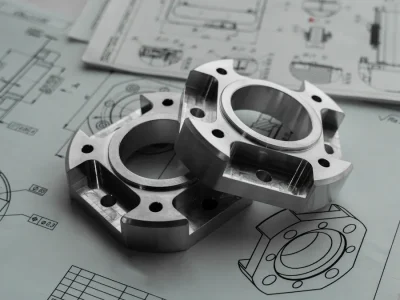

When designing boxes for electronics, you face unique challenges. CNC machining electronics enclosures offers a reliable solution for creating durable and high-performance enclosures. This method is excellent for EMI shielding, achieving tight tolerances, and delivering attractive finishes. By choosing cnc machining electronics enclosures, you gain several advantages, including the use of conductive materials, precise machining, and innovative design strategies.

Conductive materials such as aluminum and copper are ideal for cnc machining electronics enclosures, providing effective heat dissipation and EMI shielding.

Precision machining ensures that cnc machining electronics enclosures are consistently accurate and fit perfectly every time.

Advanced surface finishes enhance the durability and appearance of cnc machining electronics enclosures.

By combining smart design with modern manufacturing techniques, you can produce robust and high-quality cnc machining electronics enclosures for your electronic devices.

Key Takeaways

CNC machining makes electronics enclosures very exact and the same each time, so they always fit right.

Using materials like aluminum and copper helps block EMI and move heat away, which keeps electronics safe.

Special surface finishes like anodizing and powder coating make enclosures last longer and look better, and they stop rust.

CNC machining can make parts with very small tolerances, as tiny as ±0.01 mm, which stops EMI and makes sure parts fit together.

If you think about EMI shielding when you design enclosures, you can save time and not have to fix mistakes later.

Why CNC Machining Is Ideal for Electronics Enclosures

Key Requirements of Electronics Enclosure Manufacturing

Structural precision and repeatability

Your enclosures must fit together the same way every time. Electronics enclosure cnc machining gives you very good accuracy. It also makes sure each enclosure is just like the last one. You can count on your custom electronic enclosures to protect your electronics from harm.

EMI and RF shielding capability

Shielding is very important when making electronic enclosures. You want your enclosures to stop unwanted signals and keep circuits safe. Electronics enclosure cnc machining lets you use metals like aluminum and stainless steel. These metals give strong EMI and RF shielding. They help your high-precision electronics enclosures meet rules like MIL-STD-461G and IEEE 299.

Surface quality and durability

Surface quality is important for how things look and work. With electronics enclosure cnc machining, you can pick finishes like anodizing or powder coating. These finishes make your enclosures last longer and fight off wear, dust, and water. You also get choices for both how it works and how it looks.

Tip: Always pick materials and finishes that fit your safety and environment needs.

Requirement Category | Key Points |

|---|---|

Mechanical Performance | Enclosures must stay strong and stiff during normal use. |

Access Control | Stops easy access to live parts but lets you do repairs. |

Material Selection | Steel, stainless steel, and aluminum are best for most places. |

Electrical Safety Design | Stops dangers like shock and fire. |

Environmental Specs | Must fight dust, water, and temperature changes. |

Benefits of CNC Machining for Electronic Housings

High precision for complex enclosure geometry

CNC machining for electronics gives you very tight tolerances, sometimes up to ±0.001 mm. You can make shapes and features that other ways cannot do. This accuracy makes sure your enclosures fit well and protect your electronics.

Compatibility with conductive materials

You can use many metals and plastics for your enclosures. Electronics enclosure cnc machining works with aluminum, stainless steel, copper, and plastics like ABS or polycarbonate. This gives you lots of options for your needs.

Flexible for prototypes and low-volume production

You can quickly make a CNC prototype part or small batches. This saves time and money. Electronics enclosure cnc machining helps you test your designs before making a lot. This flexibility is a big advantage of cnc machining.

Key benefits of cnc machining electronics enclosures:

Get tight tolerances (up to ±0.01 mm)

Make sure assembly is right with good holes and threads

Good for prototypes and small runs

Feature | Detail |

|---|---|

Tolerances | Up to ±0.001 mm |

Precision | Very high precision for parts |

Prototyping Speed | Fast prototyping saves time and money |

You can trust electronics enclosure cnc machining for accuracy, custom parts, and great results. This process cuts down on mistakes and waste, so it is a smart way to make things.

Materials for CNC Machined Electronics Enclosures

Aluminum Electronics Enclosures

EMI shielding performance

People pick aluminum for enclosures because it blocks signals. This metal keeps your electronics safe from outside interference. Aluminum enclosures help your devices follow strict EMI shielding rules. Alloys like 6061 and 6063 are good for enclosures. They do not rust and can handle pressure, water, and heat changes.

Property | Description |

|---|---|

Lightweight & Strong | High strength-to-weight ratio means it is tough but not heavy. |

Superior Heat Dissipation | It stops parts from getting too hot and helps them last longer. |

Corrosion Resistant | A natural layer keeps it safe from rust and tough places. |

EMI/RFI Shielding | It blocks signals so your device works well. |

Lightweight structure and thermal conductivity

Aluminum enclosures are light but still strong. You can move and put them in place without problems. These enclosures also take heat away from your electronics. This helps your devices stay cool and last longer.

Tip: Pick aluminum enclosures if you need EMI shielding and good heat control.

Stainless Steel Enclosures

High strength and environmental resistance

Stainless steel enclosures are very strong and safe. You use them where things get rough or dirty. Stainless steel does not rust or break down, even in wet or chemical places.

Feature | Stainless Steel | Polycarbonate |

|---|---|---|

Strength | Very strong and lasts a long time | Not as strong as steel |

Environmental Resistance | Great against rust and weather | Not as good with sun or chemicals |

EMI Shielding | Not as good for EMI shielding | |

Weight | Heavy and harder to move | Light and easy to carry |

When durability and shielding are critical

You choose stainless steel when you need strong EMI shielding and toughness. These enclosures are used in military and factories. They block some magnetic fields and keep your electronics safe.

Plastic Enclosures and Hybrid Designs

When CNC-machined plastics are suitable

Plastic enclosures are light and can take a hit. You use them for things you carry or move a lot. Polycarbonate and thermoplastics do not get hurt by chemicals or water. Hybrid designs mix plastics and metals for better results.

Polycarbonate enclosures are tough and easy to move.

Thermoplastics keep out chemicals and insulate well.

Limitations of plastics for EMI shielding

Plastics do not block EMI as well as metals do. You might need to add coatings or metal parts to help. If you need strong EMI protection, use aluminum or stainless steel instead.

Material | Advantages | Limitations |

|---|---|---|

Polycarbonate | Tough, takes hits, light to carry | May not block EMI well |

Thermoplastics | Good insulation, fights chemicals, keeps out water | Not as strong as metals |

Carbon Fiber Composites | Light, strong, good for things you carry | Costs more, needs special tools |

Note: Always pick your material for cnc machined enclosures based on how much shielding, strength, and protection you need.

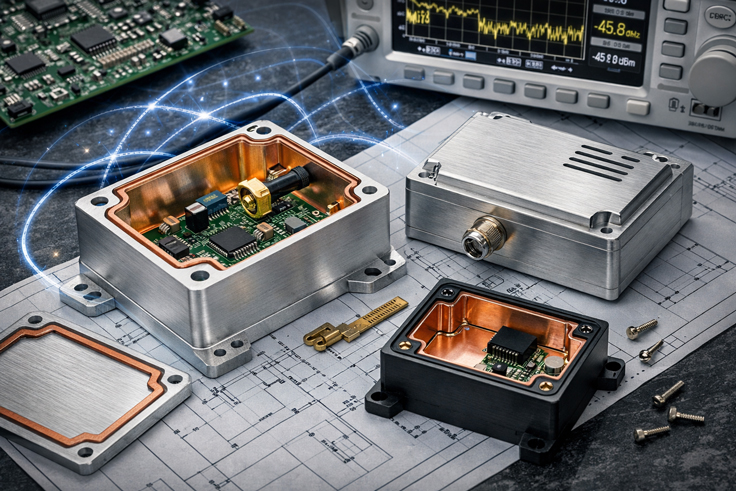

EMI Shielding in CNC Machined Electronics Enclosures

How CNC Machining Supports EMI and RF Shielding

Conductive enclosure design principles

You need strong EMI shielding to keep your electronics safe. CNC machining electronics enclosures lets you use metals that block signals. You can make custom electronic enclosures that stop unwanted signals. With electronics enclosure cnc machining, you can design boxes with tight seams and smooth surfaces. This keeps EMI from getting in or out. You also get to pick the best material selection for cnc machined enclosures. This is important for good shielding.

CNC machining helps you make your enclosure very exact.

You can make fewer gaps and seams, so shielding works better.

You can add special features for better EMI shielding solutions.

Seam control and enclosure integrity

Seams and joints can make rf shielded enclosures weaker. Electronics enclosure cnc machining lets you control how parts fit together. Tight seams and strong joints keep the box solid and help with shielding. You can add things like overlapping edges to make shielding even better. This control is a big reason to use cnc machining.

CNC Design Considerations for EMI Shielding

Wall thickness and enclosure gap control

Wall thickness is important for EMI shielding in rf shielded enclosures. Thicker walls block more interference. You should keep gaps as small as you can. Electronics enclosure cnc machining lets you pick the wall thickness and control every gap. This helps you see the importance of emi shielding in enclosures.

Grounding features and contact surfaces

Good grounding is important for rf shielded enclosures. You can add grounding spots and smooth contact surfaces with cnc machining for electronics. These features help send unwanted signals away from your electronics. They also make it easier to put the box together and make shielding better.

Tip: Always plan your grounding features early so you do not have problems later.

Surface Finishes That Improve EMI Shielding

Conductive coatings and anodizing

Surface finishes are important for EMI shielding. Conductive coatings like chromate conversion, tin plating, and nickel plating take away the oxide layer from metals. This helps your rf shielded enclosures have good electrical contact. Anodizing can protect the surface, but you must pick the right kind to keep conductivity.

Surface continuity and electrical contact

A smooth, even surface helps keep electrical contact across the box. This makes shielding better and keeps EMI out. The right surface finish makes your rf shielded enclosures look good and work well.

Key Considerations in Designing Electronic Enclosures | Why It Matters for EMI Shielding |

|---|---|

Tight seams and joints | Stops signal leakage |

Proper wall thickness | Blocks more interference |

Good grounding points | Directs EMI away from electronics |

Improves electrical contact and shielding |

You get the benefits of cnc machining for electronics enclosures when you focus on these things. By using the right design, material, and finish, you make rf shielded enclosures that keep your electronics safe and follow strict rules.

Tolerances in Electronics Enclosure CNC Machining

Why Tight Tolerances Matter for Electronics Enclosures

Impact on EMI shielding effectiveness

Tight tolerances help stop electromagnetic interference. If there are small gaps, signals can get through. This makes the shielding weaker. Using metals that conduct electricity helps block interference. Precise machining keeps your electronics safe.

CNC machining makes tight fits and tricky shapes possible.

The material’s properties affect how well it blocks signals.

Assembly fit and component alignment

All parts should fit together just right. Tight tolerances keep out gaps. This helps put everything together easily. It also keeps parts in the right place. Accurate manufacturing means your design works well. Your electronics stay safe.

Typical CNC Tolerances for Electronics Enclosures

General CNC tolerance ranges

CNC machining uses different tolerance levels. Most enclosures use these:

±0.10 mm (±0.004 in) for most jobs

±0.05 mm (±0.002 in) for better precision

±0.01 mm (±0.0004 in) for very tight fits

These ranges help balance cost, speed, and performance.

Critical tolerance zones for enclosures

Some spots need extra care. Watch these areas:

Seams and joints for EMI shielding

Holes for mounting circuit boards

Edges where covers and bases meet

Industries like medical, robotics, and aerospace need these tolerances for safety.

Achieving Precision in CNC Machined Enclosures

CNC machine capability and process control

Advanced cnc machines give high precision. A 5-axis cnc machine makes complex shapes and smooth surfaces. Teams set up machines to reduce tool wear. They check every part for accuracy.

Feature | Description |

|---|---|

CNC Machining Centre | 5-axis machines make complex enclosures |

Surface Finish | Smooth finish, Ra≤0.4μm for good contact |

Machining Optimization | Less tool wear, better quality |

Design-for-manufacturing considerations

Design enclosures so cnc machining is easy. Simple shapes and clear tolerances help a lot. Prototyping lets you test and change your design fast. Certified processes like ISO 9001 and ISO 13485 make sure your enclosures meet standards.

Tip: Always check your design with your cnc machining partner before you start.

Surface Finishes for CNC Machined Electronics Enclosures

Common Surface Finishes for Electronics Housings

Surface finishes change how enclosures look and work. You can pick from different finishing methods for your electronics enclosure cnc machining project. Each finish has good and bad points.

Advantages | Disadvantages | |

|---|---|---|

Anodizing | Great at stopping rust, makes the surface harder, many colors | Needs careful control for color, costs more |

Sandblasting + Anodizing | Looks fancy, smooth surface, good for parts that must look nice | Can hide small marks, costs a bit more |

Plating | Stops rust well, helps electricity flow | Does not stick well to some materials, can hurt the environment |

Black Oxide Treatment | Cheap, does not change size, fights rust | Not as good at stopping rust, rough surface |

Passivation | Stops rust, better for the environment | Does not change how it looks much, needs careful work |

Polishing & Brushing | Shiny like a mirror, smooth lines | Scratches easily, price changes with quality |

Painting & Powder Coating | Many colors, stops rust | Can peel off, not good for very tight parts |

Anodizing

Anodizing makes aluminum enclosures stronger and adds color. This finish makes the surface harder and keeps it from rusting. You can pick many colors for branding or to tell parts apart. Anodizing is good for parts that need to last and look clean. You must watch the process closely to keep colors the same.

Powder coating

Powder coating puts a tough, colorful layer on enclosures. You can choose almost any color you want. This finish does not scratch or get hurt by chemicals easily. Powder coating is good for enclosures that must look nice and last in tough places. The layer can peel if you use the box roughly. It also makes the enclosure thicker, which can be a problem for tight fits.

Bead blasting

Bead blasting gives a smooth, dull surface. You can use this finish to hide small scratches and make enclosures look even. Bead blasting works well before anodizing or painting. It does not make the enclosure thicker, so your design stays the same. This finish is good for enclosures that need a simple, modern look.

Impact of Surface Finishes on Performance and EMI

Surface finishes change how enclosures work and how they protect electronics from emi. You should think about how well electricity flows, how long the finish lasts, and how well it stops rust.

Aspect | Evidence |

|---|---|

Electrical Performance | Black chrome plating looks nice but does not let electricity flow well. |

EMI Shielding | Plating puts a thin, metal layer on the part, like a Faraday cage. |

Durability | Black chrome needs care on moving parts so it does not wear out. |

Anodizing and plating stop rust and make the surface harder.

Plating helps electricity flow, which is good for emi shielding.

Powder coating covers the surface, so it can block electricity.

Bead blasting does not change how electricity flows but makes the surface tougher.

Tip: Pick a finish that fits your enclosure’s needs for electricity and strength.

Electrical conductivity versus insulation

You must decide if your enclosure should let electricity flow or block it. Plating and anodizing keep the surface able to carry electricity, which helps with emi shielding. Powder coating and painting block electricity, so they can stop contact. You need to match the finish to what your electronics enclosure cnc machining project needs.

Wear resistance and corrosion protection

Surface finishes keep enclosures safe from scratches, chemicals, and rust. Anodizing and powder coating give strong protection. Plating stops rust and helps electricity flow. Bead blasting hides marks and keeps the surface even. These finishes help enclosures last longer and look better.

Choosing the Right Finish for Your Application

You must pick a surface finish based on how you will use your enclosure. Think about how it works and how it looks.

Functional versus cosmetic requirements

How a product looks and feels matters if people see or touch it.

How well it works changes how it handles its job.

Strong finishes help enclosures last in tough places.

How well coatings stick depends on the surface.

Less friction and heat help moving parts work better.

Good electricity flow and heat control help electronics work well.

Controlling shine and light helps with optical parts.

Note: Enclosures for sensitive electronics and heat sinks need special finishes to stop emi and help electricity flow.

Cost and production volume considerations

You must think about price and how many you need. Anodizing and plating cost more but protect better and help electricity flow. Powder coating and painting are good for making lots of enclosures and come in many colors. Bead blasting costs less and is good for testing or small batches. Cnc machining helps you make enclosures that are always the same.

Electronics and chips need special finishes for emi and electricity.

Medical and factory enclosures need strong finishes to last a long time.

You can make your design and manufacturing better by picking the right finish for your cnc machined enclosures.

Design Tips for CNC Machined Electronics Enclosures

Enclosure Design Best Practices

Draft angles, fillets, and internal features

You should add draft angles and fillets to your design. Draft angles help you take parts out after cnc machining. Fillets are rounded corners that make parts stronger. They also help tools last longer. Use a radius of at least 0.0625 inches for inside corners. This makes the cnc process easier and helps stop cracks. Keep inside features simple when you plan them. Do not use deep pockets or sharp corners. Make sure pocket depth is not more than six times the tool’s width.

Avoiding sharp internal corners

Sharp corners are not good for cnc machining. They wear out tools faster and make rougher surfaces. Use fillets instead of sharp corners. This helps your part last longer and be easier to make. Your enclosure will also be stronger.

Common Design Mistakes to Avoid

Over-tight tolerances

Some people make tolerances too tight. This makes cnc machining take longer and cost more. Use ±0.1 mm for most parts. Only use tighter tolerances, like ±0.01 mm, where you really need them. Do not use tight tolerances everywhere. Only mark the spots that need a perfect fit.

Ignoring EMI requirements early

If you forget about EMI shielding at the start, you may have to change your design later. Think about EMI needs from the beginning. Add grounding points and control wall thickness early. Use 3D CAD models to check how things fit together. This helps you find problems before you start making parts.

Common Mistakes | Description | Solutions |

|---|---|---|

Overly tight tolerances | Makes things cost more and take longer | Use normal tolerances when you can |

Sharp internal corners | Wears out tools and makes parts weaker | Use fillets and keep pockets shallow |

Ignoring EMI early | Means you might have to redesign later | Plan EMI features from the start |

Optimizing Enclosure Design for CNC Machining

Reducing machining time and cost

You can save time and money by keeping your design simple. Do not add features that need special tools or many setups. Use normal drill sizes and keep holes shallow. Try to group features so they can be made from one side. Pick materials that are easy to machine but still work for your needs.

Improving consistency and production yield

Talk to your machinist early in your project. Use 3D CAD models to check if parts fit together. Follow DFM rules to make your design easier to build. If your design is hard, split it into more than one part. These steps help you get the same results every time and make more good parts.

Tip: Simple shapes and normal features make cnc machining faster and better. Always check your design with your manufacturing partner before you start making parts.

CNC Machined Electronics Enclosures Applications

Industrial Electronics and Control Systems

Automation equipment housings

You use rf shielded enclosures to keep electronics safe in machines. These boxes stop dust, water, and bad signals from getting in. CNC makes strong housings that fit your machines just right. The enclosures also block interference from reaching PCBs, sensors, and batteries.

Keeps important electronics safe from tough places

Blocks harm from gears and motors

Helps machines work safely and well

Control panel enclosures

Control panels need rf shielded enclosures that last a long time. CNC machining gives you the same good results every time. These boxes keep switches and screens safe from damage. You can trust CNC to make enclosures that are always high quality.

Application Area | What the Enclosures Protect |

|---|---|

Electronics | |

Industrial Equipment | Gears, motors |

Medical and Diagnostic Equipment

Medical device housings

CNC helps make enclosures for medical devices that must be strong and exact. These rf shielded enclosures help devices work well in hospitals and clinics. You need special materials that are safe for people and can be cleaned many times.

Gives support to important medical parts

Makes sure devices follow health rules

Stays strong after cleaning and sterilizing

Precision diagnostic enclosures

Diagnostic tools need rf shielded enclosures to protect tiny sensors. CNC machining lets you make very exact parts. The enclosures keep your tools working right and safe. You must pick materials that last and do not get hurt by chemicals.

Communication and RF Devices

RF shielding enclosures

You need rf shielded enclosures for communication tools. These boxes stop outside noise and keep signals from leaking out. CNC machining helps control heat and keeps signals clear. The enclosures help your devices work even in hard places.

Communication equipment housings

You use rf shielded enclosures for radios, satellites, and radar. These boxes are strong and help control heat. CNC gives you the accuracy needed for fast signals. You can count on CNC to make enclosures that protect your equipment.

Tip: Always design your enclosure for what your device needs. Strong rf shielded enclosures help your devices work better and last longer.

Conclusion: Why CNC Machining Is the Right Choice for Electronics Enclosures

Summary of Shielding, Tolerance, and Finishing Advantages

You want your electronics to stay safe and work well. CNC machining electronics enclosures gives strong shielding, tight fits, and smooth finishes. You can count on cnc machining for electronics to make high-precision electronics enclosures that block emi and fit your devices just right. The benefits of cnc machining for electronics enclosures include making custom parts for your needs and giving steady performance.

Here is a table that shows why cnc machining is good:

Advantage | Description |

|---|---|

EMI Shielding | Enclosures can use gaskets or conductive coatings for emi shielding solutions. |

Tight Tolerances | CNC machining ensures precision and accuracy in manufacturing. |

Surface Finishes | Smooth surfaces improve fit, alignment, and appearance. |

You can pick custom electronic enclosures to fit your project. CNC machining lets you choose the best material selection for cnc machined enclosures, like aluminum for blocking signals or copper for carrying electricity. You learn the importance of emi shielding in enclosures and what to think about when designing electronic enclosures.

When to Choose CNC Machining for Electronics Enclosure Projects

Pick electronics enclosure cnc machining if you need prototypes, small batches, or very exact parts. CNC machining helps you make and test new designs fast. You can make a few parts without spending a lot on tools. CNC machining can make tricky shapes and keeps custom parts accurate.

Here is a table that shows when cnc machining is best:

Scenario | Benefit |

|---|---|

Prototyping | Fast creation of prototypes with tight tolerances. |

Low-volume production | Small batches without high setup costs. |

High-precision requirements | Complex designs and accuracy for precision parts. |

You can use cnc machining electronics enclosures for projects that need good shielding and strong surfaces. CNC gives you choices and lets you make special parts. You can pick materials like aluminum, copper, or plastics for your enclosures. CNC machining takes your design from a CAD file to a finished part quickly. You get steady results and all the advantages of cnc machining for your electronics.

Tip: Pick cnc machining if you need your enclosures to be exact, block signals, and fit your needs.

When you pick cnc machining electronics enclosures, you get strong EMI shielding, tight fits, and nice finishes. Smart design and careful electronics enclosure cnc machining help keep your devices safe and working well. To get the best from cnc machining, you can do these things:

Make your design easy to build and not too expensive.

Use DFM rules to make machining simpler.

Pick materials that fit what you need to make.

Change your design to use less material and waste less.

Build and test a prototype before making a lot.

Try thermal simulation to help control heat better.

FAQ

What materials work best for CNC machined electronics enclosures?

You can use aluminum, stainless steel, or polycarbonate. Aluminum is light and blocks signals well. Stainless steel is very strong and tough. Polycarbonate is good if you want something light. Pick the material that fits your device’s needs.

How does CNC machining help with EMI shielding?

CNC machining lets you make boxes with tight seams. You can use metals that block signals. This keeps your electronics safe from unwanted signals. You can also add grounding spots and choose finishes that help with shielding.

What surface finishes can you choose for electronics enclosures?

You can choose anodizing, powder coating, bead blasting, or plating. Each finish changes how your box looks and protects it. Anodizing adds color and stops rust. Powder coating puts on a hard layer.

How tight are CNC machining tolerances for enclosures?

CNC machining can make parts with tolerances as small as ±0.01 mm. This means your parts fit together very well. Small gaps help block signals better. You get the same good results every time.

Can you use CNC machining for prototypes and small batches?

Yes, CNC machining is great for making a few parts or testing ideas. You can try out your design and change it fast. You do not need to spend a lot of money on special molds.

LKprototype

LKprototype