Share a little biographical information to fill out your profile. This may be shown publicly.

Computer Numerical Control (CNC) technology changes manufacturing by using machines. These machines work automatically and make parts with great accuracy. CNC systems help create complex parts quickly and with the same quality every time. The global CNC market is growing fast. It is expected to rise from $90.5 billion in 2024 to $144.4 billion by 2033. This means it will grow about 5.06% each year. By 2030, over 2.8 million CNC machines may be needed. New high-speed machining makes this possible. This technology helps factories work faster and grow easily. Key Takeaways CNC machines help make parts faster and more…

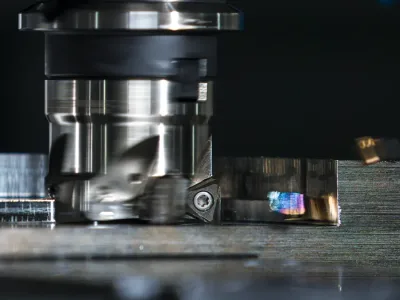

Introduction Bronze is one of the oldest metal alloys, yet it remains highly relevant in modern manufacturing. This copper-based alloy (typically copper mixed with tin, aluminum, silicon, or other elements) offers a blend of strength, corrosion resistance, and machinability that make it popular for precision components (A Guide to Different Types of Bronze Alloys - MetalTek). In CNC machining, working with bronze can be rewarding for beginners if they understand its basic properties and how to address common challenges. This blog post provides an accessible overview of bronze alloys, the challenges of machining them, effective CNC techniques, key industrial applications,…

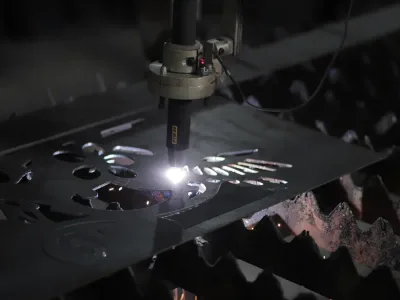

Imagine a CNC machine metal device that turns raw metal into precise parts. That’s what CNC machines do. They change manufacturing by using automation and programming to make perfect results every time. CNC machines have changed industries by working faster, wasting less, and repeating tasks perfectly. Here’s how they’ve made a difference: Valve factories using CNC machine metal technology cut setup time a lot between 1997 and 2002. Companies using CNCs needed more workers with engineering skills (from 52% to 72%) and programming skills (from 14% to 43%). CNC machines run fast all the time, saving time and keeping products…

CNC machines for metal have transformed how we work with this material. They can perform challenging tasks automatically, making them extremely valuable in industries such as car manufacturing, defense, and aerospace. Did you know the CNC market might reach $129 billion by 2026? This significant growth highlights the importance of CNC machines for metal in today's world. By 2025, advancements in technology like robots and 3D printing will enhance CNC machines for metal even further. These improvements will increase precision, conserve materials, and accelerate production. Whether you are producing small components or large structures, selecting the right CNC machine for…

Machining bronze adds great value to your projects. This strong metal lasts long, resists rust, and is easy to shape. Many industries prefer it for these reasons. But, machining bronze can be tricky. Tools can wear out, and heat can build up. Using the right tools and methods solves these problems. Bronze parts are used in boats and electrical systems. They work well because they are strong and dependable. With these special traits, bronze is perfect for making top-quality products. Key Takeaways Machining bronze is strong and doesn’t rust, so it lasts long. Picking the right bronze type makes machining…

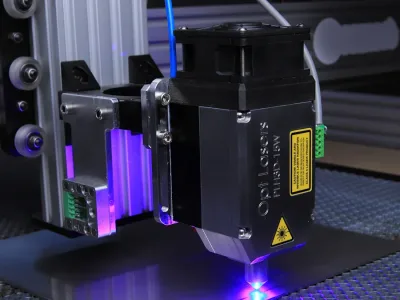

Choosing the right metal CNC machine is very important today. It helps make products the same every time with fewer mistakes. These machines use computers to follow exact instructions. They can work nonstop, making things faster and producing more items. They also save materials, which lowers costs and increases profits. Picking a machine that fits your needs gives better results. This choice improves work speed and helps you reach your goals easily. Key Takeaways Picking the right metal CNC machine makes work faster and better. It helps you reach your production goals easily. CNC machines, like milling, lathes, or laser…

Precision is very important in CNC machining bronze. Bronze is strong, resists rust, and handles heat well, making it great for producing parts like bushings and gears. However, its unique traits can make CNC machining tricky. To achieve good results, it's essential to use the right tools and methods. With practice, you can address issues like worn tools or rough surfaces, which helps create high-quality parts. Key Takeaways Pick the correct bronze type for your work. Each type has special traits that affect strength and use. Use strong carbide tools to cut bronze. They last longer and make smooth surfaces.…

CNC metal machining uses computers to shape metals very precisely. This technology has changed manufacturing by making it faster and better. For example, CNC machines work up to 15 times faster than hand tools. They also waste less material, saving money and keeping exact measurements. These features make CNC machining important for making detailed parts for planes, cars, and electronics. Using CNC machines helps you get the same results every time and makes production easier. Key Takeaways CNC machining works faster and is more accurate than old methods. It is important for industries like airplanes and cars. Picking the right…

CNC polycarbonate changes manufacturing by using smart machining and strong materials. It combines tough polycarbonate with advanced tools for better results. Clear polycarbonate is very strong and lasts a long time. It has low haze and no distortion, improving visibility for things like security windows. Its clear look and fire resistance make it great for military and safety gear. This flexibility helps make things faster, wastes less, and saves money over time. Key Takeaways CNC polycarbonate is tough and lasts long, great for safety tools. CNC machining works fast and cuts waste, saving time and cash. Polycarbonate is light but…

Acrylic CNC service uses computer-run machines to cut or shape acrylic. These machines can also engrave designs with great accuracy. This method makes sure the work is neat and allows for detailed designs. Many industries, like signage and manufacturing, use this service because it is fast and flexible. The world market for acrylic edge bending machines was worth USD 723 million in 2023. It might grow to USD 1,012 million by 2032. More need for accurate manufacturing and better automation tools are causing this growth. Companies in the signage business buy these machines to make top-quality ads. This rising use…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.