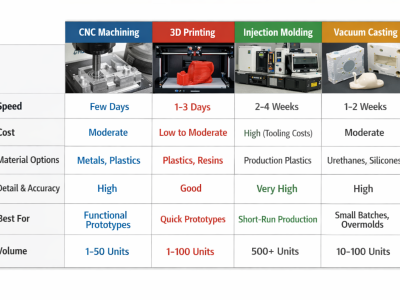

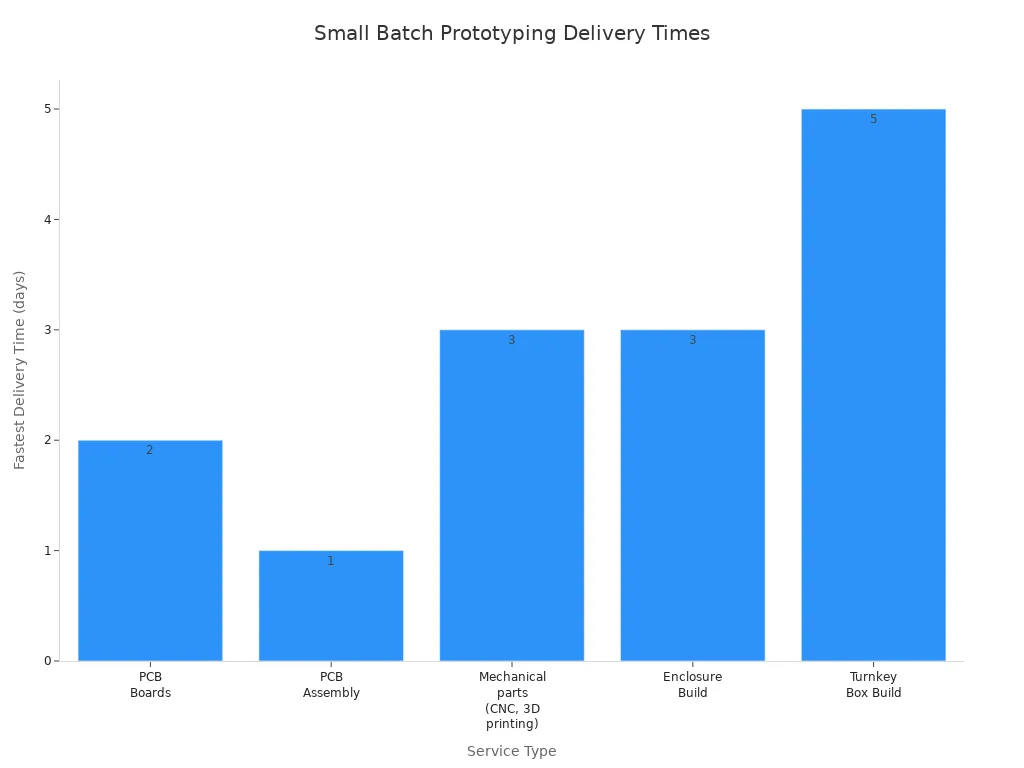

Small batch prototyping delivery time from China is usually fast. Rapid prototyping can take just 1 to 10 days. More complex prototype projects may need 2 to 4 weeks. The time depends on technology, how hard the order is, getting materials, and shipping. The table below shows common delivery times for different prototype services:

Technology / Service | Typical Fastest Delivery Time |

|---|---|

PCB Boards | 2 days |

PCB Assembly | 1 day |

Mechanical parts (CNC, 3D printing) | 3 days |

Enclosure Build | 3 days |

Turnkey Box Build | 5 days |

Chinese prototyping service providers use rapid prototyping and advanced automation. This helps them work fast and save money. Many customers pick these services for small batch production. They get prototypes quickly and pay less.

Key Takeaways

Small batch prototypes from China are made fast. Simple projects can be done in 1 to 10 days. Harder projects can take up to 4 weeks. - Fast technologies like 3D printing help make prototypes quickly. PCB assembly also makes testing faster. - Talking clearly and planning well with suppliers stops delays. It also makes the quality better. - Suppliers with lots of experience do good work. They check quality and deliver on time. - Picking the best shipping way helps avoid delays. Having the right papers gets prototypes to you faster.

Delivery Time Overview

Typical Ranges for Small Batch Prototyping

Delivery time for small batch prototyping from China can change. It depends on the manufacturing technology and what the project needs. Rapid prototyping, like 3D printing, can make a prototype in a few hours or days. CNC machining is used for metal and plastic parts. It usually takes 10 to 30 days for orders with less than 500 pieces. For short runs, CNC machining might take up to 30 days. Large CNC orders can need 30 to 45 days.

Manufacturing Technology | Typical Delivery Time Range (Small Batch Prototyping) | Notes |

|---|---|---|

CNC Machining | 10 to 30 days | For prototyping and low-volume runs (<500 pieces) |

CNC Machining (Short Runs) | 20 to 30 days | Supports rapid prototyping and small-batch production |

Large-scale CNC Orders | 30 to 45 days | Depends on complexity and volume |

3D Printing | Hours to a few days | Fastest for simple prototypes |

Rapid prototyping services in China can deliver PCB boards in 2 days. PCB assembly can be done in just 1 day. Mechanical parts, like enclosures, can be ready in 3 days. These fast times help companies test and change designs quickly.

Note: Rapid prototyping in China uses advanced automation and strong supply chains. This helps make lead times shorter and projects finish faster.

Fastest and Longest Scenarios

The fastest delivery time happens when using rapid prototyping, like 3D printing or PCB assembly. If the design is simple, a prototype can ship in 1 to 3 days. Companies use this speed to check ideas or react to changes fast.

The longest delivery times are for complex projects or big orders. CNC machining for hard parts or large batches can take up to 45 days. Getting materials or special requests can also make it take longer.

China’s supply chain system helps cut lead times by up to 70%. This makes production and getting materials faster. It helps businesses finish projects quickly and meet deadlines. Compared to other places, China has lower costs and good delivery times for small batch prototyping. For example:

Region | Delivery Time | Cost per Hour | Notes |

|---|---|---|---|

China | 4 to 8 weeks | $15 - $50 | Lower cost, longer lead times, good for cost-sensitive projects |

USA | 2 to 4 weeks | $75 - $150 | Shorter lead times, high precision, fast for urgent batches |

Europe | 3 to 5 weeks | 60 - 120 euros | Moderate lead times, high quality, strict rules |

A German car parts supplier cut lead times from 8 weeks to 5 weeks by moving production to China. This happened because of bigger orders and better supply chains. In another case, a robotics startup in Silicon Valley got 100 sensor mounts from a US provider in 48 hours. This shows the USA is very fast for urgent, small batch prototyping.

Small batch prototyping delivery time from China is very competitive for most jobs. Rapid prototyping is very fast for simple prototypes. Strong supply chains help deliver more complex projects quickly.

Factors Affecting Small Batch Prototyping Delivery Time from China

Many things can change how fast small batch prototyping is in China. These include the technology used, how hard the order is, getting materials, and shipping. Knowing about each part helps companies plan better and finish projects on time.

Technology and Process

The type of technology used makes a big difference in speed. Chinese companies often use both 3D printing and CNC machining together. This lets them make first parts fast with 3D printing. Then, they use CNC machining to make the parts more exact and smooth. New machines with automation and AI help work go even faster.

3D printing is good for making simple parts quickly, sometimes in just a few hours.

CNC machining is best for tricky parts that need to be very exact, but it can take longer to set up and finish.

Smart factories in China can change what they make quickly to help with small orders.

Using both 3D printing and CNC machining helps make prototypes fast. It works for both easy and hard projects.

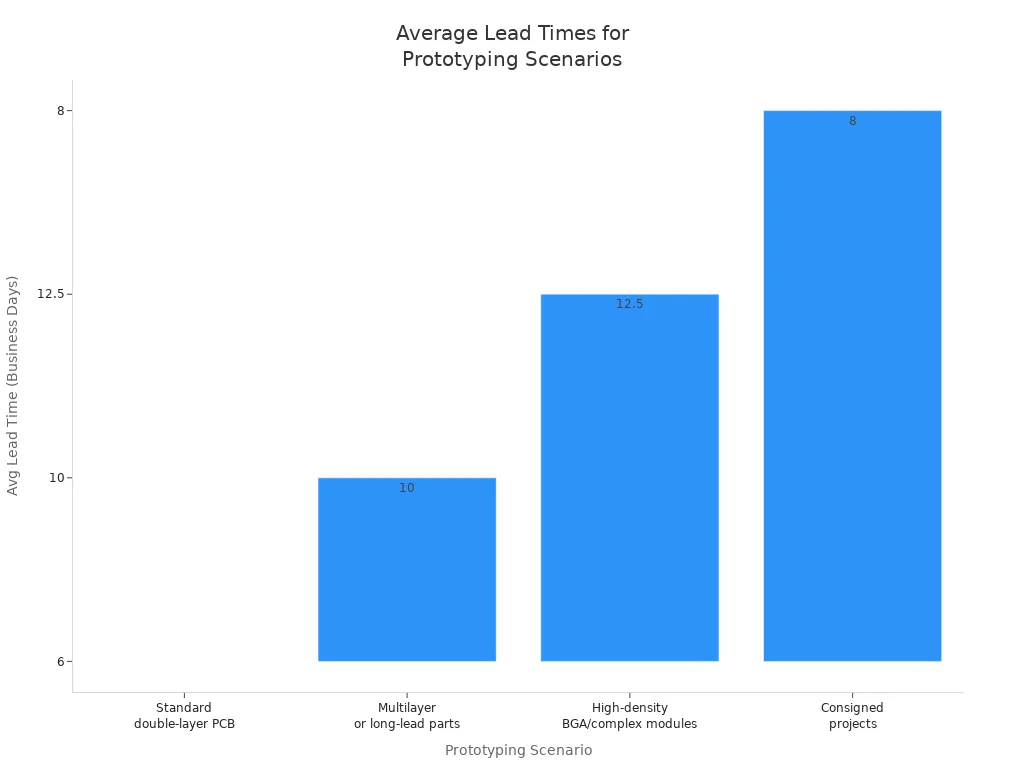

Prototyping Scenario | Average Lead Time (Business Days) | Notes |

|---|---|---|

Standard double-layer PCB | 5 - 7 | Can be shortened to 3 - 5 days with turnkey services |

Multilayer boards or with long-lead parts | 8 - 12 | Extended due to PCB fabrication and component sourcing |

High-density BGA or complex modules | 10 - 15 | Requires more precise assembly and testing |

Consigned projects (customer-provided parts) | 6 - 10 | Lead time depends on material completeness and delivery efficiency |

Chinese companies can make simple prototype pcb boards in about 3 days. If the customer is in another country, shipping can add 6 to 10 more days. People closer to China get their parts faster. How fast a prototype is made depends on the machines, workers, and how well things are organized.

Order Complexity

How hard the order is changes how long it takes to finish. Easy designs with normal materials are done faster. Harder jobs, like high-density pcb assemblies or special cases, need more steps and careful work.

Special software, 3D printing, and CNC machining help with tough designs.

Machines check each part to make sure it is made right.

Some Chinese companies are very good at making small numbers of tricky products, like new gadgets or custom clothes.

Jobs with many layers, special parts, or tight rules need more time to make and test. For example, a high-quality prototype pcb with lots of layers or tiny parts can take up to 15 days. If customers send in their own parts, the time depends on if those parts arrive on time and are complete.

Material Sourcing

Getting the right materials can slow down small batch prototyping in China. Some common problems can make things take longer:

Suppliers might promise fast times but not count real problems with making or shipping.

Using outside companies can make it harder to see what is happening, which can cause delays.

Language problems or bad communication can lead to mistakes and extra work.

If quality checks miss something, the part may need to be made again.

Not talking to suppliers early can make the project take longer.

A big reason for delays is not sharing information clearly. If a design change, like adding Bluetooth, is not explained well, teams might have to redo their work. Good communication and clear instructions help keep prototype pcb making on track.

Shipping and Logistics

Shipping and moving parts is very important for getting a prototype delivered. The way you ship changes how fast and how much it costs. Express shipping is the most popular for small batches because it is quick and easy.

Shipping Method | Suitability for Small Batch Prototypes | Typical Transit Time | Key Characteristics |

|---|---|---|---|

Express Shipping | Most suitable for small parcels and prototypes due to speed and convenience | 3 to 7 days | Fastest option, door-to-door delivery, tracking available, premium cost |

Air Freight | Suitable for medium-sized or urgent shipments, less ideal for very small batches | 5 to 10 days | Faster than sea freight, flexible for smaller batches, higher cost than sea freight but cheaper than express for some sizes |

Sea Freight | Less suitable for small batch prototypes, best for bulk shipments | 25 to 40 days | Cost-effective for large volumes, longer transit times, requires inventory planning |

It is important to have the right customs papers to avoid delays when shipping to other countries. Using experts for shipping and customs helps stop problems. Local knowledge about customs rules makes things go faster and smoother.

Picking the best shipping route and method can save time and money. For example, a Chinese car company got special parts made in 3 days, but shipping and customs made the total time 12 days. Companies should remember these steps when planning how long their project will take.

Chinese Prototyping Service Process

Quotation and Design Review

A normal chinese prototyping service begins when the customer sends design files or samples. The supplier looks at these files and gives a quick, correct price. They also check the prototype pcb fabrication needs closely. The supplier makes sure the design can be made and points out any problems. Customers look at the price and details, then say yes to the order.

Standard process flow:

Customer sends design files or samples.

Supplier checks and gives a price.

Customer agrees to the order.

Supplier gets ready to make the prototype.

This way, the prototype will fit all technical needs before making starts. Fast answers and clear talks help stop delays early on.

Production and Quality Control

After the order is set, the chinese prototyping service starts making the prototype. The team begins with prototype pcb fabrication. They use CNC machining, 3D printing, or other ways. For pcb jobs, suppliers often have cheap pcb manufacturing with quick-turn services. They can make low-cost prototype pcb boards in just 24 hours.

Quality control is very important during making. Workers check the product at each step. They use CMM machines and look for problems by eye. Final checks make sure the prototype pcbs are high quality and meet all rules. Some companies ask outside groups to check for extra safety. A feedback system helps make quality control better over time.

Quality control checklist:

Factory checks and supplier proof

Checks during making

Final product checks

Outside checks (if needed)

Getting feedback from customers

Packaging and Shipping

When the prototype passes all checks, the team gets it ready to ship. Packaging keeps the pcb and other parts safe from harm. Delays can happen if tariffs change packaging costs or if there are not enough materials. Some companies use local packaging to keep times short and prices steady.

Shipping choices are express, air freight, or sea freight. Good shipping partners help make sure delivery is on time. The customer gets the prototype and lets the team know it arrived. Fast, safe packaging and shipping are very important for small batch jobs that need to move quickly.

Tip: Picking the best packaging and shipping partner helps stop delays and keeps the prototype safe while it travels.

How to Optimize Rapid Prototyping Lead Time

Communication and Preparation

Good communication and planning help make rapid prototyping faster. Teams should use simple words and short sentences. This helps everyone understand, especially when working with Chinese pcb suppliers. Using bullet points and numbers in emails makes tasks clear. Messaging apps like WeChat let people ask questions fast. This stops delays that happen with slow emails.

Repeat what you need so suppliers know what to do.

Some suppliers may not say "no," so check what they can really do.

Build trust by meeting in person or having meals together.

Use outside checks to make sure suppliers can do the job.

Keeping design documents the same helps at every pcb prototyping step. Making virtual prototypes early with CAD software lets teams fix designs before making real parts. This saves time and cuts down on mistakes. Doing Design for Manufacturing (DFM) checks early finds problems before they cost money. Teams can design and test at the same time to save time. Getting materials ready and using special fast lines also helps pcb projects move quickly.

Choosing the Right Prototype Supplier

Picking the best supplier is key for fast rapid prototyping. Companies should pick suppliers with lots of experience and good quality checks. Price is important, but quality and service matter more. Suppliers who answer quickly and give updates help keep pcb projects on track.

Ask for samples of old pcb work to check quality.

Talk to other customers who had similar needs.

Visit the supplier’s factory if you can to see their tools and meet the team.

Don’t pick a supplier without checking them or knowing all costs.

Make sure the supplier has a plan and keeps your ideas safe.

A good supplier with a strong history in pcb rapid prototyping will deliver on time and meet your needs.

Shipping Options

Choosing how to ship is important for small batch and rapid prototyping. The type of supplier and where they are changes how fast pcb parts arrive. The table below shows how long different suppliers take and what is good or bad about each:

Supplier Type | Typical Lead Times | Advantages | Limitations |

|---|---|---|---|

Small Workshops | 5-10 days | Flexible, personal attention | Limited capacity, less consistent |

Mid-sized Manufacturers | 7-14 days | Good balance of capacity/attention | May prioritize larger clients |

Large Factories | 10-21 days | High capacity, comprehensive | Less flexibility, longer chains |

Companies can split orders to get some pcb parts faster by air and send the rest by sea. Giving all technical details early and using DFM to make pcb parts easier helps save time. Working with the same suppliers for a long time helps get faster service when it is busy. Setting real goals and checking what suppliers promise stops delays.

Small batch production in China uses new technology and strong supply chains. This helps rapid prototyping, quick delivery, and faster sales for new pcb products.

Small batch prototyping from China is very quick. Simple projects can be done in 1 to 10 days. The main things that affect speed are technology, how hard the order is, getting materials, and shipping. Companies can make lead time better and know what to expect by doing these things:

Pick suppliers who are good at making things and checking quality.

Have honest and clear talks with the people who make your parts.

Use online tools to help manage the supply chain well.

Make sure design files and assembly steps are correct and easy to follow.

Try different ways to ship so there are fewer problems.

Chinese prototyping services are fast and save money. This helps companies make new products quicker.

FAQ

How fast can a company get a prototype from China?

Most companies get simple prototypes in 1 to 10 days. Harder projects can take up to 4 weeks. Using express shipping makes delivery faster.

What documents help avoid shipping delays?

Clear invoices, packing lists, and customs forms help stop delays. Companies should check all papers before sending out shipments.

Can a company track its prototype shipment?

Yes. Most Chinese suppliers give tracking numbers for express and air shipping. Customers can watch their package online.

What if a company needs changes after production starts?

Suppliers can make changes, but this adds time and cost. Telling suppliers about design changes early helps stop delays.

LKprototype

LKprototype