Understanding the melting temperature of plastic is crucial for making informed decisions in various projects. Different plastics have unique melting temperatures when exposed to heat. Being aware of the melting temperature of plastic helps prevent errors and material issues. Manufacturers rely on this knowledge to ensure quality, while designers use it to select plastics that offer the right balance of strength and durability. Hobbyists also benefit by crafting safely and efficiently. By learning about the melting temperature of plastic, you can achieve better outcomes and minimize waste in any project. Key Takeaways Knowing plastic melting points helps pick the right…

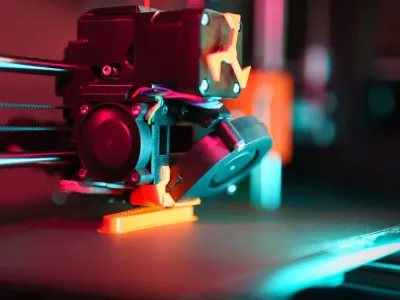

Image Source: pexels ABS plastic prototypes and regular ABS have different uses in making things. Prototypes made from ABS-like materials act like regular ABS. They are strong, resist impacts, and handle heat well. These are great for testing designs before making many copies. Regular ABS, however, is used in finished products because it is tough and flexible. The differences between them decide how they are used. For example: ABS-M30, a prototype material, is 70% stronger than regular ABS. This makes it good for testing strong structures. ABS-CF10, mixed with carbon fiber, is 50% stiffer than regular ABS. It works better…

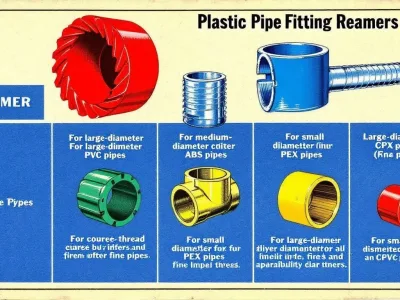

A plastic pipe reamer is a tool used to remove old fittings from plastic pipes, ensuring a clean surface for new connections. It’s essential for plumbing repairs and installations. In this article, we’ll explore how plastic pipe reamers work, different types available, key features to look for, and maintenance tips. Key Takeaways Plastic pipe reamers are essential for removing fittings and preparing pipes for new installations, enhancing efficiency in plumbing tasks.The Clean Ream Extreme® reamer is notable for its ability to clean and reuse fittings, which minimizes material costs and waste.High-quality reamers feature durable designs with carbide cutting inserts and…

Selecting the right silicone rubber for mold-making is key to successful projects. Silicone rubber is flexible, durable, and easy to use, making it ideal for detailed molds. This guide details everything you need to know to make the best choice. Key Takeaways Selecting the right silicone rubber enhances mold quality. It emphasizes factors like flexibility, tear strength, and curing time for successful applications. A 1:1 mix ratio of silicone components simplifies the preparation process. It ensures consistent results while minimizing bubbles and imperfections. Fast-curing silicones facilitate quick production cycles. Their versatility allows for casting across various surfaces, making them essential…

Plastic weld adhesives create strong bonds between plastic materials by chemically fusing them. This article explains how they work, reviews the best options, and provides usage tips. Key Takeaways Plastic weld adhesives create strong molecular bonds between plastics, making them ideal for durable repairs on various thermoplastics like PVC and acrylic. The effectiveness of these adhesives relies on proper surface preparation, capillary action, and quick setting times, often curing within minutes. Safety precautions, including protective eyewear and ventilation, are essential when using plastic weld adhesives to prevent injuries and ensure a safe working environment. Understanding Plastic Weld Adhesives Adhesives known…

The melting point of plastic material is key in manufacturing and product design. This guide explains what the melting point is, lists melting points for common plastics, and discusses their impact on applications. Key Takeaways The melting point of plastic materials determines their processing, performance, and application suitability, impacting product quality and innovation in manufacturing.Different common plastics exhibit varying melting points, such as HDPE at 130°C and polypropylene reaching up to 280°C, which informs manufacturers’ material selection based on specific applications.Factors such as molecular weight, crystallinity, and additives significantly influence the melting point, which is crucial for optimizing production processes…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.