You should pick CNC text marking if you want deep and lasting marks on your parts. Laser marking is best for high accuracy, fast work, and clear marks. The CNC engraving process uses a computer system and a CNC engraving machine to cut into materials, while laser marking employs a laser engraver or laser marking machine that does not touch the part. Here is how CNC text marking vs laser marking differs: FeatureCNC Text MarkingLaser MarkingProcessTouches part, tool changesDoes not touch, quick setupDepthDeep (more than 0.5 mm)Shallow (0.1-0.3 mm)LegibilityHigh, depends on how deepHigh, always the sameCompatibilityWorks with many materialsNot for…

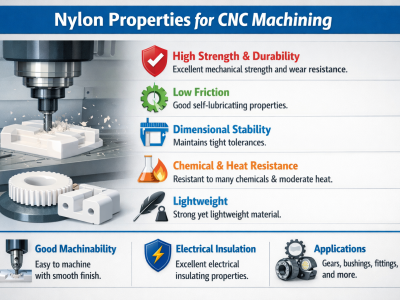

CNC Machined Nylon Parts: Strength, Precision, and Versatility CNC machined nylon parts have become a top choice for industries requiring durable, lightweight, and chemically resistant components. Nylon’s unique combination of mechanical strength, wear resistance, and low friction makes it ideal for applications where precision and longevity are critical. From automotive gears and bushings to electrical housings and industrial machinery components, machined nylon components deliver reliable performance under demanding conditions. One of the key advantages of nylon in CNC machining is its flexibility and toughness. Unlike metals, nylon can absorb impacts without cracking, while maintaining dimensional stability when exposed to moderate…

You use kovar machining services when you want very exact custom parts. Kovar is special because it is very strong, does not wear out easily, and can be welded well. These qualities make kovar good for tough places.Skilled workers and advanced methods help you get precise results with kovar machining. Many industries like electronics, aerospace, telecommunications, and medical devices use kovar for important parts. Key Takeaways Kovar machining makes custom parts that are strong and steady. These parts work well for electronics, aerospace, and medical uses. Advanced CNC machining uses special methods for tight tolerances. This means parts fit well…

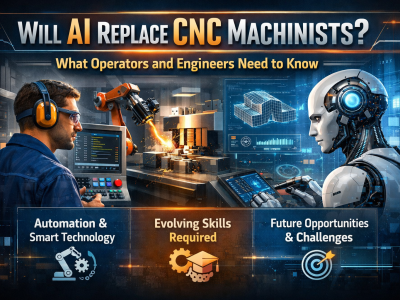

You might wonder, will AI replace CNC machining? The answer is no. Machinists remain crucial in the industry. While AI can enhance how you use CNC technology, it cannot fully replace what you do. Operators and programmers may notice some changes, as AI makes certain tasks easier, but your skills and adaptability are still essential. The future of CNC machining depends on humans and AI working together, not on the question of will AI replace CNC machining entirely. Key Takeaways AI will not take the place of CNC machinists. Your skills are still needed for hard jobs. Use AI tools…

When you need a prototype, understanding the differences between CNC milling vs turning prototypes is crucial. Opt for milling if your part has intricate shapes or unique features. On the other hand, choose turning if your part is round or cylindrical in shape. Selecting the appropriate process can significantly save you time and money. Refer to this table to see how your choice between CNC milling vs turning prototypes affects cost and speed: CNC Process TypeImpact on CostImpact on TimeSimple DesignsLower costsFaster machining timeComplex GeometriesHigher costsSlower machining time3-axis CNCMost cost-effective for simple partsQuick setup and machining5-axis CNCMore expensive but faster…

You check CNC Machining Tolerances to see if a part is made the right way. Many machines can make parts with a tolerance of ±0.02 mm. This is much thinner than a human hair. Some special machines can go as tight as ±0.0025 mm. The table below shows usual tolerances for different CNC processes: CNC ProcessTolerance (inches)Tolerance (mm)3-axis CNC Milling± 0.0050.135-axis CNC Milling± 0.0050.13Lathe± 0.0050.13 Many things can change how close your parts are to the design: Material properties Type of machining Things like tool wear and how good the operator is You need to know these things to pick…

You pick the best CNC machining material by matching it to your project. Think about what your part needs to do. Does it need to stand up to heat? Does it need to resist chemicals? Does it need to look a certain way? When considering CNC machining material selection, check the main things to think about: CriteriaDescriptionEnvironmentalStands up to heat, fire, or chemicals.ElectricalCarries or blocks electricity.MechanicalIs strong, tough, or hard to wear out.CosmeticGives color, see-through look, or feel.SizeFits the size of the material you have.CostMakes sure price and quality are balanced. Ask experts for help if you are not sure.…

When you focus on CNC prototype parts design, you consider what machines can do quickly and efficiently. Effective CNC prototype parts design allows you to create metal and plastic prototypes with fewer errors and reduced costs. CAD modeling plays a crucial role in rapid prototyping, enabling you to make quick adjustments and achieve precise results. CNC machining is faster than molding and more accurate than 3D printing. You can achieve tolerances as tight as ±0.01 mm. A prototype can be completed in 24 to 72 hours, allowing for rapid testing and refinement of your design. By following the right steps,…

Imagine you need a working prototype very quickly. You want it to be exact, but there are many problems. You might have trouble choosing the best material. You may find it hard to work with tricky designs. You could also have a short time to finish. CNC machining for prototyping helps you solve these problems. It lets you change designs fast. It keeps things very precise. It gives you good quality you can trust. With machines doing the work, you get parts that look how you want. You also get them on time. Key Takeaways CNC machining helps make prototypes…

You have an important job in medical device prototype development. This process helps you change an idea into a real prototype. The prototype can help patients and make care better. In 2025, you will see new problems and chances in medical device design, testing, and prototyping. Every step, from idea to pilot prototype, affects the final product. You need to know about the materials, costs, and steps in development. This helps you make good choices and build safe, useful devices. Key Takeaways Learn about how to make a medical device prototype. Start with an idea. Then test it to make…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.