Metal injection molding combines fine metal powders with binders to form precise shapes, making it a key process for producing accurate components. This technique is essential for manufacturing small, complex parts with tight tolerances and high strength. Many industries rely on metal injection molding to produce millions of intricate parts each year. The table below highlights the expanding market for metal injection molding, reflecting its growing importance in high-volume production:

Market Statistic | Value | Significance |

|---|---|---|

Market size in 2024 | USD 5.75 billion | There is a big need for exact parts |

Expected market size by 2030 | USD 11.09 billion | More people are using metal injection molding |

CAGR 2024-2030 | 11.6% | It is growing fast because it saves money and is exact |

Metal injection molding supports industries such as automotive, electronics, and medical devices by providing advanced metal injection molding solutions for complex designs.

Key Takeaways

Metal injection molding forms tiny metal powders into strong parts. These parts have detailed shapes and close measurements.

This process saves money and materials. It makes many small, detailed parts fast. There is very little waste.

MIM is good for medical devices, cars, planes, and electronics. These industries need strong and exact metal parts.

The process uses special metal powders and binders. This helps make parts that are dense, strong, and dependable.

MIM gives lots of design choices, saves money, and is very exact. It is better than other ways to make metal parts.

What Is Metal Injection Molding?

MIM Basics

Metal injection molding shapes metal powders into solid parts. It works a lot like plastic injection molding. First, fine metal powders mix with a binder. This makes a material called feedstock. The feedstock is turned into small pellets. These pellets get heated up. Then, they are pushed into a mold. This forms a "green part." Next, the binder is taken out. This step is called debinding. After debinding, you have a weak "brown part." The last step is sintering. Sintering heats the brown part almost to the metal’s melting point. This step sticks the metal particles together. It also removes any leftover binder. Now, the part is strong and dense.

Metal injection molding needs careful control of powder size. Binder amounts and temperature must also be watched closely. These controls help every part meet strict quality rules. Parts must have the right density, shape, and strength.

This process lets companies make parts with tricky shapes and tiny details. Metal injection molding can make parts that are very dense, over 95%. Each part comes out with the same good quality.

Why MIM?

Metal injection molding is important for making precise parts. It helps make small, strong, and detailed pieces. Other ways to make these parts can be hard or costly. Many fields use this process, like electronics, medical devices, and cars. They need tiny and tough parts. The process makes parts almost the right shape right away. This means less waste and leftover powder can be used again.

Metal injection molding is known for being flexible and saving money, especially when making lots of parts.

The process makes millions of exact parts every year. It helps high-tech companies get the same results each time.

Makers can use metal injection molding with other methods, like additive manufacturing, to get even better results.

Metal injection molding is a trusted way to make hard metal parts in large numbers. It is a key part of modern precision manufacturing.

Metal Injection Molding Process

The metal injection molding process has many steps. These steps turn metal powders into strong, detailed parts. Each step helps make tricky shapes. The process also lets companies make lots of parts with less waste.

Feedstock Mixing

Engineers mix fine metal powders with a binder. This mix is called feedstock. The feedstock must flow well and handle heat. Engineers test how thick it is and how it acts under pressure. Metal feedstock moves heat better than plastic. This helps control the process. Careful mixing lets the process make tricky metal shapes.

Molding Stage

The feedstock is heated up. Then, it is pushed into a mold. The mold shapes the feedstock into a “green part.” Computer models help guess how the feedstock fills the mold. These models use real pressure and heat data. This step makes shapes that are hard to make in other ways. The molding stage is quick and good for making many parts.

Cooling takes most of the time in injection molding. How far apart the channels are, their size, and how fast coolant moves all matter. The type of coolant also matters. Good cooling stops warping and shrinking. This means better parts and faster work.

Debinding

After molding, the binder must come out. This step is called debinding. It leaves a weak “brown part.” Heat or chemicals take out the binder. The shape does not get ruined. Leftover binder and powder can be used again. This keeps waste low.

Sintering

Sintering heats the brown part almost to melting. The metal particles stick together. This makes the part strong and dense. Sintering also shrinks the part to its final size. This step lets the process make tight, dense parts.

Finishing

Some parts need extra work like grinding or coating. Finishing makes the surface better and adds features. Most parts need little finishing. This saves time and money.

Metric | Conventional Mold Steel | Rapid Tooling Technology (RTT) | Improvement / Note |

|---|---|---|---|

Production Cost (NT$) | 13,550 | 9,430 | About 30% less cost |

Manufacturing Time (hours) | 76 | 53 | About 30% less time |

Mold Service Life (cycles) | ~100,000 | 1,300 | Shorter life, but molds are faster and cheaper |

Metal injection molding wastes less material than old methods. Milling and other ways keep less than 10% of the starting material. Molding uses almost all the feedstock. This makes the process great for making millions of tricky parts.

Materials for Metal Injection Molding

Metal Powders

Metal injection molding uses tiny metal powders. These powders must be high quality. The Metal Powder Industries Federation (MPIF) makes rules for these powders. These rules help companies pick the best powder for each job.

MPIF Standard 35 lists types of materials and how strong they must be.

The rules also say what chemicals can be in the powder and how to test it.

MPIF has 48 ways to test metal powders and products made from them.

These rules match with ASTM and ISO rules used around the world.

MPIF also teaches people and shows how to test powders.

These rules make sure every batch of powder makes strong parts. Companies know their parts will work well.

Binders

Binders are very important in metal injection molding. They mix with metal powders to make feedstock. The binder helps the feedstock fill the mold. It also helps the part keep its shape later. The binder you pick changes how well the part does in debinding and sintering. Some binders dissolve in liquids, so debinding is gentle. This helps the part keep its shape. Some binders need heat to come out, which can cause cracks or shape loss. Studies show that feedstock with dissolving binders keeps its shape better. It also gets denser and stronger after sintering. MIM parts with the right binder can be up to 95% dense. They can also be harder and stronger than parts made other ways.

Material Choices

Engineers can use many metals for injection molding. Stainless steel is popular because it does not rust and is strong. Companies also use low-alloy steels, tool steels, and superalloys for special jobs. Titanium and copper are good for medical or electric parts. Each metal has its own good points. The best metal depends on what the part must do, how strong it needs to be, and the cost. This big choice of metals makes metal injection molding helpful for many industries.

Applications of Metal Injection Molding

Metal injection molding helps many industries. It makes small, complex metal parts and tiny pieces. These parts are used in medical, aerospace, electronics, cars, and special products. Each industry likes that these parts are strong and made with great care.

Medical Devices

The medical field uses metal injection molding for tiny, exact parts. These parts must be safe for the body. Companies make things like surgical tools, drug delivery parts, test machines, and heart devices. These items need special shapes and must be very safe.

A report says more medical devices need tiny, safe, and exact parts. Stainless steel is used a lot because it does not rust. Big companies make special materials for medical use. The report also says Asia-Pacific is growing fast, and North America and Europe have many factories.

Some examples of parts in medical devices are:

Surgical scissors and forceps that must be very exact (±0.002 inches)

Drug delivery parts made from tungsten alloys to block radiation

Biopsy tools that are hard and smooth

Stents and lens frames made from titanium alloys for safety in the body

Application Area | Performance Benefits | Typical Tolerances / Metrics |

|---|---|---|

Surgical Instruments | Complex shapes, does not rust | ±0.002 inches, >85,000 psi strength |

Drug Delivery Systems | Exact tungsten alloy parts for blocking radiation | ±0.001 inches, up to 98% tungsten |

Diagnostic Equipment | Hard shapes, smooth finish, lasts long | ±0.003 inches, up to 45 HRC hardness |

Cardiovascular Devices | Safe for the body, does not rust, tricky shapes | ±0.002 inches, ~95% material use |

Ophthalmic Applications | Light, lines up well, safe for the body | ±0.002 inches, Ti-6Al-4V alloy |

Prosthetics | Strong, does not rust, good for joints | ±0.001 inches, stainless steel 316L |

Automotive

Car makers use metal injection molding for small, tough parts. These parts must last a long time and not break. The process makes things like gears, turbo parts, and sensor covers. These parts are light but strong, which helps make cars use less fuel.

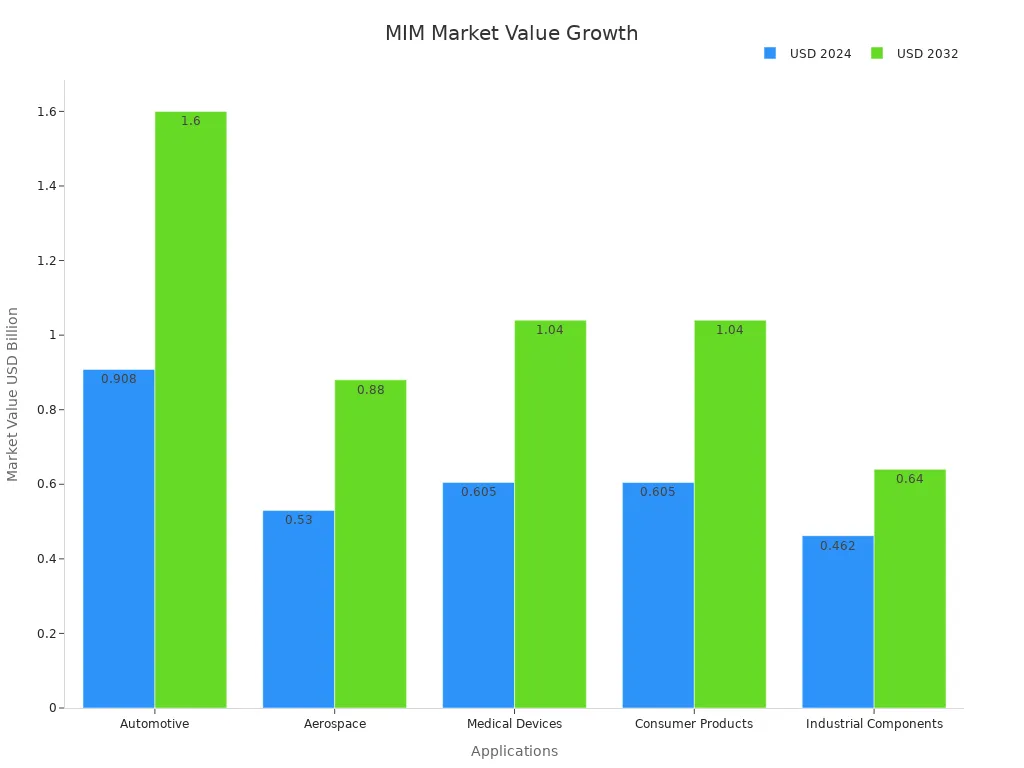

Application | Market Value 2024 (USD Billion) | Market Value 2032 (USD Billion) | Key Adoption Drivers and Notes |

|---|---|---|---|

Automotive | 0.908 | 1.6 | Needed for light, strong parts; helps new car ideas and electric cars grow. |

Car engineers pick metal injection molding for:

Gears with tricky teeth shapes

Lock parts and moving pieces

Fuel system parts that do not rust

Tiny parts for sensors and plugs

Making lots of these tricky parts with little waste is why car makers like this process.

Aerospace

Airplane companies need parts that are light and strong. These parts must be safe and work well. Metal injection molding makes small, tricky parts for engines, frames, and wires.

MIM makes detailed, exact airplane parts with hard shapes.

Airplane parts use stainless steel, titanium, and superalloys for strength.

Lighter parts help planes use less fuel.

MIM parts meet tough airplane rules and are very strong.

Uses include frame parts, engine pieces, and tiny electric parts.

North America, Europe, and Asia-Pacific use MIM a lot because of new ideas and support.

MIM lets designers try new shapes and make test parts fast.

Making many tricky parts at once saves money.

More planes and space parts need these strong, light pieces.

Application | Market Value 2024 (USD Billion) | Market Value 2032 (USD Billion) | Key Adoption Drivers and Notes |

|---|---|---|---|

Aerospace | 0.53 | 0.88 | Focus on better performance and saving fuel; MIM parts help make planes lighter and stronger. |

Electronics

Electronics companies use metal injection molding for tiny, exact parts with smooth surfaces. These parts are in phones, smart watches, and cable ends. The process works with many metals, which is good for magnetic and stainless steel parts.

Aspect | Metal Injection Molding (MIM) | Die Casting |

|---|---|---|

Complexity | Good for tricky, hard shapes | Good, but less flexible for hard shapes |

Materials | Many choices, like stainless steel and titanium | Mostly aluminum, zinc, and magnesium |

Part Size | Small parts (up to about 10x10 inches) | Small to medium parts (up to about 30x30 inches) |

Tolerances | Very exact (1-2%) | Not as exact (2-3%) |

Surface Finish | Very smooth, often needs no extra work | Medium, may need more work |

Applications in Electronics | Small, tricky parts like phone pieces, smart wearables, cable ends | Bigger parts like boxes and antenna holders |

Cost Considerations | Tools cost more, best for tricky, exact parts | Cheaper for bigger, simple parts |

MIM gives a better finish and more design choices, so it is great for making tricky, exact parts in electronics. Die casting is good for bigger parts but cannot match MIM for detail and metal choices.

Metal Injected Custom Parts

Many companies need special metal parts for their own uses. These custom parts often have hard shapes and must work a certain way. Metal injection molding helps make these parts for things like home goods, machines, and special markets.

The world market for custom metal parts is getting bigger. People want smaller, better, and lighter parts. MIM lets companies make tricky shapes that are strong and save money.

Application | Market Value 2024 (USD Billion) | Market Value 2032 (USD Billion) | Key Adoption Drivers and Notes |

|---|---|---|---|

Medical Devices | 0.605 | 1.04 | Needs to be clean and exact; MIM makes tricky shapes that follow rules. |

Consumer Products | 0.605 | 1.04 | People want strong, cheap parts, so MIM is used more. |

Industrial Components | 0.462 | 0.64 | Helps machines work better; smaller market but still important. |

The world MIM market could grow from $3.2 billion in 2023 to $6.1 billion by 2032. This is because more cars, medical tools, and home goods need strong, tricky metal parts.

Advantages of Metal Injection Molding

Design Flexibility

Metal injection molding lets engineers make many shapes. It can form metal into almost any design. Thin walls and tiny holes are possible. Designers can add undercuts, threads, or curves. These shapes are hard to make with other ways. The table below shows how different methods compare for design choices:

Aspect | Metal Injection Molding (MIM) | CNC Machining | Die Casting | 3D Printing |

|---|---|---|---|---|

Complexity of Parts | Great for small, tricky parts with tight shapes | Good for simple or medium parts; not best for very tricky ones | Better for big parts; not good for tiny details | Good for testing new shapes but not exact for lots of parts |

Material Efficiency | Uses almost all material, even expensive metals | Wastes a lot of material because it cuts away | Less waste than CNC but needs more for big parts | Good for small parts but sometimes needs extra for support |

Cost-Effectiveness | Saves money when making lots of small, tricky parts | Costs a lot for hard parts or big jobs; better for small batches | Cheaper for big, simple parts; setup costs are high | Good for small batches and testing; costs more for lots of parts |

Part Size | Best for small and medium parts; not for very big ones | Works for many sizes, small to big | Best for big parts; not for tiny, tricky ones | Used for small and medium parts; size depends on printer |

Metal injection molding is good for saving money and making new shapes. It helps make parts with good shape and size. This helps new ideas in medical, electronics, and car industries.

Designers can put many parts together into one. This means fewer steps and stronger parts. This is a big reason why metal injection molding is helpful.

Cost Efficiency

Companies pick metal injection molding to save money. Most costs come from machines and molds. Machines can cost $50,000 to $200,000. Making molds with CNC adds more cost. But making lots of parts makes the process cheaper.

Method | Cost per Part | Tooling Cost (Year 1) | Total Year 1 Cost |

|---|---|---|---|

Metal Injection Molding (MIM) | $2.50 | $100,000 (4 molds) | $250,000 |

CNC Machining | $6.15 | $615,000 (machine, labor, etc.) | $615,000 |

This table shows metal injection molding can save up to half the cost. MIM also needs less extra work and makes tricky shapes in one step. Die casting costs change with material, shape, and number, but MIM is often better for small, detailed parts.

Metal injection molding uses almost all the starting metal. This means less waste and more savings. It is a smart choice for making lots of parts.

Precision and Tolerances

Metal injection molding makes very exact parts. After sintering, most parts are within ±0.3%. Parts are 96% to 99% dense, which is better than many other ways. Shrinkage is between 15% and 20%, so parts keep their size and shape.

Tools like CMMs, 3D scanners, and CT scanners check size.

Tests check how strong, hard, and tough the parts are.

X-rays and dye tests look for hidden problems.

These checks show that MIM parts are very exact and reliable.

A study on sensor parts showed MIM made walls as thin as 0.4 mm. The parts passed leak tests with no helium leaks. Other methods have a hard time matching this quality.

By picking the right powder, binder, and heat steps, makers get strong, hard, and rust-proof parts.

MIM vs. Other Methods

Metal injection molding has many good points over other ways. It makes parts close to the final shape, so there is less waste and less work after.

MIM mixes the best parts of plastic molding and powder metal work.

It makes shapes that are hard to cut or cast.

The process can hold tight sizes, often within ±0.1 mm.

Less extra work means less waste and faster jobs.

Feature | Metal Injection Molding (MIM) | Die Casting |

|---|---|---|

Material Types | Works with many metals like titanium, nickel, and stainless steel | Mostly uses aluminum, zinc, and magnesium |

Part Complexity | Great for small, tricky, exact parts | Better for big, simple parts |

Production Volume | Good for making lots of small, tricky parts | Good for making lots of big parts |

Cost | Costs more at first because of extra steps | Usually cheaper, up to 30% less |

Speed | Fast molding but slower overall because of extra steps | Faster overall because there are fewer steps |

Applications | Used for guns, medical tools, car parts, electronics, planes | Used for cars, electric parts, planes, home goods |

MIM is great for making lots of small, tricky parts. It uses less material, which is good for the planet and saves money.

The main benefits of metal injection molding are saving money, making new shapes, and using material well. These make MIM a top pick for companies that need strong, tricky metal parts.

Metal injection molding is a great way to make exact parts. Companies use it to make strong and detailed things for cars, medical tools, and electronics. This process uses less material and costs less money. It also helps make parts quickly.

MIM can make parts that are almost as dense as solid metal. These parts can be made very close to the right size, so they work well for tough jobs.

The market is growing fast in Asia-Pacific and North America.

You can read more tips and expert help from top MIM companies and magazines.

FAQ

What metals can companies use in metal injection molding?

Engineers pick metals like stainless steel, low-alloy steel, titanium, and copper. Each metal is good for different things. Stainless steel does not rust. Titanium is light and very strong. Copper lets electricity move through it easily. The best metal depends on what the part will do.

How does MIM compare to traditional machining?

Metal injection molding uses less material than machining. MIM makes tricky shapes faster and costs less for big groups of parts. Machining is better for just a few parts or really big ones.

Can MIM parts be as strong as solid metal parts?

Yes. MIM parts can be almost as dense as solid metal. They are strong and hard, almost like solid pieces. Careful work with powders and heat makes sure the parts are high quality.

What industries use metal injection molding the most?

Industry | Common MIM Parts |

|---|---|

Medical | Surgical tools, implants |

Automotive | Gears, sensor housings |

Electronics | Connectors, phone parts |

Aerospace | Engine and frame parts |

These fields need small, tough, and detailed metal pieces.

LKprototype

LKprototype