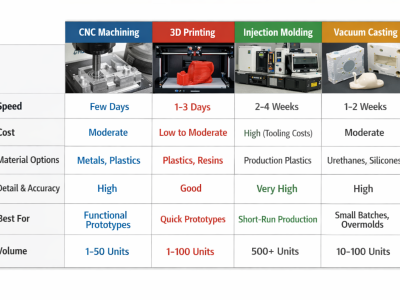

You need to know how to choose the best prototyping method for your project. Your goals, materials, how many you need, budget, and time all matter. Matching the method to your needs helps users get better feedback. Picking the right way lets users see ideas come to life. It helps users agree on choices. It also lets users spot problems early. Manufacturing MethodCost EffectivenessLead TimeMaterial Compatibility3D PrintingCost changes with amount; cost stays the same for small numbersQuick setup, slower for big batchesWorks with many materials, good for tricky shapesCNC MachiningNot great for very small batches; better for bigger batchesFast after…

You have an important job in medical device prototype development. This process helps you change an idea into a real prototype. The prototype can help patients and make care better. In 2025, you will see new problems and chances in medical device design, testing, and prototyping. Every step, from idea to pilot prototype, affects the final product. You need to know about the materials, costs, and steps in development. This helps you make good choices and build safe, useful devices. Key Takeaways Learn about how to make a medical device prototype. Start with an idea. Then test it to make…

Small batch prototyping delivery time from China is usually fast. Rapid prototyping can take just 1 to 10 days. More complex prototype projects may need 2 to 4 weeks. The time depends on technology, how hard the order is, getting materials, and shipping. The table below shows common delivery times for different prototype services: Technology / ServiceTypical Fastest Delivery TimePCB Boards2 daysPCB Assembly1 dayMechanical parts (CNC, 3D printing)3 daysEnclosure Build3 daysTurnkey Box Build5 days Chinese prototyping service providers use rapid prototyping and advanced automation. This helps them work fast and save money. Many customers pick these services for small batch…

You should choose the best prototyping method for your project by considering how many parts you need, how quickly you need them, the material you want, and your budget. Urethane casting over 3D printing prototyping offers a smoother finish and stronger parts for small to medium quantities. It’s ideal if you want parts that resemble injection molding. On the other hand, 3D printing is fast and can create complex shapes quickly. Many companies now combine both methods, using 3D printing to create tools for urethane casting. This approach speeds up the process and reduces costs for custom parts. Key Takeaways…

Choosing vacuum casting prototype parts China offers you a significant advantage. You can receive your initial prototypes within just 3 to 7 days, which is much faster compared to the typical 2 to 6 weeks elsewhere. Suppliers in China maintain low prices and don’t require large orders, helping you save money while providing more options. They utilize advanced technology and employ skilled workers, ensuring high precision and rapid production. The key benefits of vacuum casting are evident in every project. Vacuum casting prototype parts China enable you to work efficiently and stay ahead in your industry. Key Takeaways Vacuum casting…

When learning how to design for prototyping in China factory settings, it’s important to start with a clear plan. First, define your product’s goals and sketch out your ideas. Next, create digital models to visualize your concepts more effectively. As you move forward with how to design for prototyping in China factory environments, use rapid methods like CNC machining or 3D printing to build physical prototypes and test your design. Protect your intellectual property with patents or NDAs. Prepare detailed drawings and a bill of materials. Choose materials and manufacturing processes that align with your plan. For the best results…

China is the leading destination for prototype mold making China, producing more molds than any other country. With over a million skilled workers employed in this field, you benefit from advanced technology and expert craftsmanship. Additionally, China offers flexible manufacturing options at lower costs. Many international clients have concerns about IP protection, contract issues, and mold misuse. To address these concerns: Use contracts like NNN agreements. Register IP in China. Conduct regular audits.Following these steps helps safeguard your designs and ensures excellent results in prototype mold making China. Key Takeaways China is the top country for prototype mold making. It…

Product prototyping gives you a practical way to turn ideas into testable models. A prototype lets you explore design, function, and user experience before full production. You use prototyping to spot design flaws early, gather user feedback, and reduce costly mistakes. The product prototyping market reached US$ 19.34 billion in 2023, showing its growing importance across industries. When you create a product prototype, you help teams align and make better choices. Early-stage prototyping encourages creativity and speeds up learning. Digital tools and market-driven approaches make prototyping faster and more effective than ever. Key Takeaways Product prototyping turns ideas into testable…

Custom silicone molds are important tools for work and hobbies. They are useful because they can change and are dependable. You can see them used in baking and making products. Their special features—like being bendable, strong, and safe—make them popular with workers and DIY fans. Here are some ways industries use these molds: Car makers use them for parts like gaskets and seals that handle tough conditions. Electronics companies use them to protect parts from dust and water. The healthcare industry likes silicone because it is safe for the body, so it’s great for medical tools. Builders use silicone for…

Silicone moulds have revolutionised baking and crafting due to their ease of use. Their non-stick surfaces make them ideal for intricate designs. Perfect for cakes, chocolates, resin, and soap projects, these moulds are increasingly sought after as more people embrace custom and eco-friendly tools. With the growing popularity of home cooking and crafting, silicone moulds enable creative designs while being both practical and visually appealing. Key Takeaways Silicone moulds are useful for baking and crafting. They have non-stick surfaces, so items come out easily without breaking. Use food-safe silicone moulds for baking to stay safe. Check for FDA-approved labels to…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.