If you’re navigating the world of product development, understanding the various rapid prototyping types is essential. From proof-of-concept and low-fidelity to high-fidelity, looks-like, and works-like prototypes, each type serves a unique function in design and testing. This article breaks down these types and shows you when and how to use them effectively. Key Takeaways Rapid prototyping is essential in product development, enabling quick iterations and varying levels of fidelity to validate design and functionality effectively. Different types of prototypes, including low-fidelity, high-fidelity, works-like, and looks-like, serve specific purposes in the development process, from concept validation to final testing. Material selection…

Searching for metal fab parts means you need information on how these parts are made, the materials used, and the different types available. This article covers the essential processes in metal fabrication, the most common types of metal fab parts, material options, and finishing techniques. Understanding these aspects will help you choose the right parts for your project. Key Takeaways Metal fabrication involves processes like cutting, bending, and welding to create durable and customized metal parts for various industries. Understanding the properties of materials like steel, aluminum, and specialty metals is crucial for selecting the right components to ensure optimal…

3D printing tolerances are crucial for ensuring your printed parts meet the desired dimensions and function as intended. Understanding and controlling these tolerances can significantly improve the accuracy and quality of your prints. This article explores what 3D printing tolerances are, why they matter, and how you can achieve precise results in your projects. Key Takeaways 3D printing tolerances are essential for ensuring dimensional accuracy and functional performance of printed parts, significantly impacting overall print quality. Factors influencing tolerances include material properties, printer calibration, and settings like layer thickness and print speed, which must be optimized for precision. Effective tolerance…

5-axis CNC machining services enable the creation of complex parts with high precision using advanced technology. This article explains what 5-axis machining is, why it’s beneficial, and what you should expect from these services. Key Takeaways 5-axis CNC machining offers superior precision and efficiency, enabling the production of intricate geometries and complex parts with fewer setups. The technology supports a wide variety of materials, including metals and plastics, making it versatile for applications across industries such as aerospace, automotive, and medical. Choosing a reliable 5-axis CNC machining service provider involves evaluating experience, customer satisfaction, and scalability to meet business production…

Cylindricity is a vital aspect of GD&T that ensures an object is perfectly round and straight along its entire length. For components like shafts, bushings, and precision pins, accurate cylindricity is crucial for proper fit and efficient function. This article will break down what cylindricity involves, why it matters in manufacturing, and the best methods for measuring it accurately. Key Takeaways Cylindricity measures how closely a feature approximates a true cylinder, impacting fit, function, and component lifespan. The cylindricity tolerance zone consists of two coaxial cylinders defining the acceptable boundaries for the feature’s surface. Accurate cylindricity measurements are crucial for…

Choosing the right prototype tooling plastics is essential for efficient and cost-effective prototype production. This guide covers the top methods and materials to help you create high-quality prototypes quickly, including 3D printing, CNC machining, and injection molding. Key Takeaways Prototype tooling plastics enable rapid and cost-effective production of prototypes, facilitating early design validation and testing.Key methods for creating prototype tooling include 3D printing, CNC machining, and injection molding, each offering unique benefits for different prototyping needs.The benefits of using prototype tooling plastics include faster time to market, significant cost savings, and improved design validation, making them essential in various industries.…

Selecting the right silicone rubber for mold-making is key to successful projects. Silicone rubber is flexible, durable, and easy to use, making it ideal for detailed molds. This guide details everything you need to know to make the best choice. Key Takeaways Selecting the right silicone rubber enhances mold quality. It emphasizes factors like flexibility, tear strength, and curing time for successful applications. A 1:1 mix ratio of silicone components simplifies the preparation process. It ensures consistent results while minimizing bubbles and imperfections. Fast-curing silicones facilitate quick production cycles. Their versatility allows for casting across various surfaces, making them essential…

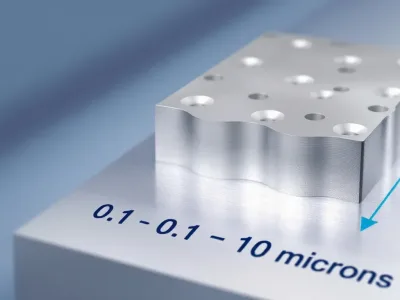

RMS surface finish quantifies the smoothness of a surface’s microscopic peaks and valleys. A lower RMS value indicates a smoother and higher-quality surface. This article explains what RMS surface finish is, its importance, and how to measure it. Key Takeaways RMS surface finish is a crucial measure of surface quality in manufacturing. It indicates smoother surfaces with lower roughness values compared to other metrics. Calculating RMS involves determining the square root of the average of the squared deviations from mean profile height. This offers a detailed analysis of surface texture. Various contact and non-contact methods exist for measuring RMS surface…

Precision CNC machined components are essential in creating parts with high accuracy and quality. Key industries such as automotive, aerospace, and medical rely on them. This article explores their importance, the machines and materials used, and their benefits and applications. Key Takeaways CNC precision machining transforms raw materials into high-quality components with exceptional accuracy, vital for industries like automotive, aerospace, and medical. Various specialized CNC machines, including milling machines, lathes, and EDMs, are used to achieve tighter tolerances and meet diverse manufacturing needs. Precision CNC machining offers multiple advantages, including enhanced accuracy, cost efficiency, and flexibility, making it a preferred…

Wondering whether MIG and stick welding is right for your needs? This article breaks down the key differences, pros, and cons of each welding method. Key Takeaways MIG welding offers faster and cleaner welds with a continuous wire feed but is less effective outdoors and for thick metals. Stick welding is versatile and strong on dirty surfaces, excelling in thicker materials, but operates slower and requires more skill. Choosing between MIG and stick welding involves considering project requirements, material types, and environmental factors. Understanding MIG Welding MIG welding, commonly referred to as Metal Inert Gas welding, involves the use of…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.