CNC machines are essential for creating parts with precision machine capabilities and exceptional accuracy. This process plays a critical role in industries such as aerospace, medical, and manufacturing. In aerospace, precision machine components must fit perfectly to ensure safety and optimal performance. Medical tools also require exact machining to comply with strict regulations. Advancements in technologies like AI and automation have made this process faster and more efficient. These innovations contribute to producing strong, reliable parts that meet your specific needs.

Key Takeaways

Precision machining creates exact and reliable parts, important for planes and healthcare tools.

CNC machines lower costs by cutting waste and needing less work, making tricky designs cheaper.

This method can make few or many items while keeping them high-quality.

Picking a good machining company matters; check their reviews, tools, and work quality.

Using precision machining saves time and boosts speed, helping finish projects on time.

What Is Precision Machining?

Definition and Overview

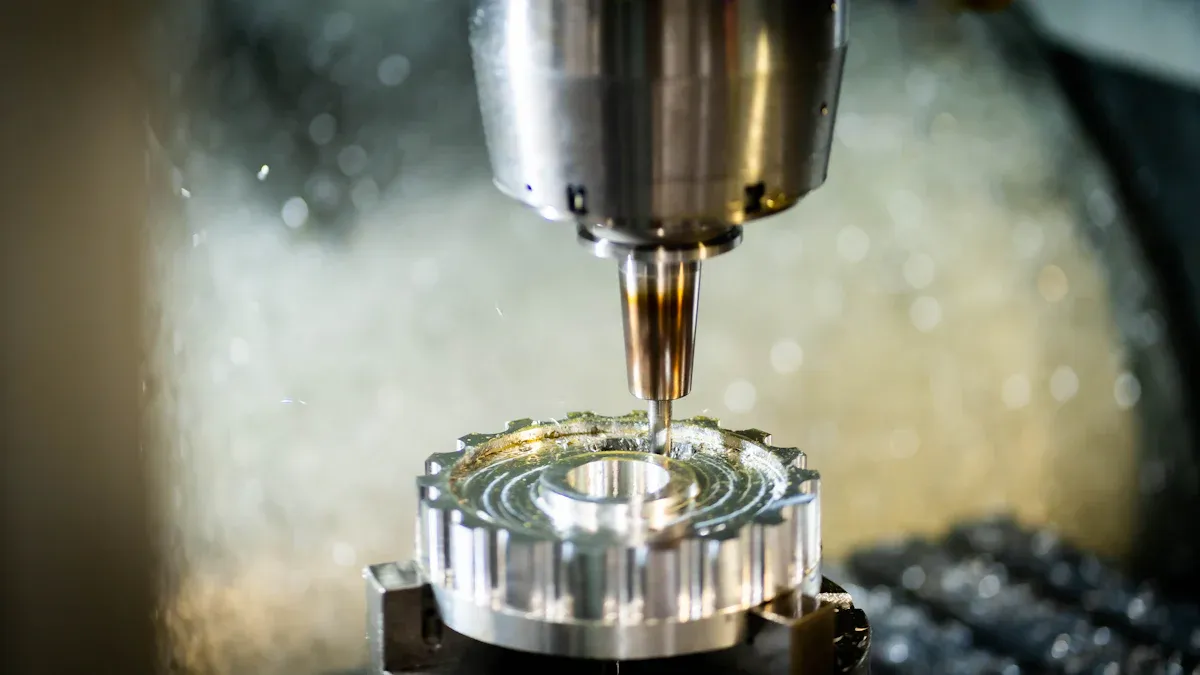

Precision machining is a way to make very accurate parts. It uses advanced machines controlled by CNC systems to guide tools. This process is important for industries like aerospace, medical, and manufacturing. Even small mistakes can cause problems with safety or how things work.

Think of precision machining as turning raw materials into exact parts. It ensures every piece meets strict rules and tight measurements. This makes it perfect for detailed designs and small tolerances. Whether making airplane engine parts or surgical tools, it gives reliable and consistent results.

How Precision Machines Work

Precision machines follow programmed instructions to shape or cut materials. Special software creates these instructions, which guide the machine's movements. CNC machining automates this process, reducing human mistakes.

The process has several steps, like milling, turning, and EDM:

Milling cuts away material to form complex shapes.

Turning spins the material while a tool shapes it.

EDM uses sparks to carve patterns into hard materials.

These methods create high-quality parts, even with tricky designs. Precision machining can repeat this quality for large production runs, making it useful for busy industries.

Importance of Tight Tolerances

Tight tolerances mean parts must be made with exact measurements. This ensures they fit and work properly. For example, in aerospace, parts like shafts need extreme precision to function well.

Keeping tight tolerances helps parts fit perfectly and work as planned. But being too strict can raise costs and slow production. Choosing the loosest tolerance that still works saves money and time.

Precision machining meets these needs by making accurate parts with tight tolerances. It’s great for detailed designs, like medical implants or airplane parts. By reducing mistakes and repeating results, it solves tough manufacturing challenges.

Did You Know?

CNC precision machining is faster and more accurate than older methods. It handles complex designs and reduces human errors. That’s why it’s so popular in modern manufacturing.

Applications of Precision Machining

Precision machining is key for making parts that need to be exact. It’s used in industries like aerospace, medical, and industrial production. These parts help machines work smoothly and without problems. Let’s see how this technology helps these important fields.

Aerospace: Aircraft Components and Engine Parts

In aerospace, precision machining is very important. Airplane parts like turbine blades and engines must be perfect. Even small mistakes can cause safety or performance issues. Precision machining makes sure these parts fit and work correctly.

CNC machining has changed how airplane parts are made. It offers better accuracy than older methods. For example, the LS RPF process makes parts last longer and work better. Here’s a comparison of CNC parts and forged parts:

Feature | Forged Parts | LS RPF Process |

|---|---|---|

Crack life span | 8,000 cycles | |

Torque tolerance | ±10% | ±3% |

Maintenance time | 3,000 hours | 12,000 hours |

Also:

Tenon life increases from 8,000 to 25,000 flight hours.

Maintenance time improves from 5,000 to 15,000 hours with better finishes.

These improvements make planes safer and reduce downtime.

Medical: Surgical Tools and Implantable Devices

Precision machining is also vital in making medical tools. Surgical tools and implants need to be very accurate. This ensures they meet rules and keep patients safe. Parts like implants and dental tools must work perfectly for their jobs.

For example, surgical tools often have sharp, detailed designs. Precision machining makes them smooth, so they don’t harm tissue during surgery. Implants like hip joints or pacemakers must fit the body exactly. Precision machining ensures they are comfortable and reliable.

Advanced CNC techniques make it easy to create complex medical designs. This ensures high quality and repeatability. Precision machining is a big part of modern healthcare.

Industrial: Machinery Parts and Custom Equipment

In industry, precision machining helps make machine parts and custom tools. Gears, shafts, and other parts are made to fit specific needs. These parts help machines run well and last longer.

Machine shops now use CNC machining for custom metal parts. Here’s how precision machining helps industries:

Aspect | Details |

|---|---|

Industry Role | Machine shops make custom metal parts using machining. |

Market Growth | Data shows how the market is growing. |

Financial Benefits | Metrics show cost savings from precision machining. |

Customization | Metal stock is shaped into parts based on customer needs. |

Tech Improvements | New CNC tech improves accuracy and speed in production. |

Precision machining also allows for scaling production without losing quality. Whether you need one part or many, it works for all needs. Using precision parts reduces downtime, boosts performance, and extends machine life.

Benefits of Precision Machining

High Accuracy and Consistency

Precision machining makes parts that match exact measurements. This is very important for industries like aerospace and medical. It creates parts with the same quality every time, even in big batches. For example, surgical tools need smooth surfaces and exact sizes to work safely. Precision machining removes human mistakes and keeps measurements tight to ensure this.

LKprototype specializes in making accurate parts. Their advanced CNC machines create items that meet your specific needs. Whether you need detailed medical tools or strong industrial parts, their skills ensure great results every time.

Tip: Making parts consistently lowers the chance of mistakes. This saves both time and money.

Cost-Effectiveness for Complex Designs

Making complicated designs can cost a lot with older methods. Precision machining is cheaper because it uses less material and avoids waste. CNC machines don’t need special tools, making them perfect for tricky designs.

Here’s how CNC machining saves money:

Cost Factor | |

|---|---|

Labor costs | Less manual work means big savings over time. |

Production costs | Fewer mistakes and waste lower overall costs. |

Tooling costs | Flexible tools reduce the need for special equipment. |

Material costs | Less waste means fewer materials are needed. |

Time savings | Faster production speeds up delivery times. |

LKprototype offers affordable solutions made just for you. Their team helps improve designs and cut costs while keeping quality high.

Scalability for Production Needs

Precision machining works for small or large orders. Whether you need one part or thousands, it keeps the same high quality. You can increase production without worrying about mistakes or bad performance.

LKprototype’s services grow with your business. They let you change order sizes as your needs change. Their focus on customer satisfaction means you’ll get great help at every step of your project.

Did You Know? Scaling production with precision machining reduces downtime and boosts efficiency. This helps you meet tight deadlines.

Materials and Processes in Precision Machining

Common Materials: Metals, Alloys, and Plastics

Precision machining uses different materials for specific jobs. Metals like steel, aluminum, and brass are strong and long-lasting. Alloys, which mix metals, are made for special uses. Plastics are lightweight and resist rust, making them great for medical and aerospace needs.

For instance, brass and aluminum are often compared for their features:

Property | Brass | Aluminum |

|---|---|---|

Density | Lower (2.7 g/cm³) | |

Hardness | Higher (200 HV) | Lower (70 HV) |

Tensile Strength | Higher (up to 500 MPa) | Lower (around 250 MPa) |

Corrosion Resistance | Excellent | Good |

Machinability | Good | Excellent |

Metals like 4140 steel and titanium are also common. They are very strong and last a long time, making them perfect for tough jobs.

Key Processes: CNC Milling, Turning, and EDM

Precision machining uses advanced methods to shape materials exactly. CNC milling cuts material to make detailed shapes. CNC turning spins the material to create round designs. Electrical Discharge Machining (EDM) uses sparks to cut through hard materials.

These methods improve production in many ways:

Specific smoothness levels can save money and improve use.

A polished finish makes parts look better.

Fast machining, smart tool controls, and better tool designs make work quicker. For example, coated carbide tools in CNC turning save time and improve accuracy.

Surface Finishing and Quality Control

Surface finishing makes parts both useful and nice-looking. Methods like powder coating, anodizing, and painting add strength and style. Powder coating, for example, gives thicker, even layers and better rust protection than paint.

Quality control checks every part for problems. It measures sizes, checks for flaws, and ensures consistency. Advanced CNC systems help keep high standards. By combining precise machining with strict checks, you get dependable and perfect results.

Tip: Picking the right surface finish can boost performance and save money.

Accessing Custom Precision Machining Services

Picking the Best Service Provider

Choosing the right machining company is key to success. Find providers with good reviews, modern tools, and a focus on quality. Compare their skills, customer feedback, and industry knowledge. For instance, LKprototype delivers top-notch parts with tight tolerances. They have skilled CNC machinists and advanced facilities.

To decide wisely, check industry standards. Here’s a comparison of top providers:

Supplier | Overall Rating | Advantages | Disadvantages | Typical Case |

|---|---|---|---|---|

Supplier A | Clear pricing, supports small batch orders | Slow delivery, poor response for urgent needs | Good with titanium alloys, but late delivery | |

Supplier B | 4.8/5 | Full service, strong technical help | Expensive, best for bigger companies | Great for prototypes and mass production, but costly |

Supplier C | 4.3/5 | Low prices, good for large orders | Poor communication, slow after-sales help | Cost-effective for big orders, but slow support |

LKprototype shines with fair pricing and great customer care. They meet your needs quickly and effectively.

Planning Costs for Custom Machining

Budgeting is important to control project expenses. Use cost tools to estimate and simplify quotes. These tools help you get fair prices and stay profitable.

Cost software makes quoting easier for machine shops. It helps them give fast, accurate quotes, keeping customers happy and winning more jobs.

These tools also find ways to cut waste and improve efficiency. LKprototype offers clear pricing and works with you to save money. They ensure affordable solutions without lowering quality.

Guaranteeing Quality and Skill

Quality checks are crucial in custom machining. Trusted providers use strict controls to ensure consistent results. Metrics help predict problems and review past work. Core metrics match business goals to maintain high standards.

Metric Type | Description | Importance in Custom Machining |

|---|---|---|

Leading Indicators | Predict future issues and allow early fixes. | Prevents defects before they happen. |

Lagging Indicators | Show past performance and results. | Reviews quality after production. |

Foundational Metrics | Match goals with quality checks. | Ensures smooth operations and high standards. |

LKprototype ensures every part meets your needs. Their trained CNC machinists and quality checks deliver precise, reliable results. Success stories show how they solve tough challenges for industries like aerospace and medical.

Tip: Work with companies that focus on quality to avoid delays and extra costs.

Precision machining is important for industries like aerospace, medicine, and manufacturing. It helps make parts that meet strict rules and work well. This technology has changed how things are made, offering great accuracy and reliability.

Aspect | Details |

|---|---|

Technology | |

Impact | Needed for making top-quality parts in electronics, medicine, and computing |

Growth Model | Gompertz model used to study past trends and predict future growth |

Historical Start | UPM started in the 1990s and grew fast in the 2000s |

Future Projection | Expected to grow until 2050, helped by AI and blockchain |

Key Decade | The year 2000 saw big progress from major programs and efforts |

Custom machining services give you solutions made just for your needs. These services save time, cut costs, and keep quality high. Try precision machining now to see how it can help your projects.

FAQ

What industries use precision machining the most?

Precision machining helps aerospace, medical, and industrial fields. It makes airplane parts, surgical tools, and machine components. These industries need it for safety, strength, and good performance.

How do CNC machines stay accurate?

CNC machines use programmed instructions to shape materials. Special software controls their movements to avoid mistakes. This system gives consistent and precise results, even for tricky designs.

Can precision machining handle small orders?

Yes, it works for both small and big orders. You can get prototypes or a few parts without losing quality. This makes it great for custom projects.

What materials are used in precision machining?

It uses metals like aluminum, steel, and titanium. Alloys and plastics are also common. Each material has special features like strength or being lightweight.

How do I pick the best machining service?

Choose companies with good reviews and modern tools. Check their skills, prices, and customer service. A good provider will deliver high-quality parts made just for you.

LKprototype

LKprototype