China is the leading destination for prototype mold making China, producing more molds than any other country. With over a million skilled workers employed in this field, you benefit from advanced technology and expert craftsmanship. Additionally, China offers flexible manufacturing options at lower costs. Many international clients have concerns about IP protection, contract issues, and mold misuse. To address these concerns:

Use contracts like NNN agreements.

Register IP in China.

Conduct regular audits.

Following these steps helps safeguard your designs and ensures excellent results in prototype mold making China.

Key Takeaways

China is the top country for prototype mold making. It has skilled workers and new technology. This means you get good quality for less money. - Picking Chinese factories helps you save money. Labor costs are low. Production is fast. Supply chains are strong. You can even order small amounts. - Fast delivery happens because of quick prototyping methods. Smart factory steps make design, testing, and production faster. - Quality control in China uses strict checks. Workers are skilled. Factories have certifications. This makes sure molds are exact and dependable. - Good communication and picking the right supplier are important. They help keep your designs safe. They also make projects go well.

Prototype Mold Making China

Industry Overview

China is a top country for prototype mold making China. The industry grew fast after the 1980s. This happened because of more factories, foreign money, and new machines. Now, China makes over half of the world’s molds. Places like Guangdong, Zhejiang, and Jiangsu are big centers for making molds. Guangdong is called the "hometown of Chinese molds" because it makes and ships out the most.

Factories in China use new technology to do better work. AI helps them know when machines need fixing. This means less time is wasted. They use real-time checks to keep quality high and save materials. Machine learning finds mistakes better than people can. Robots and automation have grown a lot since 2019. This makes things faster and more exact. The government helps by putting money into 3D printing and research. These things help China stay ahead in prototype mold making China.

Chinese factories use many strong materials. You can pick from aluminum, steel, brass, and special plastics like polyetherimide (PEI) and polyphenylene sulphide (PPS). These materials are good quality but cost less. Factories make both prototype and production molds. This gives you choices for your projects.

Tip: When you buy prototype molds from China, you use a strong supply chain and modern roads, ports, and airports. This helps your molds get to you on time.

Key Benefits

Choosing prototype mold making China gives you many good things:

Lower labor costs help you spend less money.

Big factories make lots of molds, so each one costs less.

Many types of factories let you find almost any product, saving time and effort.

Fast production means you get your molds quickly, which is important for e-commerce and electronics.

Good supply chains and quick shipping make your production faster and easier.

New technology like AI, robots, and 3D printing keeps quality high and products exact.

Strong quality checks, using machine learning and cameras, keep mistakes very low.

You can find good factories on websites like Alibaba. These sites show you many suppliers. You can see ratings and "Gold Supplier" badges to help you choose. But you should always check their details, ask for samples, and look at their factory before you decide.

Sourcing websites help you find Chinese factories for prototype mold making China. They make searching easier, but you still need to check carefully.

Note: Good contracts, safe payments, and clear talks help protect your ideas and deals when working with Chinese suppliers.

Cost Advantages

Low-Volume Production

You can save money with low-volume production in China. Many factories take small orders, so you can test your product first. This helps you avoid spending a lot at the start. Labor costs are lower, and making many items at once saves money. Factories in Shenzhen use advanced machines like 5-axis CNC and mirror EDM. These machines make detailed molds fast. You get high-quality molds even if you only need a few.

Here are some main reasons why small batches cost less:

Labor in China costs much less than in the U.S. or Europe.

Factories put orders together to lower setup costs.

Automation and robots work all day and night, so there are fewer mistakes.

Manufacturing hubs make it easy to get materials and ship products quickly.

Tip: Low-volume production helps you find design problems early. You can fix them before making lots of products. This saves you money and time.

Competitive Pricing

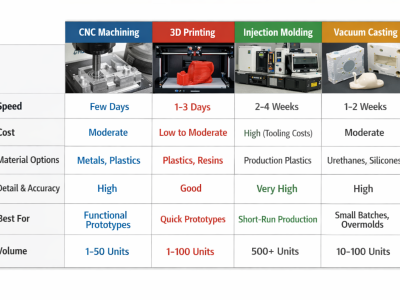

Chinese manufacturers have some of the best prices worldwide. You pay less because labor is cheaper and supply chains work well. Factories use advanced technology to keep costs down. The table below shows how costs compare in different places:

Region | Cost Difference Compared to China | Key Factors Influencing Cost Differences |

|---|---|---|

United States | 20% to 50% higher | Labor and overhead cost more; being close and better IP protection are benefits |

Europe | 30% to 60% higher | Higher labor, strict rules, and slower delivery make it cost more |

China | Baseline | Labor is cheaper, materials cost less, fewer extra costs, faster work, and strong supply chains |

You also save money because of:

Lower raw material and tooling costs.

Making lots of items at once lowers the price for each one.

Quality checks like ISO 9001 and first article inspections.

Teams speak many languages and know global standards, so mistakes are avoided.

A U.S. startup paid $6,800 for a mold in China. The same mold in the U.S. cost $19,000. This shows you can save a lot without losing quality.

Fast Delivery

Rapid Prototyping

You want your ideas to become real products fast. Chinese mold makers use new rapid prototyping methods to help you. These methods let you test and change your designs quickly.

Fused Deposition Modeling (FDM) makes cheap, simple prototypes for early tests.

Stereolithography (SLA) builds detailed models that show small features.

Selective Laser Sintering (SLS) makes strong parts for testing how things work.

CNC machining cuts aluminum and steel into exact molds with smooth sides.

Hybrid manufacturing mixes 3D printing and machining for better detail.

You also get help from rapid tooling. This uses 3D CAD models to make molds fast. Direct rapid tooling lets you test your design with small batches. Indirect rapid tooling makes master molds for more tests and checks. These ways use 3D printing, CNC machining, and vacuum casting to speed things up. Rapid injection molding with aluminum or S50C steel gives short molding cycles and easy steps. Most prototype molds ship in about four weeks. This helps you keep up with fast markets.

Tip: Rapid prototyping helps you find design problems early. This saves you time and money before making many products.

Efficient Processes

Chinese factories have made their processes faster and better. You get quick results because of strong supply chains and smart factory plans.

Good supply chains give you fast materials and parts.

One-stop shops handle design, prototyping, mold making, and injection molding together.

Artificial intelligence and automation make things more exact and fast. This means fewer mistakes and delays.

Here is a table that shows some important process improvements:

Process Improvement | Description |

|---|---|

Material Considerations | Picking the right plastic resins for better speed and cost. |

Gate Location Optimization | Putting mold gates in good spots to make better parts and fewer mistakes. |

Special Mold Features | Adding holes or undercuts to stop mistakes and allow flexible work. |

Adjusting Formulation Parameters | Changing temperature, speed, pressure, and cooling time for faster cycles and exact parts. |

Optimizing Run Size | Changing batch sizes to keep machines working well and lower costs. |

Supervising Production Rates | Managing teams to keep work moving fast and smooth. |

Scrap Reduction | Cutting waste to save money and help things flow better. |

Mold Preventative Maintenance | Doing maintenance during breaks to stop delays. |

You get these benefits because they make delivery times shorter and keep quality high. New machines and simple mold designs also help you get your prototype molds fast and for less money.

Quality & Precision

Material Choices

When you order prototype molds from China, you can pick from many materials. Each material has its own good and bad points. Picking the right one helps your product work well and last longer. The table below lists some common materials, their features, and how they change your product:

Material | Key Properties | Typical Applications | Impact on Product Performance |

|---|---|---|---|

ABS | Tough, impact and chemical resistant, low shrink | Cosmetic parts, housings, tools | Good toughness and chemical resistance; stable size; blends improve thick molding |

PC | High impact and heat resistance, low shrink | Lenses, lighting, medical devices | Strong and heat resistant; good finish; can have voids in thick parts |

PMMA | Optical clarity, high gloss, scratch resistant | Light pipes, lenses, signs | Clear and glossy; can be brittle; needs draft angles |

POM | Tough, stiff, fatigue resistant | Gears, pumps, switches | Good for moving parts; needs even wall thickness; hard to paint |

PP | Flexible, chemical resistant, low cost | Hinges, lids, medical tubing | Flexible and cheap; can warp in cold; good for chemical use |

Strong, heat resistant, easy to process | Automotive, electronics | Combines best features of ABS and PC; better for thick parts |

You should use the same material for your prototype and your final product. This helps you find problems early, like warping or surface marks. ABS is good for strong, steady parts. Polycarbonate gives strength and a smooth look. Polypropylene works best for cheap, bendy items.

Tip: Always test your prototype with the material you want for your real product. This way, you will not get any surprises later.

Quality Control

Chinese mold makers use careful steps to make sure your molds are exact and dependable. They use new machines and skilled workers to help you. Many factories have ISO 9001, which means they follow world quality rules. Some, like Deep Mould, also have IATF 16949:2016 for cars.

Here are some common steps for quality control:

Design Verification: Experts check the mold design for shape and thickness.

Material Inspection: Teams test the raw materials for strength and purity.

CNC Machining and EDM: Machines cut and shape metal very accurately.

Heat Treatment: Factories make metal parts harder so molds last longer.

Surface Finishing: Workers polish and add texture for smooth mold surfaces.

Assembly and Fitting: Careful work makes sure all parts fit just right.

Testing and Trial Runs: Factories make sample parts to look for mistakes.

Final Approval: Only molds that pass every test go to mass production.

Outside groups like SGS or Intertek also check the factories. These checks make sure factories follow safety and industry rules. Factories watch temperature and pressure during molding to keep every part the same. This focus on quality helps you get molds that always meet your needs.

Choosing a Manufacturer

Evaluating Capabilities

When picking a Chinese mold maker, you need to check if they fit your needs. First, look at their past work and what people say about them. Ask for proof of old projects and reviews from customers. See if they have certificates like ISO 9001, which means they follow world quality rules. Good suppliers have strong quality checks and skilled workers.

Here are some key things to look for:

They have made good molds and plastic parts before.

Their prices are fair but do not lower the quality.

They always deliver on time.

They have staff who speak English and help customers well.

They want to work with you on design and testing.

They check quality during every step.

Verification Aspect | What to Look For |

|---|---|

Industry Experience | Has worked with your kind of product |

Production Capacity | Can handle your order size and timing |

Quality Control Systems | Has clear plans and skilled inspectors |

Certifications | Has ISO 9001 or similar certificates |

References and Testimonials | Can give feedback from customers |

Communication and Service | Answers quickly and clearly |

Collaboration During Phases | Works with you from start to finish |

You can also send an engineer to the factory to watch mold tests. This helps you find problems before shipping. It gives you more control and makes you feel better.

Top Chinese companies offer custom design, project help, and support for many prototype needs. They use advanced CAD design, fast prototyping, and strong supply chains. Many have teams who speak two languages and offices in other countries to help you work easily.

Communication Tips

Talking clearly helps your project go well. Follow these steps to stop mistakes:

Give exact design details like size, material, and finish.

Share 3D CAD models so the factory can see your part.

Add photos or samples to show what you want.

Set times for updates and feedback. Use video calls if needed.

Use drawings with notes and symbols to avoid mix-ups.

Ask the factory to repeat your needs to make sure they understand.

Pick suppliers who speak English well and know global work.

Tip: Good talking and clear project plans help you avoid delays and costly mistakes.

Picking prototype mold making China gives you many good things. You pay less and get your molds quickly, so you can move fast. Factories use new machines and have workers who do careful work. They can make just a few molds or many, depending on what you need. They check quality at every step and help you after you buy, so you can trust them. To begin, look up different factories, see if they have the right certificates, and ask for a price or a meeting. Websites like Plasticmoulds.net help you find good suppliers easily.

FAQ

What is a prototype mold?

A prototype mold helps you make a small number of parts for testing. You use it to check your design before making many products. This saves you time and money.

How long does it take to get a prototype mold from China?

Most Chinese factories finish prototype molds in two to four weeks. You get faster results if you share clear designs and answer questions quickly.

Can I protect my design when working with Chinese mold makers?

Yes. You can use NNN agreements and register your IP in China. You should also choose trusted suppliers and ask for regular updates.

What materials can I use for prototype molds?

You can choose from aluminum, steel, brass, and many plastics. Each material has different strengths. Pick the one that matches your product needs.

LKprototype

LKprototype