NC (Numerical Control) and CNC (Computer Numerical Control) machines have revolutionized manufacturing. NC machines rely on manual programming with punched cards or tape, while CNC machines utilize computers to automate tasks. This key difference fundamentally alters how production is carried out.

Understanding these distinctions is crucial for making informed decisions in manufacturing. CNC machines operate continuously and require minimal supervision. They significantly reduce setup time and offer high precision. This leads to fewer errors, less material waste, and more efficient resource utilization. Choosing the right NC CNC machine can enhance productivity, cut costs, and elevate quality.

Key Takeaways

NC machines need manual programming with punched cards. CNC machines use computers to automate tasks. This makes CNC machines faster and more accurate.

CNC machines need less human help. They can run all the time and lower labor costs. This makes them work better and have fewer mistakes.

CNC machines are more flexible and handle tricky designs easily. They switch tasks quickly, making them great for custom jobs.

Both NC and CNC machines need regular care. CNC machines have smart tools to find problems early, so they break down less.

Pick the right machine based on your needs. NC machines are good for simple, repeated work. CNC machines are best for precise and complex jobs.

What Are NC and CNC Machines?

NC Machines Overview

NC (Numerical Control) machines are the start of automated tools. They use punched cards or tapes to work. Think of them as the first step in making machines smarter. Skilled workers must program and watch these machines closely.

NC machines are great for tasks like drilling and milling. They give steady results for repeated jobs, which is good for uniform work. But, manual programming makes them less flexible. Important things to check for NC machines are cutting speed, feed rate, and material removal rate. These help decide how well they fit certain jobs.

CNC Machines Overview

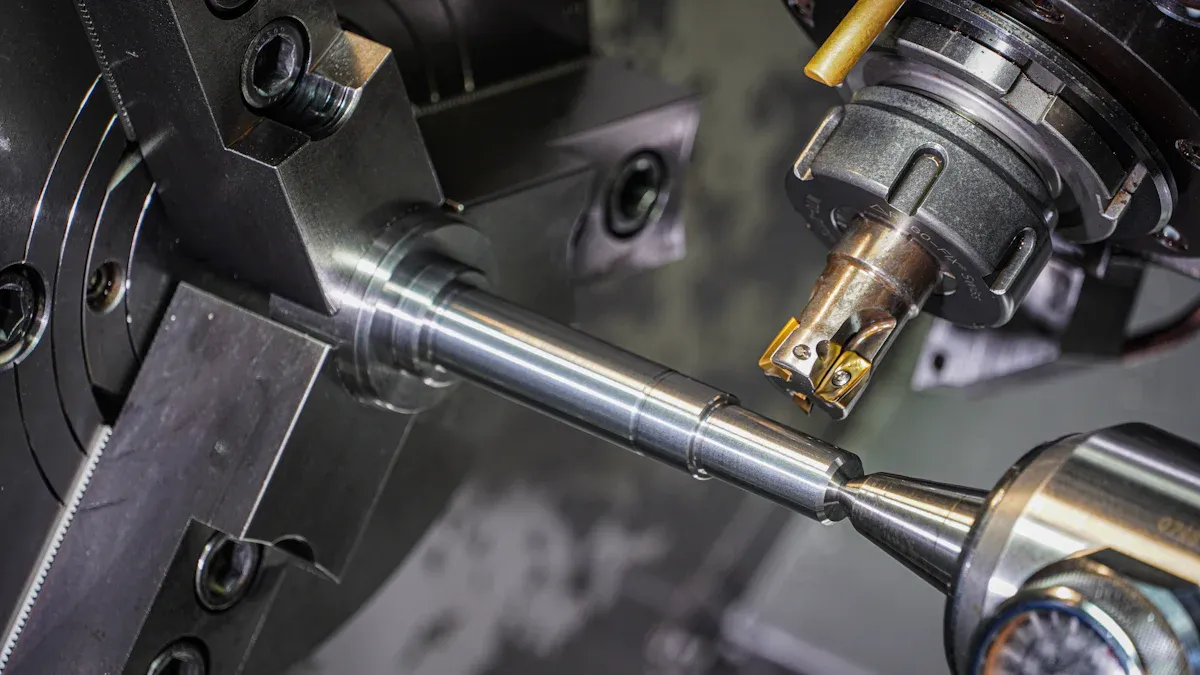

CNC (Computer Numerical Control) machines are more advanced. Unlike NC machines, they use computers to run tasks. This lets them do harder jobs with better accuracy and flexibility. CNC machines can move in many directions for detailed designs.

These machines are very popular today because they save time and adapt easily. For example, CNC lathe machines made up 28% of the market in 2023. Advanced ones, like five- and six-axis lathes, are used for fine, detailed work. CNC machines also work with CAD/CAM software, making them key in industries like cars, planes, and medical tools.

Evolution from NC to CNC

The change from NC to CNC machines shows years of progress. In the 1940s and 1950s, punched tape systems started the idea of numerical control. By the 1950s, NC machines were used for tasks like drilling and milling.

In the 1960s, computers were added to machines. This allowed real-time changes and led to CNC technology. From the 1970s to 1990s, new features like multi-axis machining and CAD/CAM made manufacturing even better. Today, CNC machines are the best for precision and speed, helping many industries grow.

Key Differences Between NC and CNC Machines

Programming and Control Mechanisms

NC and CNC machines differ in how they are programmed. NC machines use punched cards or tapes for instructions. Operators must manually program them, which takes skill and time. Real-time changes are not possible with NC machines. CNC machines, however, use computers to automate programming. You can quickly adjust settings and even test operations before starting.

Here’s a simple comparison of their features:

Feature | NC Machines | CNC Machines |

|---|---|---|

Control | Manual control | Computerized automated control |

Accuracy | Good accuracy | Better accuracy with automation |

Flexibility | Limited flexibility | Highly flexible with visual tools |

Human-Machine Interface (HMI) | Basic interface | Advanced interface for easier use |

CNC machines also work with CAD/CAM software. This makes programming easier and reduces mistakes. These advanced controls make CNC machines better for detailed and complex tasks.

Automation and Operational Flexibility

CNC machines excel in automation. Unlike NC machines, they don’t need constant human monitoring. Once programmed, CNC machines run on their own. This reduces labor costs and human errors. For example:

In aerospace, CNC machines make complex parts faster and cheaper.

In medical manufacturing, CNC machines create precise tools for better results.

CNC machines are also very flexible. They switch tasks quickly without much reprogramming. This makes them perfect for industries needing custom designs. CNC machines also cut materials precisely, reducing waste. This saves money and helps the environment.

Precision, Accuracy, and Efficiency

CNC machines are more precise and efficient than NC machines. NC machines are good for repetitive tasks, but CNC machines are better for detailed work. They can achieve tolerances as small as ±0.001 inches, perfect for intricate designs.

Metric | NC Machines | CNC Machines |

|---|---|---|

Tolerance | N/A | ±0.001 inches |

Production Speed Increase | N/A | Up to 50% |

First-Pass Yield Rate | N/A | Over 95% |

CNC machines also save time and improve quality. They use less energy and waste fewer materials. This makes them eco-friendly and cost-effective. These benefits make CNC machines essential for modern manufacturing.

Maintenance and Technological Upgrades

Taking care of machines and upgrading them is very important. Both NC and CNC machines need maintenance, but CNC machines are more complex.

Maintenance of NC Machines

NC machines use mechanical parts and manual programming. You should check gears, belts, and motors often to avoid damage. Clean the punched tape readers and check the manual programming for accuracy.

Tip: Plan regular checks to prevent sudden breakdowns. Lubricate parts and align them to make the machine last longer.

Maintaining NC machines is easier, but they don’t have smart diagnostic tools. You must rely on your skills to find and fix problems early.

Maintenance of CNC Machines

CNC machines have built-in tools that help with maintenance. These tools watch the machine’s performance and warn you about issues. This helps reduce downtime and keeps the machine running smoothly.

Important tasks for CNC machines include:

Software Updates: Update the software to use new features.

Hardware Checks: Look at motors, spindles, and cooling systems regularly.

Calibration: Check the machine’s axes to keep it accurate.

Some CNC machines use smart tools to predict problems before they happen.

Technological Upgrades

Upgrading machines can make them work better. NC machines have fewer upgrade options because they are manual. You can replace old parts or improve programming, but their main functions stay the same.

CNC machines, however, can be upgraded a lot. You can add features like multi-axis machining, faster processors, or better CAD/CAM tools. These upgrades help you do harder jobs with more speed and accuracy.

Note: Upgrading CNC machines can make your business stronger. Better automation and precision lower costs and improve product quality.

When choosing between fixing or upgrading your NC or CNC machine, think about your needs and budget. Regular care keeps machines reliable, while upgrades give them new abilities.

Advantages and Limitations of NC and CNC Machines

Benefits of NC Machines

NC machines are great for repeated tasks. They make identical parts with high accuracy. This makes them perfect for bulk production. These machines work nonstop, improving efficiency and reducing delays.

Another advantage is reducing mistakes. NC machines follow programmed steps, using materials wisely. This cuts waste and saves money. For example, industries needing uniform drilling or milling often pick NC machines for their steady performance.

Aspect | NC Machines Benefits |

|---|---|

Precision | Accurate and consistent results for repeated tasks |

Efficiency | Continuous work boosts productivity |

Error Reduction | Automation lowers human mistakes |

Material Utilization | Uses materials efficiently, reducing waste |

Drawbacks of NC Machines

NC machines also have some downsides. Setting them up costs a lot, and skilled workers are needed to program them. Maintenance can take time since they lack smart diagnostic tools.

They are not very flexible. NC machines work with limited software and materials. This makes them less useful for custom or complex designs. Manual programming can also cause setup errors, delaying production.

Tip: Regular care and trained operators can reduce these problems and keep things running smoothly.

Benefits of CNC Machines

CNC machines are very flexible and can handle many tasks. They work with different materials, making them useful in industries like aerospace and medical tools. With CAD/CAM software, CNC machines can do detailed and complex jobs.

These machines save money over time. Although they cost more upfront, they lower labor costs and reduce waste. For example, CNC machines work faster, helping meet deadlines easily.

Metric | CNC Machines Benefits |

|---|---|

Versatility | Can handle many tasks and materials |

Complex Operations | CAD/CAM helps create detailed designs |

Cost Efficiency | Saves money despite high starting costs |

Production Speed | Faster work improves efficiency |

CNC machines also cut waste and use less energy. This helps the environment and boosts productivity. Smart maintenance tools reduce downtime, increasing worker efficiency by up to 83%.

Drawbacks of CNC Machines

CNC machines have many benefits, but they also have challenges. Knowing these issues can help you pick the right machine.

One big drawback is the high start-up cost. These machines are expensive to buy and set up. Small businesses or low-production jobs may find this cost too high. The price includes the machine, software, training, and installation.

Another issue is working with complex geometries. CNC machines are precise, but detailed designs take more time and money. For example, parts with tight curves or small details need special tools and slower speeds.

The cutting tools used in CNC machines also have limits. Some shapes can’t be made because of how the tools are designed. This makes it hard to create unique or unusual designs.

Here’s a summary of these challenges:

Limitation | Description |

|---|---|

High Start-up Costs | Buying and setting up is costly, especially for small jobs. |

Complexity in Geometry | Detailed designs take longer and cost more to produce. |

Limitations of Cutting Tools | Tool design restricts the shapes that can be created. |

Tip: Plan your projects carefully to reduce these problems. Think about whether CNC machines are worth the cost for your needs.

CNC machines also need skilled workers and regular care. Even though they are automated, trained operators must program and check them. Software updates and part inspections are also needed to keep them working well.

By considering these points, you can decide if CNC machines fit your goals.

Applications of NC and CNC Machines in Manufacturing

Typical Uses of NC Machines

NC machines are great for repeated tasks needing consistency. They are used in industries like cars, planes, and general manufacturing. These machines are best for drilling, milling, and turning jobs. They follow programmed steps, giving steady results for bulk production.

Here’s how NC machines are used in different industries:

Case Study | Application | Outcome |

|---|---|---|

TMAC | Oil and gas manufacturing | Stopped a costly machine crash |

TMAC | Machining graphite iron engine blocks | Cut cycle time by 41% |

ToolConnect | General manufacturing | Removed costly operator data mistakes |

ToolConnect | Firearm manufacturing | Saved $4,000 from operator error |

ToolConnect | Automotive manufacturing | Lowered setup time and scrap |

AutoComp | Aerospace manufacturing | Stopped scrap of key parts |

AutoComp | Contract manufacturing | Boosted productivity by 200% |

DTect-IT | General manufacturing | Greatly reduced scrapped parts |

These examples show how NC machines save time, reduce waste, and ensure accuracy in large-scale production.

Typical Uses of CNC Machines

CNC machines are flexible and handle hard tasks easily. They are used in industries needing detailed designs, like aerospace, medical tools, and car manufacturing. CNC machines work with CAD/CAM software for precise machining, making them perfect for custom parts.

Key benefits of CNC machines include:

Predictive maintenance stops sudden breakdowns and keeps machines running longer.

Real-time monitoring checks quality and catches problems early.

Operators can track downtime reasons to improve processes.

Linking machine data to ERP systems improves job speed and standards.

These features make CNC machines essential for better production and quality control.

Industries Leveraging CNC Technology

CNC technology has changed high-value industries. Aerospace companies use CNC machines to make detailed parts like turbine blades. Car makers use CNC systems for precise engine and transmission parts. Medical companies use CNC machines to create implants and surgical tools with exact details.

New ideas like hybrid systems and 3D printing make CNC machines even better. These upgrades allow for complex tasks, making CNC technology vital for industries needing precision. Reports show companies using CNC machines are more productive and efficient, proving their value.

CNC machines help industries grow by meeting modern production needs with speed and accuracy.

Choosing Between NC and CNC Machines

Key Factors to Consider

Picking between NC and CNC machines depends on your needs. Think about your production goals, budget, and expected results. Follow these steps to decide:

Know Your Needs

What parts will you make?

How many and how often will you produce?

How precise do your products need to be?

Learn About Machine Types

Use Vertical Machining Centers (VMCs) for drilling and milling.

Horizontal Machining Centers (HMCs) are great for large production.

Turning Centers are best for turning and boring tasks.

Grinding Machines are ideal for smooth surface finishes.

Check Machine Details

Look at spindle power, speed, and axis movement.

Make sure the control system works with your software.

Confirm the machine meets your accuracy needs.

Look for Extra Features

Automation can reduce manual work.

Coolant and chip systems improve efficiency.

Safety features protect workers.

Ask Experts and Visit Dealers

Talk to professionals for advice.

Visit dealers to see machines in action.

Compare and Choose

List the pros and cons of each machine.

Tip: Use net present value (NPV) to check if a machine’s earnings will cover its costs. A positive NPV means it’s a good investment.

When NC Machines Are the Right Choice

NC machines are great for simple, repeated tasks. They work well for industries like cars and planes. These machines are best for drilling, milling, and turning jobs.

Feature | NC Machines |

|---|---|

Initial Cost | Lower initial costs |

Maintenance Cost | Can be expensive to maintain |

Flexibility | Limited flexibility |

Feedback Mechanism | Lacks feedback |

Production Volume | Suited for low-volume production |

Program Modifications | Time-consuming |

If you need low-volume production and don’t change programs often, NC machines are a smart choice. They are also good for businesses with smaller budgets or simple tasks.

Note: While NC machines are less flexible, their lower cost makes them a good option for small-scale jobs.

When CNC Machines Are the Right Choice

CNC machines are perfect for tasks needing precision and flexibility. They are ideal for industries like aerospace, medical tools, and cars. These machines handle detailed designs and custom jobs easily.

Why choose CNC machines?

Efficiency: They cut cycle times by 25% and boost productivity by 30%.

Cost Savings: Though expensive upfront, they save money by reducing waste and energy use.

Advanced Features: They work with Industry 4.0 tech like IoT and data tools.

ROI: Many businesses see returns within three years due to better productivity and less waste.

For example, spending ₹2 Crores on a CNC machine can bring big benefits. Using better tool paths and predictive maintenance can cut waste by 18% and raise productivity by 30%.

Tip: If your work needs high precision and frequent changes, CNC machines are worth it. They handle complex tasks and adapt to new tech, making them essential for modern factories.

Knowing the differences between NC and CNC machines helps you choose wisely. NC machines need manual programming, while CNC machines use computer automation. This affects how precise, fast, and efficient they are.

Key Performance Indicator | NC Machines | CNC Machines |

|---|---|---|

Precision | Less accurate results | |

Human Error Reduction | More chances of mistakes | Cuts errors by up to 25% |

Production Rate | Slower work speed | Boosts output by up to 40% |

Production Time | Takes longer to finish | Saves 30% of production time |

Pick the machine based on what your project needs. CNC machines have changed manufacturing with better speed, accuracy, and flexibility. They help you handle tough tasks with ease and confidence.

FAQ

What is the main difference between NC and CNC machines?

NC machines use punched cards or tapes for programming. CNC machines use computers to automate tasks and programming. CNC machines are faster, more accurate, and handle complex jobs better.

Can CNC machines replace NC machines completely?

CNC machines are more flexible and precise than NC machines. But NC machines are still good for simple, repeated tasks. If your needs are basic and your budget is small, NC machines are a good choice.

Are CNC machines harder to maintain than NC machines?

CNC machines need more care because they are advanced. They have tools that help find and fix problems quickly. NC machines need manual checks, which take more time.

How do I decide which machine is right for my business?

Think about how much you need to produce and your budget. NC machines are good for small jobs and simple tasks. CNC machines are better for big jobs and detailed designs needing accuracy.

Do CNC machines save money in the long run?

Yes, CNC machines save money by cutting labor costs and waste. They also work faster, saving time. Even though they cost more at first, they help you save more later.

Start your project with LKprototype

LKprototype company simplifies procurement for custom manufacturing, Suitable for making your products or prototypes with a variety of materials, such as metal or plastic, silicone rubber, from 3D Printing to CNC Machined Parts and Vacuum Casting , with a focus on speed and efficiency. Our platform provides instant quotes. With LKprototype, You can connect with the team to communicate your project to ensure quality and on-time delivery.

Start with an instant quote and experience how our technology and expertise can make custom part procurement faster and easier.

LKprototype

LKprototype