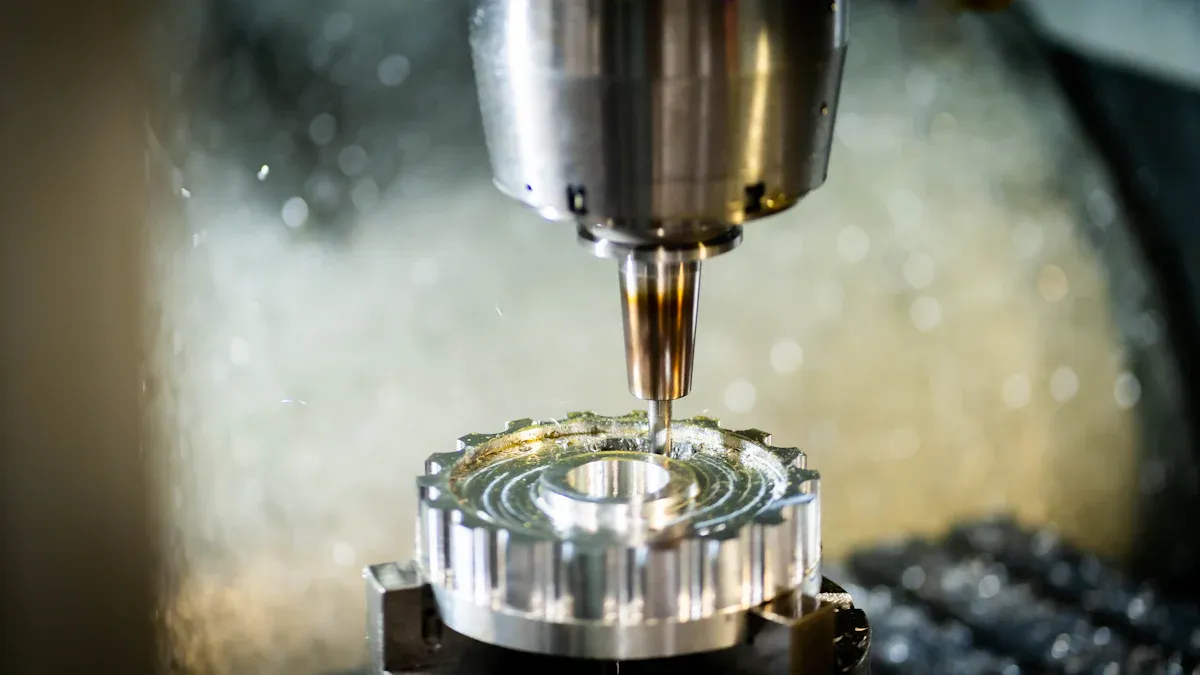

CNC, or Computer Numerical Control, uses computers to run machines. Instead of people controlling machines by hand, CNC machines follow programmed instructions. Think of it like a computer telling the machine exactly how to cut, drill, or shape materials.

The process starts with engineers designing a part using CAD software. This design is turned into instructions called G-code. The CNC machine reads these instructions and works on its own. Once the program is loaded, the machine does the job without needing much help from people. This makes sure the work is accurate and can be repeated perfectly, even for tricky designs.

CNC machining is important today because it is fast, precise, and flexible. It helps make parts quickly while lowering costs and mistakes. Industries like electronics depend on CNC machines to meet strict quality rules.

Benefits of CNC machining include:

Making parts quickly and exactly as needed.

Using materials efficiently with less waste.

Keeping quality consistent, even for large batches.

Differences between CNC and traditional machining

CNC machining is very different from older methods. Traditional machining needs skilled workers to control machines by hand. CNC machines, however, use computer programs to do the work. This changes how accurate and fast the process is.

Feature | CNC Machining | Manual Machining |

|---|---|---|

Control | Computer-controlled | Controlled by machinists |

Automation | Works mostly on its own | Needs constant human input |

Complexity | Handles hard designs easily | Best for simple tasks |

Setup Time | Takes time to set up programs | Quicker setup but needs adjustments |

Cost | Costs more upfront but saves money later | Cheaper to start but costly for big jobs |

Lead Time | Faster due to automation | Slower because of manual work |

Accuracy | Very precise | Depends on worker skill |

Repeatability | Always consistent | Can vary due to human error |

Production Volume | Great for making lots of parts | Better for smaller batches |

CNC machines are great for making detailed designs quickly and accurately. They also save time, which is important for industries needing speed. Traditional machining still works for simpler jobs or smaller projects. But as technology improves, CNC machines are becoming the better choice for most tasks.

Key components of CNC machines

To understand CNC machines, you need to know their main parts. Each part helps the machine work smoothly and accurately.

Controller: This is the machine's brain. It reads the G-code and tells the machine what to do.

Machine Bed: The bed keeps everything steady and aligned during work.

Spindle: The spindle holds the cutting tool and spins it fast to shape materials.

Cutting Tools: These tools do the actual cutting, drilling, or shaping. They come in different sizes for different jobs.

Motors and Drives: These parts move the machine along its axes (X, Y, and Z) with precision.

Coolant System: This system keeps the tools and materials cool to avoid overheating.

Workholding Devices: These devices hold the material in place so it doesn’t move during machining.

These parts work together to make CNC machines accurate and efficient. By automating tasks, CNC machines avoid problems like uneven results or human mistakes.

Tip: Take care of CNC machines regularly to keep them working well. Maintenance helps them last longer and perform better.

Benefits of CNC Machining

Precision and accuracy

CNC machines are very precise, making them important for industries needing accuracy. They can create parts with tiny tolerances, like ±0.005 mm, which is crucial in aerospace. In medical device production, CNC machines achieve about 95% precision, ensuring top-quality results.

Industry | Tolerance | Precision Rate |

|---|---|---|

Aerospace | ±0.005 mm | N/A |

Medical Devices | N/A | Close to 95% |

To keep this accuracy, CNC uses tools like SPC and Cpk. These tools check and improve processes for consistent results. Whether making detailed designs or many parts, CNC ensures precision every time.

Efficiency and reduced waste

CNC machining is efficient and reduces waste. Automation means less manual work, which boosts production speed. Robots also help by cutting downtime and improving productivity.

Modern CNC machines connect to networks for real-time material tracking. This helps reduce waste and save resources. CNC also ensures every part matches the design, lowering errors. By wasting less, businesses save money and help the environment.

Scalability for diverse production needs

CNC machines can handle small or large production jobs easily. They are perfect for industries with changing demands. You can switch between making one item or thousands without losing quality.

Skilled machinists program CNC machines for different designs and materials. This flexibility helps meet customer needs while keeping results consistent. With CNC, you can grow your business while staying efficient and precise.

Improved safety and fewer human mistakes

CNC machining makes workplaces safer and reduces human mistakes. In older methods, workers had to be near sharp tools and heavy machines. This increased the chance of accidents. With CNC, machines are programmed to work on their own. Workers stay away from dangerous tasks.

Automation means less manual work, lowering errors from tiredness or wrong decisions. For instance, in manual work, a small measuring mistake can ruin parts or damage machines. CNC avoids this by following exact instructions. This ensures the same perfect results every time.

Modern CNC machines have safety features like emergency stop buttons and protective covers. Sensors also help prevent accidents. Simulation software lets you test programs before using real machines. This helps find and fix problems early, making work safer.

By keeping workers away from risky jobs, CNC protects them and builds their confidence. Workers can focus on improving processes instead of worrying about safety. This leads to a safer and more productive workplace.

In industries needing safety and accuracy, CNC is very helpful. It keeps production steady while protecting workers. This way, businesses can work faster and stay safe at the same time.

Applications of CNC in Modern Manufacturing

Aerospace: Precision in aircraft components

In aerospace, accuracy is very important. Even tiny mistakes can be dangerous. CNC machines make airplane parts with incredible precision. They create items like turbine blades and engine casings with tolerances as small as ±0.005 mm. This ensures every part fits perfectly and works well under tough conditions.

CNC machines also work with strong materials like titanium and carbon composites. These materials are hard to shape by hand, but CNC machines handle them easily. Automation helps keep quality consistent while meeting strict industry rules.

Note: The aerospace industry depends on CNC machines for safe and efficient flights.

Automotive: Mass production and customization

CNC machines are key in making car parts. They ensure parts like engines and transmissions are uniform and precise. With high accuracy, they reduce mistakes and waste. This helps cars perform better and stay reliable.

Car makers use CNC machines for quick prototypes and custom designs. They can make special parts to match customer needs. For example, luxury cars often have custom interiors made by CNC machines.

CNC machines are great for making many parts fast. Automation speeds up production lines while keeping quality high. This is important as demand for cars grows.

Accuracy and Consistency: Parts meet exact specifications every time.

Efficiency: Automation makes production faster and saves time.

Flexibility: Machines switch tasks easily to meet market needs.

By combining precision, speed, and adaptability, CNC machines improve car manufacturing.

Medical: Tailored medical devices

The medical field uses CNC machines to make precise devices. They create items like implants, prosthetics, and surgical tools. For example, CNC machines can make custom knee implants that fit a patient perfectly. This improves comfort and recovery.

CNC machines work with safe materials like titanium and stainless steel. These materials must be smooth and accurate for use inside the body. CNC machines ensure they meet strict standards.

Automation reduces human mistakes, which is vital in healthcare. Even small errors can cause big problems. CNC machines help make high-quality devices that follow strict rules.

Tip: Use CNC machines to create advanced and custom medical devices for better healthcare solutions.

Electronics: Making complex circuit boards

CNC machines are important in making circuit boards for electronics. These boards are found in devices like phones, computers, and medical tools. CNC helps create tiny, detailed designs with great accuracy.

Circuit boards need small holes and cuts for electrical paths. CNC machines are perfect for this job. They use fast spindles and special tools to drill holes as tiny as 0.1 mm. This ensures circuits work properly without mistakes.

Did you know? CNC machines can make up to 1,000 boards an hour. This makes them great for large-scale production.

CNC machines also work well with materials like copper and fiberglass. These materials are strong and conduct electricity. CNC cuts them neatly, wasting less and saving money.

Feature | How It Helps Circuit Boards |

|---|---|

Fast and precise | Makes accurate cuts and drills |

Automation | Speeds up making boards |

Works with many materials | Handles copper, fiberglass, and more |

CNC machines can easily switch to new designs. You just update the program to make a different board. This makes it easy to keep up with new ideas and market needs.

Using CNC machines means making high-quality boards quickly. This helps businesses stay ahead in the fast-moving electronics world while keeping quality high.

Business Impact of CNC Technology

Cost savings and waste reduction

CNC technology helps businesses save money in many ways. By automating tasks, CNC machines need less manual work. Unlike older methods, these machines can run all day without stopping. This lowers labor costs, which is helpful for industries where paying workers is expensive.

CNC machines also reduce material waste. Traditional methods often waste materials because of mistakes or inefficiency. CNC machines use materials carefully and with precision, leaving less waste behind. This is especially useful in industries like aerospace and medical manufacturing, where materials like titanium and stainless steel cost a lot. Using CNC machines helps save materials and cut production costs.

Tip: Check and maintain your CNC machines often. This keeps them working well and saves even more money.

Increased productivity and faster delivery

CNC machines make manufacturing faster and more productive. They handle repetitive tasks automatically, so parts are made quicker than with manual methods. CNC machines can work nonstop, 24/7, which boosts efficiency. This is important for meeting tight deadlines and making large amounts of products.

For example, CNC machines shorten lead times by speeding up setup and machining. Once programmed, they work with little downtime, keeping production on track. This means faster deliveries and the ability to take on more projects without losing quality.

Metric | What It Measures |

|---|---|

Production Efficiency | How many good parts are made compared to wasted ones. |

Labor Utilization | Time workers spend on useful tasks versus unnecessary ones. |

Setup Time vs Machining Time | Time spent preparing a part compared to the time spent making it. |

Using CNC machines helps you produce faster while keeping quality high. This gives your business an advantage over competitors.

CNC machines work nonstop, improving efficiency.

They run 24/7, cutting idle time and speeding up production.

This helps meet deadlines and handle big orders easily.

Support for innovation and complex designs

CNC machines allow businesses to create new and complex designs. They are perfect for industries like aerospace, automotive, and electronics. Whether it’s detailed circuit boards or custom medical implants, CNC machines can make it happen.

Modern CNC systems work well with advanced tools like 3D printing and data analytics. This combination helps improve production and test new ideas. For example, using CNC with 3D printing makes detailed prototypes while wasting less material.

Trend | How It Helps Manufacturing |

|---|---|

Speeds up work and reduces mistakes. | |

Connectivity | Links machines for better production tracking. |

Analytics | Uses data to improve decisions and processes. |

3D Printing Integration | Makes complex designs and saves materials. |

Combined Approaches | Improves efficiency and uses resources wisely. |

By using CNC technology, businesses can stay ahead of trends and create innovative products. This builds a strong reputation and helps companies lead in modern manufacturing.

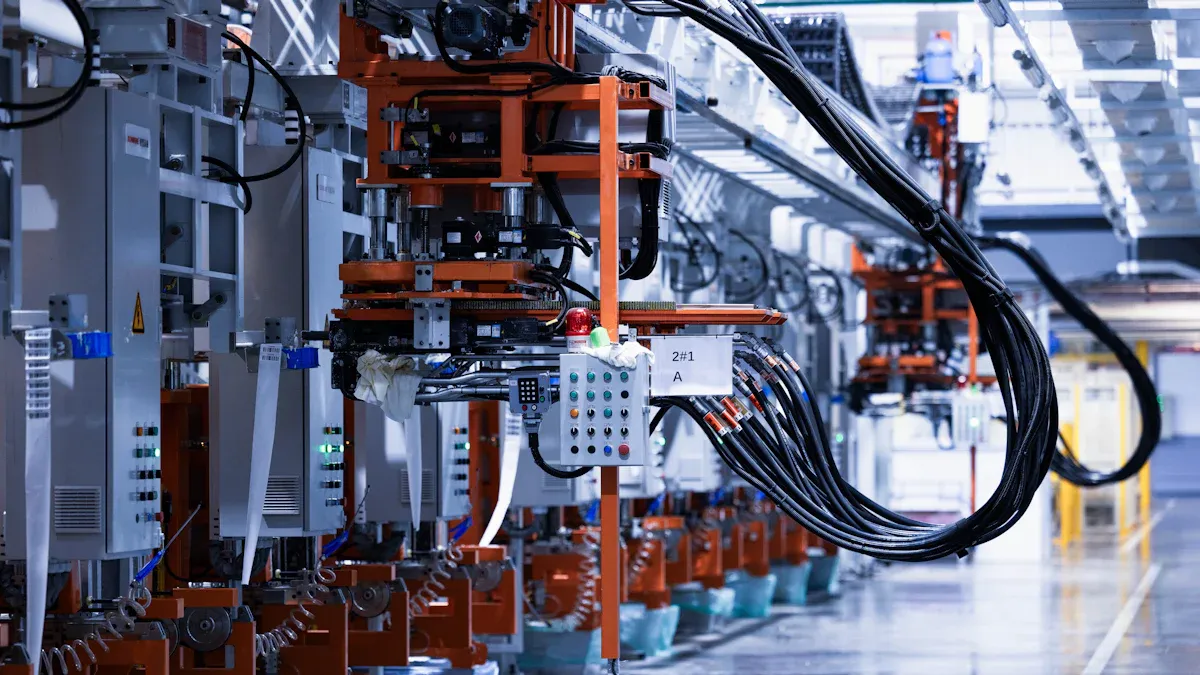

Alignment with Industry 4.0 and smart manufacturing

Industry 4.0 is the next big step in manufacturing. It focuses on using smart systems with advanced tools like automation, connectivity, and data analytics. CNC machines are a key part of this change. They fit perfectly into Industry 4.0, helping factories work smarter and faster.

How CNC fits into Industry 4.0

CNC machines do more than just cut and shape materials. Now, they connect with other systems and share information instantly. This lets factories track work, improve processes, and make better decisions using data.

Here’s how CNC machines support Industry 4.0:

Automation: They work on their own, needing little human help. This makes work faster and more reliable.

Connectivity: Modern CNC machines link to networks. You can check their performance and fix problems from anywhere.

Data Analytics: They collect useful data while working. This data helps improve efficiency and predict when repairs are needed.

Tip: Add IoT sensors to your CNC machines for better insights into your factory’s performance.

Benefits of CNC in smart manufacturing

Smart manufacturing needs systems that adjust to changes quickly. CNC machines are perfect for this. They are precise, flexible, and can handle both small and large jobs.

Feature | Benefit in Smart Manufacturing |

|---|---|

Automation | Cuts downtime and boosts production. |

Real-time Monitoring | Helps make better decisions faster. |

Predictive Maintenance | Stops expensive breakdowns early. |

Scalability | Works for both small and big projects. |

Using CNC machines in smart factories saves money and improves efficiency. They help businesses stay ahead in a fast-changing world.

CNC and the future of Industry 4.0

The future of Industry 4.0 will use tools like artificial intelligence (AI) and machine learning. CNC machines are already keeping up with these trends. For example, AI-powered CNC machines can plan better tool paths and predict wear. This keeps them running smoothly for longer.

IoT-enabled CNC machines are also shaping the future. These machines connect to smart factories and share data. This creates fully automated systems that adjust to real-time changes.

Did you know? IoT-enabled CNC machines can lower energy use by up to 30%.

As Industry 4.0 grows, CNC machines will stay important in manufacturing. Their ability to adapt and work with new technology ensures they will lead the way in modern production.

Future of CNC in Manufacturing

AI and machine learning integration

Artificial intelligence (AI) and machine learning are changing CNC machines. These tools study data to make processes better. They predict when machines need repairs, stopping sudden breakdowns. AI watches operations live to keep machines running smoothly. This improves product quality and reduces mistakes.

AI also makes machining faster and saves materials. It adjusts settings automatically for better accuracy. For example, AI can find patterns in production data and suggest improvements. This helps CNC machines work smarter and more reliably.

Impact | How It Helps |

|---|---|

Efficiency | Predicts repairs and monitors machines to avoid delays. |

Cost Savings | Cuts repair costs and makes machines last longer. |

Better Quality | Finds and fixes defects quickly, reducing wasted parts. |

Process Improvements | Uses data to make machining more accurate and faster. |

Smart Factories | AI lets machines adjust automatically using live data. |

Adding AI boosts productivity and keeps businesses competitive in manufacturing.

IoT-enabled CNC machines

The Internet of Things (IoT) is making CNC machines smarter. Sensors collect data while machines work, helping monitor them live. This data allows quick changes to reduce mistakes and improve control. IoT also predicts problems before they happen, avoiding downtime.

IoT helps CNC machines save energy by adjusting operations to match needs. This lowers waste and cuts costs. For example:

Live monitoring improves control and reduces errors.

Predictive repairs keep machines running smoothly.

Energy-saving features reduce waste and help the environment.

IoT technology makes CNC machines more efficient and ready for modern challenges.

Automation and autonomous machining

Automation is the next step for CNC machines. Machines now do tasks with little human help. This lowers mistakes and speeds up production. Autonomous machining goes further. Machines change settings on their own using live data.

For example, autonomous CNC machines can switch tools or change speeds without workers. This makes handling tricky designs and big jobs easier. Automation also makes workplaces safer. Workers don’t need to do dangerous tasks near heavy machines.

Using automation increases speed, lowers costs, and improves safety. Autonomous machining keeps operations ahead in today’s competitive world.

Sustainability in CNC processes

Sustainability is very important in manufacturing today. CNC machines help by cutting waste, saving energy, and protecting the environment.

Reduced Material Waste

CNC machines use materials carefully. They make cuts that match designs exactly, leaving little waste. Unlike older methods, CNC machines save materials by being precise. For example, industries like aerospace use CNC machines to work with costly materials like titanium without wasting them.

Tip: Test your designs with simulation software first. This prevents mistakes and saves materials.

Energy Efficiency

Modern CNC machines use less energy than older methods. They run with settings that save power during production. IoT-enabled CNC machines are even better. They track energy use live, letting you adjust to save power while staying productive.

Feature | How It Saves Energy |

|---|---|

Real-time Monitoring | Finds ways to use less energy |

Automation | Stops wasting power during idle time |

Predictive Maintenance | Avoids energy loss from breakdowns |

Eco-Friendly Materials

CNC machines work well with green materials. They can handle recycled metals or biodegradable plastics without losing quality. This helps businesses stay eco-friendly while making great products.

Longer Machine Lifespan

Taking care of CNC machines keeps them working for many years. This means fewer replacements, saving resources and reducing waste. Well-maintained machines last longer, which is good for the planet and saves money.

Did you know? A well-maintained CNC machine can last up to 20 years, cutting down on waste from making new machines.

Using CNC machines helps businesses follow eco-friendly practices. This protects the environment and shows customers you care about sustainability.

CNC technology has changed manufacturing by offering precision, speed, and creativity. It allows nonstop production, lowers mistakes, and keeps workers safe. This makes it essential for industries like aerospace, cars, and electronics.

Impact Area | How It Helps |

|---|---|

Runs nonstop, increasing how much can be made. | |

Precision | Makes detailed parts accurately, wasting less material. |

Safety | Keeps workers away from risky tasks, improving safety. |

Innovation | Uses smart tech to create better products and avoid delays. |

Mass Production | Produces many identical parts quickly and easily. |

CNC also greatly helps businesses. It cuts costs, improves speed, and fits well with new trends like smart factories and AI. Studies show it helps companies work better, use digital tools, and focus on customer needs.

Marks a new level of success with digital tools.

Shows how digital systems improve factory work and save time.

Explains new tech making CNC machines even better.

As factories grow, CNC stays key to progress. It helps businesses create, expand, and succeed in tough markets. Its ability to use new tech ensures it will shape the future of manufacturing.

FAQ

What industries benefit the most from CNC machining?

CNC machining helps industries like aerospace, cars, medical, and electronics. These fields need accurate, fast, and flexible production. CNC machines make high-quality parts, meet strict rules, and adjust to different needs.

Tip: If your work needs precision and speed, CNC can help a lot.

How does CNC machining reduce production costs?

CNC machines save money by automating jobs and using less material. They also work nonstop, making more parts quickly. Over time, these savings make up for the upfront cost, making CNC a smart choice for factories.

Can CNC machines handle custom designs?

Yes, CNC machines are great for custom designs. You can program them to make special parts with exact details. This is useful for industries like medical and cars, where unique items are needed.

What materials can CNC machines work with?

CNC machines can shape many materials like metals (aluminum, titanium, steel), plastics, composites, and wood. Their ability to handle different materials helps factories meet various needs.

Are CNC machines environmentally friendly?

CNC machines help the environment by wasting less material and energy. Smart CNC systems use energy wisely, and precise cutting reduces scraps. Using green materials makes them even better for the planet.

Did you know? Taking care of CNC machines makes them last longer, cutting waste and helping the environment.

LKprototype

LKprototype