Silicone is a safe and reliable choice for cooking and storing food. If you're wondering, "Is silicone non-toxic?"—the answer is absolutely yes. It is durable, non-toxic, and ensures your food remains safe. Silicone maintains its properties in both hot and cold conditions, making it an excellent option for kitchen use.

Key Takeaways

Silicone is safe and non-toxic for food use. It doesn’t release bad chemicals, so it’s good for cooking and storing food.

Check for FDA food grade silicone labels. These labels mean the silicone is safe and has no harmful stuff.

Silicone handles very hot and very cold temperatures, from -103°F to +500°F. This makes it great for baking or freezing, helping you save money and reduce waste.

Why Is Silicone Non Toxic and Safe for Food Use?

Chemically Stable and Inert Properties

Silicone is special because it stays stable and does not react. Unlike some plastics, it won’t break down or release bad chemicals into food. This makes it a great option for touching food directly. Food-grade silicone stays strong, even after many uses in cooking or storage.

Research proves silicone is safe for food use. For example:

High-quality food-grade silicone doesn’t leak harmful chemicals into food.

Silicone is more stable than other materials, lowering chemical risks.

Study Source | Findings |

|---|---|

Journal of Food Science and Technology | Found silicone migration into food is far below safety limits. |

Silicone’s non-reactive nature also makes it useful in medical tools and implants. This shows how safe it is for food-related purposes.

Free from Harmful Substances Like BPA, Phthalates, and Lead

Food-grade silicone does not contain harmful chemicals like BPA, phthalates, or lead. These chemicals, found in some materials, can harm your health. Silicone keeps your food safe and free from toxins.

Many plastics release bad chemicals when heated, but silicone does not. This makes it safer for baking and cooking. FDA food grade silicone is tested to meet strict safety rules. Using certified silicone protects you and your family’s health.

Resistance to Extreme Temperatures and Environmental Factors

Silicone can handle very high and low temperatures, making it perfect for the kitchen. FDA food grade silicone works from -103°F to +500°F. You can freeze leftovers or bake at high heat without worry. Silicone stays strong in cold or heat and doesn’t release toxins.

Its ability to handle extreme conditions means silicone lasts longer. This reduces waste and saves money. Unlike other materials, silicone stays durable even with frequent use. It’s a safe and long-lasting choice for storing and preparing food.

Tip: Always check for FDA food grade silicone labels to ensure top safety standards.

How to Identify Food Grade Silicone

When picking silicone for your kitchen, safety is key. Food grade silicone is made for safe food contact, but not all silicone is the same. Here’s how to check if silicone is food-safe and right for you.

Look for FDA Food Grade Silicone Certifications

Start by checking for FDA certification. The FDA has strict rules to make sure silicone is safe for food. Food grade silicone must follow the guidelines in 21 CFR 177.2600. These rules list the materials allowed for food use.

Key things to check:

FDA approval means the silicone is safe and toxin-free.

Certified silicone uses only FDA-approved ingredients.

Such products work well for food and medical purposes.

Using FDA-certified silicone ensures safety for countertops and food tasks.

Check for Labels Saying Food-Safe Silicone Sealant

Labels help you find food-safe silicone sealant. Look for words like "food grade silicone sealant" or "food-compliant silicone sealant." These labels mean the product is tested for food contact.

Food-safe silicone sealants are non-toxic, heat-resistant, and free of harmful chemicals like BPA and lead. They are great for baking, cooking, and storing food. Certifications from groups like the FDA or EU confirm the product’s safety.

Tip: Read the label carefully. If it doesn’t mention food safety, don’t use it in the kitchen.

Avoid Silicone with Fillers or Unsafe Additives

Some silicone products have fillers or additives that lower safety. Fillers can make silicone break down, especially with heat or fatty foods. This can release harmful substances into your food.

Studies show some additives, like siloxanes, can leak from silicone. For example:

Research found more siloxanes leach from bakeware with fatty foods.

A Danish study linked siloxanes to health risks like fertility issues.

To stay safe, pick 100% food grade silicone. Avoid items that feel too soft or smell bad, as they may have fillers. Clear labels and certifications help you choose wisely.

By following these tips, you can pick silicone that’s safe, strong, and perfect for your kitchen.

Benefits and Applications of Food Safe Silicone

Key Benefits: Durability, Flexibility, and Reusability

Food-grade silicone is strong, bendable, and reusable. It lasts long, even with daily use. Silicone handles both hot and cold temperatures well. You can bake or freeze without damage. Its flexibility makes it useful for many cooking tasks. Since it’s non-toxic, you can use it again and again. This helps the environment by reducing waste.

Note: Using silicone saves money and cuts down on trash. It’s a smart and eco-friendly choice for your kitchen.

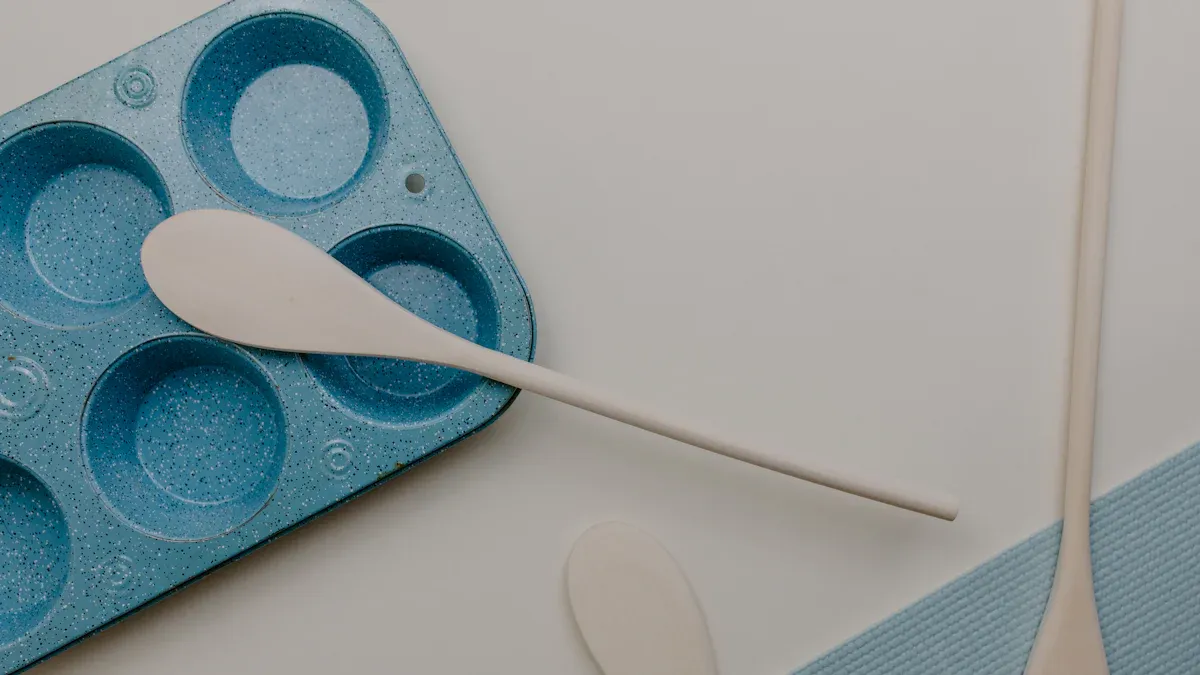

Common Kitchen Uses: Baking Mats, Utensils, and Storage Containers

Silicone tools are popular in kitchens because they are safe and useful. Here are some common uses:

Silicone baking mats replace parchment paper and need no grease.

Silicone molds and utensils handle heat and protect non-stick pans.

Reusable silicone bags and containers cut food waste and help the planet.

Silicone liners for air fryers are non-stick and easy to clean.

People like silicone kitchenware for its bright colors and designs. It works well for baking, cooking, and storing food because it resists heat and doesn’t stick.

Applications in the Food Industry: Molds, Seals, and Gaskets

Silicone is important in the food industry for safety and efficiency. The table below shows its uses:

Application Type | Key Benefits |

|---|---|

Stop leaks and keep food safe; seal machines tightly. | |

FDA silicone tubing | Safe, bendable, and heat-resistant; stops bacteria during liquid transfer. |

Food-grade conveyor belts | Handles heat and cleans easily; keeps food safe from contamination. |

Baking mats and oven seals | Non-stick and heat-safe; easy to clean and food-friendly. |

O-rings and seals in dairy processing | Keep food clean; stay flexible in different temperatures. |

Beverage dispensing systems | Allow smooth liquid flow; safe and odor-free for drinks. |

Silicone gaskets in meat processing | Keep food clean; resist grease and high-pressure cleaning. |

Silicone sponge gaskets in refrigeration | Seal cold storage tightly; stay flexible in freezing temperatures. |

These examples show how silicone helps keep food safe and high-quality in many industries.

Food-grade silicone is a safe and useful kitchen material. It is non-toxic, has no smell, and is eco-friendly. It stays strong in extreme temperatures from -40°C to 220°C. Approved by groups like the FDA and NSF, it’s used in baby items, tools, and green tableware. More people want safe materials, so food-grade silicone is becoming popular. Experts predict the market will grow to USD 6.5 billion by 2032. Choosing certified silicone helps keep your cooking and storage safe and sustainable.

FAQ

What is food-grade silicone, and how is it different?

Food-grade silicone is made safe for touching food. It follows strict safety rules. Regular silicone might have unsafe fillers or chemicals.

Can silicone kitchenware handle high heat?

Yes, silicone works in heat up to 500°F. It’s great for baking and cooking without releasing harmful substances.

How do you clean silicone kitchen tools?

Clean silicone with warm, soapy water. For tough stains, soak or scrub with baking soda paste. Silicone doesn’t hold smells and is safe for dishwashers.

LKprototype

LKprototype