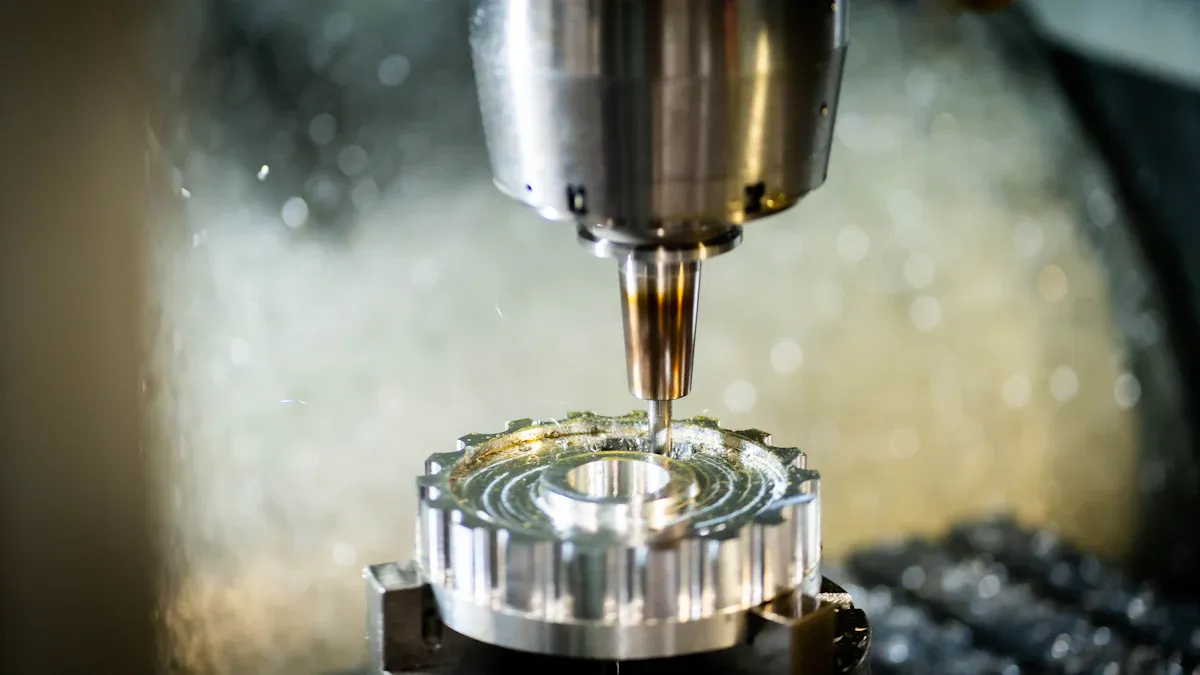

Imagine you need a working prototype very quickly. You want it to be exact, but there are many problems. You might have trouble choosing the best material. You may find it hard to work with tricky designs. You could also have a short time to finish. CNC machining for prototyping helps you solve these problems. It lets you change designs fast. It keeps things very precise. It gives you good quality you can trust. With machines doing the work, you get parts that look how you want. You also get them on time.

Key Takeaways

CNC machining helps make prototypes quickly. It can take days instead of weeks.

This method is very exact. It makes sure parts fit and work right.

CNC machining lets you use many materials. You can pick metals or plastics to test your designs.

The process is flexible. You can change designs fast. You do not need special molds or tools.

CNC machining saves time and money. It helps you find and fix problems early.

Why CNC Machining for Prototyping?

If you want a prototype that works and looks real, cnc machining for prototyping is a great choice. This way, you can make a few parts fast. You can use metals or plastics. Many fields, like aerospace and cars, use cnc machining for prototypes. It gives strong parts that follow strict rules.

Speed and On-Demand Production

You need your prototype quickly. Cnc machining for prototyping is fast. Machines work all day and night. You get your parts in days, not weeks. This quick process lets you test and change designs fast. If you want to change something, update your CAD file. You can start a new run almost right away.

Tip: Fast turnaround helps you try more ideas and make your product better.

Here is a table that shows how cnc machining for prototyping compares to older ways:

Aspect | Traditional Methods | CNC Machining |

|---|---|---|

Time from concept to part | Weeks to months | Days |

Error rate | Higher | Lower |

Material waste | Higher | Lower |

Cnc machining for prototyping saves time and lowers mistakes. In aerospace, this speed helps you finish on time and sell your product faster. Some companies cut their prototype time from three months to three weeks with cnc machining for prototypes.

Precision and Tight Tolerances

Your prototype should match your design. Cnc machining for prototyping gives tight tolerances and high accuracy. This means your parts fit well and work right. Cnc machines use smart programming to follow your design, even for hard shapes.

Here are some common tolerances you can get:

Tolerance Type | Typical Value | Common Use Case |

|---|---|---|

Standard Prototype | ±0.005 in. (±0.127 mm) | Most prototype and production parts |

Precision Tolerance | ±0.002 in. (±0.051 mm) | Tight fits and performance-critical components |

Reamed Hole Tolerance | ±0.0005 in. (±0.0127 mm) | Precision fits for pins/shafts |

Cnc machining for prototyping makes parts that look and work like the final product. This helps you and your team see how the part will be. You can trust every part is the same, even if you make many.

Cnc machining gets the smallest tolerances, which is hard by hand.

You get strong prototypes you can test in real life.

Cnc machines repeat the same process with the same accuracy.

Material Versatility

You might want to test your prototype in different materials. Cnc machining for prototyping gives you lots of choices. You can pick metals like aluminum or steel. You can use plastics like ABS or nylon. Some projects use ceramics or composites like carbon fiber.

Here is a quick look at the types of materials you can use:

Material Type | Examples |

|---|---|

Metals | Aluminum, Stainless Steel |

Plastics | ABS, Acrylic |

Composites | Carbon Fiber, Fiberglass |

Others | Wood, Vinyl |

This helps you test your design in the same material as your final product. Cnc machining for prototyping works for simple or complex parts, no matter the material. That is why cars, medical, and electronics use cnc for metal and plastic prototypes.

You can make detailed shapes in almost any material.

Cnc machining for prototyping keeps tight tolerances, even with tough materials.

You can switch materials easily between runs to compare and choose the best.

Note: Cnc machining for prototyping does not need special molds or tools. You can change materials or designs without extra cost or waiting.

What Is CNC Prototype Machining?

Definition and Core Concepts

Cnc prototype machining helps you make real parts from digital designs. You start by making a 3D design on your computer. The machine reads your design and follows exact steps. Cnc prototype machining uses computer numerical control to move tools. These tools cut, drill, and shape your part with great accuracy. This way is faster and more exact than old methods. You can get very close tolerances, like ±0.01–0.05 mm. Your cnc machined prototype will look almost just like your design. The main ideas are speed, accuracy, and being able to change things. You can make changes fast and trust the results.

Efficiency: You get parts quickly, so you can test and fix your design.

Precision: The machine copies your design, so every part matches.

Flexibility: You can use many shapes and materials for your cnc prototype machining.

Tip: Cnc prototype machining lets you go from idea to part fast.

Subtractive Manufacturing Process

Cnc prototype machining uses a subtractive process. You start with a solid block of material. The machine takes away what you do not need. This is not like 3D printing, which builds parts in layers. With cnc prototype machining, you get a strong part with solid material. You can use the same materials as your final product. The surface is smooth, and you can pick different looks. Cnc prototype machining often saves time. For example, you might finish a part in 28 minutes, but 3D printing could take over 3 hours.

Subtractive manufacturing gives you strong, solid parts.

You can use end-use materials for your cnc machined prototype.

Surface finishes are smooth and can look different.

Key Machine Types for Prototypes

You have many choices when you use cnc prototype machining. Each machine type is good at different things. Here is a table to show the main types and what they do best:

CNC Machine Type | Advantages |

|---|---|

CNC Milling Machines | Makes many shapes, works on many axes, very useful |

CNC Lathe Machines | Best for round parts, shapes things fast and with care |

CNC Grinding Machines | Makes smooth finishes, holds tight tolerances for very exact parts |

CNC Drilling Machines | Drills holes well, repeats the same hole easily |

CNC Waterjet Cutting Machines | Cuts many materials, no heat damage, keeps material safe |

You can pick the best machine for your cnc prototype machining project. This helps you get the results you want. Each cnc machined prototype can be made with the right machine, so you get the part you need.

How CNC Machining for Prototypes Works

From CAD Model to Finished Part

You start the cnc machining process by creating a 3D design. This design uses CAD software. The journey from idea to finished prototype follows clear steps:

The Design Phase (CAD Modeling): You make a detailed 3D model of your part.

Programming (CAM Software): You import your model into CAM software. This step creates the G-code for the cnc machine.

Material Selection: You pick the right material for your prototype. Your choice depends on how you want the part to perform.

The Machining Process: The cnc machine follows the G-code to shape your part.

Each step helps you move from a digital idea to a real, physical part. You can see your design come to life with cnc machining.

Tip: Careful planning at each step leads to better prototypes and fewer mistakes.

CNC Programming and G-code

Programming is a key part of cnc machining. You use G-code to tell the machine what to do. G-code controls every move, cut, and drill. This code makes sure your parts match your design.

Here is how G-code helps you:

Aspect | Description |

|---|---|

Precision | G-code gives you accurate control of the machine’s movements. Your parts come out precise. |

Repeatability | You can reuse the same program to make identical parts every time. |

G-code automates the cnc machining process. You do not need to guide the machine by hand.

This reduces human error. Your finished parts have high quality and reliability.

Common Machining Operations

You use cnc machining to make high-quality prototypes for many industries. This process gives you precision and lets you use many materials. Both are important for good part quality.

Cnc machining helps you create low-volume prototype parts quickly.

You can speed up product development and make sure your parts meet design needs.

Quality control in cnc machining checks that your parts have the right size and shape.

This step keeps your products strong and your customers happy.

Note: Cnc machining lets you test, improve, and trust your prototypes before moving to full production.

Advantages and Limits of CNC Prototyping

Benefits Over Other Prototyping Methods

When you look at cnc prototyping and other ways to make prototypes, you see many good things. You get parts that are very exact and strong. You can use metals and engineering plastics. This helps you test your design with real materials. The parts have tight tolerances and smooth surfaces. These things help you check if your prototype fits and works right.

You can make a prototype that looks and feels like the real thing.

Cnc prototyping works with lots of materials, so you can try different ones.

You get better accuracy than 3D printing, which builds parts in layers.

You can use your prototype for real tests, not just for show.

Cnc prototyping also saves time and money. You do not need to make many prototypes to get the right one. You can change your design and make a new prototype fast. This helps you go from idea to product quicker.

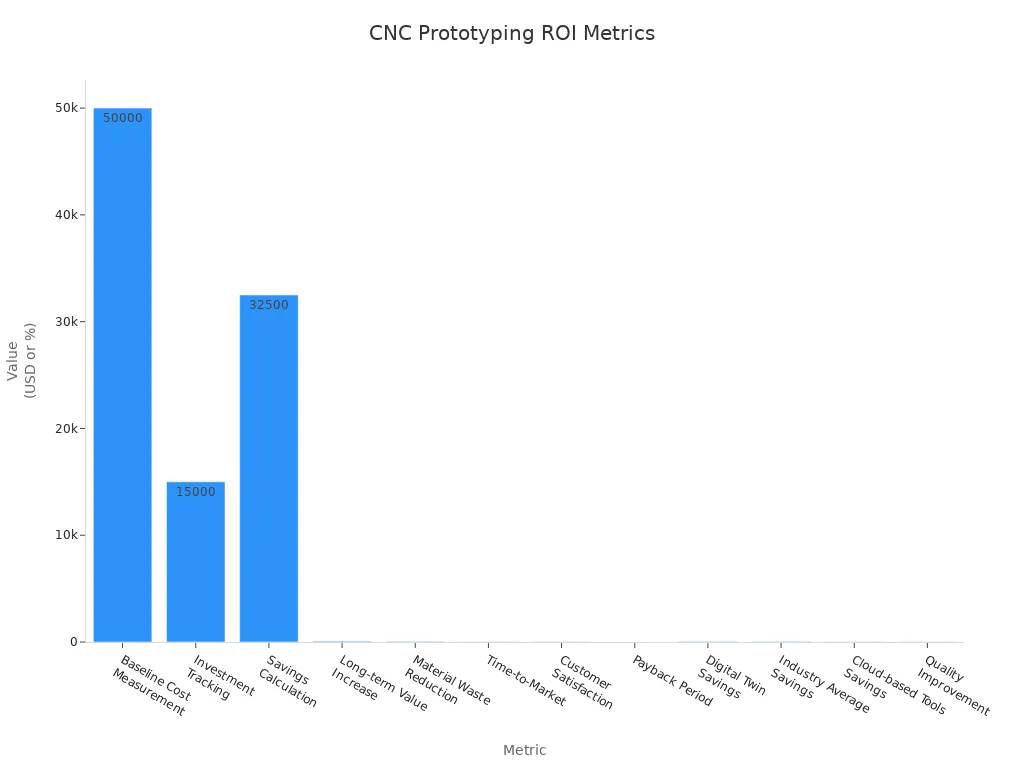

Here is a table that shows how cnc prototyping helps you save money and time:

Benefit | Description |

|---|---|

Cost-Effectiveness | Cnc prototyping cuts waste and uses resources well. You do not need lots of prototypes, so you spend less and keep quality high. |

Speed | Cnc prototyping makes the design cycle faster. You can go from idea to prototype quickly, unlike older ways. |

You also get more value for your money. You spend less on materials and labor. You get your product to market faster. You see happier customers and better quality.

Limitations and Considerations

Cnc prototyping has some limits you should know about. Some materials are hard to machine. Ceramics and some composites can break or wear out tools. If you only need one prototype or a very tricky part, cnc prototyping can cost more than other ways. 3D printing is often cheaper for small batches or hard shapes.

Here is a table that shows the main limits of cnc prototyping:

Limitation Type | Description |

|---|---|

Material Constraints | Some materials, like ceramics and composites, are hard to machine because they are brittle or tough. |

Cost for Low Volumes | Making just one or a few prototypes with cnc prototyping can be expensive. Material costs are higher. |

Complexity | Very complex parts can cost more with cnc prototyping. 3D printing may be better for these cases. |

You need to think about what your project needs. If you want a prototype made from a special material, check if cnc prototyping can do it. If you only need a few prototypes, look at the costs. Sometimes, other ways work better for small batches.

You also need to look at labor and material costs. Cnc prototyping is good for making strong, exact prototypes. For simple plastic parts, 3D printing may save you money. If you want to make many prototypes, cnc prototyping has lower costs for each part.

When to Choose CNC Prototyping

You should pick cnc prototyping when you need tight tolerances and real materials. If you want to test your prototype in real life, cnc prototyping gives you the best results. You get fast turnaround, so you can change your design and test again quickly.

Here are some reasons to pick cnc prototyping:

You need a prototype with high precision.

You want to test your design with metals or engineering plastics.

You need to make changes quickly and see results fast.

Your design is tricky and needs detailed machining.

You want to save money on big runs of prototypes.

Your field has strict rules, like aerospace or medical, and needs traceable parts.

You also need to think about your team and project. If your team knows how to use cnc machines, you get better results. If your timeline is short, cnc prototyping helps you meet your goals.

Here is a table that shows what to think about when choosing cnc prototyping:

Factor | Description |

|---|---|

Project Complexity | Cnc prototyping works well for tricky designs. |

Budget Constraints | For simple needs, other ways may save money. |

Timeline Pressures | Cnc prototyping is fast when you need quick results. |

Material Types | Strong materials work best with cnc prototyping. |

Industry Regulations | Some fields need cnc prototyping for safety and rules. |

Team Expertise | Teams with cnc skills get better prototypes. |

You can see how well cnc prototyping works by looking at cost savings, faster time to market, and better customer feedback. You see less waste and more value over time. You get your money back in just a few months and make your product better.

Tip: Use cnc prototyping when you want a working prototype that matches your final product and helps you test your design in real life.

CNC machining helps you make prototypes fast and with good accuracy. It does not cost too much money. You can pick from many materials. This lets you test your real design before making lots of parts. Here are some main reasons to use CNC machining:

You save both time and money when making a few parts.

You can find mistakes in your design early and fix them.

You get strong parts that fit well because of tight tolerances.

Aspect | Why It Matters |

|---|---|

Speed | You can test ideas quickly |

Accuracy | Your parts fit and work the right way |

Material Options | You can use the same materials as final parts |

As CNC technology gets better with smart tools and more automation, you will find new ways to make your prototypes even better.

FAQ

What is a cnc prototyping service?

A cnc prototyping service turns your computer designs into real parts. This helps you test ideas fast. You can see if your design works before making lots of parts.

How does rapid prototyping help new product development?

Rapid prototyping lets you make and test models quickly. You can find design problems early. This helps you finish new products faster and bring better ones to market.

Why should you choose high-quality cnc prototypes for your prototyping needs?

High-quality cnc prototypes are strong and very exact. You can use them to check if parts fit, work, or look right. These parts help you make smart choices for your project.

What are the main cnc processes used in prototype machining?

Cnc processes like milling, turning, and drilling shape your part. They start with solid material. These methods give you exact parts for fast testing.

How do cnc machining services support you from prototype to production?

Cnc machining services help you go from one part to many. You can test your design, change it, and order more parts. This makes it easy to grow your project and reach your goals.

LKprototype

LKprototype