When you need a prototype, understanding the differences between CNC milling vs turning prototypes is crucial. Opt for milling if your part has intricate shapes or unique features. On the other hand, choose turning if your part is round or cylindrical in shape. Selecting the appropriate process can significantly save you time and money. Refer to this table to see how your choice between CNC milling vs turning prototypes affects cost and speed:

CNC Process Type | Impact on Cost | Impact on Time |

|---|---|---|

Simple Designs | Lower costs | Faster machining time |

Complex Geometries | Higher costs | Slower machining time |

3-axis CNC | Most cost-effective for simple parts | Quick setup and machining |

5-axis CNC | More expensive but faster overall | More setup for complex parts |

Batch Production | Lower per-unit cost | More efficient production |

Key Takeaways

Pick CNC milling if your part has a tricky shape or many features. It is great for making detailed designs with high accuracy.

Use CNC turning if your prototype is round or shaped like a cylinder. This method is quicker and gives smooth surfaces for simple, round parts.

Think about how much each process costs and how long it takes. CNC milling can cost more for tricky designs. CNC turning is usually cheaper for simple parts.

Look at the material you want to use. Both milling and turning can work with many materials. Some materials are easier to cut than others.

Make a checklist to help you decide. Check your part’s shape, what features you need, and how many you want to make. This will help you pick the best CNC process.

Introduction

Choosing the right CNC process for your prototype can make a big difference. You want your prototype to match your design, fit your budget, and arrive on time. CNC milling and CNC turning are two main ways to shape parts. Each process has its own strengths. You need to know which one fits your project best.

Tip: Think about the shape of your part first. If you see lots of flat surfaces, slots, or pockets, CNC milling might be your answer. If your part looks like a tube, rod, or ring, CNC turning could be the better choice.

You may wonder why this decision matters so much. The process you pick affects:

The shapes you can create

The speed of production

The cost of your prototype

The surface finish and accuracy

Imagine you need a part with holes on different sides. Milling can handle this with ease. If you need a smooth, round shaft, turning will give you the best result. Picking the wrong process can lead to wasted time and money.

In this blog, you will learn:

What CNC milling and turning are

How each process works

The main differences between them

When to use each process for prototypes

How to decide which one fits your needs

You will also see tips and checklists to help you make the right choice. By the end, you will feel confident about picking the best CNC process for your next prototype.

CNC Milling vs Turning Prototypes

What Is CNC Milling?

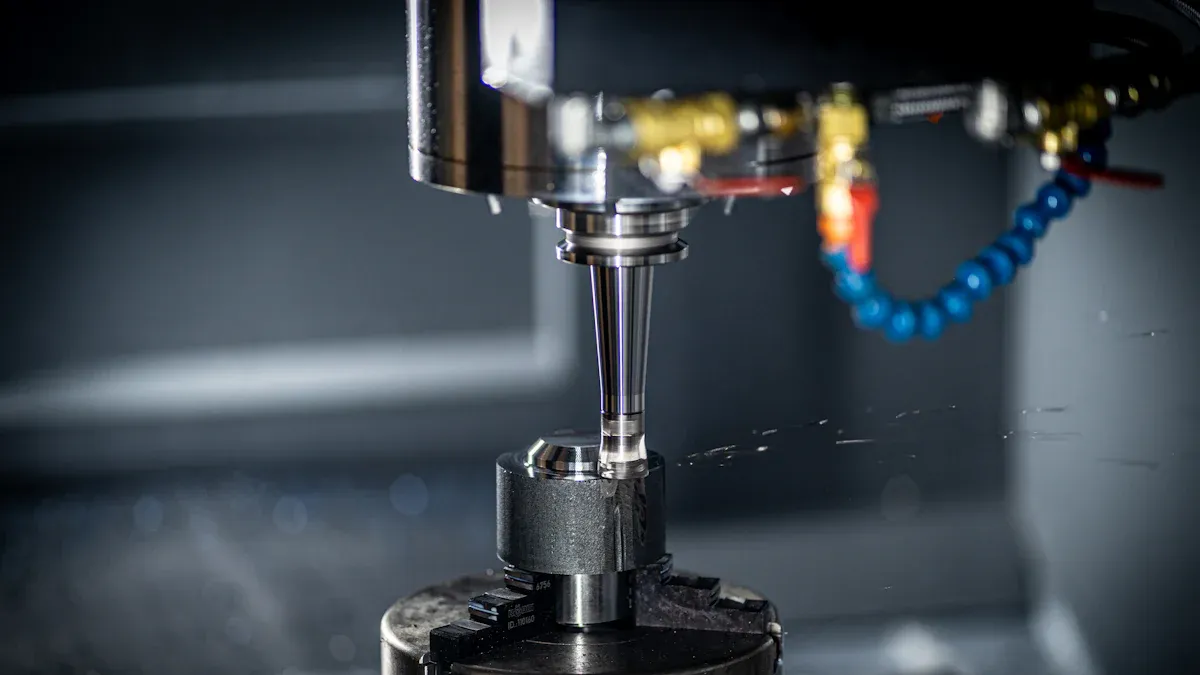

CNC milling shapes parts with flat areas, slots, or pockets. The cutting tool spins and moves over the part. It removes material to make detailed shapes. This process is good for prototypes that need to be very exact. You can use metals, plastics, or composites. CNC milling machines work with CAD software. This helps you turn designs into real parts fast. You get the same results every time. Small batches cost less.

High accuracy and precision

Great repeatability

Works with many materials

Saves money for prototypes

Quick setup, no molds needed

What Is CNC Turning?

CNC turning shapes parts by spinning the part. The cutting tool stays still and cuts away material. This process is best for round or tube-shaped parts. You get smooth surfaces and even results. CNC turning is great for making lots of parts fast. It works well for parts that must stay round. These machines can use metals, plastics, and more. They are good for many prototype needs.

Key Differences

Here are the main differences between cnc milling vs turning prototypes:

Feature | CNC Milling | CNC Turning |

|---|---|---|

Process | Cutting tools spin and cut a still part. | The part spins while the tool cuts it. |

Applications | Good for tricky shapes and quick prototypes. | Best for round parts and making many at once. |

Advantages | Very exact, flexible, and fast. | Quick, smooth finish, and steady results. |

Limitations | Takes longer to set up and tools wear out. | Only works for round shapes and some inside parts. |

Milling uses a spinning tool on a still part. Turning spins the part against a still tool. Milling makes flat or many-sided shapes. Turning makes round or cone-shaped parts.

When to Use Each Process

Pick cnc milling for parts with tricky shapes or features on many sides. Use cnc turning for parts that are mostly round or need a smooth surface. Your choice depends on the shape and job of your part. 5-axis milling makes very detailed parts. CNC turning is quicker for simple, round shapes. Think about your design, material, and how many you need. Both cnc machining and cnc milling vs turning help you get the best prototype for your project.

CNC Milling vs Turning: Process Comparison

How Milling Works

CNC milling uses a spinning cutting tool to shape your part. You start with a CAD model of your design. The process follows these steps:

You design your part using CAD software.

You convert the design into a CNC program using CAM software.

You secure the workpiece and set up the milling tools.

You run the program, and the machine removes material as the tool spins at high speed.

This method gives you precise control over the shape and size of your prototype. CNC milling works well for parts with flat surfaces, slots, or pockets.

How Turning Works

CNC turning shapes your part by spinning it on a lathe. The cutting tool stays still while the part rotates. You use this process for parts that need to be round or have a tube shape. Turning gives you smooth surfaces and keeps the part perfectly round. CNC turning is fast and works well for making many parts that look the same.

Complexity and Geometry

You need to think about the shape of your part before you choose a process. CNC turning is best for simple, round parts. It gives you great surface finishes and keeps everything centered. CNC milling is better for complex shapes. You can add holes, pockets, and patterns on many sides. If your part has many features or needs detailed work, milling is the better choice. Turning works best for parts that are the same all the way around, but it may need extra steps for more complex features.

Note: Part complexity plays a big role in your decision. Milling handles tricky shapes and multiple features. Turning is best for simple, round parts.

Programming and Operation

Both cnc milling and cnc turning use computer programs to control the machines. You create a digital model, then turn it into instructions for the machine. Milling programs often need more steps because the tool moves in many directions. Turning programs are simpler since the tool only moves along a few axes. You need to set up the machine, load the tools, and check the program before you start machining. Both processes give you repeatable results, but the setup and programming can be different based on your part’s shape.

CNC Turning vs Milling: Advantages & Limitations

Milling Advantages

CNC milling has many good points for prototypes. It is fast and very accurate. You can use it for many different shapes. Here are the main benefits:

Advantage | Description |

|---|---|

Speed | You get prototypes quickly. This helps you finish your product faster. |

Precision | CNC milling makes parts with tight tolerances. Results are high-quality. |

Material Versatility | You can use metals, plastics, and composites for your parts. |

Quick Iterations | You can change designs and test new ideas quickly. |

CNC milling helps lower costs from design mistakes. You get great prototypes for cars and electronics.

CNC machining lets you use many materials. You can pick metals like aluminum, titanium, and stainless steel. You can also use plastics such as PEEK, ABS, and PMMA.

Milling Limitations

CNC milling has some downsides. It can take longer than other methods. Making hollow parts is hard. You cannot make lightweight designs easily. Milling wastes more material because you cut away from a solid block.

Some projects take longer to finish

Hard to make hollow, light parts

More material waste than additive manufacturing

Turning Advantages

CNC turning is quick and works well for round parts. You get smooth surfaces and shapes that match every time. Turning is good for making many of the same part. It is reliable for shafts, rods, and rings. You can use metals and plastics. Setup is fast and results are repeatable.

Turning Limitations

CNC turning cannot make every shape. It only works for round or tube-like parts. Flat surfaces and tricky features are hard to do. Turning does not work for parts with many sides or deep pockets. You may need extra steps if your part has features turning cannot make.

Tip: Always choose the right process for your part’s shape when you compare CNC turning vs milling.

Material & Application Guide

Materials for CNC Milling

You can pick from many materials for cnc milling. This process works with metals, plastics, woods, foams, ceramics, and composites. Aluminum is popular because it is strong and easy to cut. Steel is a good choice if you need something tougher. If you want clear parts, acrylics are a smart pick because you can see through them.

Some plastics used for cnc milling are:

Acrylonitrile Butadiene Styrene (ABS)

Thermoplastic Polyvinyl Chloride (PVC)

Acetal-Delrin (POM)

Acrylic (PMMA)

Nylon

Pick your material based on what your prototype needs. Each one gives different strength, weight, and look.

Materials for CNC Turning

Cnc turning also works with many materials. You can use metals like aluminum, brass, and steel. Plastics such as nylon and ABS are good for turning too. This process is best for rods and tubes, so you start with round pieces. Turning makes smooth parts and keeps them round. You can use soft or hard materials, depending on your design.

Tip: Make sure your material fits your part’s job. Some materials are easier to cut, which can save time and money.

Typical Prototype Applications

Cnc machining is used for many types of prototypes. Milling is good for parts with flat areas, slots, and pockets. You might use it for brackets, housings, or covers. Turning is best for making shafts, bushings, and rings. If you need a round or tube-shaped part, turning is the way to go.

Here is a quick guide:

Application Type | Best Process | Example Parts |

|---|---|---|

Flat or complex shapes | Milling | Brackets, covers, plates |

Round or tube shapes | Turning | Shafts, rods, bushings |

Mixed features | Both | Custom connectors |

You can use both cnc milling and turning for parts with different features. This lets you design more freely and get better results for tricky prototypes.

Decision Guide: Choosing CNC Milling or Turning

Selection Checklist

You want to choose the right cnc process for your prototype. This checklist can help you decide:

Check your part’s shape. If it is flat or has many sides, use milling.

If your part is round or shaped like a tube, use turning.

Think about how many parts you need. Milling is good for small batches with tricky shapes. Turning is faster if you need lots of round parts.

Look at the material you will use. Both cnc milling and turning work with metals and plastics.

Decide what kind of surface you want. Turning makes round parts smooth. Milling gives sharp edges and flat faces.

Tip: If your part has both flat and round shapes, you might need both cnc milling and turning.

Factors to Consider

Think about these things before you pick a cnc process:

Complexity: Milling is good for tricky shapes. Turning is better for simple, round parts.

Speed: Turning is usually faster for round parts. Milling takes longer for detailed shapes.

Accuracy: Both cnc processes are very precise. Milling is best for parts with lots of features.

Cost: Milling costs more for tricky designs. Turning is cheaper for simple, round parts.

Material waste: Milling cuts away more material. Turning wastes less.

Combining Processes

Some prototypes need both cnc milling and turning. You can use mill-turn machining to do both in one setup. This helps you make parts with tricky shapes and many features. You save time and get better accuracy. Mill-turn machining is efficient and gives you more design choices.

Aspect | Description |

|---|---|

Integration | Mill-turn machining does both turning and milling in one setup. |

Capabilities | Lets you make parts with tricky shapes and many features. |

Advantages | Saves setup time, improves accuracy, works faster, and gives more options. |

Mill-turn machining is used in many fields:

Aerospace

Automotive

Medical devices

Electronics

Note: Using both cnc milling and turning helps you make advanced prototypes for tough projects.

Accuracy, Tolerances & Surface Finish

Typical CNC Milling Tolerances

CNC milling gives you very exact parts. Most shops can make parts with a tolerance of ± 0.005″ or 0.13 mm. This is true for both 3-axis and 5-axis machines. These tight tolerances help your parts fit together well. They also make sure your parts work the way you want. Look at the table below to see common tolerances:

CNC Process | Tolerance |

|---|---|

Milling (3-axis) | ± 0.005″ or 0.13 mm |

Milling (5-axis) | ± 0.005″ or 0.13 mm |

You can trust CNC milling for making parts with tight tolerances. It is a great choice when you need very exact prototypes.

Typical CNC Turning Tolerances

CNC turning also makes very exact parts. You often get tolerances as tight as ± 0.005″ or even better. This process is good for round parts that need to be the right size. CNC turning gives you smooth surfaces and steady results. High precision is important for things like shafts, bushings, and rings. You can count on CNC turning for parts that must be round and accurate.

Implications for Prototype Quality

Precision is important for every part of your prototype. Tolerances tell you how much a part’s size can change. If you want parts to fit together, you need high precision. Surface finish matters too. A rough finish can cause more friction and make parts wear out faster. It can also make it harder to put parts together.

Factor | Impact on Prototype Quality |

|---|---|

Tolerances | Show how much a part’s size can change. Tight tolerances help parts fit and work well. |

Surface Finish | Changes how a part looks and works. Rough surfaces can cause more friction and wear. |

Think about these things:

A rough finish can make friction go up.

It can make parts wear out faster.

Bad surface finish can make assembly harder.

What you use the part for decides how exact it must be.

Tighter tolerances cost more to make.

Standard tolerances save money if you do not need high precision.

CNC machining gives you very exact parts. Both milling and turning are good for high precision. You need to think about how much accuracy you need and how much you want to spend. If you need very exact prototypes, CNC is the best choice.

Cost and Production Considerations

Cost Comparison Between Milling and Turning

When you plan your prototype, you need to think about cost. The price for cnc milling and cnc turning can change based on your part’s design and the process you choose. Simple parts made with cnc milling often cost less. You might pay around $150 for a basic part. If your design is complex, the cost for cnc milling can go up to $450 or more. Labor costs for cnc milling usually range from $150 to $250 for each job. This means that cnc milling can get expensive if your part has many features or tight tolerances.

Cnc turning has different cost factors. You may see costs change because of labor and material waste. Cnc turning often uses less material, which can help you save money. Labor costs for cnc turning can be lower if your part is simple and round. You should always compare both processes before you decide.

Here is a quick look at the cost factors:

Cnc milling costs more for complex shapes and tight tolerances.

Cnc turning can save money for simple, round parts.

Labor costs for cnc milling are often higher than for cnc turning.

Material waste is usually less with cnc turning.

Tip: Always ask for a quote for both cnc milling and cnc turning. This helps you pick the best option for your budget.

Production Speed and Small Batch Considerations

Production speed matters when you need your prototype fast. Cnc turning is usually quicker for round parts. The setup is simple, and the machine can make many parts in a short time. If you need a small batch of shafts or rings, cnc turning is a smart choice.

Cnc milling takes more time for setup, especially for complex parts. The machine must move in many directions, which can slow down the process. If your prototype has flat surfaces, slots, or pockets, cnc milling will take longer. For small batches with tricky shapes, cnc milling gives you the detail you need, but you may wait longer for your parts.

Cnc machining helps you get repeatable results. Both cnc milling and cnc turning work well for small batches. You should choose the process that matches your part’s shape and your timeline.

Process | Best For | Speed for Small Batches |

|---|---|---|

Cnc turning | Round, simple parts | Fast |

Cnc milling | Complex, flat shapes | Slower for tricky designs |

Note: If you need both round and flat features, you can combine cnc milling and cnc turning to save time and get the best results.

Conclusion

You now have a clear understanding of how cnc processes can shape your prototypes. Choosing between milling and turning depends on your part’s shape, material, and function. Milling works best for parts with flat surfaces, slots, or complex features. Turning gives you smooth, round parts quickly and with high accuracy. Both cnc methods offer strong benefits for prototyping.

When you start a new project, look at your design first. Ask yourself these questions:

Does your part have mostly flat or angled surfaces?

Do you need a round or tube-shaped part?

Will your prototype need both types of features?

What material do you plan to use?

How many parts do you need?

If you answer these questions, you can match your needs to the right cnc process. Milling and turning both use cnc machines, but each has unique strengths. Milling lets you create detailed shapes and pockets. Turning is faster for round parts and uses less material.

Tip: If your prototype has both round and flat features, you can combine cnc milling and turning. This approach gives you more design freedom and better results.

Cnc machining helps you get accurate, repeatable prototypes. You save time and money by picking the right process early. If you feel unsure, talk to a cnc expert. They can help you choose the best method for your project.

FAQ

Can CNC turning create complex shapes?

You might wonder if cnc turning can handle complex shapes. Cnc turning works best for parts that are round or have a tube shape. The process spins the part while a tool cuts away material. You can make grooves, threads, and tapers with cnc turning. Some advanced cnc machines allow you to add extra features, but most turning jobs focus on simple, round designs. If your part needs flat surfaces or pockets, cnc milling will work better. For parts with both round and flat features, you can combine cnc turning and milling. This approach gives you more design options.

Tip: Use cnc turning for shafts, bushings, and rings. Choose cnc milling for parts with many sides or detailed features.

Which process is cheaper for prototypes?

Cost matters when you choose a cnc process. Cnc turning usually costs less for simple, round parts. The setup is fast, and you waste less material. Cnc milling can cost more, especially for parts with many features or tight tolerances. If your prototype has a basic shape, cnc turning will save you money. For complex parts, cnc milling may cost more, but it gives you the detail you need. Always compare prices for both cnc machining methods before you decide.

Process | Best For | Typical Cost |

|---|---|---|

Turning | Round, simple parts | Lower |

Milling | Complex, flat shapes | Higher for complexity |

How do tolerances differ between milling and turning?

Tolerances show how much a part’s size can change. Both cnc milling and cnc turning give you tight tolerances. Cnc turning often produces even tighter tolerances for round parts. This means your shafts or rings will fit perfectly. Cnc milling also gives you high accuracy, especially for flat or angled surfaces. The type of cnc machining you choose affects the final fit and finish of your prototype. If you need very exact parts, both cnc milling and turning can deliver. Always check with your cnc shop to see what tolerances they can meet for your project.

Note: Tighter tolerances may increase the cost of cnc machining. Choose standard tolerances if you do not need extreme precision.

You need to pick the right cnc process for your prototype. Milling is good for parts with tricky shapes. Turning works best for round designs. It is important to know what each process can and cannot do. The table below shows how cnc milling and turning compare:

Process | Strengths | Limitations |

|---|---|---|

CNC Milling | Good for parts with detailed shapes. | Does not work for round shapes. |

CNC Turning | Great for making round parts. | Only works for parts that spin. |

Cnc machines make parts very exact. You save time and material by using computer models. You can keep your designs for later cnc jobs. If you are not sure, ask a cnc expert. They can check your design and material to help you choose the best cnc process.

Can you use cnc for both metal and plastic prototypes?

Yes, you can use cnc for both metal and plastic prototypes. Milling and turning work with many materials. You can choose aluminum, steel, or plastics like ABS. This gives you flexibility for different projects.

What makes cnc milling different from cnc turning?

Cnc milling uses a spinning tool to cut a still part. Cnc turning spins the part while a tool shapes it. You use milling for flat or complex shapes. You use turning for round or tube-shaped parts.

How do you decide between cnc milling and cnc turning?

You look at your part’s shape. If you see flat surfaces or pockets, choose milling. If your part is round, pick turning. Cnc experts can help you make the best choice for your design.

Is cnc good for making just one prototype?

Yes, cnc works well for single prototypes. Milling and turning both give you fast results. You do not need molds. You can test your design quickly and make changes if needed.

Can cnc machines combine milling and turning in one process?

Some cnc machines can do both milling and turning. You can make parts with flat and round features in one setup. This saves time and improves accuracy for complex prototypes.

LKprototype

LKprototype