Global buyers often choose China for Wire EDM Machining Services. China offers very precise work and strong export skills. They also have strict rules to keep quality high. Chinese factories use smart machines and computers, which helps them work faster and make fewer mistakes. Wire EDM Machining Services in China are affordable and dependable. These services support many industries, including automotive and clean energy. They can produce just one part or many parts simultaneously. MetricData/TrendAsia-Pacific market share (2023)About 35% of the world’s High Speed Wire EDM Machine marketExpected CAGR7.5% growth is expected in the coming years China exports extensively and…

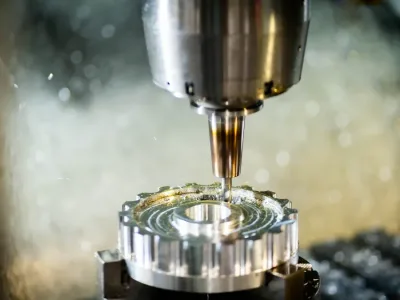

A mini milling machine lets you cut, shape, and drill small parts. It does this with great accuracy. There are different types of milling machines. Some are vertical, some are horizontal, and some are CNC. Many hobbyists and small shops like these machines. They use them for jobs that need careful work and flexibility. Mini milling machines are small and easy to use. But, they are not as strong as big machines. When picking a mini milling machine, think about its size, power, and how accurate it is. Make sure it fits your needs. Mini milling machines are used all…

Employees are operating machine tools in the processing workshop of CNC machine tool parts manufacturer Choosing the right machine parts manufacturer is crucial. It ensures your machines operate at their best. A reliable machine parts manufacturer provides genuine, precise parts, which enhances quality and builds trust. Your decision directly impacts the efficiency and growth of your business. If you require custom or original parts, the machine parts manufacturer must understand your specific needs. Their expertise in producing parts and offering warranties ensures your machines perform optimally and last longer. Partnering with the right machine parts manufacturer means collaborating with someone…

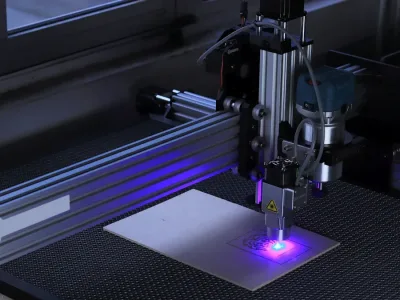

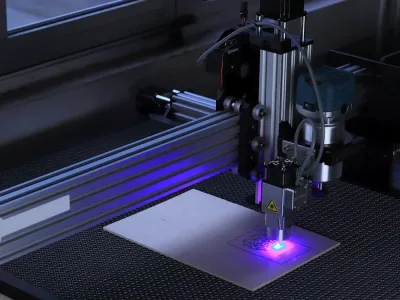

CNC machines are essential for creating parts with precision machine capabilities and exceptional accuracy. This process plays a critical role in industries such as aerospace, medical, and manufacturing. In aerospace, precision machine components must fit perfectly to ensure safety and optimal performance. Medical tools also require exact machining to comply with strict regulations. Advancements in technologies like AI and automation have made this process faster and more efficient. These innovations contribute to producing strong, reliable parts that meet your specific needs. Key Takeaways Precision machining creates exact and reliable parts, important for planes and healthcare tools. CNC machines lower costs…

Milling methods like climb vs conventional milling are crucial in machining. Climb milling moves the tool in the same direction as the feed, resulting in smoother chips and requiring less cutting force. In contrast, conventional milling moves the tool against the feed direction, producing thicker chips and demanding more effort to cut. Understanding these differences between climb vs conventional milling can significantly enhance machining outcomes. For instance: Climb milling tends to wear tools less and provides a smoother finish, making it ideal for softer materials. Conventional milling offers better control when cutting harder materials. Research indicates that climb milling can…

Choosing the right milling machine machine can improve how you work. It affects how accurate your products are and saves time and money. Many industries depend on advanced milling machine machines, especially car-making, which uses over 30% of these tools worldwide. As lighter materials like titanium alloys become popular, precise cutting is more important than ever. New CNC milling machine machines with smart sensors make work faster and reduce delays. Whether you need a milling machine machine for testing ideas or making many products, picking the right one helps you stay ahead in today's busy market. Key Takeaways Learn about…

Text milling means carving custom text onto materials using CNC machines. This process needs great accuracy to make letters neat and even. Accuracy is very important for detailed designs or big projects. Here’s why accuracy is key: Tiny milling tools make smooth surfaces and keep tight limits. Fixing problems like rough edges and sticky materials improves results. For big projects, errors as small as 90 to 1000 µm can be expensive. Using the right tools, software, and methods helps you create perfect text carvings with your CNC machine. Key Takeaways Being accurate in text milling is very important. Even small…

When you think of making products, accuracy and speed matter most. CNC machine routers have changed how businesses work to meet these goals. These machines can do hard tasks automatically, giving steady quality and faster production. For example, CNC routers with auto-calibration and nesting software use less material and avoid mistakes. This saves money and keeps quality high. Think about this: in 2023, metalworking made up 39.6% of the global CNC router market earnings. This shows how these machines help industries work better and earn more. Whether you cut soft metals or make custom furniture, a CNC router helps by…

Imagine changing a plain piece of wood into art easily. That’s the power of CNC machine woodworking. Whether you’re new or experienced, this tool helps you. It allows for accuracy and creativity that old methods can’t do. The facts are clear: CNC wood lathes sales may grow from $1.2 billion in 2024 to $1.8 billion by 2033. The global CNC market might reach $150 billion by 2032. These numbers show how CNC is changing woodworking. It gives you tools to make amazing projects simply. Key Takeaways CNC woodworking uses machines to make exact cuts and cool designs. It removes the…

Choosing the best CNC router machinery is important for your business. It affects how fast, accurate, and affordable your work is. New technology makes CNC router machinery essential for modern manufacturing. Here’s why: CNC router machinery is growing popular because it is precise and reliable. Businesses using CNC router machinery see better productivity and lower costs. Smart features make CNC router machinery flexible for many different tasks. Knowing about CNC router machinery helps you pick the right one. This saves time and boosts profits. Key Takeaways Picking the right CNC router helps save time and money. Think about what your…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.