Selecting the right machine parts manufacturer is crucial for your project's success. The choice of a machine parts manufacturer can significantly impact your results. You need a machine parts manufacturer that understands the importance of precision, with machining accuracy reaching as close as ±0.005mm. A reliable machine parts manufacturer ensures on-time delivery more than 95% of the time. Many teams face budget overruns in CNC projects, with up to 68% of cases caused by errors. Working with a knowledgeable machine parts manufacturer who offers rapid prototyping and expertise in materials like ABS or aluminum increases your chances of success. The rapid prototyping market, now valued at $3.33 billion, highlights why selecting the right machine parts manufacturer is more important than ever.

Key Takeaways

Pick a manufacturer who knows a lot about materials. This helps your prototype last longer and match your design. Use rapid prototyping services to test your design fast. This can help you save time and money. Always protect your ideas with NDAs. Make sure your manufacturer keeps your data safe. Choose a CNC machining partner who makes accurate parts every time. They should deliver on time and talk to you clearly. Look at quality control steps and customer reviews. This helps you find a manufacturer you can trust. They should give good value and deliver parts quickly.

Choosing a Machine Parts Manufacturer

Material Expertise

When you begin your prototype, you need a machine parts manufacturer who knows a lot about materials. The right partner understands how steel, aluminum, ABS, silicone, or resins can change how your prototype works. You want a rapid prototype manufacturer who can help you pick the best material for your design and use. This makes sure your prototype is strong, lasts long, and fits the needed size.

Look for manufacturers who use Technical Performance Measures (TPMs) to check material strength and if it meets rules. These numbers help you know your prototype will work well. Many rapid prototype manufacturers also use Engineering Verification Tests (EVT) and Design Validation Testing (DVT) to see if your prototype matches design and industry rules. These tests show the manufacturer has good processes and can make quality parts.

Certifications like Six Sigma Green Belt or knowing the IDOV (Identify, Design, Optimize, Validate) method also show strong material knowledge. These skills mean the manufacturer can make your prototype with fewer mistakes. Picking a rapid parts manufacturer with good material knowledge lowers risks and helps you succeed.

Tip: Start with small orders to check if the manufacturer is good and fits your budget. This helps you see their material skills and how well they make parts before you order more.

Rapid Prototyping Services

A rapid prototype manufacturer should offer more than just basic machining. You need a partner who gives many prototyping services, like CNC machining, 3D printing, injection molding, and vacuum casting. These services let you pick the best way to make your prototype based on speed, price, and how hard it is.

Rapid prototyping services help you make custom parts fast. Additive manufacturing, like 3D printing, lets you make parts when you need them and change designs quickly. This means you can test your prototype, find problems early, and fix them without waiting long. Experts say rapid prototyping can cut wait times from weeks to just hours. This speed is important when you want to sell your product fast.

You should compare rapid prototype manufacturers by how well they make small batches and work with different materials. A good rapid parts manufacturer will help you balance price, speed, and quality. They will collect data from each prototype, like how long it takes and the cost, to help you plan better next time.

Here are some best ways to check rapid prototyping services:

Make sure the manufacturer can do tooling and molding to save money.

Check their quality checks for finishing and shipping.

Make sure they meet deadlines so you do not lose business.

Ask for clear bills of materials so you understand costs.

Note: Rapid prototyping lets you change designs fast and find problems early, which makes your product faster and saves money.

NDA and IP Protection

Keeping your intellectual property (IP) safe is very important when making prototypes. Before you share your designs, you must have a signed Non-Disclosure Agreement (NDA) with your rapid prototype manufacturer or contract manufacturer. A good NDA says what is secret and what happens if someone breaks the rules.

You should also check that your rapid parts manufacturer uses strong safety steps for your data. This means locked cabinets, encrypted files, and firewalls to stop people from stealing your prototype data. Updated safety rules help keep your IP safe from new dangers.

Many companies, like biotech startups and engineering firms, need NDAs before sharing technical details with manufacturers. This keeps your prototype safe and your ideas private. Some groups even use NDAs and intellectual property insurance to pay for court costs if someone breaks the rules.

NDAs warn everyone about legal risks.

Adding NDAs to onboarding makes sure everyone knows to keep secrets.

Fast legal action, like warning letters or lawsuits, can stop leaks and limit harm.

Tip: Always use NDAs and check your manufacturer’s safety steps before starting any prototype project. This builds trust and keeps your ideas safe.

Evaluating CNC Machining Manufacturer Options

CNC Capabilities

When you pick a cnc machine shop, check what they can do. A good cnc machining manufacturer works with many materials and makes different parts. They should handle tight tolerances and tricky shapes. They also need to keep up with fast design changes.

You can use key performance indicators to see how well a cnc machining manufacturer does:

Dimensional accuracy and tolerance: Parts must be the right size.

Surface finish and roughness: Smooth parts look and work better.

Shape accuracy: The part’s shape should match your drawing.

Position accuracy: Holes and slots must be in the right place.

Consistency: Every part should look the same, even in small groups.

Reproducibility: The cnc machine shop should make the same part every time.

Quality control: Watching parts as they are made helps stop mistakes.

A cnc machine shop with high accuracy can make parts within ±0.001 mm. This is important for parts that fit together tightly. Multi-axis machines help make pockets and slots in one go. You get your cnc prototypes fast, sometimes in just a few days.

Tip: Ask your cnc machining partner for sample parts and inspection reports. This lets you check their work before you order more.

Equipment and Technology

The best cnc machine shop uses new machines and software. You want a machining partner who buys the latest tools. High-speed machining makes parts faster and smoother. Five-axis and six-axis machines help make hard parts with fewer steps.

The cnc machine market is getting bigger. It could reach $129 billion by 2026. In the United States, it will grow from $25.09 billion in 2024 to $37.61 billion by 2031. This is because of industries like medical devices, aerospace, and electric cars.

Aspect | Evidence Summary |

|---|---|

Market Growth | Global cnc machine market projected to reach $129B by 2026; US market size $25.09B in 2024, growing to $37.61B by 2031 at 5.4% CAGR |

Economic Impact | cnc machining creates jobs, helps local businesses, and grows the economy. |

Investment Drivers | Medical devices, EVs, telecom, aerospace, defense, and chips make the market grow. |

Technology Integration | IoT, AI, and smart tools help watch machines, fix problems early, and make work better. |

Software Advancements | New cnc software makes parts better and faster; easy-to-use programs help workers learn. |

Sustainability Trends | Energy-saving machines and green materials help the planet and save money. |

Your cnc machine shop should use IoT machines to watch work in real time. AI and machine learning help plan tool moves and guess when tools will break. Digital twin technology lets your machining partner test jobs before making parts. Hybrid machines mix cnc and 3D printing for more choices.

Note: New machines and software help your cnc machining partner make better parts faster and waste less.

Trusted CNC Partner Qualities

A trusted cnc partner gives more than just machines. You need a machining partner who cares about quality, talks clearly, and keeps secrets. Pick a cnc machine shop that delivers on time and checks quality well. Certifications like ISO 9001:2015, AS9100D, and RoHS show they follow rules.

You should get:

Good prices without losing quality

High-quality parts with strong checks

Fast and on-time delivery

Clear and quick answers to your questions

NDAs to keep your ideas safe

Honest about what they can and cannot do

Close by for easy visits and talks

Criteria Type | Examples of Criteria |

|---|---|

Qualitative | Good communication, NDAs, quality system (ISO 9001), quality papers, past work, product details, samples |

Quantitative | On-time rates, scrap rates, how much they can make, inspection papers, certifications, quality and production numbers |

Your cnc machine shop should always work to improve quality. Training and caring about quality help make good prototypes. Watching parts as they are made helps your machining partner stop mistakes and keep standards high.

Tip: Pick a cnc machining partner who talks clearly and answers fast. This builds trust and helps you avoid mistakes in your prototype project.

Quality and Communication

Quality Control Systems

You need strong quality control when picking a machine parts manufacturer for your prototype. Quality control means checking each step, from start to finish. This helps you find problems early and keep your project on track. You should see regular checks, audits, and live data reviews.

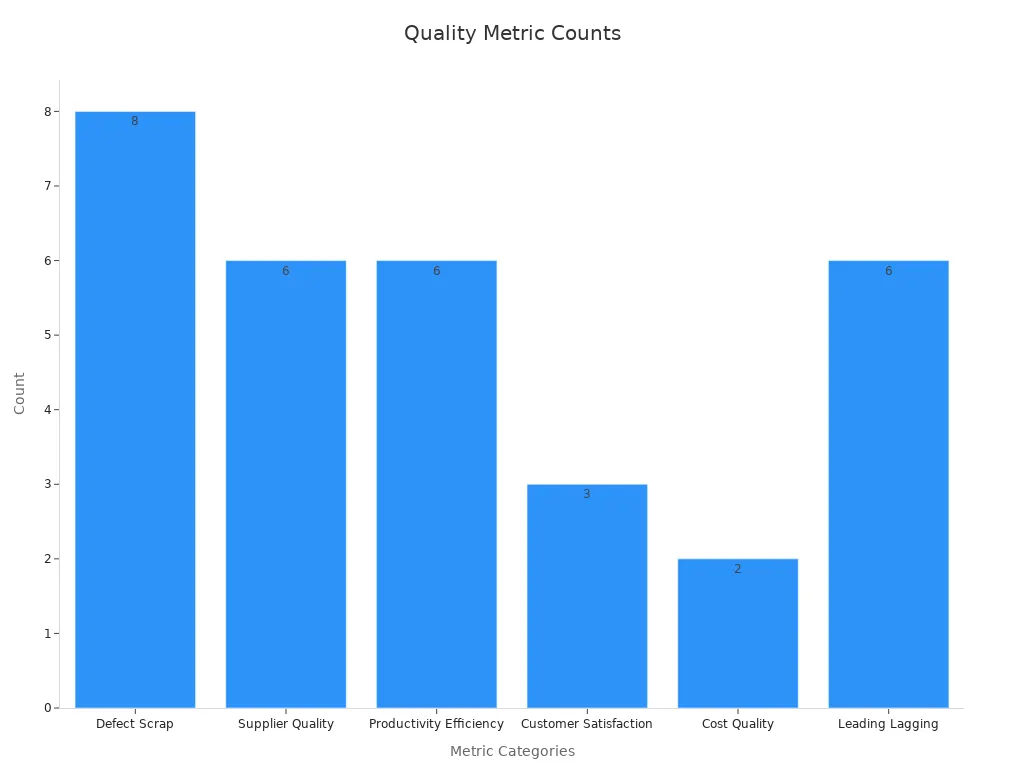

A good manufacturer uses many ways to measure quality. These measurements help you see if they follow the rules. Here is a table with some important quality control measurements:

Metric | Definition and Calculation |

|---|---|

Rework Rate | (Units reworked / Total units produced) x 100 |

Work-in-Process (WIP) | Value of unfinished goods divided by production costs |

Throughput | Units produced per day |

Cycle Time | Production time (hours) / Total units produced |

Overall Equipment Effectiveness (OEE) | Availability x Performance x Quality |

Mean Time Between Failure (MTBF) | Total operating time / Number of failures |

Look for quality steps like end-of-line tests, material checks, and batch tests. These steps make sure your prototype meets all the rules. Training workers and using live data help lower mistakes and make better parts. If you see few mistakes and high scores, the manufacturer cares about quality.

Tip: Quality control checks the parts. Quality assurance builds the system to stop mistakes.

Communication and Responsiveness

Clear talk and quick answers help you avoid delays and mistakes. You want a manufacturer who replies fast and keeps you in the loop. A good response time is less than four hours. If you wait over 24 hours, you might have bigger problems.

Communication Metric | Healthy Response Time | Warning Response Time | Crisis Response Time |

|---|---|---|---|

Response Time to Inquiries | Less than 4 hours | 4–24 hours | More than 24 hours |

Set clear rules for talking with your manufacturer. Ask for updates and feedback often. Good talk builds trust and helps fix problems early. When your manufacturer values quality and good talk, your prototype will meet your needs and arrive on time.

Note: Fast, clear talk is as important as strong quality control. Both help you get a good prototype and a smooth project.

Comparing the Best Rapid Parts Manufacturer

Cost and Value

When you look at rapid parts manufacturers, check both price and value. The best rapid parts manufacturer gives more than just a cheap price. You want someone who helps you save money and get good results. Different ways to make parts, like thermoforming and injection molding, cost different amounts and have their own benefits.

Aspect | Thermoforming | Injection Molding |

|---|---|---|

Tooling Cost | Lower upfront tooling costs (~$2,200 and up) | Higher tooling costs (up to $28,000 or more) |

Production Cost/Part | Higher per-part cost (~$2.80) | Lower per-part cost in high volume (~$0.28) |

Order Size Impact | More economical for small production runs | More economical for large production volumes |

Production Speed | Rapid cycle times, suitable for prototyping | Efficient for high-volume, precision parts |

Application Focus | Flexible for large, thin-walled parts | High precision, complex designs |

You should also check how well the company controls costs. Things like maintenance cost per unit, overtime, and waste change your final price. If a manufacturer keeps these numbers low, you get more for your money. Some companies use cost-plus, value-based, or fixed pricing. Pick the one that fits your project and budget. Always ask if the manufacturer can explain their prices and show how they save money.

Tip: The best rapid parts manufacturer gives you good value, not just low prices. They help you make smart choices for your prototype.

Delivery and Lead Times

You need your prototype delivered fast and on time. The best rapid parts manufacturer buys new machines and uses better ways to work, so you wait less. If a company uses just-in-time manufacturing or real-time tracking, you get your parts sooner. Good suppliers and strong inventory management also help stop delays.

Reports show that supply chain problems can slow things down. Sometimes, delays last up to 20 days. A good rapid parts manufacturer plans for these risks and tells you what is happening. They use technology and smart planning to keep your project moving. When you get your prototype on time, you can test and sell your product faster.

Note: Getting your parts on time helps you beat your competition and keeps your project on track.

References and Reviews

Before you pick a manufacturer, check what others say about them. Ask for feedback from other customers and look for case studies. You want proof that the manufacturer makes good parts and meets deadlines. Good reviews mean other people trust the company with their prototypes.

Use this checklist to check a manufacturer:

Ask for recent customer references.

Read online reviews and ratings.

Request sample parts or case studies.

Check if they have experience with your type of prototype.

Look for awards or certifications.

Tip: Good references and reviews help you find a manufacturer you can trust for your next prototype.

Picking the best partner for your prototype takes careful checking. You need to look at important numbers like manufacturability index, defect rate, and how fast the supplier works. These numbers help make sure your prototype is good and finished on time. Good quality checks and strong safety steps, like TISAX audits, keep your IP safe and help you get your prototype faster. When you trust your manufacturer, your project can do well for a long time. Working closely with your partner gives you better prices, more choices, and steady results. This helps your project succeed for many years.

FAQ

What should you look for in a machine parts manufacturer?

Check if they have lots of experience. Make sure they can work with your materials. See if they have good quality control steps. They should offer fast prototyping and keep your designs safe. Always ask for samples and read customer reviews before picking.

How do you protect your design when working with a manufacturer?

Sign a Non-Disclosure Agreement (NDA) before sharing files. Ask how the manufacturer keeps your data safe. This helps keep your design private and protected.

Why does rapid prototyping matter for your project?

Rapid prototyping helps you test ideas quickly. You can spot problems early and fix them fast. This saves both time and money. It also helps you sell your product sooner.

How can you check a manufacturer’s quality?

Ask for inspection reports and sample parts to check quality. Look for certifications like ISO 9001. Read reviews from other customers. Ask about their quality control steps.

What if your prototype needs changes after the first sample?

You can ask the manufacturer to change the design. Good partners help you make changes quickly. They should give feedback and new samples until the part is right.

LKprototype

LKprototype